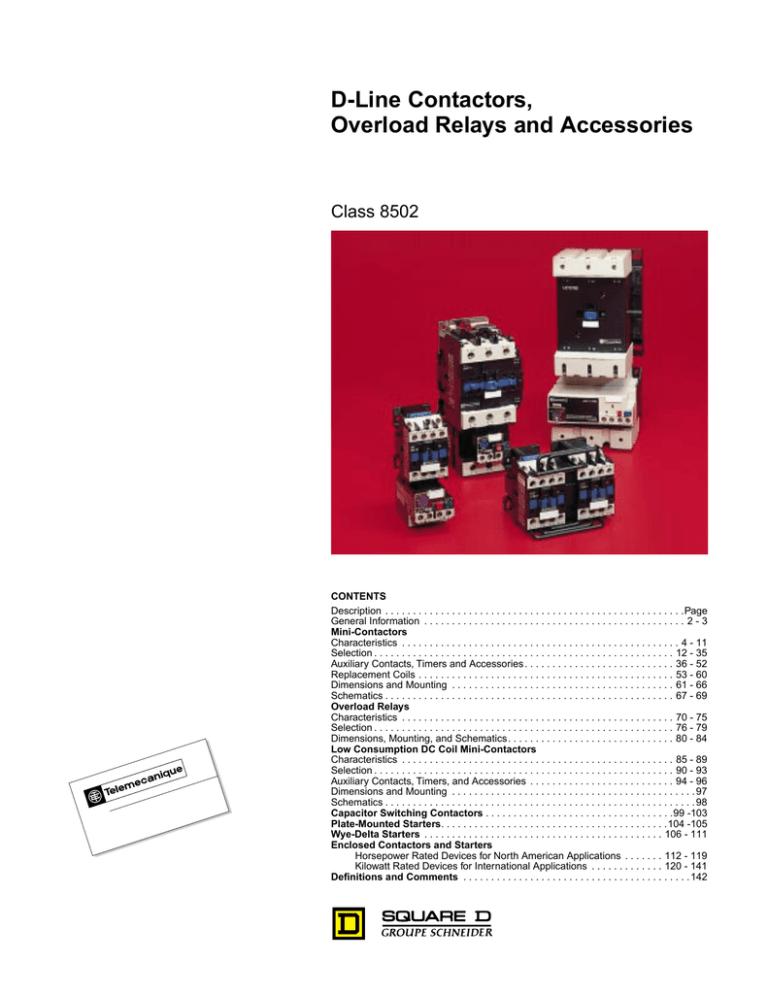

D-Line Contactors,

Overload Relays and Accessories

Class 8502

CONTENTS

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3

Mini-Contactors

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 - 35

Auxiliary Contacts, Timers and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 - 52

Replacement Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 - 60

Dimensions and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 - 66

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 - 69

Overload Relays

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70 - 75

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 - 79

Dimensions, Mounting, and Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 - 84

Low Consumption DC Coil Mini-Contactors

Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 - 89

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 - 93

Auxiliary Contacts, Timers, and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 94 - 96

Dimensions and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Capacitor Switching Contactors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99 -103

Plate-Mounted Starters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104 -105

Wye-Delta Starters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 - 111

Enclosed Contactors and Starters

Horsepower Rated Devices for North American Applications . . . . . . . 112 - 119

Kilowatt Rated Devices for International Applications . . . . . . . . . . . . . 120 - 141

Definitions and Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

D-Line Contactors, Overload Relays and Accessories

General Information

Introduction

The Telemecanique family of IEC style contactors and starters are the largest selling motor control

devices in the world. When the application calls for world class products, select the Telemecanique IEC

style contactors and starters for products that are marketed and sold in over 160 countries. Most devices

are UL listed, CSA certified, CE marked, meet IEC 947 standards and are approved by most other

international approved agencies.

The Telemecanique family of IEC style contactors and starters include the following:

K-Line mini-contactors and overload relays are for general purpose starting and protection in a small

package for loads up to 12 Amps or resistive loads up to 20 Amps.

D-Line contactors and overload relays offer the largest offering of accessories for maximum flexibility

in customer applications and automated systems up to 150 motor full-load Amps or 200 Amp resistive

loads.

F-Line contactors and solid state overload relays are for inductive loads up to 800 Amps or resistive

loads up to 1350 Amps and share common accessories with the D-Line.

GV manual starters provide manual isolation, manual motor control and overcurrent protection in one

compact unit. They are approved for Group Motor Installations when used alone or with D-Line

contactors.

Integral self-protected starters combine all the functions of a disconnect switch, circuit breaker,

contactor and overload relay in one coordinated unit to reduce required panel space by as much as 60%

and reduce installation and wiring time.

Selection of Telemecanique K-Line, D-Line and F-Line contactors are based on Utilization Categories,

a combination of application and duty cycle rates defined by the following:

• The type of application (inductive motor loads or resistive loads)

• The conditions under which making or breaking current takes place (motor starting or running,

reversing, plugging or jogging, locked rotor or stalled motor)

• Number of making and breaking operations (or cycles) required for the life of the contactor

When specifying Telemecanique IEC contactors and starters refer to the following Square D documents:

Catalog No. 8502CT9801

Catalog No. 8502CT9703

Catalog No. 8502CT9704

Catalog No. 8502CT9702

Catalog No. 2520CT9501

Catalog No. 8539CT9201

IEC Contactors Selection Guide

K-Line Contactors, Overload Relays and Accessories

D-Line Contactors, Overload Relays and Accessories

F-Line Contactors, Overload Relays and Accessories

GV2/GV3 Manual Starters and AK5 Panel Busbar System

Integral Self-Protected Starters

2

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

General Information

The D-Line Contactors and Overload Relays are the largest selling line of contactors and

starters in the world. They offer high reliability with long mechanical and electrical life and the

most complete line of accessories in the industry.

Contactor ratings

D-Line contactors and overload relays are available in eleven contactor ratings for the USA market for

inductive motor applications up to 150 full load Amps and resistive loads up to 200 Amps. They offer

motor control and overload protection for motors rated up to 100 horsepower at 480 VAC or 125

horsepower at 600 VAC.

3-pole and 4-pole contactor versions available.

Most contactors include built-in auxiliary contacts.

All screw connections have IP20 rated Finger-safe terminals with both North American and

International terminal markings.

D-Line contactors can be panel mounted with screws or DIN rail mounted.

Available in 3-pole contactor versions with built-in auxiliary contact for holding circuit or 4-pole

contactor versions

Easily installed Accessories

Auxiliary contact blocks with serrated wiping action

Front mount dust tight auxiliary contact blocks

Pneumatic time delay blocks

Transient voltage surge suppressors

Interface modules and electronic timers

Mechanical latching blocks

Control circuit flexibility

The D-Line contactors are available with AC or DC operating coils. Several devices utilize a low

consumption DC coil with built-in transient suppression for operation with a low level DC signal from a

computer or PLC without need for an interposing relay.

Overload relays

Class 10 or Class 20 bimetallic overload relays are available up to 140 Amps. They are ambient

compensated and are available with or without single phase sensitivity for phase unbalance and phase

loss protection. New solid state overload relays are available for 90 to 150 Amp applications. Both

bimetallic and solid-state overload relays include the following features: isolated N.C. trip contact and

N.O. alarm contacts, Manual or Automatic reset function, tamper resistant window for FLA settings and

Test trip button.

3

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Characteristics

Type LCkD and LPkD contactors

Type

LC1-D09

LC1-D12

LC1-D18

LC1-D25

LP1-D09

LP1-D12

LP1-D18

LP1-D25

Environment

Rated insulation voltage (Ui)

Rated impulse withstand voltage

(Uimp)

UL/CSA

V

690

690

690

690

To IEC 947-4-1, overvoltage

category III, degree of pollution: 3

V

1000

1000

1000

1000

Conforming to UL, CSA

V

600

600

600

600

Conforming to IEC 947

kV

8

8

8

8

Meets the essential requirements of the

LV & EMC directives

Conforming to standards

E164862

CCN NLDX

Approvals

Degree of protection c

Protective treatment

Conforming to VDE 0106

IEC 947-1, 947-4-1, NFC 63-110, VDE 0660, BS 5424, JEM 1038., EN 60947-1, EN 60947-4-1.

ASE, UL, CSA, DEMKO, NEMKO, SEMKO, FI, Conforming to SNCF, Sichere Trennung

recommendations

LR43364

Class 3211 04

Power connections

Protection against direct finger contact IP 2X

Coil connections

Protection against direct finger contact IP 2X

Conforming to IEC 68

“TH”

Storage

- 60 to + 80°C (-76 to +176°F)

Ambient air temperature around the

Operation at 80 to 110% nominal control voltage

device

Permissible at nominal control voltage

- 5 to + 55°C (-23 to +131°F)

- 40 to + 70°C (-40 to +158°F)

Maximum operating altitude

Without derating

3000m (8900 ft)

Operating positions

Without derating

± 30° possible, in relation to normal vertical mounting plane

Conforming to UL 94

V1

V1

V1

Conforming to IEC 695-2-1

960°

960°

960°

960°

Shock resistance a

1/2 sine wave = 11ms

Contactor open

10 g

10 g

10 g

8g

Contactor closed

15 g

15 g

15 g

15 g

Vibration resistance a

5 to 300 Hz

Contactor open

2g

2g

2g

2g

Contactor closed

4g

4g

4g

4g

Flame resistance

V1

Pole characteristics

Number of poles

Rated operational current (Ie)

3

3 or 4

3

3 or 4

In AC-3, θ ≤ 55°C (131°F)

A

9

12

18

25

In AC-1, θ ≤ 40°C (104°F)

A

20

25

32

40

Rated operational voltage (Ue)

Up to

V

690

690

690

690

Frequency limits

Of the operational current

Hz

25 to 400

25 to 400

25 to 400

25 to 400

Rated thermal current (Ith)

θ ≤ 40°C (104°F)

A

20

25

32

40

Rated making capacity (1 rms)

Conforming to IEC 947-4

A

220-380-415-440 V

Rated breaking capacity (1 rms)

Conforming to IEC 947

500 V

A

690 V

Permissible short time rating from

cold state, no current flowing for

previous 15 minutes, at θ ≤ 40 °C

Short-circuit protection

250

250

300

450

250

250

300

450

175

175

250

400

85

85

120

180

For 1 s

A

210

210

240

380

For 10 s

A

105

105

145

240

For 1 min

A

61

61

84

120

For 10 min

A

30

30

40

50

By circuit breaker

Select circuit breaker in accordance with NEC and local codes

By fuses

Maximum 400% of motor full load Amps

Average impedance per pole

A Ith and 50 Hz

mΩ

2.5

2.5

2.5

2

Power dissipation per pole for the

above operational currents

AC-3

W

0.20

0.36

0.8

1.25

AC-1

W

1.56

1.56

2.5

3.2

c Protection provided for the cable c.s.a. indicated on pages 10 and 11 and for cable connections.

a In the least favorable direction, without change of contact state (coil supplied at Ue).

4

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Characteristics

LC1-D32

LC1-D38

LP1-D32

LC1-D40

LC1-D50

LC1-D65

LC1-D80

LP1-D40

LP1-D50

LP1-D65

LP1-D80

LC1-D95

LC1-D115

LC1-D150

690

690

690

690

690

690

690

690

690

1000

1000

1000

1000

1000

1000

1000

1000

1000

600

600

600

600

600

600

600

600

600

8

8

8

8

8

8

8

8

8

IEC 947-1, 947-4-1, NFC 63-110, VDE 0660, BS 5424, JEM 1038., EN 60947-1, EN 60947-4-1.

ASE, UL, CSA, DEMKO, NEMKO, SEMKO,

FI, Conforming to SNCF, Sichere Trennung –

recommendations

UL, CSA

Protection against direct finger contact IP 2X

Protection against direct finger contact IP 2X except LP1-D40 to D80

“TH”

- 60 to + 80°C (-76 to +176°F)

- 5 to + 55°C (-23 to +131°F)

- 40 to + 70°C (-40 to +158°F)

3000m (8900 ft)

± 30° possible, in relation to normal vertical mounting plane

V1

V1

V1

V1

V1

V1

V1

V1

V1

960°

960°

960°

960°

960°

960°

960°

960°

960°

8g

8g

8g

8g

8g

8g

8g

6g

6g

15 g

10 g

10 g

10 g

10 g

10 g

10 g

15 g

15 g

2g

2g

2g

2g

2g

2g

2g

2g

2g

4g

4g

3g

3g

3g

3g

3g

4g

4g

3

3

3 or 4

3

3 or 4

3 or 4

3

3 or 4

3

32

38

40

50

65

80

95

115

150

50

50

60

80

80

125

125

200

200

690

690

1000

1000

1000

1000

1000

1000

1000

25 to 400

25 to 400

25 to 400

25 to 400

25 to 400

25 to 400

25 to 400

25 to 400

25 to 400

50

50

60

80

80

125

125

200

200

550

–

800

900

1000

1100

–

–

–

550

–

800

900

1000

1100

–

–

–

450

–

800

900

1000

1100

–

–

–

180

–

400

400

630

640

–

–

–

430

430

720

810

900

990

1100

1100

1400

260

310

320

400

520

640

800

950

1200

138

150

165

208

260

320

400

550

580

60

60

72

84

110

135

135

250

250

Select circuit breaker in accordance with NEC and local codes

Maximum 400% of motor full load Amps

2

2

1.5

1.5

1

0.8

0.8

0.6

0.6

2

2

2.4

3.7

4.2

5.1

7.2

7.9

13.5

5

5

5.4

9.6

6.4

12.5

12.5

24

24

5

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Characteristics

Type LCkD and LPkD contactors

Type

LC1-D09

LC1-D12

LC1-D18

LC1-D25

Control circuit characteristics

Rated control circuit voltage (Uc)

50 or 60 Hz

V

21 to 660

Operational

0.8 to 1.1 Uc

Drop-out

0.3 to 0.6 Uc

50 or 60 Hz coils

Control voltage limits (θ ≤ 55 °C)

Operational

0.85 to 1.1 Uc at 60 Hz

Drop-out

0.3 to 0.6 Uc

50/60 Hz coils

50 Hz coil

Inrush

VA

Cos ϕ

60

60

60

90

0.75

0.75

0.75

0.75

50/60 Hz coil

VA

70

70

70

10

50 Hz coil

VA

7

7

7

7.5

0.3

50 Hz AC

Sealed

Cos ϕ

0.3

0.3

0.3

50/60 Hz coil

VA

8

8

8

8.5

60 Hz coil

VA

70

70

70

100

0.75

Average consumption at 20 °C and at Uc

Inrush

Cos ϕ

0.75

0.75

0.75

50/60 Hz coil

VA

70

70

70

100

60 Hz coil

VA

7.5

7.5

7.5

8.5

60 Hz AC

Sealed

Cos ϕ

0.3

0.3

0.3

0.3

VA

8

8

8

8.5

50/60 Hz

W

2 to 3

2 to 3

2 to 3

2.5 to 3.5

Closing “C”

ms

12 to 22

12 to 22

12 to 22

15 to 24

Opening “O”

ms

50/60 Hz coil

Heat dissipation

Operating time c

Mechanical durability in millions of

operating cycles

Maximum operating rate at ambient

temperature ≤ 55 °C

4 to 19

4 to 19

4 to 19

5 to 19

50 or 60 Hz coil

20

20

16

16

50/60 Hz coil at 50 Hz

15

15

15

12

In operating cycles per hour

3600

3600

3600

3600

c The closing time “C” is measured from the moment the coil supply is switched on to initial contact of the main poles. The opening time “O” is measured from the moment the coil supply is

switched off to the moment the mains poles separate.

6

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Characteristics

LC1-D32

LC1-D38

LC1-D40

21 to 660

24 to 660

0.8 to 1.1 Uc

0.85 to 1.1 Uc

LC1-D50

LC1-D65

LC1-D80

LC1-D95

LC1-D115

LC1-D150

24 to 50

–

0.3 to 0.6 Uc

0.3 to 0.5 Uc

0.85 to 1.1 Uc at 60 Hz

–

0.8 to 1.15 Uc at 50/60 Hz

0.3 to 0.6 Uc

0.3 to 0.5 Uc

90

90

200

200

200

200

200

300

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.8

–

0.9

100

100

245

245

245

245

245

450

450

7.5

7.5

20

20

20

20

20

22

–

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.9

8.5

8.5

26

26

26

26

26

6

6

100

100

220

220

220

220

220

300

–

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.8

0.9

100

100

245

245

245

245

245

450

450

8.5

8.5

22

22

22

22

22

22

–

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.3

0.9

8.5

8.5

26

26

26

26

26

6

6

2.5 to 3.5

2.5 to 3.5

6 to 10

6 to 10

6 to 10

6 to 10

6 to 10

7 to 8

6 to 7

15 to 24

15 to 24

20 to 26

20 to 26

20 to 26

20 to 35

20 to 35

20 to 50

25 to 35

5 to 19

5 to 19

8 to 12

8 to 12

8 to 12

6 to 20

6 to 20

6 to 20

20 to 55

16

16

16

16

16

10

10

8

–

12

12

6

6

6

4

4

8

8

3600

3600

3600

3600

3600

3600

3600

2400

1200

7

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Characteristics

Type

LP1-D09, D12, D18

LP1-D25, D32

LP1-D40, D50, D65

LP1-D80

LC1-D115

LC1-D150

Control circuit characteristics

Rated control circuit voltage (Uc)

Control voltage limits

(θ ≤ 55 °C)

DC

Operational

V

Standard coil

Wide range coil

Drop-out

Average consumption at 20 °C and at Uc

Operating time c average at Uc

DC

12 to 440

12 to 440

24 to 440

0.8 to 1.1 Uc

0.85 to 1.1 Uc

0.7 to 1.2 Uc

0.7 to 1.25 Uc

0.75 to 1.2 Uc

–

0.1 to 0.25 Uc

0.1 to 0.3 Uc

0.2 to 0.4 Uc

Inrush

W

9

11

22

22

6

Sealed

W

9

11

22

22

6

Closing “C”

ms

40 to 48

52 to 64

85 to 110

95 to 130

25 to 35

Opening “O”

ms

6 to 14

8 to 14

20 to 35

20 to 35

20 to 35

Note: the arcing time depends on the circuit switched by the poles. For normal three-phase applications, arcing time is normally less than 10 ms.

The load is isolated from the supply after a time equal to the sum of the opening time and the arcing time.

Mechanical durability at Uc

In millions of operating cycles

30

25

20

20

8

Maximum operating rate at ambient

temperature ≤ 55 °C

In operating cycles per hour

3600

3600

3600

3600

1200

c The operating times depend on the type of contactor electromagnet and its control mode. The closing time “C” is measured from the moment the coil supply is switched on to initial contact

of the main poles. The opening time “O” is measured from the moment the coil supply is switched off to the moment the mains poles separate.

8

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Characteristics

Type LCkD and LPkD contactors

Integrated auxiliary contacts

Rated operational voltage (Ue)

Rated insulation voltage (Ui)

Rated thermal current (Ith)

Up to

V

690

Conforming to IEC 947-1

V

1000

Conforming to UL, CSA

V

600

For ambient temperature≤ 40 °C (104° F)

A

10

Hz

25 to 400

U min (minimum voltage)

V

17

I min (minimum current)

mA

5

Frequency of operational current

Minimum switching capacity

Short-circuit protection

Conforming to IEC 947-5-1

Rated making capacity

Conforming to IEC 947-5-1, I rms

A

140 AC, 250 DC

gG fuse: 10 A

1s

A

100

Short time rating

Permissible

for

500 ms

A

120

100 ms

A

140

MΩ

> 10

1.5 on energization and on de-energization

Insulation resistance

Non-overlap time

Guaranteed between N.C. and N.O. contacts

ms

Operational power of contacts

conforming to IEC 947-5-1

AC supply categories AC-14 and AC-15

Electrical durability (up to 3600 operating cycles/hour) on an inductive load

such as the coil of an electromagnet: making power (cos ϕ 0.7) = 10 times

the power broken (cos ϕ 0.4).

DC supply category DC-13

Electrical life (up to 1200 operating cycles/hour) on an inductive load such as

the coil of an electromagnet, without economy resistor, the time constant

increasing with the load.

V

24

48

110/ 127

220/230

380/400

440

600

V

24

48

110

220

440

600

1 million operating cycles

VA

150

300

400

480

500

500

500

W

120

90

75

68

61

58

3 million operating cycles

VA

80

170

250

290

320

320

320

W

70

50

38

33

28

27

10 million operating cycles

VA

30

65

90

120

130

130

130

W

25

18

14

12

10

9

Occasional making capacity

VA

1200

2600

7000

13 000

15 000

13 000

9000

W

1000

700

400

260

220

170

1 Breaking limit of contacts for:

maximum of 50 operating cycles at

10 s intervals. (power broken =

making power x cos ❊ 0.7).

Power broken in VA

220

440 600 V

2 Electrical durability of contacts:

- for 1 million operating cycles (2a).

- for 3 million operating cycles (2b).

- for 10 million operating cycles

(2c).

3 Breaking limit of contacts for:

maximum of 20 operating cycles at

10 s intervals and with current

passing for 0.5 s per cycle.

4 Thermal limit.

Power broken in VA

16 000

1000

10 000

8000

6000

5000

4000

3000

4

700

500

1

3

300

2000

1000

800

600

500

400

300

4

200

2a

250

200

200

100

80

60

50

40

30

140

100

2b

20

2c

50

100

80

60

2a

2b

2c

10

8

6

20

12

40

24

48

110

120

220

24

48

110

380 500

440 690 V

9

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Characteristics

Type LCkD and LPkD contactors

Power and control circuit connections

LC1-D09

LP1-D09

Type

LC1-D12

LP1-D12

LC1-D18

LP1-D18

LC1-D25

LP1-D25

18-8

Power circuit connections

Connector type

Stranded cable without cable end

Flexible cable with cable end

Cabling

Solid cable without cable end

Screw clamp terminals

1 conductor

AWG

18-10

18-10

18-8

2 conductors

AWG

18-10

18-10

18-8

18-8

1 conductor

mm2

1/4

1/4

1.5/6

1.5/10

2 conductors

mm2

1/4

1/4

1.5/6

1.5/6

1 conductor

AWG

18-6

18-6

18-3

18-3

2 conductors

AWG

18-10

18-10

18-6

18-3

1 conductor

mm2

1/4

1/4

1/6

1/6

2 conductors

mm2

1/2.5

1/2.5

1/4

1/4

1 conductor

AWG

18-8

18-8

18-8

18-8

2 conductors

AWG

18-8

18-8

18-8

18-8

1 conductor

mm2

1/4

1/4

1.5/6

1.5/6

2 conductors

mm2

1/4

1/4

1.5/6

1.5/6

Phillips head type

N° 2

N° 2

N° 2

N° 2

Screwdriver Ø

Ø6

Ø6

Ø6

Ø6

Hexagon spanner

–

–

–

–

Tightening torque

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

15 lb.-in.

1.7 Nkm

15 lb.-in.

1.85 Nkm

Connection by bus bar or ring tongue terminals

Bar c.s.a.

Bus bar connection

–

–

–

–

Lug external Ø

mm

8

8

8

10

Screw Ø

mm

M3.5

M3.5

M3.5

M4

Phillips head type

N° 2

N° 2

N° 2

N° 2

Screwdriver Ø

Ø6

Ø6

Ø6

Ø6

Hexagon spanner

–

–

–

–

Tightening torque

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

15 lb.-in.

1.7 Nkm

15 lb.-in.

1.85 Nkm

Control circuit connections

Connection by cable

Screw clamp terminals

Stranded cable without cable end

Cabling

Stranded cable with cable end

Solid cable without cable end

1 or 2 conductors

AWG

18-14

18-14

18-14

18-14

1 conductor

mm2

1/4

1/4

1/4

1/4

2 conductors

mm2

1/4

1/4

1/4

1/4

1 conductor

mm2

1/4

1/4

1/4

1/4

2 conductors

mm2

1/2.5

1/2.5

1/2.5

1/2.5

1 conductor

mm2

1/4

1/4

1/4

1/4

2 conductors

mm2

1/4

1/4

1/4

1/4

N° 2

N° 2

N° 2

N° 2

Ø6

Ø6

Ø6

Ø6

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

Phillips head type

Screwdriver Ø

mm

Tightening torque

Connection by bus bar or ring tongue terminals

Lug external Ø

mm

8

8

8

Screw Ø

mm

M3.5

M3.5

M3.5

8

M3.5

Phillips head type

N° 2

N° 2

N° 2

N° 2

Screwdriver Ø

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

Tightening torque

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

10

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Characteristics

LC1-D32

LP1-D32

LC1-D38

LC1-D40

LP1-D40

14-6

–

10-3

14-6

–

2.5/10

LC1-D50

LP1-D50

LC1-D65

LP1-D65

LC1-D80

LP1-D80

LC1-D95

10-3

10-3

10-2

–

8-250 mcm

10-4

10-4

10-4

10-4

–

8-0+8-250 mcm

8-0+8-250 mcm

2.5/10

2.5/25

2.5/25

2.5/25

4/50

4/50

10/120

10/120

2.5/10

2.5/10

2.5/16

2.5/16

2.5/16

4/25

4/25

10/120+ 10/50

10/120+ 10/50

18-3/0

–

10-4

10-4

10-4

10-4

–

–

–

14-2

–

12-2

12-2

12-2

12-2

–

–

–

1/10

1/10

2.5/25

2.5/25

2.5/25

4/50

4/50

10/120

10/120

1.5/6

1.5/6

2.5/10

2.5/10

2.5/10

4/16

4/16

10/120+ 10/50

10/120+ 10/50

14-8

–

10-3

10-3

10-3

10-3

–

8-250 mcm

8-250 mcm

10-8

–

–

–

–

–

–

8-0+ 8-250mcm

8-0+8-250 mcm

1.5/10

1.5/10

2.5/25

2.5/25

2.5/25

4/50

4/50

10/120

10/120

2.5/10

2.5/10

2.5/16

2.5/16

2.5/16

4/25

4/25

10/120+ 10/50

10/120+ 10/50

N° 2

N° 2

–

–

–

–

–

–

–

Ø6

Ø6

Ø 6 to Ø 8

Ø 6 to Ø 8

Ø 6 to Ø 8

Ø 6 to Ø 8

Ø 6 to Ø 8

–

–

–

–

4 mm

4 mm

4 mm

4 mm

4 mm

4 mm

4 mm

20 lb.-in.

2.5 Nkm

–

2.5 Nkm

45 lb.-in.

5 Nkm

45 lb.-in.

5 Nkm

45 lb.-in.

5 Nkm

100 lb.-in.

9 Nkm

–

9 Nkm

100 lb. in.

12 Nkm

100 lb. in.

12 Nkm

Box lug terminals

LC1-D115

LC1-D150

LA9D11560• terminals

8-250 mcm

Connection by bus bar or ring tongue terminals

–

–

–

–

–

3 x 16

3 x 16

5 x 25

5 x 25

10

10

13

16

16

17

17

25

25

M4

M4

M5

M6

M6

M6

M6

M8

M8

N° 2

N° 2

–

–

–

–

–

–

–

3/16 in.

Ø 6 mm

3/16 in.

Ø 6 mm

–

–

–

–

–

–

–

–

–

–

–

–

10 mm

10 mm

13 mm

13 mm

2.5

2.5

6

8

8

8

8

14

14

Connection by cable

Screw clamp terminals

18-14

18-14

18-14

18-14

18-14

18-14

18-14

18-14

18-14

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2.5

1/2.5

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2.5

1/2.5

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/2.5

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2.5

1/2.5

1/4

1/4

1/4

1/4

1/4

1/4

1/4

1/2.5

1/2.5

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

Ø6

Ø6

Ø6

Ø6

Ø6

Ø6

Ø6

Ø6

Ø6

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

7 lb.-in.

1.2 Nkm

8

Connection by bus bar or ring tongue terminals

8

8

8

8

8

8

8

8

M3.5

M3.5

M3.5

M3.5

M3.5

M3.5

M3.5

M3.5

M3.5

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

N° 2

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

3/16 in.

Ø6

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

7 lb.-in.

1.2

11

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: AC

Kilowatt ratings for international applications

3-pole contactors with Fingersafe™ terminals for power cabling

Standard power ratings of 3-phase motors 50/60 Hz

in category AC-3

220V

230V

380V

400V

415V

440V

500V

660V

690V

1000V

kW

kW

kW

kW

kW

kW

kW

2.2

4

4

4

5.5

5.5

–

Rated operating

current in AC-3

440V up to

Instantaneous

auxiliary contacts *

A

N/O

N/C

–

9

LC1-D0901kk

3

4

5.5

LC1-D2510kk

7.5

9

LC1-D9511kk

5.5

5.5

7.5

5.5

9

11

9

11

15

18

–

18.5

18.5

12

–

15

18.5

18.5

–

10

15

15

18.5

7.5

10

11

15

18.5

7.5

25

–

18.5

32

–

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

Weight

–

LC1-D0900kk

0.340 (0.75)

1

–

LC1-D0910kk q

0.340 (0.75)

–

1

LC1-D0901kk q

0.340 (0.75)

–

–

LC1-D1200kk

0.345 (0.77)

1

–

LC1-D1210kk q

0.345 (0.77)

–

1

LC1-D1201kk q

0.345 (0.77)

–

–

LC1-D1800kk

0.355 (0.79)

1

–

LC1-D1810kk q

0.365 (0.81)

–

1

LC1-D1801kk q

0.365 (0.81)

–

–

LC1-D2500kk

0.400 (0.89)

1

–

LC1-D2510kk q

0.530 (1.18)

–

1

LC1-D2501kk q

0.530 (1.18)

–

–

LC1-D3200kk

0.545 (1.21)

1

–

LC1-D3210kk q

0.555 (1.21)

–

1

LC1-D3201kk q

0.555(1.23)

1

–

LC1-D3810kk

0.555 (1.23)

–

1

LC1-D3801kk

0.555 (1.23)

kg (lb.)

38

11

18.5

22

22

22

30

22

40

1

1

LC1-D4011kk q

1.400 (3.11)

15

22

25

30

30

33

30

50

1

1

LC1-D5011kk

1.400 (3.11)

18.5

30

37

37

37

37

37

65

1

1

LC1-D6511kk

1.400 (3.11)

22

37

45

45

55

45

45

80

1

1

LC1-D8011kk

1.590 (3.53)

25

45

45

45

55

45

45

95

1

1

LC1-D9511kk

1.610 (3.58)

30

55

59

59

75

80

75

115

–

–

LC1-D11500kk

2.420 (5.38)

40

75

80

80

90

100

90

150

–

–

LC1-D15000kk

2.440 (5.42)

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D38: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

aAC Coil Selection

Volts

24

42

48

110

120

208

220

230

240

277

380

400

415

440

480

500

575

600

660

LC1-D09 to D95

50 Hz

B5

D5

E5

F5

–

–

M5

P5

U5

–

Q5

V5

N5

R5

–

S5

–

X5

Y5

60 Hz

B6

D6

E6

F6

G6

L6

M6

–

U6

W6

Q6

–

–

R6

T6

–

S6

X6

–

Q7

V7

N7

R7

T7

S7

–

–

–

LC1-D09 to D150 (coils D115 and D150 with built-in surge suppression)

50/60

Hz

B7

D7

E7

F7

FE7

M7

P7

U7

Other voltages from 24 to 660 V, see pages 53 to 56.

LC1-D11500kk

12

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: AC

Horsepower ratings for North American applications

3-pole contactors with Fingersafe™ terminals for power cabling

Maximum horsepower ratings

1-phase 50/60 Hz

3-phase 50/60 Hz

115/

120V

230/

240V

200/

208V

220/

240V

460/

480V

575V

600V

hp

hp

hp

hp

hp

hp

0.5

1

2

2

5

7.5

Maximum

inductive

current in AC-3

category 600V

Instantaneous

auxiliary contacts

A

N/O

N/C

–

9

LC1-D0901kk

1

1

2

LC1-D2510kk

2

2

3

3

3

5

3

5

7.5

5

7.5

10

10

7.5

12

15

15

10

10

18

20

20

25

30

32

Not UL listed or CSA certified

Not for North American applications

Weight

–

LC1-D0900kk

0.340 (0.75)

1

–

LC1-D0910kk q

0.340 (0.75)

–

1

LC1-D0901kk q

0.340 (0.75)

–

–

LC1-D1200kk

0.345 (0.77)

1

–

LC1-D1210kk q

0.345 (0.77)

–

1

LC1-D1201kk q

0.345 (0.77)

–

–

LC1-D1800kk

0.355 (0.79)

1

–

LC1-D1810kk q

0.365 (0.81)

–

1

LC1-D1801kk q

0.365 (0.81)

–

–

LC1-D2500kk

0.400 (0.89)

1

–

LC1-D2510kk q

0.530 (1.18)

–

1

LC1-D2501kk q

0.530 (1.18)

–

–

LC1-D3200kk

0.545 (1.21)

1

–

LC1-D3210kk q

0.555 (1.21)

–

1

LC1-D3201kk q

0.555(1.23)

1

–

LC1-D3810kk

0.555 (1.23)

–

1

LC1-D3801kk

0.555 (1.23)

kg (lb.)

38

3

5

10

10

30

30

40

1

1

LC1-D4011kk q

1.400 (3.11)

3

7.5

15

15

40

40

50

1

1

LC1-D5011kk

1.400 (3.11)

5

10

20

20

50

50

65

1

1

LC1-D6511kk

1.400 (3.11)

7.5

15

25

30

60

60

80

1

1

LC1-D8011kk

1.590 (3.53)

95

1

1

LC1-D9511kk

1.610 (3.58)

Not UL listed or CSA certified

Not for North American applications

LC1-D9511kk

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

–

–

30

40

75

100

115

–

–

LC1-D11500kk

2.420 (5.38)

–

–

40

50

100

125

150

–

–

LC1-D15000kk

2.440 (5.42)

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D38: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

aAC Coil Selection

Volts

24

42

48

110

120

208

220

230

240

277

380

400

415

440

480

500

575

600

660

LC1-D09 to D95

50 Hz

B5

D5

E5

F5

–

–

M5

P5

U5

–

Q5

V5

N5

R5

–

S5

–

X5

Y5

60 Hz

B6

D6

E6

F6

G6

L6

M6

–

U6

W6

Q6

–

–

R6

T6

–

S6

X6

–

Q7

V7

N7

R7

T7

S7

–

–

–

LC1-D09 to D150 (coils D115 and D150 with built-in surge suppression)

50/60

Hz

B7

D7

E7

F7

FE7

M7

P7

U7

Other voltages from 24 to 660 V, see pages 53 to 56.

LC1-D11500kk

13

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: AC

Kilowatt ratings for international applications

3-pole contactors for ring-tongue terminals or bus bar power connections

Standard power ratings of 3-phase motors

50/60 Hz in category AC-3

220V

230V

380V

400V

415V

440V

500V

660V

690V

1000V

kW

kW

kW

kW

kW

kW

kW

2.2

LC1-D115006kk

3

4

5.5

7.5

9

4

5.5

7.5

11

15

18.5

4

5.5

9

11

15

18.5

4

5.5

5.5

9

7.5

10

11

15

15

18.5

18.5

18.5

5.5

7.5

10

15

18.5

18.5

–

–

–

–

–

–

Rated operating

current in AC-3

440V up to

Instantaneous

auxiliary contacts

A

N/O

N/C

–

9

12

18

25

32

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

Weight

–

LC1-D09006kk

0.335 (0.74)

1

–

LC1-D09106kk

0.335 (0.74)

–

1

LC1-D09016kk

0.335 (0.74)

–

–

LC1-D12006kk

0.335 (0.74)

1

–

LC1-D12106kk

0.335 (0.74)

–

1

LC1-D12016kk

0.335 (0.74)

–

–

LC1-D18006kk

0.345 (0.77)

1

–

LC1-D18106kk

0.352 (0.78)

–

1

LC1-D18016kk

0.352 (0.78)

–

–

LC1-D25006kk

0.390 (0.87)

1

–

LC1-D25106kk

0.520 (1.15)

–

1

LC1-D25016kk

0.520 (1.15)

–

–

LC1-D32006kk

0.535 (1.18)

kg (lb.)

1

–

LC1-D32106kk

0.545 (1.21)

–

1

LC1-D32016kk

0.545 (1.21)

1

–

LC1-D38106kk

0.545 (1.21)

–

1

LC1-D38016kk

0.545 (1.21)

38

11

18.5

22

22

22

30

22

40

1

1

LC1-D40116kk

1.320 (2.93)

15

22

25

30

30

33

30

50

1

1

LC1-D50116kk

1.320 (2.93)

18.5

30

37

37

37

37

37

65

1

1

LC1-D65116kk

1.320 (2.93)

22

37

45

45

55

45

45

80

1

1

LC1-D80116kk

1.600 (3.55)

25

45

45

45

55

45

45

95

1

1

LC1-D95116kk

1.600 (3.55)

30

55

59

59

75

80

75

115

–

–

LC1-D115006kk

2.110 (4.69)

40

75

80

80

90

100

90

150

–

–

LC1-D150006kk

2.130 (4.69)

3-pole contactors for connection with slip-on connectors

For contactors LC1-D09 and LC1-D12 only, replace the last digit 6 in the above catalog numbers, with a 9.

Example: LC1-D09016kk becomes LC1-D09019kk.

These contactors include slip-on connectors: UL Recognized

E164862 NLDX2

2 x 6.35 mm (0.25 in.) on the power poles and 1 x 6.35 mm (0.25 in.) on the coil terminals.

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D38: clIp-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

a Standard control circuit voltages see page 12.

14

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: AC

Horsepower ratings for North American applications

3-pole contactors for ring-tongue terminals or bus bar power connections

Maximum horsepower ratings

1-phase 50/60 Hz

3-phase 50/60 Hz

115/

120V

230/

240V

200/

208V

220/

240V

460/

480V

575V

600V

hp

hp

hp

hp

hp

hp

0.5

LC1-D115006kk

1

1

2

2

1

2

3

3

5

2

3

5

7.5

10

2

3

5

7.5

10

5

7.5

10

15

20

7.5

10

15

20

30

Not UL listed or CSA certified

Not for North American applications

Maximum

inductive current

in AC-3 category

600V

Instantaneous

auxiliary contacts

A

N/O

N/C

–

9

12

18

25

32

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

Weight

–

LC1-D09006kk

0.335 (0.74)

1

–

LC1-D09106kk

0.335 (0.74)

–

1

LC1-D09016kk

0.335 (0.74)

–

–

LC1-D12006kk

0.335 (0.74)

1

–

LC1-D12106kk

0.335 (0.74)

–

1

LC1-D12016kk

0.335 (0.74)

–

–

LC1-D18006kk

0.345 (0.77)

1

–

LC1-D18106kk

0.352 (0.78)

–

1

LC1-D18016kk

0.352 (0.78)

–

–

LC1-D25006kk

0.390 (0.87)

1

–

LC1-D25106kk

0.520 (1.15)

–

1

LC1-D25016kk

0.520 (1.15)

–

–

LC1-D32006kk

0.535 (1.18)

1

–

LC1-D32106kk

0.545 (1.21)

–

1

LC1-D32016kk

0.545 (1.21)

1

–

LC1-D38106kk

0.545 (1.21)

–

1

LC1-D38016kk

0.545 (1.21)

kg (lb.)

38

3

5

10

10

30

30

40

1

1

LC1-D40116kk

1.320 (2.93)

3

7.5

15

15

40

40

50

1

1

LC1-D50116kk

1.320 (2.93)

5

10

20

20

50

50

65

1

1

LC1-D65116kk

1.320 (2.93)

7.5

15

25

30

60

60

80

1

1

LC1-D80116kk

1.600 (3.55)

95

1

1

LC1-D95116kk

1.600 (3.55)

Not UL listed or CSA certified

Not for North American applications

–

–

30

40

75

100

115

–

–

LC1-D115006kk

2.110 (4.69)

–

–

40

50

100

125

150

–

–

LC1-D150006kk

2.130 (4.69)

3-pole contactors for connection with slip-on connectors

For contactors LC1-D09 and LC1-D12 only, replace the last digit 6 in the above catalog numbers, with a 9.

Example: LC1-D09016kk becomes LC1-D09019kk.

These contactors include slip-on connectors: UL Recognized

E164862 NLDX2

2 x 6.35 mm (0.25 in.) on the power poles and 1 x 6.35 mm (0.25 in.) on the coil terminals.

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D38: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

a Standard control circuit voltages see page 13.

15

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: DC

Kilowatt ratings for international applications

3-pole contactors with Finger-safe™ terminals for power cabling

Standard power ratings of 3-phase motors 50/60 Hz

in category AC-3

220V

230V

380V

400V

415V

440V

500V

660V

690V

1000V

kW

kW

kW

kW

kW

kW

kW

2.2

4

4

4

5.5

5.5

–

Rated operat.

current in AC-3

440V up to

Instantaneous

auxiliary contacts

A

N/O

N/C

1

–

4

5.5

LC1-D2510kk

5.5

7.5

11

5.5

5.5

9

7.5

9

11

10

11

15

7.5

10

15

Weight

LP1-D0910kk

0.640 (1.42)

kg (lb.)

9

LC1-D0910kk

3

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

–

–

1

LP1-D0901kk

0.640 (1.42)

1

–

LP1-D1210kk

0.640 (1.42)

12

–

–

1

LP1-D1201kk

0.640 (1.42)

1

–

LP1-D1810kk

0.650 (1.44)

18

–

–

1

LP1-D1801kk

0.650 (1.44)

1

–

LP1-D2510kk

0.925 (2.05)

25

7.5

15

15

15

18.5

18.5

–

32

11

18.5

22

22

22

30

22

40

–

1

LP1-D2501kk

0.925 (2.05)

1

–

LP1-D3210kk

0.950 (2.11)

–

1

LP1-D3201kk

0.950 (2.11)

1

1

LP1-D4011kk

2.185 (4.85)

15

22

25

30

30

33

30

50

1

1

LP1-D5011kk

2.185 (4.85)

18.5

30

37

37

37

37

37

65

1

1

LP1-D6511kk

2.190 (4.87)

22

37

45

45

55

45

45

80

1

1

LP1-D8011kk

2.525 (5.61)

30

55

59

59

75

80

75

115

–

–

LC1-D11500kk

2.440 (5.42)

40

75

80

80

90

100

90

150

–

–

LC1-D15000kk

2.440 (5.42)

Note: Auxiliary contact blocks and modules: see pages 42 to 49.

c For LP1-D09 to D32: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LP1-D40 to D80: clip-on mounting on 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

aDC Coil Selection

Volts

12

24

36

48

60

72

110

125

220

250

440

LP1-D09 to D32

LC1-D6511kk

U 0.8 to

1.1 Uc

JD

BD

CD

ED

ND

SD

FD

GD

MD

UD

RD

U 0.7 to

1.25 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

U 0.7 to

1.25 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

LP1-D40 to D80

U 0.85 to

1.1 Uc

JD

BD

CD

ED

ND

SD

FD

GD

MD

UD

RD

U 0.75 to

1.2 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

ND

SD

FD

GD

MD

UD

RD

LC1-D115 and D150 (coils with built-in surge suppression)

U 0.7 to

1.2 Uc

–

BD

–

ED

Other voltages from 12 to 440 V, see pages 57 to 60.

LC1-D11500kk

16

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: DC

Horsepower ratings for North American applications

3-pole contactors with Finger-safe™ terminals for power cabling

Maximum horsepower ratings

1-phase 50/60 Hz

3-phase 50/60 Hz

115/

120V

230/

240V

200/

208V

220/

240V

460/

480V

575V

600V

hp

hp

hp

hp

hp

hp

0.5

1

2

2

5

7.5

Maximum

inductive

current in AC-3

category 600V

Instantaneous

auxiliary contacts

A

N/O

N/C

1

–

LP1-D0910kk

0.640 (1.42)

–

1

LP1-D0901kk

0.640 (1.42)

1

–

LP1-D1210kk

1

2

2

LC1-D2510kk

2

3

3

5

3

3

5

7.5

0.640 (1.42)

–

1

LP1-D1201kk

0.640 (1.42)

1

–

LP1-D1810kk

5

7.5

10

10

10

0.650 (1.44)

–

1

LP1-D1801kk

0.650 (1.44)

1

–

LP1-D2510kk

7.5

0.925 (2.05)

–

1

LP1-D2501kk

0.925 (2.05)

1

–

LP1-D3210kk

10

0.950 (2.11)

–

1

LP1-D3201kk

0.950 (2.11)

18

20

20

kg (lb.)

12

15

15

Weight

9

LC1-D0910kk

1

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

25

30

32

3

5

10

10

30

30

40

1

1

LP1-D4011kk

2.185 (4.85)

3

7.5

15

15

40

40

50

1

1

LP1-D5011kk

2.185 (4.85)

5

10

20

20

50

50

65

1

1

LP1-D6511kk

2.190 (4.87)

7.5

15

25

30

60

60

80

1

1

LP1-D8011kk

2.525 (5.61)

–

–

30

40

75

100

115

–

–

LC1-D11500kk

2.440 (5.42)

–

–

40

50

100

125

150

–

–

LC1-D15000kk

2.440 (5.42)

Note: Auxiliary contact blocks and modules: see pages 42 to 49.

c For LP1-D09 to D32: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LP1-D40 to D80: clip-on mounting on 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

aDC Coil Selection

Volts

12

24

36

48

60

72

110

125

220

250

440

LP1-D09 to D32

LC1-D6511kk

U 0.8 to

1.1 Uc

JD

BD

CD

ED

ND

SD

FD

GD

MD

UD

RD

U 0.7 to

1.25 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

U 0.7 to

1.25 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

LP1-D40 to D80

U 0.85 to

1.1 Uc

JD

BD

CD

ED

ND

SD

FD

GD

MD

UD

RD

U 0.75 to

1.2 Uc

JW

BW

CW

EW

–

SW

FW

–

MW

–

–

ND

SD

FD

GD

MD

UD

RD

LC1-D115 and D150 (coils with built-in surge suppression)

U 0.7 to

1.2 Uc

–

BD

–

ED

Other voltages from 12 to 440 V, see pages 57 to 60.

LC1-D11500kk

17

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: DC

Kilowatt ratings for international applications

3-pole contactors for ring-torque terminals or bus bar power connections

Standard power ratings of 3-phase motors

50/60 Hz in category AC-3

220V

230V

380V

400V

415V

440V

500V

660V

690V

1000V

kW

kW

kW

kW

kW

kW

kW

2.2

3

4

LC1-D115006kk

5.5

4

5.5

7.5

11

4

5.5

9

11

4

5.5

5.5

9

11

7.5

10

15

5.5

7.5

10

15

–

–

–

–

Rated operat.

current in AC-3

440V up to

Instantaneous

auxiliary contacts

A

N/O

N/C

1

–

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw

mounting

Weight

kg (lb.)

LP1-D09106kk

0.630 (1.40)

9

–

1

LP1-D09016kk

0.630 (1.40)

1

–

LP1-D12106kk

0.630 (1.40)

–

1

LP1-D12016kk

0.630 (1.40)

1

–

LP1-D18106kk

0.640 (1.42)

–

1

LP1-D18016kk

0.640 (1.42)

1

–

LP1-D25106kk

0.915 (2.03)

–

1

LP1-D25016kk

0.915 (2.03)

1

–

LP1-D32106kk

0.940 (2.09)

12

18

25

7.5

15

15

15

18.5

18.5

–

32

–

1

LP1-D32016kk

0.940 (2.09)

11

18.5

22

22

22

30

22

40

1

1

LP1-D40116kk

2.175 (4.83)

15

22

25

30

30

33

30

50

1

1

LP1-D50116kk

2.175 (4.83)

18.5

30

37

37

37

37

37

65

1

1

LP1-D65116kk

2.180 (4.84)

22

37

45

45

55

45

45

80

1

1

LP1-D80116kk

2.515 (5.59)

30

55

59

59

75

80

75

115

–

–

LC1-D115006kk

2.130 (4.73)

40

75

80

80

90

100

90

150

–

–

LC1-D150006kk

2.130 (4.73)

3-pole contactors for connection with slip-on connectors

For contactors LC1-D09 and LC1-D12 only, replace the last digit 6 in the above catalog numbers, with a 9.

Example: LC1-D09016kk becomes LC1-D09019kk.

These contactors include slip-on connectors: UL Recognized

E164862 NLDX2

2 x 6.35 mm (0.25 in.) on the power poles and 1 x 6.35 mm (0.25 in.) on the coil terminals.

Note: Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D32: clIp-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D80: clip-on mounting on 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

a Standard control circuit voltages see page 16.

18

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Motor Control

Control Circuit: DC

Horsepower ratings for North American applications

3-pole contactors for ring-torque terminals or bus bar power connections

Maximum horsepower ratings

1-phase 50/60 Hz

3-phase 50/60 Hz

115/

120V

230/

240V

200/

208V

220/

240V

460/

480V

575V

600V

hp

hp

hp

hp

hp

hp

0.5

1

1

LC1-D115006kk

2

1

2

3

3

2

3

5

7.5

2

3

5

7.5

5

7.5

10

15

7.5

10

15

20

Maximum

inductive

current in AC-3

category 600V

Instantaneous

auxiliary contacts

A

N/O

N/C

1

–

LP1-D09106kk

–

1

LP1-D09016kk

0.630 (1.40)

1

–

LP1-D12106kk

0.630 (1.40)

–

1

LP1-D12016kk

0.630 (1.40)

1

–

LP1-D18106kk

0.640 (1.42)

–

1

LP1-D18016kk

0.640 (1.42)

1

–

LP1-D25106kk

0.915 (2.03)

–

1

LP1-D25016kk

0.915 (2.03)

1

–

LP1-D32106kk

0.940 (2.09)

Weight

Catalog number.

Complete with code

indicating control circuit

voltage a

c DIN rail or screw mounting

kg (lb.)

0.630 (1.40)

9

12

18

25

2

5

10

10

20

30

32

–

1

LP1-D32016kk

0.940 (2.09)

3

5

10

10

30

30

40

1

1

LP1-D40116kk

2.175 (4.83)

3

7.5

15

15

40

40

50

1

1

LP1-D50116kk

2.175 (4.83)

5

10

20

20

50

50

65

1

1

LP1-D65116kk

2.180 (4.84)

7.5

15

25

30

60

60

80

1

1

LP1-D80116kk

2.515 (5.59)

–

–

30

40

75

100

115

–

–

LC1-D115006kk

2.130 (4.73)

–

–

40

50

100

125

150

–

–

LC1-D150006kk

2.130 (4.73)

3-pole contactors for connection with slip-on connectors

For contactors LC1-D09 and LC1-D12 only, replace the last digit 6 in the above catalog numbers, with a 9.

Example: LC1-D09016kk becomes LC1-D09019kk.

These contactors include slip-on connectors: UL Recognized

E164862 NLDX2

2 x 6.35 mm (0.25 in.) on the power poles and 1 x 6.35 mm (0.25 in.) on the coil terminals.

Note: Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D32: clIp-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D80: clip-on mounting on 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

a Standard control circuit voltages see page 17.

19

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Resistive Loads

Control circuit: AC

3 or 4-pole contactors with Fingersafe™ terminals for power cabling

Non-inductive loads maximum current

(θ ≤ 55 °C) Utilization category AC-1

Number of poles

A

N/O

Instantaneous

auxiliary contacts

N/C

N/O

–

3

–

N/C

kg (lb.)

–

1

or

–

or

25

LC1-D112004kk

32

LC1-D11500kk

0.340 (0.75)

LC1-D1210kk q

0.345 (0.77)

LC1-D0901kk

0.340 (0.75)

LC1-D1201kk q

0.345 (0.77)

LC1-D12004kk

0.350 (0.77)

2

2

–

–

LC1-D12008kk

0.350 (0.77)

–

–

LC1-D1800kk

0.355 (0.79)

1

–

LC1-D1810kk

0.365 (0.81)

–

1

LC1-D1801kk

0.365 (0.81)

–

–

LC1-D2500kk

0.400 (0.89)

1

–

LC1-D2510kk

0.530 (1.18)

–

1

LC1-D2501kk

0.530 (1.18)

–

–

4

–

–

–

LC1-D25004kk

0.530 (1.18)

2

2

–

–

LC1-D25008kk

0.535 (1.19)

–

–

LC1-D3200kk

0.545 (1.21)

LC1-D3210kk

0.555 (1.23)

3

200

0.345 (0.77)

LC1-D0910kk

–

LC1-D65004kk

125

or

LC1-D1200kk q

–

40

80

1

0.340 (0.75)

–

3

60

–

LC1-D0900kk

4

3

50

Weight

Catalog number.

Complete with code indicating

control circuit voltage a.

c DIN rail or screw mounting

–

1

–

–

1

or

LC1-D3810kk

LC1-D3201kk

or

0.555 (1.23)

LC1-D3801kk

3

–

1

1

LC1-D4011kk

1.400 (3.11)

4

–

–

–

LC1-D40004kk

1.440 (3.20)

2

2

–

–

LC1-D40008kk

1.450 (3.22)

LC1-D5011kk

1.400 (3.11)

LC1-D6511kk q

1.400 (3.11)

3

–

1

1

4

–

–

–

LC1-D65004kk

1.440 (3.20)

2

2

–

–

LC1-D65008kk

1.450 (3.22)

3

–

1

1

LC1-D8011kk

1.590 (3.53)

LC1-D9511kk q

1.610 (3.58)

4

–

–

–

LC1-D80004kk

1.760 (3.91)

2

2

–

–

LC1-D80008kk

1.840 (4.09)

LC1-D11500kk

2.420 (5.38)

LC1-D15000kk q

2.440 (5.42)

LC1-D115004kk

2.860 (6.35)

3

–

–

–

4

–

–

–

or

or

or

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages ???? to ?????.

c For LC1-D09 to D38: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

aAC Coil Selection

Volts

24

42

48

110

120

127

208

220

230

240

277

380

400

415

440

480

500

575

600

660

LC1-D09 to D95

50 Hz

B5

D5

E5

F5

–

G5

–

M5

P5

U5

–

Q5

V5

N5

R5

–

S5

–

X5

Y5

60 Hz

B6

D6

E6

F6

G6

–

L6

M6

–

U6

W6

Q6

–

–

R6

T6

–

S6

X6

–

U7

–

Q7

V7

N7

R7

T7

–

–

–

–

LC1-D09 to D150 (coils D115 and D150 with built-in surge suppression)

50/60

Hz

B7

D7

E7

F7

FE7

–

–

M7

P7

Other voltages from 24 to 660 V, see pages 53 to 56.

q Selection according to number of operating cycles, see AC-1 curve in IEC Contactors Selection Guide 8502CT9801.

20

© 1998 Square D All Rights Reserved

7/98

D-Line Contactors, Overload Relays and Accessories

Selection – Resistive Loads

Control Circuit: AC

3 or 4-pole contactors for ring tongue terminals or bus bar power connections

Non-inductive loads

maximum current

(θ ≤ 55 °C) Utilization

category AC-1

Number of poles

Instantaneous

auxiliary contacts

A

N/O

N/O

N/C

–

3

–

1

32

80

125

200

0.335 (0.74)

–

–

–

1

kg (lb.)

or

or

0.335 (0.74)

0.335 (0.74)

LC1-D12106kk q

0.335 (0.74)

LC1-D09016kk

0.335 (0.74)

LC1-D12016kk q

0.335 (0.74)

–

–

LC1-D120046kk

0.340 (0.75)

2

2

–

–

LC1-D120086kk

0.340 (0.75)

–

–

LC1-D18006kk

0.345 (0.77)

1

–

LC1-D18106kk

0.352 (0.78)

–

1

LC1-D18016kk

0.352 (0.78)

–

–

LC1-D25006kk

0.390 (0.87)

1

–

LC1-D25106kk

0.520 (1.15)

–

1

LC1-D25016kk

0.520 (1.15)

3

–

–

or

LC1-D12006kk q

LC1-D09106kk

–

40

60

LC1-D09006kk

4

3

50

Weight

N/C

25

LC1-D115006kk

Catalog number. Complete with code

indicating control circuit voltage a.

c DIN rail or screw mounting

4

–

–

–

LC1-D250046kk

0.520 (1.15)

2

2

–

–

LC1-D250086kk

0.525 (1.17)

–

–

LC1-D32006kk

0.535 (1.19)

LC1-D32106kk

0.545 (1.21)

3

–

1

–

–

1

or

or

LC1-D38106kk

0.545 (1.21)

LC1-D32016kk

0.545 (1.21)

LC1-D38016kk

0.545 (1.21)

3

–

1

1

LC1-D40116kk

1.320 (2.93)

4

–

–

–

LC1-D400046kk

1.430 (3.18)

2

2

–

–

LC1-D400086kk

1.440 (3.20)

LC1-D50116kk

1.320 (2.93)

3

–

1

1

LC1-D65116kk q

1.320 (2.93)

4

–

–

–

LC1-D650046kk

1.430 (3.18)

2

2

–

–

LC1-D650086kk

1.440 (3.20)

LC1-D80116kk

1.600 (3.55)

or

3

–

1

1

LC1-D95116kk q

1.600 (3.55)

4

–

–

–

LC1-D800046kk

1.750 (3.89)

2

2

–

–

LC1-D800086kk

1.830 (4.07)

LC1-D115006kk

2.110 (4.68)

LC1-D150006kk

2.130 (4.73)

LC1-D1150046kk q

2.450 (5.44)

3

–

–

–

4

–

–

–

or

or

3 or 4-pole contactors for connection with slip-on connectors

For contactors LC1-D09 and LC1-D12 only, replace the last digit 6 in the above catalog numbers, with a 9.

Example: LC1-D09016kk becomes LC1-D09019kk.

These contactors include slip-on connectors: UL Recognized

E164862 NLDX2

2 x 6.35 mm (0.25 in.) on the power poles and 1 x 6.35 mm (0.25 in.) on the coil terminals.

Note: 3-pole contactors without auxiliary contacts conform to standard EN 50012.

Auxiliary contact blocks and modules: see pages 42 to 49.

c For LC1-D09 to D38: clip-on mounting on 35 mm ( DIN rail AM1-DP or screw mounting.

For LC1-D40 to D95: clip-on mounting on 35 mm ( DIN rail AM1-DE or 75 mm ( DIN rail AM1-DL or screw mounting.

For LC1-D115 and D150: clip-on mounting on 2 x 35 mm ( DIN rails AM1-DP or screw mounting.

a Standard control circuit voltages: see page 20.

q Selection according to number of operating cycles, see AC-1 curve in IEC Contactors Selection Guide 8502CT9801.

21

7/98

© 1998 Square D All Rights Reserved

D-Line Contactors, Overload Relays and Accessories

Selection – Contactors for Resistive Loads

Control Circuit: DC

3 or 4-pole contactors with Fingersafe™ terminals for power cabling

Non-inductive loads maximum

current (q ≤ 55 °C) Utilization

category AC-1

Number of poles

Instantaneous

auxiliary contacts

A

N/O

N/O

N/C

1

–

0.640 (1.42)

LP1-D1210kk q

0.640 (1.42)

kg (lb.)

–

LP1-D0901kk

0.640 (1.42)

LP1-D1201kk q

0.640 (1.42)

LP1-D12004kk

0.640 (1.42)

LP1-D12008kk

0.640 (1.42)

1

or

32

LP1-D0910kk

–

25

LC1-D112004kk

Weight

N/C

or

3

Catalog number. Complete with code

indicating control circuit voltage a.

c DIN rail or screw mounting

4

–

–

–

2

2

–

–

1

–

LP1-D1810kk

0.650 (1.44)

–

1

LP1-D1801kk

0.650 (1.44)

1

–

LP1-D2510kk

0.925 (2.05)

–

1

LP1-D2501kk

0.925 (2.05)

3

3

or

–

–

40

50

4

–

–

–

LP1-D25004kk

0.930 (2.07)

2

2

–

–

LP1-D25008kk

0.930 (2.07)

1

–

LP1-D3210kk

0.950 (2.11)

–

1

LP1-D3201kk

0.950 (2.11)

3

60