B160

advertisement

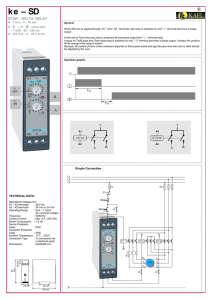

ACME ENGINEERING & MANUFACTURING CORP. P.O. BOX 978 Muskogee, OK 74402 Phone: 918/682-7791 Fax: 800/382-2263 acmehort@thefanpeople.com www.acmehort.com SEMS-1 STANDARD GREENHOUSE APPLICATION • FAN-JET OR HAF • BENCH HEATER • TWO STAGES OF OVERHEAD VENT • 2 EXHAUST FANS INCLUDING ONE 2 SPEED • GABLE SHUTTER (FIRST COOLING STAGE) • SHUTTER OR END VENT AIR INLET • EVAPORATIVE PAD COOLING SYSTEM BENEFITS • EASY INSTALLATION • EASY SET-UP • EASY OPERATION • RUGGED LONG LIFE The Standard EMS is designed to control the basic greenhouse. The SEMS comes completely configured and wired ready for mounting on the wall. FEATURES • ACC I ENVIRONMENTAL CONTROLLER • 10 POWER RELAYS • BYPASS SWITCHES FOR POWER RELAYS • SAFE 24 VAC CONTROL WIRING • PREWIRED AT FACTORY • TEMP. SENSOR WITH 75’ CABLE • PHOTOCELL OPTION • DEHUMIDIFICATION OPTION • SEALED FIBERGLASS ENCLOSURE • ENVIRONMENTALLY PROTECTED • HINGED ENCLOSURE FOR EASY ACCESS The SEMS is a complete station for environmental control. The computer used in this system is the ACC I. This is set up with 3 Heating stages and 4 Cooling stages. The temperature can be monitored with up to 500 feet between the sensor and the controller. A convenient front panel display shows the current room temperature alternating with a display of the stage in operation. The SET POINT or ideal temperature can be easily input or displayed from the front panel. Optional features include the night time temperature set back, dehumidification control and cooling lockout. An optional photocell is used to switch the night time heating temperature to a lower setting. By adding an optional humidistat to the ACC I, the first cooling stage can be operated during SET POINT to exhaust humid air. Stages above the second cooling stage can be locked out on sunny cold days with the addition of an optional external temperature sensor. The Computer automatically sequences the stages when powered up. This feature minimizes the TURN ON current surges by gradually stepping the equipment on after a power failure. All settings are automatically saved during a power outage. The controller is wired to a set of power relays designed to operate the greenhouse equipment. In an emergency, any power relay may be bypassed and the corresponding equipment energized using the AUTO/OFF/ON switch located inside the enclosure. The enclosure is a waterproof gasketed fiberglass box designed to be mounted inside of your greenhouse. The unit is set up with staging as shown in Table 1. At each temperature stage specific pieces of equipment are designed to be actuated this computer will operate the building from turning on up to 3 heating systems on a cold winter day to the operation of two exhaust fans and an evaporative cooling system on the warmest summer day. CONTROLS FORM B160B September 2000 SEMS-1 SPECIFICATIONS AND DETAILS Input Voltage 120 VAC 50/60 Hz Input Circuit Breaker 15A Recommended SPST (single pole single throw Rating 1 HP 120 VAC Number One per output relay Type DPDT (double pole double throw) Rating Function Disconnect Switches 11/2 HP 240 VAC 11/2 HP 2 Pole 120 VAC 2 HP 2 Poles 240 VAC H3 Auto/Off/On Switch completely disconnects power relay from the circuit in the manual (Off/On) mode. H2 Number One per output relay Type DPDT (double pole double throw) Rating 11/2 HP 2 Pole 120 VAC 2 HP 2 Poles 240 VAC Function Auto/Off/On Switch completely disconnects power relay from the circuit in the manual (Off/On) mode. Control Voltage 24 VAC 100 VA Transformer Temp Sensor Solid State with 75 feet of cable Enclosure Heavy Fiberglass with Gasketed Door. Full Length Stainless Steel Hinge Quick Connect Stainless Steel Latches H1 X X X X X X X X X SP C1 SIDE VENT / SHUTTER Type FAN #2 1 PUMP #1 Output Relay R52 Number FAN #1 (LOW) N.C. 3A Output Relay R52 FANFET / HAP N.O. 3HP 220 VAC HEATER #1 N.O. 1HP 120 VAC GABLE SHUTTERS DPDT (double pole double throw) Rating HEATER #2 8 Type HEATER #3 Number FAN #1 (LOW TO HIGH) Output Relays R11-R42 CONTROLLER OUTPUT STAGE X X X X C2 X X C3 X X X C4 X X X X X X X X TABLE 1 Lockable Rain and Dust Tight Mounting Exterior Brackets Designed wall mounting using #14 (1/4) screws or bolts (by others) Controller ACC I 8 stage µP based Controller LIMITED WARRANTY Acme Engineering and Manufacturing Corporation warrants the products manufactured by Acme to be free from original defects in workmanship and material for two years subject to the terms and conditions of its published limited warranty. Warranties on purchased products are subject to the vendor’s warranty. Refer to current Form MS149 for complete limited warranty terms and conditions. WARNING Acme products are designed and manufactured to provide reliable performance but they are not guaranteed to be 100% free of defects. Even reliable products will experience occasional failures and this possibility should be recognized by the User. If these products are used in a life support ventilation system where failure could result in loss or injury, the User should provide adequate back-up ventilation, supplementary natural ventilation or failure alarm system, or acknowledge willingness to accept the risk of such loss or injury. WARNING DO NOT use in HAZARDOUS ENVIRONMENTS where fan’s electrical system could provide ignition to combustible or flammable materials unless unit is specifically built for hazardous environments. DISCLAIMER The Company has made a diligent effort to illustrate and describe the products in this literature accurately; however, such illustrations and descriptions are for the sole purpose of identification, and do not express or imply a warranty that the products are merchantable, or fit for a particular purpose, or that the products will necessarily conform to the illustrations or descriptions or dimension. CAUTION Guards must be installed when fan is within reach of personnel or within seven (7) feet (2.134 m) of working level or when deemed advisable for safety. The products on this brochure are covered by a limited warranty. For a complete copy of the warranty statement, see form MS149 or write to Acme Engineering and Manufacturing Corp. July 2000 Form B160 Rev. B