INSTALLATION INSTRUCTIONS

Aris LED Task and Display Luminaire

MODELS: ARIS-11, ARIS-21 and ARIS-41

CAUTION! – READ THIS FIRST --- IMPORTANT SAFETY INSTRUCTIONS

11500 Melrose Avenue

Franklin Park, Illinois 60131

Phone: 847-451-0700

Fax: 847-451-7512

www.alkco.com

WARNING:FIXTURES MUST BE INSTALLED BY A QUALIFIED ELECTRICIAN IN ACCORDANCE WITH ALL NATIONAL AND LOCAL BUILDING, ELECTRICAL AND SAFETY CODES AND REGULATIONS.

WARNING:DO NOT ATTEMPT TO INSTALL OR USE A FIXTURE UNTIL YOU READ AND UNDERSTAND THE INSTALLATION INSTRUCTIONS AND SAFETY LABELS.

WARNING:DO NOT USE A FIXTURE IF THE LENS, HOUSING, OR POWER CABLES ARE DAMAGED.

WARNING:FIXTURES HAVE LINE VOLTAGE RISK OF SHOCK AND NO USER SERVICEABLE PARTS. DO NOT ATTEMPT TO OPEN THEM.

WARNING:CLASS 1M LED PRODUCT. DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

TEST STANDARD: IEC 60825-1: 1993+A1+A2/EN 60825-1: 1994+A1+A2.

LED WAVELENGTH: 450 nm

MAXIMUM OUTPUT OF RADIATION: 1.32 nm

WARNING:ENSURE THAT MAIN POWER SUPPLY IS OFF BEFORE INSTALLING OR WIRING A FIXTURE.

WARNING:TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS: USE ONLY INSULATED STAPLES OR PLASTIC TIES TO SECURE CORDS; ROUTE AND SECURE CORDS SO THAT THEY WILL NOT BE PINCHED

OR DAMAGED WHEN THE CABINET IS PUSHED TO THE WALL.

I. START HERE

This installation guide contains important information on planning and installing your new Aris LED fixture to ensure peak performance.

Before you begin the installation, read this complete document. It contains important safety and installation instructions that will help

you install Aris quickly and safely.

II. System Layout

Aris has been designed to offer flexibility and simplicity of the installation. It is recommended that you lay out the fixture components

to review how they will be installed and to ensure that you have all the necessary components before beginning.

A. Connecting to Line Power

CAUTION: THE U.S. NATIONAL ELECTRICAL CODE (NEC) DOES NOT PERMIT CORDS TO BE CONCEALED WHERE DAMAGE TO INSULATION MAY GO UNNOTICED. TO PREVENT FIRE DANGER, DO NOT RUN CORD BEHIND WALLS,

CEILINGS, SOFFITS OR CABINETS WHERE IT MAY BE INACCESSIBLE FOR EXAMINATION. CORDS SHOULD

BE VISUALLY EXAMINED PERIODICALLY AND IMMEDIATELY REPLACED WHEN DAMAGE IS NOTED.

CAUTION: NOT INTENDED FOR RECESSED INSTALLATION IN CEILING OR SOFFITS.

NOT INTENDED FOR SURFACE INSTALLATIONS INSIDE BUILT-IN RESIDENTIAL FURNISHINGS.

CAUTION: TO PREVENT THE RISK OF FIRE, DO NOT INSTALL CLOSER THAN 0.25" (7 MM) TO CABINET WALL OR IN A

COMPARTMENT SMALLER THAN 12 INCHES BY 12 INCHES WIDE AND HIGH BY 12, 24 OR 44 INCHES LONG FOR THE 9.25, 19.25 AND 39.25 INCH FIXTURES, RESPECTIVELY.

CAUTION: DO NOT EXCEED THE MAXIMUM NUMBER OF FIXTURES CONNECTED IN A RUN OF INTERCONNECTED

FIXTURES.

CAUTION: DO NOT USE A FIXTURE FOR ANY VOLTAGE FOR WHICH IT IS NOT RATED.

DO NOT EXCEED THE SPECIFIED VOLTAGE AND CURRENT INPUT FOR ANY FIXTURE.

CAUTION: DO NOT HOT SWAP FIXTURES. ENSURE THAT POWER TO THE SERIES IS OFF BEFORE CONNECTING OR

DISCONNECTING INDIVIDUAL FIXTURES.

CAUTION: IF THE INSTALLATION INVOLVES DIMMING, ARIS FIXTURES CAN BE CONTROLLED WITH A COMMERCIALLY AVAILABLE WALL DIMMER CONTROL RATED FOR ELECTRONIC LOW VOLTAGE (ELV) LOADS.

(See Section VI – Dimming Controls)

Copyright © 2008 Alkco Lighting. All rights reserved.

PUB-000203-00

Specification subject to change without notice. Printed in PRC.

A. Connecting to Line Power

Aris fixtures are designed to allow direct connection to 120 volt power. This can be done in one of two ways:

Portable installations

hard wired installations

The Switched Leader Cable (SLC) has a 10' cord with

grounded plug and a plug box that can is plugged into

the right end of the Aris fixture (as you face the fixture).

The plug box has a switch to allow for controlling a single

or series of connected fixtures.

The Hard Wiring Compartment (HWC) and Direct Wire Compartment (DWC) have several knockouts to accept flexible metal

conduit (FMC) or non-metallic cable (NM). Both should be secured

to the HWC/DWC with appropriate strain relief connector.

The HWC must be connected to the left end of the Aris fixture by

using one of the Jumper Cables (AJC6, AJC12, AJC18, AJC60 or

AJCY).

The DWC can be plugged into the right or left end of the Aris fixture

and has a switch to allow for controlling a single or series of connected fixtures.

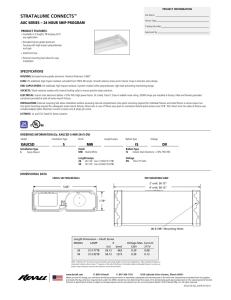

B. Aris fixtures

An Aris installation can involve a single fixture or be up to 50 linear feet and <324 watts of fixtures on a single run. Aris is available

in 3 different fixture lengths to fit the application. Lay out the fixtures for your installation to determine their location. The chart below

identifies the nominal fixture length and the installed length for each Aris fixture. The installed length includes the nominal fixture length

plus the electrical connections that must be installed on each fixture.

Fixture Model

Nominal Fixture Length

ARIS-11

9.25" (235mm)

Installed Fixture Length

Max. Power Consumption

11" (280mm)

6W

ARIS-21

19.25" (489mm)

21" (550mm)

13W

ARIS-41

39.25" (997mm)

41" (1040mm)

25W

C. Interconnecting Aris fixtures

There are a variety of jumper cables and connectors to allow you to interconnect from

one fixture to the next. The first fixture in the series will be connected to the electrical

power using one of the methods described in section A. above. If there is only one

fixture in your application, use the Termination Plug (ATRM) with the connector at the

opposite end of the fixture. A Termination Plug is provided with the Switched Leader

Cable, Hard Wire Compartment and Direct Wire Compartment.

Model Number

If there is more than one fixture in your application, you can use one of the Jumper

Cables (AJC6, AJC12, AJC18, AJC60 or AJCY) or a Flush Connector (AFC) to connect

fixtures in series. The Jumper Cables come in a variety of lengths to allow greater

spacing, to navigate around corners or to avoid obstacles. The chart below shows the

variety of lengths of Jumper Cables available. The Flush Connector (AFC) allows

fixtures to be connected end-to-end. Again, the last fixture(s) in the run need the

Termination Plug inserted into the connector at the opposite end of the fixture before

the system is energized.

Nominal Length

AJC6

6" (152mm)

AJC12

12" (305mm)

AJC18

18" (457mm)

AJC60

60" (1524mm)

AJCY

16.5" (419mm)

AFC

.875" (22mm)

D. Mounting options

Aris fixtures are mounted using the supplied mounting clips or with the optional full length brackets (AMB11, AMB21 or AMB41). For

either type of bracket, using screws is the preferred way to mount the brackets, but depending on the substrate, nuts and bolts, doublesided adhesive mounting foam, or even flat strip magnets may be used.

Once the brackets are in place, the Aris fixtures snap into the clips/bracket. In general, the best illumination results occur when the

fixtures are installed near the front edge of the cabinet, away from the wall.

E. Required tools and materials

To wire and mount an Aris system, you need:

• General tools to secure mounting clips/brackets (drill, screwdriver, level, measuring tools, etc.)

• Electrical tools and supplies (wire cutters, insulation strippers, wire nuts) to install the Wiring Compartment (if used) and to connect leader cables to a line circuit.

2

2. If multiple fixtures are to be mounted end-to-end and electrically connected with the Flush Connector (AFC), they must be precisely mounted in a straight line to avoid poor electrical contact and unreliable operation. Draw a straight line on the mounting

surface indicating the back edge of all the fixtures

to be mounted.

3. You have the option to use either the mounting clips (supplied with the fixture) or the optional full length mounting brackets. Position the clips/brackets along the marked line install to the mounting surface with screws or other hardware that is appropriate to the cabinet or substrate material. Be sure to use all of the pre-drilled holes in the clips/brackets.

STANDARD

MOUNTING

CLIPS

Figure 1

III. Installation

A. Install Mounting CLIPS or Brackets

1. Determine the location of each Aris fixture for your application. For undercabinet applications, it is

recommended that you install the fixtures near the front edge of cabinet with the lens facing toward the wall. It is also important to leave a minimum of 0.25" between the fixture and any vertical surface such as a cabinet valence. Be sure there is adequate

clearance at the ends of the fixtures for plugging in jumper cables, flush connectors or termination plug.

B. Install the Fixtures

CAUTION: TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS; USE ONLY INSULATED STAPLES OR PLASTIC TIES TO SECURE THE CORDS; ROUTE AND SECURE CORDS SO THAT THEY WILL NOT BE PINCHED OR DAMAGED WHEN THE CABINET IS PUSHED TO THE WALL.

Figure 2

1. Install the Aris fixtures by snapping them into the mounting clips/brackets. The square side of the fixture should face out toward the room and the rounded side should face toward the task surface and back wall. You should feel the bracket snap tightly around the fixture body.

2.Connect each pair of fixtures with jumper cables or flush connectors. The cables and connectors snap into the ends of each pair of fixtures. (See Figure 2)

3.If the jumper cables need to be held close to the mounting surface, ensure that you do not kink the cables or penetrate the jumper cable with a fastener.

4.Insert a termination plug in the final left side

connector (as you face the mounted fixtures) of the last fixture in the run.

Figure 3

3

OPTIONAL

FULL LENGTH

MOUNTING

Bracket

IV. Electrical Connections

CAUTION:

DO NOT HOT SWAP FIXTURES.

ENSURE THAT POWER TO THE

SERIES IS OFF BEFORE CONNECTING OR DISCONNECTING INDIVIDUAL FIXTURES.

Aris fixtures are wired just like any other line-voltage

fixtures. There are two basic methods to connect the

fixtures to electrical power – a portable installation or a

hard wired installation.

A. Portable installation

1.The Switched Leader Cable (SLC) snaps into the right end of the fixture series (as you face the

Figure 4

fixtures) and the plug is the plugged into a 120 VAC receptacle. Install the termination plug into the end

cap of the last fixture in the run. (See Figure 3)

B.hard wired installation with Hard wire compartment (HWC)

1. UL standards for permanently installed systems in North America require that a wiring compartment be mounted in close

proximity to the first fixture in the series. A line (black) circuit is connected to the line, neutral (white), and ground (green) leads in the wiring compartment. (See Figure 4)

2. A jumper cable or flush connector connects the wiring compartment to the first fixture in the series. Install the termination plug into the end cap of the last fixture of the run.

C.hard wired installation with

direct wire compartment (DWC)

The Direct Wire Compartment (DWC) is configured to

install at the right end of the fixture(s). The DWC can be

field modified to allow installation on the left end by following the additional installation instructions noted below.

1. Determine if the DWC will be installed on the right end or left end of the fixture before beginning. Figure 5 shows the DWC installed on the right end.

2. Open the DWC by removing the two Philips-head screws from the back panel. (See Figure 6)

3. When installed, the DWC

will align flush TABS

with the ENDPLATE

front

edge of a run of fixtures as shown in Figure 5.

TABS

ENDPLATE

4. The 3-pin connector, which protrudes from the end of the DWC, comes positioned for installing on the right end of a run. If this works for the installation, proceed to Step 5 below. If the installation requires the DWC to be installed on the left end of a run, follow the remaining instructions in this step.

a.) Remove the endplate from its slot by pushing the plastic tabs free of the

connector and pulling the endplate up. (See Figure 7)

b.) Slide the connector out of the endplate, and rotate the endplate 180 degrees horizontally so that the connector can be inserted on the opposite end of the endplate. Check to make sure that the arrows on the face of the endplate is still facing upward. (See Figure 8)

Figure 6

Figure 5

ENDPLATE

ENDPLATE

ENDPLATE

TABS

TABS

TABS

ENDPLATE

TABS

Figure 7

Figure 8

Figure 9

Figure 10

4

c.)

d.)

Reinsert the endplate into the slot so that the connector is now in the opposite posi-

tion as shown in Figures 9 and 10. Make sure that the plastic tabs snap over the body of the connector.

Continue to Step 5.

5.

The DWC has three knockouts for inserting the power line – one on the end of the housing and one on either side. Using a flat-blade screwdriver, remove the knockout that you want to use. (See Figure 11)

6.

Remove the hex nut from the provided strain

relief connector and insert it into the slot behind the selected knockout opening. Insert the ground

connector strip into the tab to the left of the

knockout opening so that the strip touches the

hex nut. (See Figures 12 and 13)

7.

Attach the strain relief connector to the hex nut

and tighten. (Philips-head screws should be

accessible when the DWC is installed. You may need to reposition the hex nut in its slot to properly orient the strain relief connector screws.) (See Figure 14)

8.

Insert the power line through the strain relief connector leaving enough wire inside the box

to make connections. Tighten the Philips-head screws on the strain relief connector.

L

G

N

(See Figure 15)

9.

Trim 3/8" (10mm) of insulation from the wires and attach wire nuts.

Incoming Hot – Connect to black wire

Incoming Neutral – Connect to white wire

Incoming Ground – Connect to yellow/green wire

10. Package wires in the DWC housing making

sure not to pinch them and replace the back panel

using the two Philips-head screws. (See Figure 16)

Figure 11

Figure 12

L

Figure 13

L

LL

Figure 15

Figure 14

N

NN

G

GG

L

N

G

Figure 16

11. Connect the DWC to the Aris fixture at the end of the run. Use the two mounting holes to secure the DWC to the mounting substrate with screws. (See Figure 17) Choose the appropriate supplied termi-

nation plug into the opposite end or end of the run of the fixture(s).

V. Turning the Power ON

1. Check to make sure all fixtures are connected together. Make sure the power source is connected to the first fixture and that the termination plug is

installed in the last fixture of the run.

Figure 17

2. Energize the circuit and test the installation.

Step VI: Dimming Controls on page 6

5

Vi. DIMMING CONTROLS

Aris fixtures can be dimmed with commercially available dimmer controls that are designed for electronic low voltage (ELV) loads.

These controls will provide dimming down to approximately 10% of full output with variations depending on what dimmer is being used.

Note: Aris is not compatible with all types of dimmers.

ELV dimmer controls will also be referred to as "trailing edge" or "reverse phase control" models. The chart below shows a list of

recommended dimmers. These controls have been tested and approved for use with Aris fixtures. Aris fixtures may also be compatible

with other ELV dimmers but testing, prior to permanent installation, is recommended. Compatible dimmers listed in chart below.

Manufacturer

Product

Model

Description

Lutron

Nova T

NTELV-600

600W ELV single-pole slide

Lutron

Diva

DVELV-303P

300W ELV

Leviton

Decora

6615-POW

300W double-pole ELV

Leviton

Vizia

VZEO4

600W single-pole ELV

ETC

Sensor

SR12+

Sensor SR12+ rack w/ CEM+ control & D20 dimmer

ETC

Unison

DR12

DR12 rack w/ CMEd control & D20/L20 dimmers

Entertainment

Technology

BAKPAK

IPSBP7501

750W Theatrical z dimmer, DMX512 control.

CUSTOMER SUPPORT

If you require additional information regarding this light fixture we invite you to call us at Alkco. Our business hours are:

Monday - Friday (except holidays), 8:00am to 4:30pm Central time. Phone: 847-451-0700, Fax: 847-451-7512

REPLACEMENT PARTS

Contact Alkco Lighting directly for information on replacement parts. When calling, be prepared to provide the model number

and date of manufacture of the fixture. This information is indicated on labels located on the product.

WARRANTY

Aris fixtures (for the original installation) have a driver warranty of 3 years from the date of manufacture and a LED warranty

for the specified lumen maintenance for 10 years.

.075.0081

04/11 Aris Series

6