High Performance Rack mounted programmable Current

Made by LEM Danfysik

High Performance Rack mounted programmable Current Transducer

ITP 600-SPR ULTRASTAB

For the electronic measurement of currents: DC, AC, pulsed..., with galvanic isolation between the primary circuit (high power) and the secondary circuit (electronic circuit).

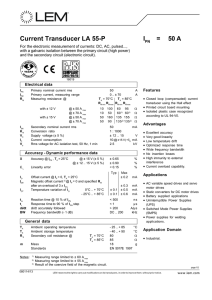

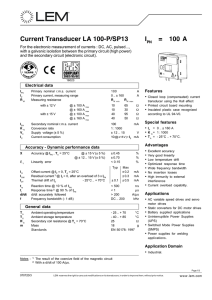

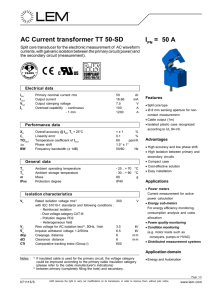

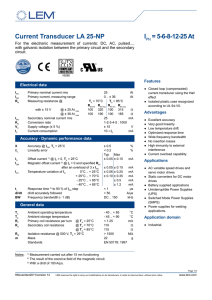

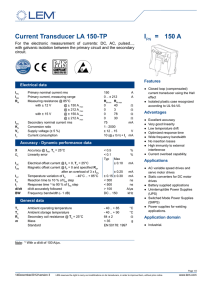

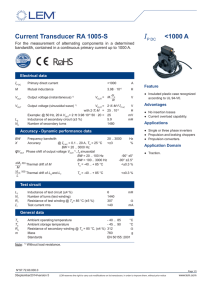

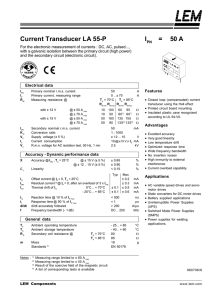

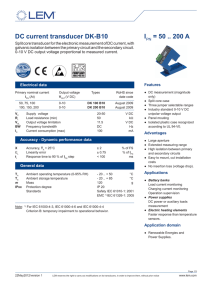

Electrical data

I

PM

= 0 .. 600 A

Programmable from 40 A to

600 A

Features

●

●

●

Closed loop (compensated) current transducer using an extremely accurate zero flux detector

Electrostatic shield between primary and secondary circuit

Made up of one measuring head

+ 19” electronics rack.

I

I

PN

PN

I

PM

I

S

I

SN

K

N

V

C

P

C

Î

P

R

M

ε

I

OE

∆ I

L

Primary nominal current DC

Primary nominal current rms

Primary current, measuring range

Max overload capability 100 ms 1)

Programmable from

Programming steps

Measuring resistance

Over operating current, temperature and supply voltage range

Secondary current

Secondary nominal current rms

Conversion ratio

Supply voltage (± 10 %) 50-60 Hz

Power consumption

Accuracy - Dynamic performance data

Linearity error 2)

OE

Offset stability (no load) 2)

TCI

OE

Temperature coefficient of I

OE

Electrical offset current + self magnetization + effect of earth magnetic field @ T

A

= 25°C 2)

(10°C .. 40°C) 2)

± 600

424

0 .. ± 600

± 3000

40

20

R

M min

R

M max

0 1.5

0 .. ± 1000

707

1 : 600

Ω mA mA

100/115/230 V AC max 50 VA

≤ 1 ppm

< 2

< 1 ppm/month

< 0.1 ppm ppm/K

A

A

A

A

A

A

Special features

●

●

●

●

D-Sub 15 pole female output interface connector

D-Sub 9 pole male status output interface connector

LED shows normal operation

LED shows overload condition.

Advantages

●

●

●

●

●

●

●

●

●

Very high accuracy

Excellent linearity

Extremely low temperature drift

Wide frequency bandwidth

High immunity to external electrostatic and magnetic fields interference

No insertion losses

High resolution

Low noise on output signal

Low noise feedback to main conductor.

R

S m m

T

A

T

S

General data

091103/0

Ambient operating temperature Head

Ambient operating temperature Electronics

0 .. + 55

10 .. + 40

Humidity (non condensing) 20 - 80 %

Ambient storage temperature Electronics and Head - 20 .. + 85

Humidity (non condensing)

Secondary coil resistance @ T

Mass-Electronics

Mass-Head

A

= 25°C

20 - 80 %

< 3.8

5

1

°C

°C

RH

°C

RH

Ω kg kg

Notes : 1) Single pulse only, not AC.

The transducer may requires a few seconds to return to normal operation

when autoreset system is running.

2) All ppm figures refer to secondary measuring range 1000 mA.

Applications

●

●

●

●

●

●

●

Feed back element in high performance power supplies...

Calibration unit

Absolute current standard reference

Test and calibration of current sources

Current extender for power analysis

Differential current measurement on power line

Metrology applications.

Application domain

● Industrial and Medical.

LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 1/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Isolation characteristics

Between primary and secondary

V b

V

V

V b d w

Rated isolation voltage rms, reinforced isolation

Rated isolation voltage rms, single isolation with IEC 61010-1 standards and following conditions

- Over voltage category III

- Pollution degree 2

Rms voltage for AC isolation test, 50/60 Hz, 1 min

Impulse withstand voltage 1.2/50 µs

Rated isolation voltage rms, reinforced isolation

Rated isolation voltage rms, single isolation with EN 50178 standards and following conditions

- Over voltage category III

- Pollution degree 2 dCp Creepage distance dCI Clearance distance

CTI Comparative Tracking Index (Group I)

300

2000

4.9

1)

9.1

600

1000

10

10

600

I f isolated cable is used for the primary circuit, the voltage category could be improved with the following table (for single isolation) (IEC 61010-1 standard):

C able isolated (primary)

HAR03

HAR05

HAR07

Category

2150 V CAT III

2250 V CAT III

2350 V CAT III mm mm

V kV kV

V

V

V

V

Note : 1) Between primary and secondary + shield.

Safety

This transducer must be used in electric/electronic equipment with respect to applicable standards and safety requirements in accordance with the manufacturer’s operating instructions.

Caution, risk of electrical shock

When operating the transducer, certain parts of the module can carry hazardous voltage (eg. primary busbar, power supply).

Ignoring this warning can lead to injury and/or cause serious damage.

This transducer is a build-in device, whose conducting parts must be inaccessible after installation.

A protective housing or additional shield could be used.

Main supply must be able to be disconnected.

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 2/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Output noise figures: @ 25°C

Random Noise ppm (rms):

0 – 10 Hz

< 0.01

0 – 10 kHz

< 3.5

0 – 100 kHz

< 6.5

Re-injected noise measured on primary cable

(DC - 100 kHz)

< 2 µV

RMS

Dynamic performance data t

BW Frequency bandwidth for small signal 5 %, of I

PN

(DC)

(± 3 dB) di/dt di/dt accurately followed r

Response time 1) to 90 % of I

PN

step

Note: 1) With a di/dt of 50 A/µs.

DC .. 300

> 50

< 1 kHz

A/µs

µs

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 3/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Status/Interlock port - Electrical specification

All signals on the Status/Interlock port are floating relay type. All signals are therefore galvanically isolated from the electrical circuits of the unit.

Maximum allowed voltage on the relay switches is 33 V AC or 70 V DC .

The Status/Interlock connector (Sub-D, 9 pole, male) contains the following signals:

Pin N°

1

2

3

4

5

6

7

8

9

Description

Normal operation Fault

When the unit status is faulty (error, overload, warning etc.), this pin is connected to the Normal operation common.

Normal operation OK

When the unit status is OK (Normal operation), this pin is connected to the Normal operation common pin.

I

P

Low common

This pin is connected to either I

P depending on the unit’s status.

Low True ot I

P

Low False

Overload warning True

This pin is connected to the Overload common pin when the current through the transducer head exceeds 30 % of the maximum programmed current.

Overload warning False

This pin is connected to the Overload common pin when the unit is in normal mode and the current through the transducer head is within the measurement area.

Normal operation common

This pin is connected to either Normal operation on or the

Normal operation off depending on the unit’s status.

I

P

Low True

This pin is connected to current.

I

P

Low common when the current through the transducer head is below 5 ‰ of the programmed

I

P

Low False

This pin is connected to current.

I

P

Low common when the current through the transducer head is above 5 ‰ of the programmed

Overload warning common

This pin is connected to either Overload warning on or Overload warning off pin depending on the unit’s status.

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 4/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Electronics - Description - Front panel indicators

19” Electronics Rack

The indicators on the front panel are:

POWER:

This LED is lit (Blue) when the system is on.

STATUS:

This LED is lit (Green) when the status of the system is OK.

I

P

LOW:

This LED is lit (Yellow) when the current passing through the transducer head is below 5 ‰ of the programmed maximum current.

600A:

This LED is lit (Yellow) when a 600 A transducer head is connected to the ITP

Electronics unit.

2000A:

This LED is lit (Yellow) when a 2000 A transducer head is connected to the ITP

Electronics unit.

5000A:

This LED is lit (Yellow) when 5000 A transducer head is connected to the ITP

Electronics unit.

OVERLOAD:

This LED is lit (Red) when the current passing through the transducer head exceeds

130 % of the maximum current for the transducer head (including programming) or the transducer head saturates.

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 5/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Electronics - Description - Back panel connectors

Refer to the drawing above for description of back panel layout and connectors:

1. IEC power inlet and voltage selector:

This connector accepts a standard IEC power cord (supplied). The voltage can

be changed using the voltage selector code wheel in order to match local

voltages.

Furthermore, the unit’s two mains fuses are located in the IEC power

inlet.

2. Punch out plate (optional):

This plate is for future expansion or customization

3.

4.

Type / Serial number plate.

Sync in:

Synchronization input when slaved to another ITP product in a multichannel

system

5. Sync out:

Synchronization out when the unit is master or part of a daisy-chain in a

multichannel system

Status /Interlock signal outputs - Sub D, 9 pole male connector 6.

7. Transducer head A:

Connection to the ITP 600 measuring head.

8. Transducer head B:

Connection to the ITP 2000 and ITP 5000 measuring head.

9. Analog out:

Output connection to a DMM or other equipment - Sub D, 15 female connector.

10. Label indicating that the electronics unit is a special type only to be used with

the stated transducer head.

11.

12.

Calibration date label (on ITP...-SBPR models only)

Serial N° label of matched transducer head. This label is only mounted if a

transducer head is delivered with the electronics unit.

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 6/8 www.lem.com

Made by LEM Danfysik

Current Transducer ITP 600-SPR ULTRASTAB

Transducer head - Description - Connectors

ITP 600

Measuring head

Miscellaneous

Bus bar free zone (length: 75 mm) (from center) r ≥ 75 mm

ITP 600-SPR standard delivery

●

●

●

● Transducer head 600 A

● Electronics for 19” rack installation

Cable, transducer - electronics, length 10 m

Cable, output, length 1.5 m

Programming plug, standard 600 A.

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 7/8 www.lem.com

A

1

B C

Made by LEM Danfysik

Dimensions ITP 600-SPR ULTRASTAB (in mm. 1 mm = 0.0394 inch)

D E F G H I J

1

2

3

Measuring Head

4

3

19” Electronics rack

88,1 482,6

4

5 5

Analogue output connection -

D Sub 15 female connector

Pin N°

1

13

14

15

10

11

12

7

8

5

6

9

2

3

4

Description

Current return

Current return

Not used

Not to be used

Not to be used

Ground

Not to be used

Not to be used

Current output

Current output

Not used

Not to be used

Not to be used

Not to be used

Not to be used

6

8

A

7

TOLERANCE: ±0.1

SCALE: 1:10

SURFACE TREATMENT (RoHS compliant):

MACHINING:

Ultrastab Saturn

Dimensions

B C

CUSTOMER: Customer

FILE:

D

89401.idw

E F

PROJECT NO.:

G

IMPORTANT!

This document contains information which is the proporty of Danfysik A/S, Denmark. It is submitted to you in confidence that it will not be disclosed or transmitted to others without Danfysik's authorization.

MATERIAL:

7

DRAWN BY SFH Digitally signed by Stig Falck Hansen

DN: CN = Stig Falck Hansen, C = DK, O = Danfysik a/ s, OU = Electronics design

Reason: First edition

Location: DK-Jyllinge

Date: 2006.07.28 14:19:17 +02'00'

DESIGN APP.

Autodesk Inventor 9

PROD. APP.

PROJ. ENGR.

DWG. NO.:

89401

8

REVISION:

DATE:

H

28-07-2006

I

SHEET 1 of 1

SIZE: A4

J

6

Mechanical characteristics

●

●

●

●

General tolerance: ± 0.1 mm

Electronics:

Width: 482.6 mm

Height: 88.1 mm

Depth: 323 mm

Transducer head

Width: 98 mm

Height: 122 mm

Depth: 57 mm

Inner hole diameter ∅ minimum: 25.4 mm

Transducer head fastening

Flat mounting: 2 x M6 x 10

Recommended fastening torque: 1.96 Nm or 1.44 Lb.-Ft

Remarks

●

●

I

S

is positive when I

50°C.

P

flows in the direction of the arrow.

Temperature of the primary conductor should not exceed

091103/0 LEM reserves the right to carry out modifications on its transducers, in order to improve them, without prior notice.

Page 8/8 www.lem.com