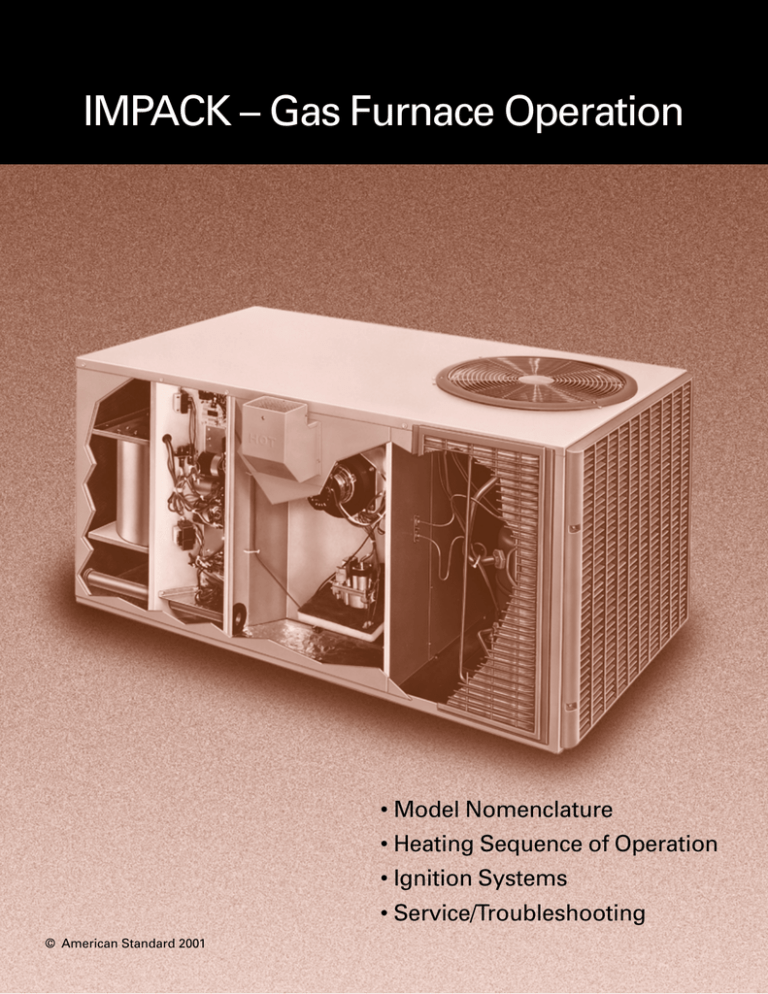

IMPACK – Gas Furnace Operation

advertisement