Planning for Installation

advertisement

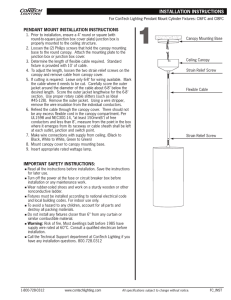

Planning for Installation Suspension On the T-Bar Non-Feed Location Detail Without Grid-mounted Hardware: 1) Cut a 3/8” hole in the ceiling tile at the support location. 2) Suspend a 1/4 – 20 threaded rod through the hole in the tile, extending rod 3/4” below tile. Rod must be supported to structure as required by code. Mounting point is now ready for attachment of cable sleeve, which also supports decorative canopy. With Grid-mounted Hardware: 1) Cut a 3/8” hole in the ceiling tile at the support location. 2) Insert a 1/4 – 20 bolt or threaded rod through Caddy #512HD hanger bar and fasten with nut and washer so bolt will extend 3/4” below tile. If code requires support at mounting point, use eyebolt for attachment of support wire. Caddy #512HD T-Grid Box Hanger (by others) 3) Snap assembly onto the T-bar, provide supports required. Mounting point is now ready for Additional Ceiling Support Wires* attachment of cable sleeve, which also supports decorative canopy. Feed Location Detail Without Grid-mounted Hardware: 1) Cut a hole (4" to 4 1/4") in the ceiling tile at the support location. With Grid-mounted Hardware: 1) Cut a hole (4" to 4 1/4") in the ceiling tile at the support location. 2) Suspend a 1/4 – 20 threaded rod through tile at the support location, extending rod 3/4" below tile. Rod must be supported to structure as required by code. 2) Remove box mounting clip from bar and insert into center knockout of electrical box, placing locking tabs in small holes. 3) Mount the J-box onto rod with washer and nut on each side of center knockout. Adjust box position so bottom is flush with ceiling. 3) Push box clip into bar slot at the desired location and rotate the electrical box and clip clockwise to “lock” the box in place. Caddy #512HD T-Grid Box Hanger (by others) Caddy #510HD mounting clip (by others) 4) Snap assembly onto the T-bar. Provide supports as required by code. 4) Pull feed cord through canopy (both provided) and complete wiring connections. Cover J-box and hole with canopy and secure with cable sleeve threaded onto rod. Cable and feed cord are now ready for attachment to fixture. Additional Parts (by others) • 4” octagonal junction box • Caddy #512HD T-grid box hanger – Includes #510HD mounting clip 258 • 1/4 – 20 threaded rod or bolt, with nuts and washers • Support wire or chain, as required by code 5) Pull feed cord through canopy (both provided) and complete wiring connections. Attach support strap with threaded stud to J-box. Cover J-box and hole with canopy and secure with cable sleeve threaded onto rod. Cable and feed cord are now ready for attachment to fixture. *12 gauge support wires (by others) are secured to building structure. Note: Consult local authority for code requirements and application approval. 4" Octagonal Junction Box (by others) Additional Ceiling Support Wires* SUPPORT STRAP (provided) CANOPY litecontrol.com Index Planning for Installation Non-Feed Location Detail Feed Location Detail Ceiling support wire (taut)* (by others) Ceiling grid clip with 1/4–20 x 5/8" stud The optional Litecontrol Canopy Box is intended for installation in a NEMA Type Canopy Box 1-1/8" KO’s G grid ceiling with a maximum T-Bar T-bar support grid (by others) 1/4-20 x 3/8" long mounting screw height of 1-1/2". The Canopy Box can be installed where fixture hanging cables are located on a main T-Bar. Can be Ceiling acoustical tile (by others) "Screw-Slot" type T-Bar. 3/32" diameter aircraft cable fixture Cover used with 9/16" T-Bar, 15/16" T-Bar, and 2" canopy - white sleeve 7/8" KO’s Cover mounting screw Ground wire 2" Cutout depth Note: the Canopy Box cannot be installed in a location with intersecting cross T-Bars. 1-5/8" Cutout width Canopy Feed Cord 1. 2. Elevation View Ceiling tile Canopy Box Cable assembly 1 2 1/4" Ceiling tile 3. Bushing Feed cord 5" Diameter feed canopy Cable assembly 1) Insert 1/4–20 x 5/8" stud through bottom of Caddy IDS clip (provided with clip). Secure clip around T-bar. 2) Attach ceiling support wire.* Support wire (by others) litecontrol.com • Canopy Box options can be used with Assemblies (ACC/F) and Field Adjustable Canopy Box mounting clip Aircraft Cable assemblies (FAI/ACC/F). Cable assembly 3) Place canopy flush with ceiling tile. Thread cable sleeve onto 1/4-20 stud. *12-gauge support wires (by others) are secured to building structure. Note: Consult local authority for code requirements and application approval. Ordering Guidelines Litecontrol Fixed Length Aircraft Cable supplied by Litecontrol Additional Parts (by others) • 1/4 – 20 threaded rod or bolt, with nuts and washers • Support wire or chain, as required by code The Litecontrol Canopy Box is UL Listed and meets National Electric Code (NEC) guideline. This system addresses requirement that feed cord must directly enter the electrical box at the ceiling plane. • The catalog designator for the Canopy Box is "LCB" NEMA Type G T-Bar (by others) • Add "LCB" to the Aircraft Cable assembly catalog number to include the Canopy Box option. (Example: FAI/ACC/F/LCB) Ceiling grid clip 1-9/32" Center of cable location • One Canopy Box is needed for each feed cable assembly located on a grid. 1. Ceiling Grid Clip (Caddy IDS) attaches to the T-Bar at each feed cable location with 1/4-20 threaded stud for fixture mounting (Caddy IDS 9.5 attaches to a Screw Slot T-Bar). 2. Canopy Box mounting clip snaps onto T-Bar 1-9/32" away from Ceiling Grid Clip. 3. Canopy Box attaches to mounting clip with one 1/4-20 x 3/8" machine screw. 4. Ceiling tile must be notched to clear lower surface of Canopy Box. 5. Bottom edge of Canopy Box is positioned below the ceiling plane and makes direct contact with the canopy after installation is completed. 259 Planning for Installation Slotted hole (Provides position adjustment of flat strap for final side-to-side leveling, if needed) #8–32 nut (for end caps only) Pendant Support System Pendant* (stem shown) end cap Support plate Note: Contractor is responsible for attachment of hickey to the outlet box and securing the entire assembly to building structure, as required by code. Hickey (provided with stem assembly) Outlet box (octagonal 3 1/2" or 4" x 2 1/8" deep by others) Locknuts Hex key Canopy 1/4" Set screw (allows canopy to be lowered to inspect electrical connections) Slip ring 5/8" feed knockout Stem Flat strap** (With large threaded hole for either Stem or FAI/ACC) Field-Adjustable Aircraft Cable (FAI/ACC) Litecontrol’s easy-hang system uses a universal flat strap for easy attachment of aircraft cables or rigid stems at either in-row joints or end-of-row locations. This allows for suspension of fixture rows on-seam. Locknuts Flat strap (attaches to fixture) Fixture Joint 1/4–20 x 3/8" slotted hex washer head machine screw *Most fixtures can readily accept cables or P6S stems as shown above. Mixed systems, such as stems only for feed locations, can also be specified. Stems may not be mounted “on the T-bar”. **Some products may be provided with a slide-on version of the flat strap. A cotter pin is used to locate and secure the strap during installation. Pendant* (stem shown) Flat strap** (Same strap used for joints and end of rows) 5/8" feed knockout Support plate Note: Some Litecontrol fixtures may be configured differently than shown, with other hardware and mounting details. 260 litecontrol.com Index Planning for Installation Fixture Connections Typical joining detail with field-adjustable cable nX 3,/44%$(%8 7!3(%2(%!$ -!#().%3#2%7 !)2#2!&4 #!",% ,/#+.54 **Some products may be provided with a slide-on version of the flat strap. A cotter pin is used to locate and secure the strap during installation. 3500/24 0,!4% &LATSTRAP 3AMESTRAPUSEDFOR JOINTSANDENDOFROWS nX 3,/44%$(%8 7!3(%2(%!$ -!#().%3#2%7 &,!4342!0 &%%$+/ 02%4(2%!$%$ n&!34%.).'(/,% %.$(%!$%2 2%&,%#4/2 Installation for many products such as the P-I-9800 and P-I-95 SAE Systems, fixtures require no nuts. The 1/4–20 x 3/8” machine screw (provided) simply joins with the attached fastener, making your installation easy and convenient. Pre-wiring Fixtures are supplied with #12 AWG type THHN wire for branch circuits. One end will have factory-installed push-in quick-connects. The other end will be stripped back 1/2" for quick connection in field. Note: Some Litecontrol fixtures may be configured differently than shown, with other hardware and mounting details. litecontrol.com 261