Daniel Lancelot. ,4? ATTORNEY

advertisement

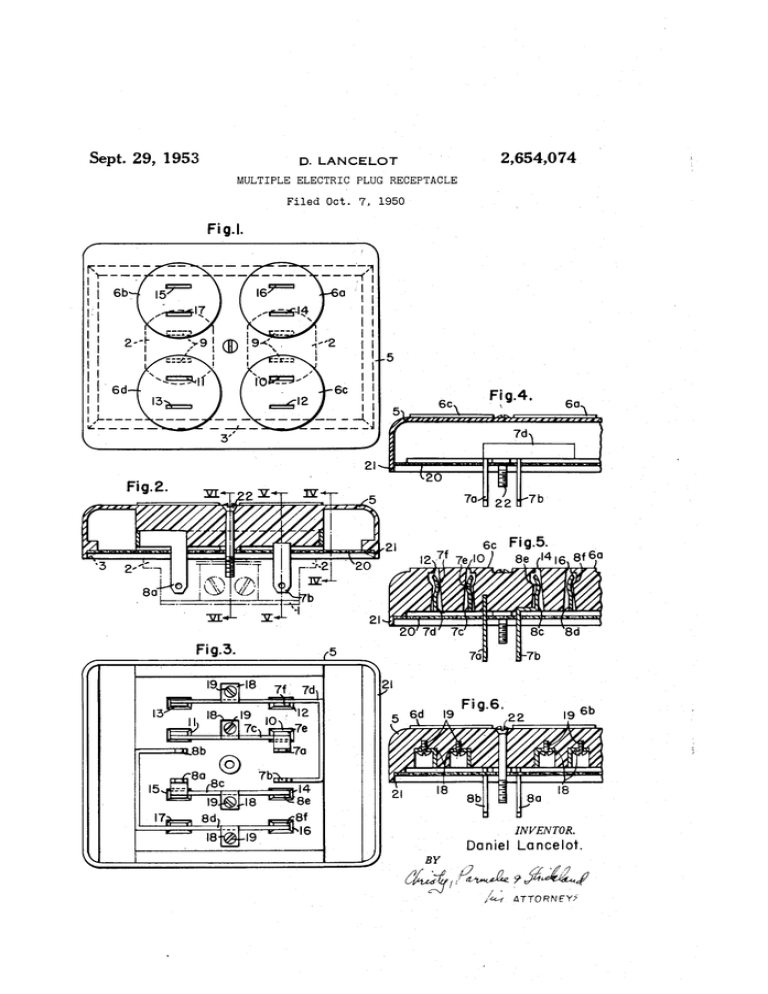

Sept. 29, 1953

D, LANCELOT

'

2,654,074

MULTIPLE ELECTRIC PLUG RECEPTACLE

Filed Oct. 7, 1950

‘

INVENTOR.

Daniel Lancelot.

,4? ATTORNEY;

Patented Sept. 29, 1.953

2,654,074

UNITED STATES PATENT‘ OFFICE

2,654,074

MULTIPLE ELECTRIC PLUG RECEPTACLE

Daniel Lancelot, Pittsburgh, Pa.

Application October 7, 1950, Serial No. 189,005

4 Claims. (01. 339-76)

1

This invention relates generally to electrical

plug receptacles and more in particular to a plug

receptacle which may be plugged into a standard

?ush mounted plug receptacle forming a perma

nent part of the wiring of a building.

Numerous variations of plug-in types of plug

receptacles are available for multiplying plug-in

facilities at a particular plug receptacle. In

plug-in plug receptacle of Fig. 1;

most of these, the plug-in receptacle comprises

spectively, of Fig. 2.

receptacle embodying the principles of this in

vention;

Fig. 2 is a longitudinal sectional view of the

Fig. 3 is a bottom plan view of the plug-in plug

receptacle of Fig. 1; and

Figs. 4, 5 and 6 are, respectively, sectional views

taken on the lines IV-IV, V—V and VI—-VI, re

.

a housing of electrical insulating material having 10

The several illustrations of the drawing illus

plug receptacles, in several of the faces thereof,

trate a preferred embodiment of this invention

connected to a pair of protruding prongs adapted

designed for plug-in connection to a standard

to plug into a standard ?ush mounted receptacle.

double ?ush mounted plug receptacle of the type

Usually three, and sometimes more, plug recep

permanently wired into a wiring system. These

15

tacles are provided in the faces of the plug-in

standard plug receptacles are usually placed in a

unit. Thus the facilities of a single outlet, by

wall of a building, in keeping with the electrical

such an expedient, are increased at least three

code, and are mounted in metal boxes, secured

fold. Thus a concentration, for example, of

to the building frame in such a position that the

household electrical devices such as appliances

edges de?ning the open end of the box are sub

and portable lighting units may be conveniently

stantially at the ?nished surface of the wall.

handled.

Such a box is not shown in the interest of sim

The mechanics of such an arrangement how

plicity. The standard plug receptacle is ?tted

ever, are poor. The entire mechanical load hangs

into the box and secured thereto by means of

on the prongs of the plug-in plug receptacle and

screws (not shown). In the case of a double

after a short period of time, mechanical failure

plug receptacle, as l (or duplex convenience out

of the ?ush mounted plug receptacle occurs.

let as it is sometimes known), when mounted in

,Since this last-named receptacle is essentially, a

the box, each plug receptacle face 2 protrudes

permanent part of the wiring system, its replace

about one-eighth of an inch beyond the wall

ment is a matter of some consequence. Plug-in

surface. A cover plate 3 of rectangular plan

receptacles of this type, therefore, do not repre

forming having a pair of openings therein neatly

sent an adequate solution to the problem.

?tting about the edges of the faces of the plug

One object of this invention is to provide a

receptacles covers the box opening and seats

plug-in type of plug receptacle which may be

against the wall. In practice, a cover plate

securely mechanically attached to a standard

mounting screw clears through the cover plate

?ush mounted plug receptacle forming a perma

and threads into a threaded hole in the plug re

nent part of a wiring system.

ceptacle between the plug receptacle faces to se

More in particular it is an object of this inven

cure the cover plate in position. Alternatively

tion to provide a plug-in type of plug receptacle

some standard receptacles may require the use:

having two pairs of plug connectors for plug-in

of two screws in mounting the cover plate.

connection with a standard double plug recep

The present invention contemplates establishtacle of the ?ush mounted type wherein provi

ing electrical connections in the two plug recep

sion is had for securely mechanically attaching

tacles of a standard double plug receptacle, for a.

the plug-in plug receptacle to the standard plug

plurality of plug receptacles in a single insulating

receptacle.

block and securing'the assembly in position by a.

It is also an object of this invention to provide

screw or screws as required clearing through the

plug-in plug receptacles of the character re

plug receptacle block and threadedly engaging

ferred to in the preceding objects with a plu

the threaded hole in the standard double plug

rality of plug receptacles therein.

receptacle.

’

The foregoing statements are merely illustra

In Figs. 1, 2 and 3, the insulating receptacle

tive of the various aims and objects of this in 50 base or housing is designated 5 and is provided

vention. Other objects and advantages will be

with four plug receptacles 6a, 6b, 6c and 6d which

come apparent upon a study of the following-dis

are grouped in pairs on opposite sides of alongi

closure when considered in conjunction with the

tudinal center line through the base. In Fig. 1,

accompanying drawing, in which:

the position of the standard double plug recep

Fig. 1 is a plan view of a plug-in type of plug 55 ‘tacle is indicated by the individual plug recep

2,654,074

3

4

connections may be extended to include any

standard receptacle cover plate 3 is also indi

cated in dotted outline. As will be seen from the

bottom view of Fig. 3, the plug-in type of plug

receptacle of this invention is provided with two

pairs of plug prongs ‘la, ‘lb and 8a, 8b, respec

tively, which are suitably spaced along the base

in correspondence with the spacing of the prong

receiving openings 9 01' the standard double plug

receptacle I.

'

'

.

illustrated, it will be appreciated that the parallel

tacle 2', in dotted outline, and the position of the

number of plug receptacles within practical lim

its. Although the present design has been made

to straddle the cover plate 3 for the standard re

ceptacle I so that the cover plate need not be

removed, it will be appreciated that other designs

may be made which are exactly the size of the

10

The prongs 1a, 1b, 8a and 8b may be an integral

standard double receptacle cover plate, removal

of the cover plate being optional. In any event.

the unit is preferably of such a size as to com

pletely cover the standard receptacle and its

mounting box as does the standard cover plate.

part of, or otherwise suitably joined to, a plurality

of current carrying strips secured in suitable

It will be appreciated that numerous variations

connections to the respective plug receptacles ‘6a 15 in ~design details with regard to the con?guration

of parts'ahd the location of the plug receptacles

through 6d. To this end, prong la is integrally

oi

plugein ~?xture may be had without de

formed with strip ‘(c which egtends between the

cavities in the insulating basc 5 to prgvide circuit

parting ‘from the spirit and scope of this inven

prong-receiving openings [0 and H of the plug

tion. Accordingly, it is intended that the fore

receptacles 6c and 611, respectively. Prong 1b is

an integral part of a u-shaped metal strip 1d, 20 going disclosure and the illustrations of the

being formed at the the of the shed leg thereaf

drawings shall be considered only as illustrative

“Pound the Pl?“ 1‘?

{$11.9 1W8 léig 0f the

U-shaped member straddles the prpngerepeiying

’1 claim:

1. An electrical convenience outlet unit for at

95th? mil-9.1.9165 hi this invention

The ‘ bi'glit of the’ U-shaped strip 1d extends

openings .1? and '13 9f P1145 receptacles 6? and 5d,

25

tachment to a standard builtfin, flush mounted,

convenience outlet having two conventional plug

receptacles and at least one threaded hole for

receiving a cover plate mounting screw, compris

ing, in combination, a base of electrical insulating

I2 adjacent one side thereof (see Fig. 5‘) to slid

sbly engage the prongs 0? a sthhdard plug @011 30' material, two pairs of metal bayonet prongs ?tted

and secured in said base in positions to plug into

n?ctol‘ to .be plugged WQ'QP- lirehgereeeivins

the two conventional plug receptacles, respec

openings II and ‘I’; have similar contact strips

respectively. Contact strips ‘bio and ‘if, which

may be an integral Part of ships 7!; and 1d. re

speh?vely, Project upwardly hit? epehinss 1? and

tiveiy; a metal strip connected to one prong of

one of said pairs of prongs and secured in said

(not shown), integrally formed with strips 1,0 and

1.11, ?tted therein. $t'rips t9 eh? Pd, renewed

ing, respectively to strips 1? and .ld, are integrally

35

formed with prongs .811 ehd {lb and each is pre

vided with contact strips projecting into prong

receiving openings “[15; i6 and 11. Contact

strips Bev and 8/‘ which are integrally iorrned with

strips _8c and 8d are shown in Fig. ‘5 intheir re

spective positions in érohg-reeeivihg ol?mllgs, U

and 1.6 .of plug receptacle ta. [l‘ihis construction

whhecis 151118" receptacles W .hhd B1? in parallel

and connects. P1148 r§9¢PP§i°1¢S 5c @4115 W in Paral

lel. doubling the Plus receptacle capacity of the

standard double plug receptacle 1.

As earlier

‘

cf the strips ‘[0, 1d and

8c, 8d are disposed in suitable cavities in the

base or housing.§. $uitable means for securing

these strips in the base is represented in the

mounting'tabs l8 integrally formed with the re,

spective strips

secured to the base by screws

f9 which clear therethrough and threaded-1y en

gage the base. The details of this mounting ap:

base, a second metal strip corresponding to the

?rst-mentioned metal strip secured to a prong .of

the other pair of prongs positioned diagonally op~

posite said ?rstementioned prong, said second

metal strip being secured in said base in a

40

45

position substantially paralleling and oppo

site to said ?rst-mentioned metal strip, metal

strips connected to the remaining prong of each

pair of prongs and secured in said base in paral

lel spaced relation with the metal strip connected

to the other prong of that pair forming spaced

pairs of metal strips, said base having spaced

pairs ‘of openings therethrough into said spaced

pairs of metal strips for permitting the entrance

ofthe prongs ,of standard electrical plugs into en

5,0 gagement-with the respective pairs-of metal strips,

whereby a plurality of parallel connections is at

forded with each pair of metal strips, and a

mounting screw clearing through said base and

adapted to engage the threaded ‘hole in the stand

bottom of this plug-in 55 ard convenience .outletto secure said base over the

pear in Figs. 3 ‘and 6.

type of Plug receptacle is covered with a sheet of

material of electrical insulating material ‘29 (not

standard convenience outlet.

2.

'

electrical convenience outlet .unit for at

shown in

3) to insnlatedly enclose the metal

strips ‘Ic, 1d, 8c and go.

la, 1b, 8a .and 81)

tachrnent to a standard built-in, ?ush mounted,

convenience outlet having two conventional plug

project through suitable openings in this sheet 20.

In the illustrated embodiment -_a marginal skirt

receptacles and at least‘ one threaded hole for

receiving a'cover plate mounting screw, compris

ing, ‘in combination, a base of electrical insulat

ing material, two pairs .of metal bayonet prongs

2| is provided, the bottom edges of which engage

the finished wall surface and space the unit a

su?icient distance from the wall surface to clear

?tted and secured in said base in positions to

the faces of plug receptacles 2 .of the standard

plug into the two conventional plug receptacles,

double plug receptacle. The unit is securely

mounted .to the standard plug receptacle _4 by a

respectively; a metal strip connected to one prong

of one of said pairs of .prongs and secured in

screw 22 which‘ clears through the insulating base

said base, a second metal strip corresponding to

the ?rst-mentioned metal strip secured to a

or how 5 has thmhsls-ihtothethrehdedho1e

in standard plug rcqeptacle l which normally rev 70 prong of the other pair of prongs located in a

position diagonally opposite said ?rst-mentioned

ceives the ‘cover plate ‘screw. affording a strong

mechanical connection completely relieuing the

prongs in the plug receptacle in through 5d of

prong, said second metal strip being secured in

said base in a position substantially parallelling

and opposite to said ?rst-mentioned meal strip,

mechanical load.

‘

While We Page 9; 19.1115 reqeptacles have been 75 metal strips connected to the remaining prong

2,054,074

5

6

of each pair of prongs and secured in said base

in parallel spaced relation with the metal strip

connected to the other prong of 'that pair forming

spaced pairs of metal strips, said base having

spaced pairs of openings therethrough into said

ard convenience outlet to secure said base over

standard convenience outlet to secure said base

over said standard convenience outlet, said base

one of said pairs of prongs and secured in said.

base, a second metal strip corresponding to the

?rst-mentioned metal strip secured to a prong

of the other pair of prongs located in a position

diagonally opposite said ?rst mentioned prong, a

?rst U-shaped metal strip having a long leg and

a short leg, said short leg being connected ad

the standard convenience outlet.

4. An electrical convenience outlet unit for at

tachment to a standard built-in, ?ush mounted,

convenience outlet, having two conventional plug

spaced pairs of metal strip for permitting the

receptacles and at least one threaded hole for

entrance of the prongs of standard electrical plugs

receiving a cover plate mounting screw, compris

into engagement with the respective pairs of

ing, in combination, a base of electrical insulat

metal strips, whereby a plurality of parallel con

ing material, two pairs of metal bayonet prongs

nections is aiTorded with each pair of metal strips, 10 ?tted and secured in said base in positions to plug

and a mounting screw clearing through said base

into the two conventional plug receptacles, respec

and adapted to engage the threaded hole in the

tively; a metal strip connected to one prong of

including a portion having marginal edges suf?

cient to completely cover the standard conven

ience outlet.

3. An electrical convenience outlet unit for at

tachment to a standard built-in, flush mounted,

convenience outlet having two conventional plug 20 jacent its extremity to the remaining prong of

receptacles and at least one threaded hole for

said one pair of prongs and the long leg thereof

receiving a cover plate mounting screw, compris

being secured in said base in a position paralleling

and spaced from the ?rst-mentioned metal strip

ing, in combination, a base of electrical insulat

ing material, two pairs of metal bayonet prongs

forming one pair of spaced metal strips, a second

U-shaped metal strip having a long leg and a

?tted and secured in said base in positions to

plug into the two conventional plug receptacles,

short leg, the short leg of the second U-shaped

respectively; a metal strip connected to one prong

metal strip being connected to the remaining

of one of said pairs of prongs and secured in

prong of the other pair of metal prongs and the

said base, a second metal strip corresponding to

long log thereof being secured in said base in

the ?rst-mentioned metal strip secured to a prong 30 a position paralleling and spaced from said sec

of the other pair of prongs located in a posi

ond metal strip forming a second pair of spaced

tion diagonally opposite said ?rst-mentioned

metal strips, said base having spaced pairs of

prong, a ?rst U-shaped metal strip having a long

openings into said spaced pairs of metal strips

leg and a short leg, said short leg being con

for permitting the entrance of the prongs of

nected adjacent its extremity of the remaining 35 standard electrical plugs into engagement with

prong of said one pair of prongs and the long

the respective pairs of metal strips whereby a

leg thereof being secured in said base in a posi

plurality of parallel connections is afforded with

tion parallelling and spaced from. the ?rst-men

each pair of metal strips, and a mounting screw

tioned metal strip forming one pair of spaced

clearing through said base and adapted to engage

metal strips, a second U-shaped metal strip hav 40 the threaded hole in the standard convenience

ing a long leg and a short leg, the short leg of

outlet to secure said base over the standard con

the second U-shaped metal strip being connected

venience outlet, said base including a portion hav

to the remaining prong of the other pair of metal

ing marginal edges sufficient to completely cover

prongs and the long leg thereof being secured

the standard convenience outlet,

in said base in a position parallelling and spaced

DANIEL LANCELOT.

from said second metal strip forming a second

pair of spaced metal strips, said base having

References Cited in the ?le of this patent

spaced pairs of openings into said spaced pairs of

UNITED STATES PATENTS

metal strips for permitting the entrance of the

Number

Name

Date

prongs of standard electrical plugs into engage

1,717,836

Conner _________ __ June 18, 1929

ment with the respective pairs of spaced metal

2,299,617

Eisenberg ________ __ Oct. 20, 1942

strips whereby a plurality of parallel connections

2,454,024

Alemaghides ______ __ Nov. 16, 1948

are afforded with each pair of metal strips, and

2,462,756

Leopold _________ __ Feb. 22, 1949

a mounting screw clearing through said base and

Bonham ________ __ Nov. 29, 1949

adapted to engage the threaded hole in the stand 55 2,489,741