sequential diagnosis for a centrifugal pump based on fuzzy neural

advertisement

CHINESE JOURNAL OF MECHANICAL ENGINEERING

·50·

Vol. 21,aNo. 5,a2008

DOI: 10.3901/CJME.2008.05.050, available online at www.cjmenet.com; www.cjmenet.com.cn

ZHOU Xiong

College of Mechanical Engineering,

Chongqing University,

Chongqing 400044, China

Engineering Training Center,

Chongqing University of Science

and Technology,

Chongqing 401331, China

SEQUENTIAL DIAGNOSIS FOR

A CENTRIFUGAL PUMP BASED

ON FUZZY NEURAL NETWORK*

WANG Huaqing

College of Mechanical and

Electrical Engineering,

Beijing University of Chemical

Technology,

Beijing 100029, China

CHEN Peng

Graduate School of Bioresources,

Mie University,

Tsu 514-8507, Japan

TANG Yike

College of Mechanical Engineering,

Chongqing University,

Chongqing 400044, China

0

Abstract: A sequential diagnosis method is proposed based on a fuzzy neural network realized by

“the partially-linearized neural network (PNN)”, by which the fault types of rotating machinery can be

precisely and effectively distinguished at an early stage on the basis of the possibilities of symptom

parameters. The non-dimensional symptom parameters in time domain are defined for reflecting the

features of time signals measured for the fault diagnosis of rotating machinery. The synthetic

detection index is also proposed to evaluate the sensitivity of non-dimensional symptom parameters

for detecting faults. The practical example of condition diagnosis for detecting and distinguishing

fault states of a centrifugal pump system, such as cavitation, impeller eccentricity which often occur

in a centrifugal pump system, are shown to verify the efficiency of the method proposed in this paper.

Key words: Sequential diagnosis Fuzzy neural network Symptom parameter Centrifugal pump

Rotating machinery

INTRODUCTION∗

In the field of machinery diagnosis, vibration signals are

often used for the detection of mechanical fault and the

discrimination of fault types. Machinery diagnosis depends

largely on the feature analysis of vibration signals measured for

condition diagnosis, so it is important that the feature of the signal

should be sensitively extracted when fault occurs at the state

change of a machine. However, the feature extraction for the fault

diagnosis is difficult since the vibration signals measured at a

point of the machine often contains strong noise [1−3].

In most cases of condition diagnosis for plant rotating

machinery, information for distinguishing faults is ambiguous

because definite relationships between symptoms and fault types

cannot be easily identified [4]. The main reasons can be explained

as follows: ① it is difficult to identify the symptom parameters

for diagnosis by which all fault types can be distinguished

perfectly; ② in an early stage of a fault, the effect of noise in the

signal measured for the diagnosis is so strong that the symptom of

the fault is not evident.

Furthermore, although many method of condition diagnosis

for rotating machinery using neural networks (NN) have been

reported by many studies, they almost dealt with the

discrimination of fault types [5−11]. The problems of the condition

diagnosis using conventional NN are that the NN can not reflect

the possibility grades of the ambiguous diagnosis problems, and it

will never converge when the symptom parameters inputted in the

1st layer have the same values in different states [12].

Based on the above reasons, in order to improve the

efficiency of fault diagnosis and distinguish fault types at an early

stage, this paper proposes a sequential diagnosis method for

rotating machinery using fuzzy neural network by which the state

of machinery can be automatically judged on the basis of the

possibility grades of normal and each abnormal state. Since the

relationship between the values of the symptom parameters and

fault types is ambiguous due to the effect of noise in the time

signals, we use the partially-linearized neural network to solve the

ambiguous problem of the fault diagnosis. Non-dimensional

* This project is supported by Sci-Tech Planning Projects of Chongqing City,

China (No. CSTC2007AA7003). Received January 29, 2008; received in

revised form August 18, 2008; accepted August 20, 2008

symptom parameters (NSP) in time domain are defined to reflect

the features of time signal measured for the fault diagnosis of

rotating machinery. The synthetic detection index (S) is also

proposed to evaluate the sensitivity of NSPs for detecting and

distinguishing faults. In this paper, practical example of fault

diagnosis of a centrifugal pump system will verify that the method

is effective. The method proposed in this paper can also be

applied to other type of rotating machinery.

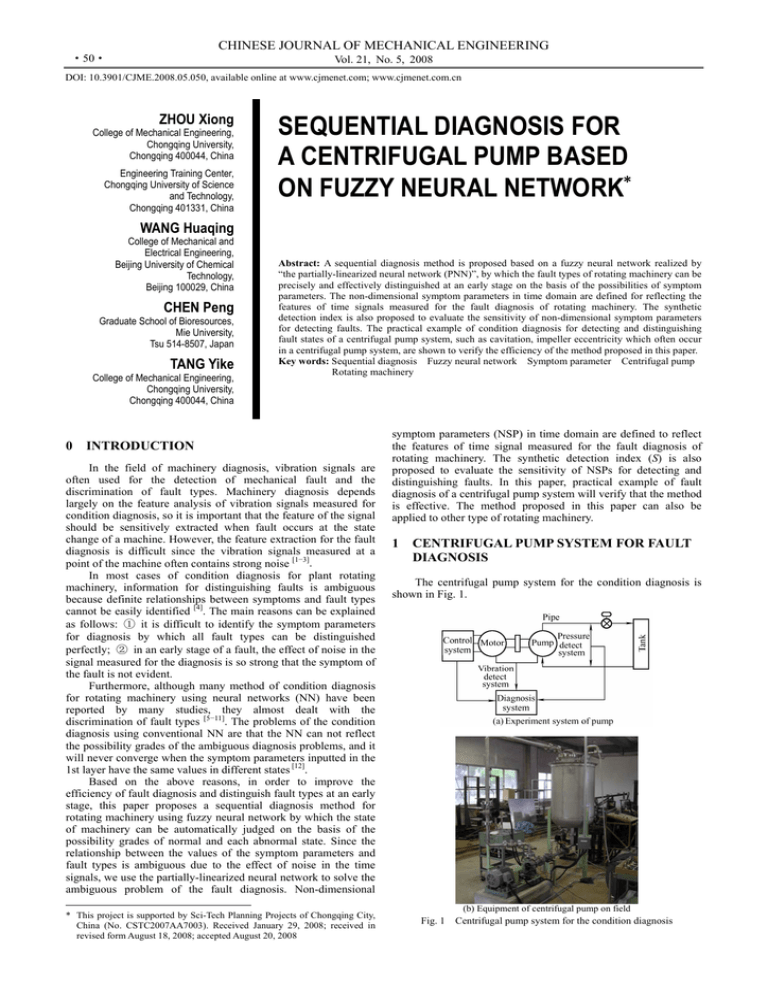

1

CENTRIFUGAL PUMP SYSTEM FOR FAULT

DIAGNOSIS

The centrifugal pump system for the condition diagnosis is

shown in Fig. 1.

(b) Equipment of centrifugal pump on field

Fig. 1

Centrifugal pump system for the condition diagnosis

CHINESE JOURNAL OF MECHANICAL ENGINEERING

The states to be diagnosed for the centrifugal pump system

are normal state, cavitation, impeller eccentricity. Cavitation

phenomenon is one of the sources of instability in a centrifugal

pump. Cavitation can cause more undesirable effects, such as

deterioration of the hydraulic performance (drop in head-capacity

and efficiency curves), damage of the pump by pitting and erosion

and structure vibration and resulting noise [13]. To prevent the

occurrence of the cavitation, we have to detect it at early stage of

cavitation phenomenon from the vibration signal of a pump

system.

There were six accelerometers used to measure vibration

signals for the detection of faults. The locations of the sensors are

shown in Fig. 2. Two sensors were put at the pump inlet, another

two at the pump outlet and one sensor at the motor and pump

housing respectively. The sampling frequency of signal measurement is 50 kHz, and the sampling time is 10 s. The vibration

signals in each state shown in Fig. 3 are measured at a constant

speed (2 500 r/min) and constant flow rate (13.5 m3/h) of water.

Fig. 2

·51·

For the purpose of making the signals comparable regardless

of differences in magnitude, the filtered signals of each state are

normalized by using the following formula before calculating the

symptom parameters

xi =

xi′ − μ ′x

σ′

(1)

where μ ′ and σ ′ are the mean and standard deviation of the

filtered signals series xi′(i = 1, 2," , N ) , respectively. xi is the

ith element of the signal series after normalization.

The location of the sensors

Fig. 4

Signals after filtration

Using the normalized signals, the ten NSPs in the time

domain are calculated as follows, respectively

N

p1 =

∑ ( xi − μ )3

i =1

( N − 1)σ 3

(2)

N

p2 =

∑ ( xi − μ ) 4

i =1

( N − 1)σ 4

p3 =

σp

μp

(3)

(4)

M

Fig. 3

Original signals measured in each state

p4 =

Low-pass filter with 800 Hz cut-off frequency is used for

canceling the noise. The vibration signals measured in each state

after filtration are shown in Fig. 4.

SYMPTOM PARAMETERS FOR FAULT

DIAGNOSIS

Non-dimensional symptom parameter

Many symptom parameters have been defined in the pattern

recognition field [14]. Here, ten of non-dimensional symptom

parameters (NSP) in time domain, commonly used for the fault

diagnosis of plant machinery, are considered.

i =1

( M − 1)σ p 3

(5)

M

p5 =

2

∑ ( x pi − μ p )3

∑ ( x pi − μ p )4

i =1

( M − 1)σ p 4

p6 =

2.1

σv

μv

(6)

(7)

K

p7 =

∑ ( xvi − μv )3

i =1

( K − 1)σ v 3

(8)

YZHOU Xiong, et al: Sequential diagnosis for a centrifugal pump based on fuzzy neural networky

·52·

the synthetic detection index (S) is defined as follows

K

p8 =

∑ ( xvi − μv )4

i =1

( K − 1)σ v 4

p9 =

M

Z

K

p10 =

Z

(9)

M

S = ∑ DI i

(17)

i =1

(10)

(11)

3

SEQUENTIAL DIAGNOSIS METHOD

For the purpose of distinguishing faults effectively, a

sequential diagnosis method is proposed (Fig. 5). The inference of

the sequential diagnosis is as follows.

where, μ and σ are the mean and standard deviation of

normalized signal series xi , respectively, x pi (i=1, 2, " , M) and

xvi (i=1, 2, " , K) are the peak value and valley value of xi,

respectively, μ p and σ p are the mean and standard deviation

of peak values x pi , respectively, μv and σ v are the mean and

standard deviation of the valley values xvi , respectively, and

Z is the number of xi passing zero.

2.2

Sensitivity evaluation of symptom parameter

The quality of a symptom parameter (SP), which will be used

for distinguishing two states, such as normal or abnormal state, is

derived in the following way. Supposing that x1 and x2 are the SP

values calculated from the signals measured in state 1 and state 2,

respectively, and they conform respectively to the normal

distributions N ( μ1 ,σ 12 ) and N ( μ2 ,σ 2 2 ) . Where, μ and σ

are the average and the standard deviation of the SP. The larger the

value of x1 − x2 is, the higher the sensitivity of distinguishing

the two states by the SP is. Because Z = x2 − x1 is conform to the

normal distribution N ( μ 2 − μ1 ,σ 2 2 + σ 12 ) , we have the density

function about Z

f ( z) =

[15−16]

⎛ [ z − ( μ2 − μ1 )]2 ⎞

⎟

exp ⎜

⎜ 2(σ 12 + σ 2 2 ) ⎟

2π(σ 12 + σ 2 2 )

⎝

⎠

1

(12)

where, μ 2 ≥ μ1 (we can obtain the same conclusion when

μ 2 ≥ μ1 ). The probability of x2 < x1 can be calculated by the

following formula

0

P0 = ∫−∞ f (z )dz

where 1 − P0

substitution

(13)

is called “distinction rate (DR)”. With the

μ=

z − ( μ2 − μ1 )

σ 12 + σ 2 2

(14)

From Eqs. (14) and (15), the P0 can be obtained by

P0 =

1

2π

− DI

∫−∞

⎛ u2 ⎞

exp ⎜ − ⎟ du

⎝ 2⎠

(15)

Fig. 5

Flow chart of sequential diagnosis for a pump

In the first step, if the possibility grades of normal state (N)

and abnormal states (A) are gN and gA, and gN>gA, then the state is

judged as “normal state (N)”, else proceed to the next step.

In the second step, if the possibility grades of cavitations (C)

and other abnormal faults (A) are gC and gA, and gC>gA, then the

state is judged as “cavitations (C)”, else proceed to the next step.

In the third step, if the possibility grades of impeller

eccentricity (E) and another fault are gD and gA, respectively, and

gD>gA, then the state is judged as “impeller eccentricity (E)”, else

it will be judged as “unknown abnormal state (UA)”.

In this paper, two best NSP pi and p j , are selected by Eq.

(17) for each state of the sequential diagnosis, respectively. The

selection results of the NSP are as follows.

p9 and p10 : for the first step to distinguish normal state

from abnormal states;

p1 and p2 : for the second step to distinguish cavitation

from other abnormal states;

p1 and p2 : for the third step to distinguish impeller

eccentricity from unknown states.

It shows the DI of the NSP ( pi and p j ) for each step to

distinguish the two kinds of state, respectively (Tables 1, 2). Since

all of those DI are larger than 2.4, all of the detection rates (DR)

are larger than 99%.

Table 1 DI of NSP for the first step

NSP

N:C

N:E

P9 p9

8.3

7.9

P10

3.5

2.4

Table 2 DI of NSP for the second step

and third step

NSP

C:E

p1

2.9

p2

3.0

The training data for the learning of fuzzy neural network

can be obtained by the values of NSP calculated by the vibration

signal measured in each state. If the pi and pj are selected for

distinguishing state k from another state, and their mean value and

standard deviation are pik , p jk and σik , σ jk , respectively, the

(16)

training data for distinguishing state k from another state are

calculated as follows.

If pik − 2σ ik < pi < pik + 2σ ik and p jk − 2σ jk < p j < p jk +

It is obvious that the larger the value of DR is, the larger the

value of DR (DR =1−P0) will be, and therefore, the better the SP

will be. So DI can be used as the index of the quality to evaluate

the distinguishing sensitivity of SP.

If the number of symptom parameters used for diagnosis is M,

else the state is judged as another state.

According to the method stated above, these show the

training data for distinguishing normal state, cavitation, impeller

eccentricity unknown states, respectively (Figs. 6−8). These

training data will be used for the learning of the fuzzy neural

network.

where, distinction index DI is calculated by

DI =

μ2 − μ1

σ 12 + σ 2 2

2σ jk , then the state is judged as state k with 100% possibility,

CHINESE JOURNAL OF MECHANICAL ENGINEERING

·53·

the symbols are used as follows.

X ( m,t ) is the value of the tth neuron in the hidden (the mth)

layer; t = 1 , 2, " , N m .

Fig. 6

Training data for distinguishing normal state from abnormal state

Wuv( m ) is the weight between the uth neuron in the mth layer

and the vth neuron in the (m+1)th layer; m=1, 2, " , M; u=1, 2, " ,

Nm; v=1, 2, " , Nm+1.

If all of these values are remembered by computer, when new

u )∗

u)

u )∗

u)

values X (1,

( X (1,

< X (1,

< X (1,

j

j

j

j +1 ) are inputted to the first

layer, the predicted value of the vth neuron ( v = 1 , 2, " , N m ) in

the (m+1)th layer ( m = 1, 2, " , M−1) will estimated by

Nm

X (j m +1, v ) = X i(+m1+1, v ) −

Fig. 7

{∑ Wuv( m ) ( X i(+m1,u ) − X (j m ,u ) )}( X i(+m1+1, v ) − X (j m +1, v ) )

v =0

Training data for distinguishing cavitation from another fault

Nm

∑ Wuv( m) ( X i(+m1,u ) − X i( m,u ) )

v =0

(18)

In the above way, the sigmoid function is partially linearized

(Fig. 9). If a function must be learned, the PNN will learn the

points indicated by symbol ● shown (Fig. 10). When new data

( S1′ , S′2 ) are input into the converged PNN, the values indicted by

symbol ■ corresponding to the data ( S1′ , S ′2 ) will be quickly

Fig. 8

4

Training data for distinguishing eccentricity from unknown faults

identified as Pe. Thus, the PNN can be used for dealing with

ambiguous diagnosis problems.

FUZZY NEURAL NETWORK FOR THE

DIAGNOSIS AND VERIFICATION

4.1

Partially-linearized neural network

The partially-linearized neural network (PNN) can solve

ambiguous diagnosis problems, and can distinguish fault types on

the basis of the probability distributions of the machine conditions

when the diagnosing is being done[4]. In present work, the PNN is

implemented for fault diagnosis, and the basic principle of the

PNN is described as follows.

The neuron number of the mth layer of an NN is Nm. The set

X (1) = { X i(1, j ) } expresses the pattern inputted to the 1st layer and

the set X ( M ) = { X i( M , k ) } is the training data for the last layer (the

Mth layer). Here, i=1, 2, " , P, j=1, 2, " , N1, k=1, 2, " , NM.

X i(1, j ) is the value inputted to the jth neuron in the input (the

1st) layer.

X i( M , k ) is the output value of the kth neuron in the output (the

Mth) layer.

Even if the NN converge by learning X (1) and X ( M ) , it

cannot adequately deal with the ambiguous relationship between

new X (1)∗ and X ( M )∗ , which have not been learned. In order to

predict X i ( M )∗ according to the probability distribution of X (1)∗ ,

partially linear interpolation of the NN is introduced (Fig. 9), we

called it “partially-linearized neural network (PNN)”.

Fig. 10

Interpolation by the PNN

The new data ( S1′ , S′2 ) inputted into the converged PNN,

which are not learned by the PNN for recognition, must satisfy the

following condition

S1(min) < S1′ < S1(max) and S 2(min) < S 2′ < S 2(max)

(19)

where S1(min) , S 2(min) and S1(max) , S 2(max) are the minimum and

maximum value of S1 and S 2 , which have been learned by the

PNN.

Therefore, in this paper the verify values of NSP ( pi* and

p*j ) input to the PNN for distinguishing the state k, must satisfy

the following condition

pik (min) < pi* < pik (max) and p jk (min) < p*j < p jk (max)

(20)

where pik (min) , p jk (min) and pik (max) , p jk (max) are the minimum

and maximum values of pi and p j , respectively.

4.2

Fig. 9

Partial linearization of the sigmoid function

In the NN which has converged by the data X (1) and X ( M ) ,

Diagnosis and verification

A back propagation neural network is only used for training

the data, and the PNN is used for testing the learned NN. Fig. 11

shows the PNN built for the fault diagnosis of a centrifugal pump

system on the basis algorithm of sequential diagnosis (Fig. 5). The

training data for the PNN learning are shown (Figs. 6−8). The

PNN are quickly convergent when the training data are being

learned. We used the data measured in each known state, which

have not been learned by the PNN to verify the diagnostic

capability of the PNN. Examples of fault diagnosis by the learnt

PNN are shown in Tables 3−5). In the cases of the verifications,

the data input to the learned PNN have not been trained, and the

YZHOU Xiong, et al: Sequential diagnosis for a centrifugal pump based on fuzzy neural networky

·54·

PNN correctly and quickly judged the states (N: normal state, C:

cavitation, E: impeller eccentricity, A: abnormal faults, UA:

unknown abnormal states), which are expressed by the

possibilities gN, gC, gE, gA and gUA.

Fig. 11 PNN for the fault diagnosis of a centrifugal pump system

Table 3

P9

1.244

1.288

Verification results for the first step

P10

1.17

1.18

gN

0.985

0.978

gA

0.005

0.007

Judge

N

N

#

#

#

#

#

1.454

1.339

1.309

1.226

0.044

0.054

0.95

0.94

A

A

#

#

#

#

#

Table 4

P1

0.033

0.012

Verification results for the second step

P2

2.175

2.185

gC

0.988

0.986

gA

0.0003

0.001

Judge

C

C

#

#

#

#

#

0.146

0.182

2.584

2.804

0.032

0.003

0.943

0.96

A

A

#

#

#

#

#

Table 5

P1

0.176

0.024

Verification results for the third step

P2

2.777

2.618

gE

0.998

0.672

gUA

0.002

0.274

Judge

E

E

#

#

#

#

#

0.339

0.317

2.739

2.756

0.034

0.131

0.938

0.93

UA

UA

#

#

#

#

#

According to the test results, the probability grades output by

the PNN show the correct judgment in each state. Therefore, the

PNN can precisely distinguish the type of pump system fault on

the basis of the possibility distributions of symptom parameters.

New experimental data are used (Tables 3−5).

5

CONCLUSIONS

(1) For the purpose of improving the efficiency of the

condition diagnosis for plant rotating machinery and

distinguishing fault types at an early stage, a sequential diagnosis

method for a pump using fuzzy neural network by which the state

of machinery can be automatically judged on the basis of the

possibility grades of the normal and each abnormal state is

proposed.

(2) Since the relationship between the values of the symptom

parameters and fault types is ambiguous owing to the effect of

noise in the time signals, PNN as a fuzzy neural network and the

possibility grade were applied to solve the ambiguous problem of

the condition diagnosis. NSP in time domain were defined, which

can reflect the characteristics of time signal measured for the fault

diagnosis of rotating machinery. The synthetic detection index

was also proposed to evaluate the sensitivity of NSP for detecting

and distinguishing faults.

(3) The practical example of diagnosis of a centrifugal pump

system for detecting fault states, such as cavitation and impeller

eccentricity which often occured in pump, were shown to verify

the efficiency of the method proposed. The method proposed can

also be applied to other type of rotating machinery.

References

[1] LIU B, LING S F. On the selection of informative wavelets for machinery diagnosis[J]. Mechanical Systems and Signal Processing, 1999,

13(1): 145−162.

[2] LIN Jingqu, LIANG Sheng. Feature extraction based on morlet wavelet

and its application for mechanical fault diagnosis[J]. Journal of Sound

and Vibration, 2000, 234(1): 135−148.

[3] WANG H, CHEN P. Condition diagnosis of blower system using rough

sets and a fuzzy neural network[J]. WSEAS Transactions on Business

and Economics, 2008, 5(4): 58−63.

[4] MITOMA T, WANG Huaqing, CHEN Peng. Fault diagnosis and

condition surveillance for plant rotating machinery using partiallylinearized neural network[J/OL]. Computers & Industrial Engineering,

doi:10.1016/j.cie.2008.03.002H.

[5] MATUYAMA H. Diagnosis algorithm[J]. Journal of JSPE, 1991, 75(3):

35−37.

[6] SAMANTA B, Al-BALUSHI K R. Artificial neural network based fault

diagnostics of rolling element bearings using time-domain features[J].

Mechanical Systems and Signal Processing, 2003, 17(2): 317−328.

[7] SAXENA A, SAAD A. Evolving an artificial neural network classifier

for condition monitoring of rotating mechanical systems[J]. Applied Soft

Computing, 2007, 7(1): 441−454.

[8] SAMANTA B, Al-BALUSHI K R, Al-ARAIMI S A. Artificial neural

networks and genetic algorithm for bearing fault detection[J]. Soft

Comput., 2006, 10(3): 264−271.

[9] LI R Q, CHEN J, WU X. Fault diagnosis of rotating machinery using

knowledge-based fuzzy neural network[J]. Appl. Math. Mech-Engl.,

2006, 27(1): 99−108.

[10] FANG R M. Fault diagnosis of induction machine using artificial neural

network and support vector machine[J]. Dynamics of Continuous

Discrete and Impulsive Systems-series A-Mathematical Analysis, 2006,

13: 658−661.

[11] TAO M, LI Y, FANG J. Study on vacuum system fault diagnosis based

on fuzzy neural network[J]. Dynamics of Continuous Discrete and

Impulsive Systems-series B-Applications & Algorithms, 2006, 13:

292−296.

[12] CHRISTOPHER B M I. Neural networks for pattern recognition[M].

Oxford: Oxford University Press, 1995.

[13] CUDINA M. Detection of cavitation phenomenon centrifugal pump

using audible sound[J]. Mechanical Systems and Signal Processing,

2003, 17(6): 1 335−1 347.

[14] FUKUNAGA K. Introduction to statistical pattern recognition[M]. NY:

Academic Press, 1972.

[15] BENDAT J S. Probability function for random processes: prediction of

peak, fatigue damage, and catastrophic failure[R]. NASA Report CR-33,

1969.

[16] CHEN P, TANIGUCHI M, TOYOTA T, et al. Fault diagnosis method for

machinery in unsteady operating condition by instantaneous power

spectrum and genetic programming[J]. Techanical Systems and Signal

Processing, 2005, 19: 175−194.

Biographical notes

ZHOU Xiong is currently a vice professor in Engineering Training Center,

Chongqing University of Science and Technology, China. He received his

master’s degree from College of Mechanical Engineering, Chongqing

University, China, in 1998. He is also a PhD candidate in College of

Mechanical Engineering, Chongqing University, China. His research interests

include fault diagnosis.

Tel: +86-23-65022027; E-mail: cq_mecc@yahoo.com.cn

WANG Huaqing received his BS degree and MS degree from School of

Mechanical and Electrical Engineering, Beijing University of Chemical

Technology, China, in 1995 and 2002, respectively. He is currently a teacher in

Beijing University of Chemical Technology and a doctoral candidate in Mie

University, Japan. His research interest includes fault diagnosis of plant

machinery and signal processing.

Tel: +86-10-64446043; E-mail: wanghq_buct@hotmail.com

CHEN Peng graduated from the doctoral course of the Kyushu University,

Japan in 1990, and is currently a professor in Department of Environmental

Science and Technology, Mie University, Japan. His research interest includes

condition diagnosis of plant machinery, information and signal processing.

Tel: +8159-2319592; E-mail: chen@bio.mie-u.ac.jp

TANG Yike was born in 1949. He is currently a professor and a doctoral

advisor in College of Mechanical Engineering, Chongqing University, China.

His research interests include mechanical vibration and fault diagnosis.

Tel: +86-23-65022027; E-mail: yktang@cqu.edu.cn