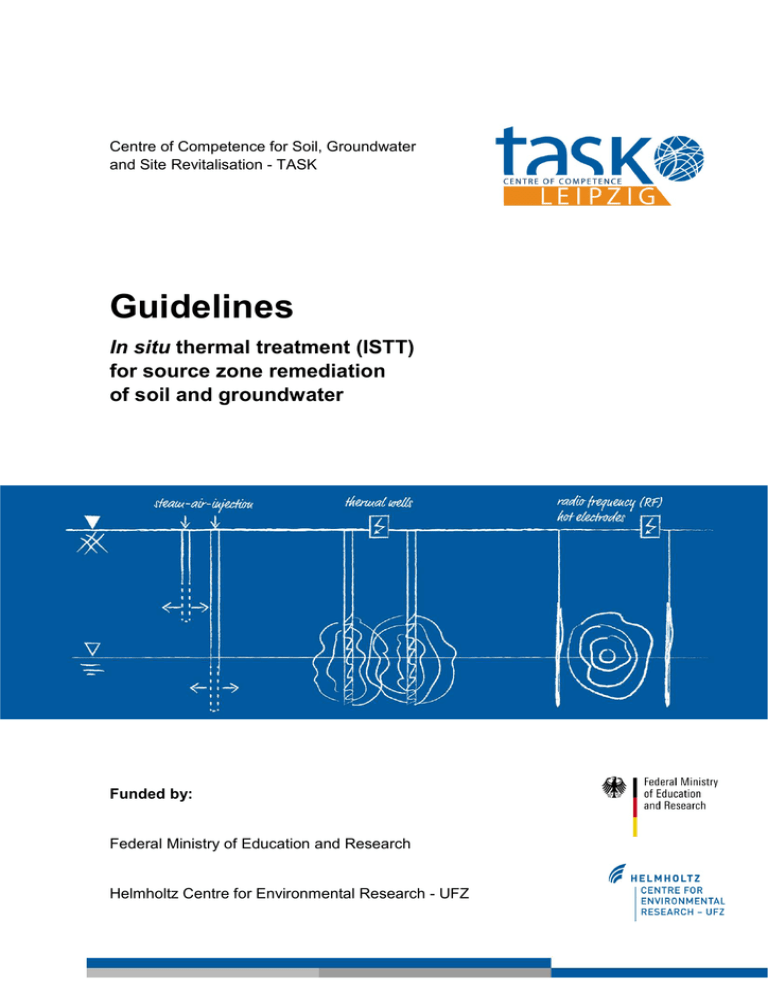

Guidelines - reconsite

advertisement