to a pdf document of this page.

advertisement

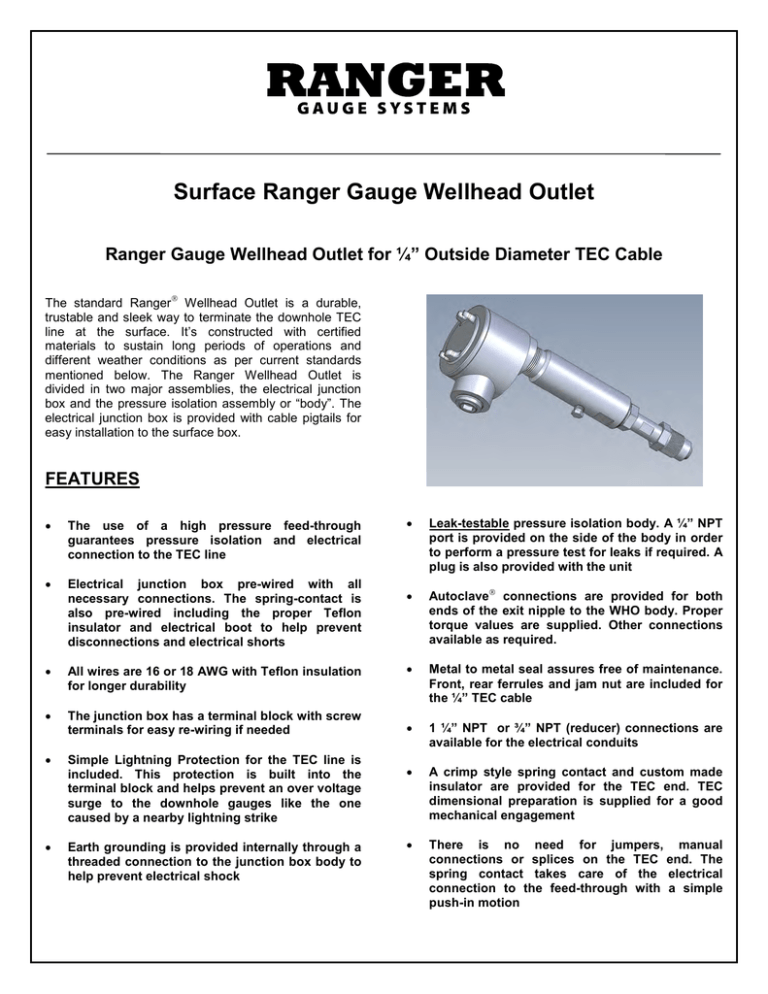

Surface Ranger Gauge Wellhead Outlet Ranger Gauge Wellhead Outlet for ¼” Outside Diameter TEC Cable The standard Ranger Wellhead Outlet is a durable, trustable and sleek way to terminate the downhole TEC line at the surface. It’s constructed with certified materials to sustain long periods of operations and different weather conditions as per current standards mentioned below. The Ranger Wellhead Outlet is divided in two major assemblies, the electrical junction box and the pressure isolation assembly or “body”. The electrical junction box is provided with cable pigtails for easy installation to the surface box. FEATURES • The use of a high pressure feed-through guarantees pressure isolation and electrical connection to the TEC line • Electrical junction box pre-wired with all necessary connections. The spring-contact is also pre-wired including the proper Teflon insulator and electrical boot to help prevent disconnections and electrical shorts • All wires are 16 or 18 AWG with Teflon insulation for longer durability • The junction box has a terminal block with screw terminals for easy re-wiring if needed • • Simple Lightning Protection for the TEC line is included. This protection is built into the terminal block and helps prevent an over voltage surge to the downhole gauges like the one caused by a nearby lightning strike Earth grounding is provided internally through a threaded connection to the junction box body to help prevent electrical shock • Leak-testable pressure isolation body. A ¼” NPT port is provided on the side of the body in order to perform a pressure test for leaks if required. A plug is also provided with the unit • Autoclave connections are provided for both ends of the exit nipple to the WHO body. Proper torque values are supplied. Other connections available as required. • Metal to metal seal assures free of maintenance. Front, rear ferrules and jam nut are included for the ¼” TEC cable • 1 ¼” NPT or ¾” NPT (reducer) connections are available for the electrical conduits • A crimp style spring contact and custom made insulator are provided for the TEC end. TEC dimensional preparation is supplied for a good mechanical engagement • There is no need for jumpers, manual connections or splices on the TEC end. The spring contact takes care of the electrical connection to the feed-through with a simple push-in motion Specifications Junction Box - 2 Inlets - 1 ¼” or ¾” NPT (reducer) inlet thread - Box material – Feraloy iron alloy - Cover material – Copper-free aluminum - Compliance: NEC/CEC: Class I, Division 1 & 2, Groups C, D Class II, Division 1, Groups E, F, G Class II, Division 2, Groups F, G Class III UL Standard: 886 ANSI Standard: C33.27 CSA Standard: C22.2 No. 30 NEMA/EEMAC 3, 4 - Neoprene "O" ring standard to meet NEMA 4 requirements - Explosion proof - Dust-Ignition proof - Rain tight - Wet Locations Operating Temperature Range o o o o -40 C to 70 C (-40 F to 158 F) Standard Operating Pressure Ranges 0 - 1379 Bars (0 - 20,000 psi). Wellhead Body and Nipple only. Dimensions (OD x L) Varies x 40cm (Varies x 15.75”) Pressure Housing and Nipple Material 316 SS Optional - Different inlet configuration could be available upon request - Longer nipple available upon request