Construction and Building Materials 48 (2013) 708–716

Contents lists available at ScienceDirect

Construction and Building Materials

journal homepage: www.elsevier.com/locate/conbuildmat

Long-term performance of surface impregnation of reinforced concrete

structures with silane

C. Christodoulou a,⇑, C.I. Goodier b, S.A. Austin b, J. Webb a, G.K. Glass c

a

AECOM, Colmore Plaza, 20 Colmore Circus Queensway, Birmingham B4 6AT, UK

Loughborough University, School of Civil and Building Engineering, Leicestershire LE11 3TU, UK

c

Concrete Preservation Technologies, University of Nottingham Innovation Lab, Nottingham NG7 2TU, UK

b

h i g h l i g h t s

Long-term performance of silane coatings on reinforced concrete.

Hydrophobic effects of silanes following 10 years of service.

Capillary absorption testing.

a r t i c l e

i n f o

Article history:

Received 24 May 2013

Received in revised form 22 July 2013

Accepted 22 July 2013

Keywords:

Reinforced concrete

Silane

Hydrophobic treatment

Impregnation

Durability

Capillary

Absorption

a b s t r a c t

Silanes can act as hydrophobic pore liners for reinforced concrete (RC) structures. They can significantly

reduce the depth of chloride penetration, a major cause of steel reinforcement corrosion. However, there

is little published information on their long-term performance. Thirty-two concrete cores were extracted

from eight full-scale RC bridge supporting cross-beams that were treated with silane 20 years ago. Their

water absorption by capillarity was measured and compared with sixteen control cores extracted from

four non-silane treated RC cross-beams constructed at the same time. Results show that silanes may provide a residual protective effect against water even after 20 years of service.

Ó 2013 Elsevier Ltd. All rights reserved.

1. Introduction

Concrete is a naturally porous material. The size and distribution of pores in concrete varies and depends on the constituent

materials, quality of compaction, the materials used in the mix design, the water-to-cement ratio, the degree of hydration, and curing [1]. Some of these pores will be interconnected to form a

network of pore space that can be penetrated by water, gas or ions.

The relevant transport mechanisms for the ingress of water,

gases and ions are [2]:

i. diffusion of free molecules or ions due to a concentration

difference;

ii. permeation of gases or liquids through water saturated

specimens due to hydraulic pressure difference; and

⇑ Corresponding author.

E-mail address: christian.christodoulou@aecom.com (C. Christodoulou).

0950-0618/$ - see front matter Ó 2013 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.conbuildmat.2013.07.038

iii. capillary suction of liquids due to surface tension acting in

capillaries.

Whilst, these mechanisms act together under natural environmental exposure conditions for atmospherically exposed concrete,

capillary suction tends to be the dominant mechanism [1–3]. Ions

such as chlorides are transported into the concrete pore system by

being dissolved into water, which subsequently cause corrosion of

the steel reinforcement and ultimately spalling of the surrounding

concrete cover.

Hydrophobic impregnation shave therefore been used in various forms in the construction industry to help prevent water and

chloride ingress and their benefits are well documented [4–9].

They can be divided into three categories: coatings, pore blockers

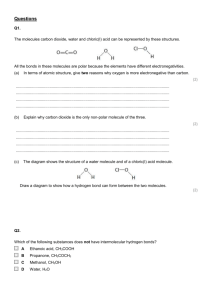

and pore liners (Fig. 1).

Silanes belong to the pore liner category and are a group of

silicones containing one silicon atom [11]. Alkoxy and alkyl silanes

are routinely used for surface impregnations. The basic composition of an alkyl alkoxy silane is shown by Fig. 2. The alkoxy groups

709

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

Fig. 1. Categories of surface impregnations : (a) coatings, (b) pore blockers and (c) pore liners [10].

Fig. 2. Typical alkyl alkoxy silane molecular structure.

(CH3O) linked to the silicate atom (Si) contain silicon–oxygen

bonds that will bond to silicates present in the concrete. The

organic alkylic (CH3) group remaining will protrude from the pore

structure and are responsible for the hydrophobic characteristics

[5,6].

Evidence from numerous studies demonstrate that the application of silanes significantly reduces water uptake, which as a result

reduces the ingress of chlorides and hence also reduces the corrosion risk to the reinforcement [6,9,12–18]. However, their performance is affected by surface imperfections, cyclic wetting and

drying, skill of the applicator, surface preparation, application rates

and local environmental conditions at the time of application.

Polder and de Vries [19] demonstrated that silane treated specimens still had a residual protective effect even after 5 years of

outdoor exposure in the Netherlands, by measuring the water

absorption and chloride content. In a similar study, Schueremans

et al. [20] demonstrated the protective effects of silanes after

12 years of exposure in an aggressive marine environment on a

RC quay-wall in a port in Belgium by measuring their chloride

content.

Work by the Transport Research Laboratory [21,22] in the UK

indicated that silanes were reasonably effective in reducing

chloride ingress into concrete structures based upon a review of

principal inspection reports, various Managing Area Contractors,

laboratory testing, and testing of cores extracted from full-scale

motorway RC structures. The performance of the silanes was tested

primarily by means of water absorption and sorptivity, but the age

of silane at time of testing was limited to 5 years.

From all of the above it is apparent that very little is known

regarding the durability of silane impregnations and their longterm residual protection (i.e. following at least 10 years of service).

Very commonly their performance is assessed by measuring chloride contamination at various depths over time. However, this is

only an indirect method and does not provide information on the

residual hydrophobic effect against water uptake. Extracting cores

for laboratory testing from full-scale structures is neither desirable

nor always feasible.

The objective of this study was to address this gap in knowledge,

improve our understanding of the efficacy and long-term service life

of silane impregnations by undertaking testing of full-scale RC structures. The findings will help contribute towards the development of

new improved corrosion management strategies and assist in a more

accurate whole life cost assessment of silane impregnations. The

findings also provide additional information regarding the maintenance requirements of RC structures with an existing silane impregnation . Early results of this work have also been reported [23].

2. Methodology

This section presents the basic theory, selection strategy for the cross-beams,

the properties of the concrete investigated, and the test methods applied including

their selection criteria.

2.1. Capillary theory

The transport of chlorides into concrete is governed by a mixed mode of capillary absorption of water and diffusion. Capillarity absorption can be defined as the

transport of liquids in porous and non-saturated solids due to surface tension acting

in capillaries and without appreciable external pressure [2]. For short-term contact

between the liquid and the porous solid surface, a non-steady-state transport

mechanism exists. This resembles conditions encountered on site by atmospherically exposed full-scale RC structures. It can be measured as the increase in mass

due to capillary water absorption as a function of the square root of time and it

is usually termed as rate of absorption. It can be also expressed as the increase in

volume as a function of the square root of time which, termed sorptivity.

Diffusion can be defined as the transfer of mass by random motion of free molecules or ions in a pore solution resulting in a net flow from regions of higher concentration to regions of lower concentration [2,24].

Concrete in contact with a salt solution will become contaminated with chlorides primarily due to capillary absorption rather than diffusion alone. Absorbed

chlorides can continue to penetrate by diffusion but at a significantly lower movement rate. Thus, measuring the rate of absorption (or sorptivity) can provide useful

information on the condition of silane impregnations.

The rate of water absorption can be expressed by Eq. (1) [2]. Sorptivity is the

uni-axial one-dimensional capillary absorption and can be expressed by following

equation [2]:

Rate of water absorption ¼

Sorptivity ¼

Vw

pffiffi

ðAc t Þ

0:5

m=h

Ww

pffiffi

ðAc tÞ

kg=m2 =h

0:5

ð1Þ

ð2Þ

where Ww (g) is the weight gained by the specimen, Ac (mm2) the surface area of the

specimen in contact with the water, t (s) the time of exposure and Vw (mm3) the volume of water absorbed.

710

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

Measurement of water sorptivity can also be related to the rate of chloride

absorption [10,25].

Table 1 provides a summary of the European Standard BS EN 13057 [26] for

measurement of the capillary water absorption of hardened concrete.

Correction factor ¼

V

ðAc 12:5Þ

ð3Þ

where V (mm3) is the volume of the specimen and Ac (mm2) the surface area of the

specimen in contact with water.

2.2. Cross-beams

2.3. Testing

Fig. 3 illustrates a typical sub-structure arrangement of the motorway bridge

supporting cross-beams that were examined during this study. Silanes have been

applied to a total of 135 similar cross-beams across the UK’s Midland Link Motorway Viaducts (MLMV). Of these, 93 cross-beams were located in the viaduct that

was chosen for these investigations, whereas the remaining were distributed

amongst four other viaducts.

The methodological procedure employed is outlined in Fig. 4. The cross-beams

were constructed between 1968 and 1970, although the exact date is not known.

Thus, 1969 is used as the average construction year for calculations of age of silane

at time of testing. Although specimens were extracted from cross-beams of the

same viaduct, hence suggesting that at least comparable concrete was used, due

to the nature of construction, there will be variations in the overall concrete quality.

Due to the age of the cross-beams, there were no historical records available providing information on concrete mix design such as maximum aggregate size. Such details could have been approximated by petrographic analysis however this was

consider outside the scope of the current study and would have required a large

number of additional site cores.

Twelve cross-beams were selected, of which eight had previously received a silane impregnation 20 years following their construction, whereas the remaining

four had not, hence were acting as control specimens (Table 2). Variations in the

performance of specimens extracted from the control cross-beams could give an insight with regards to site variations in concrete quality. The chemical composition

of the silane impregnation was isobutyl trimethoxy silane. No historical records exist detailing the exact surface preparation procedures, application rates or weather

conditions at the time of the application, important factors that can affect silane

performance.

Four cores (diameter and length of 80 mm) were extracted from each crossbeam, all from the top surface, which represented the most critical area for water

ingress (Fig. 5). This residual risk can be attributed to the simply supported articulation arrangement of the bridges with carriageway expansion joints above every

cross-beam that were known to be susceptible to water leakage. After coring, each

core hole was carefully repaired with a shrink-resistance compensating repair

mortar.

A correction factor in accordance with BS 1881-122 [27] was applied to normalise the cores into an equivalent of 75 mm diameter and to eliminate minor differences in length between the cores as a result of the coring process:

A very common testing regime to evaluate the performance of silanes is to measure chloride penetration profiles between silane and control treated specimens

[19,20,22]. One differentiating factor of this work is that this approach was not employed. The cross-beams were silane treated after approximately 20 years of service

life and there were no historical records of the chloride levels at the time of silane

application. As such, there would be no previous information to compare against

and it was thus deemed that chloride concentration testing had limited potential

for investigating the efficiency of the silane impregnations and it required destructive testing of the valuable core specimens.

Investigation of the effectiveness of the silane impregnation as a chloride barrier was therefore conducted by measuring the capillary absorption, a non-destructive technique. Two sets of tests were undertaken: the first on the original silane

treated and control cores and the second on a subset of these to which a new silane

was applied. This subset created additional background information on what could

have been the potential effectiveness of silanes on aged concrete when the silanes

are young. As the original silane proprietary product (based on isobutyl trimethoxy

silane) was no longer commercially available, a frequently commercially available

silane product was used instead. The properties of the new silane are summarised

in Table 3. In the study by Calder and McKenzie [22] it is reported as product 2.3.

The procedure outlined by BS EN 13057 [26] was adopted with the following

changes:

i. The diameter of the cores was reduced to 80 mm and their length increased

also to 80 mm. This change was required in order to be in a position to

extract cores from full-scale RC cross-beams which are heavily reinforced.

ii. The cores were oven dried at 35 °C as opposed to the recommended 40 °C.

The drying temperature was lowered in order to minimise potential damage to the chemical structure of the residual silane impregnations.

iii. The drying period was extended until the weight loss of the specimens (due

to moisture loss) became stabilised to less than 0.05% weight loss over a

period of 2 days, as opposed to the r not greater than 0.2% in 2 h. This aimed

to minimise any effects on the sorptivity due to initial water content of the

specimens as a result of their greater length.

iv. All but the test face (silane treated face) were sealed against sideways

ingress of water and evaporation of moisture with a proprietary polysulphide sealant. This approach is in line with the recommendations of Kropp

Table 1

Standard test method for the determination of water absorption of concrete.

Standard

Output properties

Testing time

Specimen size

BS EN 13057

[26]

Sorption coefficient kg/m2h0.5

or m/h0.5 (i.e. Eqs. (1) and (2) respectively)

Intervals of 12 min, 30 min, 1 h, 2 h, 4 h

and 24 h are appropriate in most cases

Diameter (100 ± 5) mm

Length (25 ± 0.5) mm

Fig. 3. Typical sub-structure arrangement of the UK’s Midland Links Motorway Viaducts (MLMV).

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

711

Fig. 4. Selection and testing programme for silane treated cross-beams.

Table 2

Age of cross-beams based on an average construction date of 1969 and age of silane

impregnation at testing.

Cross-beam

reference

Year of

silane

application

Age of crossbeam at silane

application

(years)

Age of

silane at

testing

(years)

Age of

cross-beam

at testing

(years)

A1

B1

B2

B3

B4

B5

B6

C1

D1

(No silane)

D2

D3

D4

1991

1993

1993

1993

1993

1993

1993

1999

Control

crossbeams

23

25

20

18

43

cleaning with an air lance. The specimens then received the new silane impregnation (Table 3) and were air cured indoors for 7 days. Following, they were prepared

and tested for capillary water absorption in the same procedure as the previous

cores. The aim of this approach was to demonstrate the effect on the rate of water

absorption for the control specimens following application of the new silane. In

addition, it can provide a comparison in the performance between newly applied

and old silanes.

The results for all the testing are expressed as a percentage of net weight gain

for each core which is used to calculate rate of absorption (i.e. Eq. (1)) and sorptivity

(i.e. Eq. (2)).

3. Data analysis

31

–

12

–

and Hilsdorf [2] in order to measure uniaxial rate of water absorption and

sorptivity.

v. The immersion depth was approximately 5 mm below the water line as

proposed by Hall [28] instead of 2 ± 1 mm. This approach does not alter

the results in any way as all of the non-tested surfaces of each core were

sealed against water with a proprietary polysulphide sealant.

The specimens were placed with their silane treated surface facing down in a

layer of water no deeper than 5 mm (Fig. 6). Their weights were recorded at 0, 5,

15, 30 min and thereafter every 30 min over a total period of 4 h.

The specimens from the best and worst performing control cross-beams were

selected to form a new family of 6 specimens for additional testing with a new

silane impregnation (Fig. 4). The specimens received a light surface preparation

to remove the buildup of laitance by abrading the surface with sand paper and

This section describes the data obtained and discusses the results of the tests on the original and on the newly applied silane

impregnations , together with their statistical significance.

3.1. Original silane impregnation

The net weight gain of each specimen and average for each

cross-beam’s group of specimens after 4 h of testing is shown in

Fig. 7. It can be observed that in general the specimens exhibited

variability in their performance. This may be associated with micro-structure differences of the specimens, even for the same

cross-beam, as a result of lower quality control of the concrete

on site possibly producing micro-structure inconsistencies. Silane

treated specimens from cross-beams B5 and C1 (18 and 12 years

old at time of testing) presented the lowest net weight gains.

The results were used to calculate average cumulative water

uptake for each cross-beam’s group of specimens over a period of

4 h of capillary absorption testing, on which the rate of absorption

can therefore be calculated (Fig. 8). In accordance with BS EN

712

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

Fig. 5. Coring on top of a silane-treated RC cross-beam.

13057 [26], the rate of water absorption may be calculated as the

linear portion of the slope or in cases where this does not exist,

it may be calculated as the slope from the y-axis intercept to the

last reading taken (Eq. (1)).

From Fig. 8, it can be observed that specimens from all

cross-beams initially had a high rate of water absorption over

the first 15 min of testing (0.08 h or 0.29 h0.5). After this time, for

the silane treated cross-beams, in most cases the rate of water

absorption was significantly reduced or almost eliminated, indicating steady state conditions. For the control cross-beams, in most

cases, the rate of water absorption was reduced but never

eliminated.

As such, three distinct rates of water absorption may be derived

(Table 4), i.e. initial between zero and 15 min (0–0.29 h0.5), intermediate between 15 min and 4 h (0.29–2.00 h0.5) and overall average (0–2.00 h0.5). Each cross-beam is ranked accordingly, to

provide a more informed assessment on the relative performance

of cross-beams such as B5 and C1 which had a high rate of water

absorption over the first 15 min of testing but thereafter reached

steady state conditions.

The variance in the rate of water absorption observed may be

partly explained by changes in the micro-structure of the specimens as water progress from the cover zone (where concrete

may be more porous and exhibit surface cracking) towards the core

of the specimens. The thickness of this cover zone is affected by

quality control on-site and curing conditions. In addition, as all

the specimens were extracted from the top of the cross-beams, this

effect may be exaggerated as concrete in this area will be more

prone to bleeding.

It can be observed that control cross-beams D2–D4 exhibited

high rates of water absorption, being in the top four worse

performing cross-beams for the initial, intermediate and average

rates of water absorption. Although all control structures

(D1–D4) initially performed better than silane treated cross-beam

B6, the later quickly reached near steady state conditions (refer to

Table 3

Characteristics of applied alkyl alkoxy silane impregnation.

Type

Chemical

type

Solid

content, by

weight

Flash

point

Application

method

Application

rate

Water

based

silane

Alkyl

alkoxy

silane

20%

>93 °C

Brush

applied

3–5 l/m2

Fig. 6. Cores sealed with proprietary polysulphide sealant for capillary absorption

testing.

its intermediate rate, Table 4) whereas control cross-beams continued their water absorption.

Silane treated cross-beam B3 had a very low initial rate of water

absorption when compared to all other cross-beams. However, its

intermediate rate of water absorption was the highest and it did

not approach near steady state conditions within the 4 h of the

test. Its average rate of water absorption is comparable to that of

specimens from control cross-beams and may be associated with

a diminished residual hydrophobic effect.

Cross-beam C1, with the youngest silane impregnation at

12 years at time of testing, was ranked average for its initial rate

of water absorption but thereafter reached steady state conditions

and was the best performer based on the intermediate rate of

water absorption. Cross-beam B5, with the silane impregnation

at 18 years at time of testing, was one of the best performing based

on initial, intermediateand average rates of water absorption and

reached near steady state conditions after 15 min of testing.

Cross-beam A1, with the oldest silane impregnation at 20 years

at time of testing, was one of the best performing silane treated

cross-beams.

The testing data for each cross-beam (average net weight gain,

rate of absorption, sorptivity and standard deviation) following 4 h

of capillary absorption are shown in Table 5.

3.2. Statistical analysis

From Table 5 it can be observed that in a number of cases there

was a large coefficient of variation for specimens extracted from

the cross-beam (e.g. B5, C1, and D4). To examine the significance

of this variance a simple one tail t-test was undertaken for each

group of specimens based on the average, standard deviation and

standard error values. For cross-beam C1 which exhibited the largest variance, the one tail t-test indicated a probability of less than

0.3% that the observed variance was a result of specimens belonging to a different family.

A statistical analysis was also undertaken to assess whether the

samples of silane and control specimens belong to the sample population. For the silane treated samples the variance in sorptivity

was found to be 0.0146 mm2 h1 and for the control samples

0.0075 mm2 h1. As there was a significant difference between

these values the one tail t-test for unequal variances was used.

The test yielded a probability of less than 3% that the observed difference between the variance of the two samples occurring due to

random effects, such as the choice of sample. As such, it is highly

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

713

Fig. 7. Net weight gain for each specimen and average net weight gain for each cross-beam’s group of specimens after 4 h of capillary absorption testing. Note: The change in

color within the vertical bars simply differentiates specimens between different cross-beams. The age of the silane at time of testing is also noted.

Fig. 8. Average cumulative absorption for each cross-beam’s group of specimens over 4 h of capillary absorption testing.

714

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

Table 4

Initial, intermediate and average rate of water absorption in g/m2/h0.5 for each cross-beam’s group of specimens based on 4 h of capillary absorption testing.

Cross-beam

reference

Initial rate (g/m2/

h0.5) 0–15 min

Ranking (high to

low rate)

Intermediate rate (g/m2/

h0.5) 15 min – 4 h

Ranking (high to

low rate)

Average rate (g/

m2/h0.5)

Ranking (high to

low rate)

Age of silane at

testing

A1

B1

B2

B3

B4

B5

B6

C1

D1

D2

D3

D4

841

538

593

703

805

599

1436

808

920

1178

1188

956

6

12

11

9

8

10

1

7

5

3

2

4

124

181

275

332

221

26

87

6

227

278

323

307

9

8

5

1

7

11

10

12

6

4

2

3

335

315

423

507

422

148

446

208

456

573

620

546

9

10

7

4

8

12

6

11

5

2

1

3

20 years

18 years

12 years

–

–

–

–

Table 5

Average results and coefficient of variation for each cross-beam’s group of specimens after 4 h of capillary absorption testing.

Cross-beam

reference

Age of silane at testing

Net weight gain

(%)

Coefficient of

variation

Average rate of

absorption

(g/m2 h0.5)

Average sorptivity (mm/

p

h)

Standard

deviation

A1

B1

B2

B3

B4

B5

B6

C1

D1

D2

D3

D4

20

18

0.55

0.58

0.62

0.70

0.60

0.22

0.70

0.37

0.67

0.90

0.85

0.85

0.198

0.312

0.262

0.218

0.069

0.531

0.360

0.879

0.148

0.244

0.056

0.410

335

315

423

507

422

148

446

208

456

573

620

546

0.335

0.315

0.423

0.507

0.422

0.148

0.446

0.208

0.456

0.573

0.620

546

0.1014

0.1113

0.1068

0.1101

0.0737

0.0926

0.1807

0.2109

0.1305

0.1480

0.0662

0.1823

12

Control cross-beams (No

silane)

Table 6

Comparison of control and silane treated cross-beams following the application of a new silane impregnation.

Cross-beam reference

p

Average sorptivity (mm/ h)

Comment

p

Average sorptivity (mm/ h)

Comment

B5

C1

D1

D2

0.148

0.208

0.456

0.573

18 years old silane

12 years old silane

Best performing control – no silane

Worst performing control – no silane

0.148

0.208

0.055

0.072

18 years old silane

12 years old silane

New silane – 1 month old

New silane – 1 month old

unlikely that there is no difference between the populations and

therefore the silane impregnation has an effect.

3.3. New silane impregnation

Cross-beams D1 and D2 were the best and worst performing

control. A new silane impregnation was applied in order to approximate the effect of a newly applied silane impregnation on the

sorptivity of aged concrete extracted from full-scale RC crossbeams. Table 6 compares the sorptivity in their original untreated

condition and 1 month after the application of a new silane

impregnation. These are in turn compared with the sorptivity of

the best performing and previously treated cross-beams B5 and

C1, with the silane at 18 and 12 years old respectively at time of

testing.

It can be observed that following the application of a new silane

impregnation the sorptivity for both D1 and D2 control crossbeams was significantly reduced, as would be expected. Both

cross-beams demonstrated similar sorptivities indicating similar

levels of hydrophobic effect afforded by the new silane impregnation. Based on the originally best performing control cross-beam

D1, a reduction of sorptivity of at least 90% was achieved.

When compared to cross-beam C1 with 12 year old silane at

time of testing, a reduction on the sorptivity of approximately

78% was achieved. Similarly, comparing the results to the best performing cross-beam B5 with 18 year old silane, a reduction in sorptivity of approximately 70% was achieved.

The results may be associated with a reduction in the hydrophobic effect of silanes over time. In addition, the new silane

impregnation was applied in a laboratory environment under strict

quality control conditions as opposed to site conditions where a

greater variability would be expected to exist when applying surface impregnations to large areas. Furthermore, the new silane

impregnation is a different proprietary product than the original,

as the latter is no longer available, which, albeit of similar chemical

composition, may also produce performance variations.

4. Discussion

The results suggest that the silane treated specimens exhibited

a residual protective effect even after 20 years of service life.

Specimens from cross-beams B5 and C1 (18 and 20 years old

respectively at time testing) were overall the best performing

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

715

Fig. 9. Comparison of the sorptivity of silane treated specimens examined in the study against the sorptivity of specimens from Calder and McKenzie [22].

silane treated specimens. In particular, specimens from cross-beam

C1 – which had had the most recent application – outperformed all

specimens except from cross-beam B5. Possible reasons for the difference in performance between specimens of silane treated crossbeams include time dependant effects such as weathering, surface

preparation, application rates, environmental conditions at the

time of application and differences in the quality of the concrete.

Unfortunately, no historical records exist providing these details.

The average water absorption of the specimens (Fig. 8) was

found to have a fluctuating rate throughout the duration of the

test. This is not uncommon, especially when dealing with specimens extracted from full-scale structures [22]. The variability of

concrete within site structures will generally be greater than that

of laboratory cast specimens. The specimens for this study were

extracted from the top of the RC cross-beams an area where concrete is predisposed to bleeding and segregation which can give

rise to inconsistencies of the cover zone.

The application of a new silane impregnation had a considerable hydrophobic effect on the properties of the specimens tested.

Specimens from control cross-beams D1 and D2 demonstrated a

reduction in their sorptivity of at least 90% following the application of a new silane impregnation. Comparing the performance of

the newly silane treated specimens with that from previously treated cross-beams such as B5 and C1 provides a baseline of the likely

hydrophobic effect of this type of silane on the cross-beams when

they were first applied.

Fig. 9 compares the sorptivity of the silane treated specimens of

this study against those of Calder and McKenzie [22]. It can be observed that very similar sorptivities were recorded for the new proprietary silane and their product 2.3 applied on laboratory

specimens and artificially weathered. They also evaluated the performance of other proprietary products, referenced as products 3.2

(cream based silane) and 4.1 (crystal growth pore blocker), both

being at service for 4 years prior to testing and extracted from a

bridge parapet and an abutment respectively. Some similarity

can be observed in the sorptivity between product 4.1 after 4 years

of service life and the new silane used in our study after 1 month of

application. It needs to be noted that apart from differences in proprietary materials, product 3.2 was applied to RC parapets which

are directly exposed to spray water as opposed to abutments

where product 4.1 was applied.

Polder and de Vries [19] also undertook an assessment on the

performance of silane treated specimens following 5 years of exposure to an outdoor environment in the Netherlands. However their

results are not directly comparable as they obtained readings at

approximately daily intervals with no readings in the first 4 h as

in the present work. Schueremans et al. [20] examined the performance of silanes from samples extracted from a full-scale RC quay

wall following 12 years of service based on chloride ion concentration. Rodum and Lindland [29] undertook similar investigations

with a number of proprietary products applied to a RC quay wall

in Norway, measuring chloride content at various depths over a

period of 10 years. Although both of those studies [20,29] demonstrated the long-term performance of silane impregnations it is not

possible to provide a direct comparison with the results of the

present work.

The published data on the long-term performance of silane

impregnations from full-scale RC structures remains scarce. In

addition, differences were found on the sampling, testing and

reporting methods which hinders comparisons between the studies. Additional research is required in order to develop time dependent relationships on the performance of various proprietary silane

products.

5. Conclusions

Overall, there is very little published empirical evidence that

provides insight into the durability of silane impregnations and

their long-term residual protection (i.e. following at least 10 years

of service). Such a gap in knowledge is undesirable given the scale

of infrastructure treated with hydrophobic impregnations such as

silanes. From the results the following can be concluded:

All the treated cross-beams demonstrated that the silane

impregnation still provides a residual hydrophobic effect, even

with the oldest application from 20 years ago. Statistical analysis indicated with at least 97% confidence that the variance

observed between the silane treated and control specimens

was due to a residual protective effect.

In all but one cross-beam, the most recent silane treated specimens outperformed the other older silane treated specimens,

suggesting that there is a relationship between degradation of

716

C. Christodoulou et al. / Construction and Building Materials 48 (2013) 708–716

the silane impregnation and duration of environmental

exposure.

Silane impregnations should be considered when determining

the corrosion management strategy of a RC structure. Impregnations as old as 20 years can still be present and offer a residual protective effect. Their presence and effectiveness can be

evaluated by extracting cores and testing them in the laboratory

by capillary absorption testing.

Acknowledgements

The authors would like to thank AECOM, the EPSRC (through

the Centre for Innovative and Collaborative Engineering at Loughborough University) and the Highways Agency for their commercial and financial support. This work was funded by the

Engineering and Physical Sciences Research Council (Grant No.

EP/G037272/1).

References

[1] Concrete Society. Technical Report 31. Permeability testing of site concrete.

Surrey (UK), 2008.

[2] Kropp J, Hilsdorf HK. RILEM Report 12. Performance criteria for concrete

durability. Oxford (UK): Taylor and Francis; 1995.

[3] Ungricht H. Wasserhaushalt und Chlorideintrag in Beton – Einfulls der

Exposition und der Betonzusammensetzung. In: Ph. D. thesis. Universities of

Zurich and Basel; 2004. [in German].

[4] Basheer PAM, Basheer L, Cleland DJ, Long AE. Surface treatments for concrete:

assessment methods and reported performance. Constr Build Mater

1997;11:413–29.

[5] Ibrahim M, Al-Gahtani S, Maslehuddin M, Almusallam AA. Effectiveness of

concrete surface treatment materials in reducing chloride-induced

reinforcement corrosion. Constr Build Mater 1997;11:443–51.

[6] Vries J, Polder RB. Hydrophobic treatment of concrete. Constr Build Mater

1997;11:259–65.

[7] Almusallam AA, Khan FM, Dulajan SU, Al-Amoudi OSB. Effectiveness of surface

coatings in improving concrete durability. Cem Concr Compos

2003;25:381–473.

[8] Yang CC, Wang LC, Weng TL. Using charge passed and total chloride content to

assess the effect of penetrating silane sealer on the transport properties of

concrete. Mater Chem Phys 2004;85:238–44.

[9] Medeiros MHF, Helene P. Efficacy of surface hydrophobic agents in reducing

water and chloride ion penetration in concrete. Mater Struct 2008;41:59–71.

[10] Medeiros MHF, Helene P. Surface treatment of reinforced concrete in marine

environment: Influence on chloride diffusion coefficient and capillary water

absorption. Constr Build Mater 2009;23:1476–84.

[11] Concrete Society. Technical Report 50. Guide to surface treatments for

protection and enhancement of concrete. Surrey (UK), 1997.

[12] Pfeifer DW, Scali J. Concrete sealers for protection of bridge structures,

department of transportation. NCHRP 244. Washington (DC); 1981.

[13] Thompson JL, Silsbee MR, Gill PM, Scheetz BE. Characterization of silicate

sealers on concrete. Cem Concr Res 1997;27:1561–7.

[14] Delucchi M, Barbucci A, Cerisola G. Study of the physico-chemical properties of

organic coatings for concrete degradation control. Const Build Mater

1997;11:365–71.

[15] Seneviratne AMG, Sergi G, Page CL. Performance characteristics of surface

coatings applied to concrete for control of reinforcement corrosion. Constr

Build Mater 2000;14:55–9.

[16] Al-Zahrani MM, Al-Dulaijan SU, Ibrahim M, Saricimen H, Sharif FM. Effect of

waterproofing coatings on steel reinforcement corrosion and physical

properties of concrete. Cem Concr Compos 2002;24:127–37.

[17] Moon HY, Shin DG, Choi DS. Evaluation of the durability of mortar and

concrete applied with inorganic coating material and surface treatment

system. Constr Build Mater 2007;21:362–9.

[18] Woo RSC, Zhu H, Chow MMK, Leung CKY, Jang-Kyo K. Barrier performance of

silane-clay nanocomposite coatings on concrete structure. Compos Sci Technol

2008;68:2828–36.

[19] Polder RB, de Vries H. Prevention of reinforcement corrosion by hydrophobic

treatment of concrete. Heron 2001;46:227–38.

[20] Schueremans L, Gemert DV, Giessler S. Chloride penetration in RC-structures

in marine environment-Long term assessment of a preventative hydrophobic

treatment. Constr Build Mater 2007;21:1238–49.

[21] Calder A, Anderson N, McKenzie M. Survey of impregnated structures.

Published Project Report 136. Transportation Research Laboratory; 2006.

[22] Calder A, McKenzie M. Performance of impregnants. Published Project Report

362. Transportation Research Laboratory; 2008.

[23] Christodoulou C, Goodier C, Austin S, Glass G, Webb J. Assessing the long-term

durability of silanes on reinforced concrete structures. In: 1st International

congress on durability of concrete. Trondheim (Norway), 2012, ISBN 978-828208-031-6.

[24] Glass GK, Buenfeld NR. Chloride-induced corrosion of steel in concrete. Prog

Struct Eng Mater 2000;2:448–58.

[25] Austin SA, Al-Kindy AA. Air permeability versus sorptivity: effects of field

curing on cover concrete after one year of field exposure. Mag Concr Res

2000;52:17–24.

[26] British Standards Institution. BS EN 13057:2002. Products and systems for the

protection and repair of concrete structures – test methods – determination of

resistance of capillary absorption. London: BSI; 2002.

[27] British Standards Institution. BS 1881-122:1983. Method for determination of

water absorption. BSI, London, 1983.

[28] Hall C. Water sorptivity of mortars and concrete, a review. Mag Concr Res

1989;41:51–61.

[29] Rodum E, Lindland J. Effect of different surface treatment products after 10

years of field exposure. In: Proceedings of the 1st international congress on

durability of concrete. Trondheim (Norway). June 17–21; 2012, ISBN 978-828208-031-6.