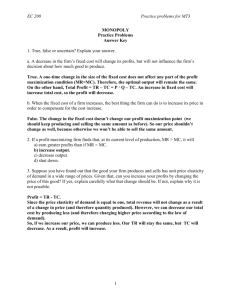

Multi-Engine GenSet Ultra Low Emissions Road

advertisement

Multi-Engine GenSet Ultra Low Emissions Road-Switcher Locomotive National Railway Equipment Co. THE N-VIROMOTIVE NEW LOCOMOTIVE CONCEPT 1. Uses Multiple 700 HP Diesel Engine GenSets In Order To Significantly Reduce NOx and PM Exhaust Emissions 2. Controls the Horsepower and RPM Levels For Each Engine In Order To Achieve Even Better Emissions Levels and Fuel Consumption Rates. 3. Manages Start / Stop Functionality To Minimize Engine Idling. 4. Provides All Electrical Power To A Common Connection So That DC Power Can Be Managed To Individual Traction Motors For Better Adhesion To The Rail and Provide All Necessary Power For The Operator’s Cab, Air Brake System And Equipment Cooling. 5. Arrange All The Major Components On The Locomotive Frame To Facilitate Replacement When Required. 1 Uses Multiple Small Diesel Engine Gensets To Reduce Harmful Exhaust Emissions To A Minimum USA EPA EMISSIONS LIMITS FOR LOCOMOTIVES VS. NREC's N-VIROMOTIVE EMISSIONS (G/BHP-H) NOx HC CO PM EPA TIER II RAIL SWITCHER LINE HAUL 8.1 5.5 0.6 0.3 2.4 1.5 0.24 0.2 N-VIROMOTIVE % LOWER LINE HAUL 67% 2.88 87% 0.06 44% 0.98 67% 0.07 SWITCHER 2.67 0.08 1.34 0.08 9 % LOWER 48% 81% 35% 67% USA EPA RAIL TIER II SWITCHER 8 7 USA EPA RAIL TIER II LINE HAUL 6 5 NREC SWITCHER SWITCHER 4 3 2 NREC SWITCHER LINE HAUL 1 0 NOx HC CO PM Controls The Horsepower And RPM Levels For Each Engine In Order To Achieve Even Better Emissions Levels And Fuel Consumption Rates.” Throttle Notch Eng 1 BHP Eng 1 THP Eng 1 RPM Idle 1 2 3 4 5 6 7 8 67 228 388 685 547 661 594 667 697 0 145 305 585 447 561 494 567 597 1200 1500 1500 1800 1800 1800 1800 1800 1800 Eng 2 BHP 390 485 514 587 686 Eng 2 THP 373 469 494 567 664 Eng 2 RPM 1500 1500 1800 1800 2000 Eng 3 BHP 429 587 686 Eng 3 THP 412 567 664 Eng 3 RPM Loco BHP Loco THP 1500 1800 2000 67 228 388 685 937 1146 1537 1841 2069 0 145 305 585 820 1030 1400 1701 1925 FUEL CONSUMPTION COMPARISON Throttle Notch % of Throttle* N-Viro BHP N-Viro Fuel Rate Gal./Hr. Idle** 1 2 3 4 5 6 7 8 55.0% 4.0% 4.0% 4.0% 4.0% 4.0% 4.0% 4.0% 17.0% 100.0% 67 228 388 685 937 1146 1537 1841 2069 2.1 12.7 21.8 35.5 51.5 61.2 83.5 97.9 110.0 ** Includes 50% Reduction in Idle from Idle Limiting % REDUCTION: * AAR Medium Duty Cycle N-Viro BHP Weighted 16-645E BHP Weighted 17 4.49 110 8.19 328 19.39 624 34.37 911 49.51 1214 65.98 1523 83.65 1854 103.99 2193 126.65 TOTAL WEIGHTED: 36.85 9.12 15.52 27.40 37.48 45.84 61.48 73.64 351.73 659.06 9.35 4.40 13.12 24.96 36.44 48.56 60.92 74.16 372.81 644.72 BSFC: 0.0513 0.060 16-645E BHP 16-645E Fuel Rate Gal./Hr. N-Viro Fuel 16-645E Fuel Rate Rate Weighted** Weighted 0.57 0.51 0.87 1.42 2.06 2.45 3.34 3.92 18.71 33.84 2.47 0.33 0.78 1.37 1.98 2.64 3.35 4.16 21.53 38.61 14% 2 20.7% Fuel Consumption Savings Throttle Notch 12 645E RPM NREC SW RPM 8 7 6 5 4 3 2 1 Idle 900 820 729 651 568 490 370 300 300 1800 1500 1500 1500 1800 1500 1500 1300 900 NREC SW ENGs RUN 2 2 2 2 1 1 1 1 1 12 645E 12 645E NREC SW Fuel Rate BHP BHP Gal/Hr 1517 1334 1016 858 641 415 221 62 10 1377 1210 1051 844 658 430 234 123 44 68.86 65.36 56.79 49.29 34.64 23.57 12.50 6.79 2.86 Duty Cycle % 0.8% 0.2% 1.5% 3.6% 3.6% 5.8% 12.3% 12.4% 59.8% Totals: 12 645E Weighted BHP NREC SW Weighted BHP 12 645E Weighted Gal/Hr NREC SW Weighted Gal/Hr 12.14 2.67 15.24 30.89 23.08 24.07 27.18 7.69 5.98 148.93 11.02 2.42 15.76 30.40 23.68 24.93 28.76 15.28 26.31 178.55 0.72 0.15 0.92 1.73 1.30 1.39 1.69 0.70 1.93 10.53 0.55 0.13 0.85 1.77 1.25 1.37 1.54 0.84 1.71 10.01 12 645E 0.0707 NREC SW 0.0561 % Diff 20.7% Weighted BSFC: 0.0707 0.08 90.6 76.4 61.1 48.0 36.0 24.0 13.7 5.6 3.2 NREC SW Fuel Rate Gal/Hr 0.0561 0.06 0.04 0.02 0.00 12 645E NREC SW 3 Throttle Schedule Not ch Posit ion Idl e 1 2 3 4 5 6 7 8 engines r unning 1 1 1 1 1 2 2 2 2 engine r pm 900 1300 1500 1500 1800 1600 1500 1500 1800 t ot al hor sepower 25 125 225 425 650 850 1000 1250 1400 dut y cycl e 59.8% 12.4% 12.3% 5.8% 3.6% 3.6% 1.5% 0.2% 0.8% hor sepower weight ed 14.95 15.50 27.68 24.65 23.40 30.60 15.00 2.50 11.20 100% 80% Idl e - 4 5-8 60% 94% 6% 40% 20% 0% Idl e - 4 5-8 4 Manages Start / Stop Functionality To Minimize Engine Idling. 55.0% Dut y Cycl e % of Idl e = 13.2 Dail y Idl e Hour s = 50% Pr oj ect ed Dail y Idl e Limit ing % = 6.6 Pr oj ect ed Dail y Idl e Limit ing Hour s = ------------------------------------------------------------------------------------------------------------------------------------------------Gal l ons Lit er s 2.10 7.95 Fuel per Hour @idl e = 13.86 52.47 Fuel Saved per Day f or 1 Locomotive = 4,158.00 15,741.00 Fuel Saved per Month f or 10 Locomotives = 505,890.00 1,915,155.00 Fuel Saved per Year f or 100 Locomotives = Electronic Propulsion Control ¾ NRE Electronics provides the Electronic Control module called the N-FORCE. This system provides all propulsion, accessory equipment, and low voltage control. The N-FORCE is equipped with an Operator Interface Panel display for the monitoring of real time events, storing fault and run time data, and performing self tests. ¾ A high voltage DC Chopper provides propulsion power to each traction motor separately for enhancing adhesion control by as much as 50% + compared to conventional DC locomotives. 5 Provide All Electrical Power To A Common Connection So That DCPower Can Be Managed To Individual Traction Motors For Better Adhesion To The Rail And Provide All Necessary Power For The Operator’s Cab, Air Brake System And Equipment Cooling. N-VIROMOTIVE #1 GENSET SIMPLIFIED SCHEMATIC OF ELECTRICAL SYSTEMS TRACTION ALT RECTIFIER AC #2 GENSET DC NFORCE RECTIFIER AC DC NFORCE NEG POS TRACTION ALT P1 #3 GENSET RECTIFIER AC DC NFORCE RECTIFIER AC DC NFORCE NEG POS NEG POS P2 NEG POS P3 P4 #1 MOTOR CONT SIG RET #2 MOTOR CONT SIG RET #3 MOTOR CONT SIG RET #4 MOTOR CONT SIG RET CURRENT TRANS SIG RET CURRENT TRANS SIG RET CURRENT TRANS SIG RET CURRENT TRANS SIG RET TRACTION ALT LVPS Low Voltage Power Supply 480 VAC to 74 VDC CONTACTOR TM3 A TM4 A NEG RV CONTACTOR T. M. BLOWER TM2 A TM1 A RV RV RV TM1 TM2 TM3 TM4 F F F F RV RV RV RV AIR COMPR 2GS14B 6 TRACTIVE EFFORT VS SPEED 2GS14B 90,000 TRACTIVE EFFORT - LBS. 80,000 62:15 Gear Ratio 40 inch Wheels 1300 THP - 129 Tons D77 Traction Motors Dispatch TE 77,406 LBS. (35,111 Kg) 70,000 Actual THP May Vary Entire Curve May Not Be Available At All Tim es Due To Lim itations of Wheel/Rail Adhesion 60,000 50,000 Dispatch TE is based on 30% adhesion Continuous TE 44,165 LBS. (20,033 Kg) 40,000 30,000 20,000 10,000 0 0 10 20 30 40 50 60 70 80 SPEED - MPH 3GS21B 7 TRACTIVE EFFORT VS SPEED 3GS21B 90,000 TRACTIVE EFFORT - LB 62:15 Gear Ratio 40 inch Wheels 1970 THP - 132.5 Tons D77 Traction Motors Dispatch TE 80,386 LBS. (36,462 Kg) 80,000 70,000 Actual THP May Vary Entire Curve May Not Be Available At All Times Due To Limitations of Wheel/Rail Adhesion 60,000 50,000 Continuous TE 46,044 LBS. (20,885 Kg) Dispatch TE is based on 30% adhesion. 40,000 30,000 20,000 10,000 0 0 10 20 30 40 50 60 70 SPEED - MPH Cummins QSK19 Tier III Engine Type = In-Line, 4-Cycle, 6-Cyl Displacement = 1159 cu. In. 19 Liters Rated Power = 510-700 BHP 379-522 kW Aspiration = Turbocharged Air-to-Air Charge Air Cooled ¾ The Engine is designed and certified as EPA Tier III Off-Road compliant ¾ Full Authority Electronic Controls ¾ Cummins Modular Common-Rail Fuel System ¾ Over 6500 QSK19 Engines in Industrial Applications 8 The GenSet in Process Work in Process 9 Work In Process Work In Process 10 GENSET INSTALLED Electric Cabinet in Process 11 Microprocessor NRE Electronics “N-FORCE” DC Chopper Compartment Chopper Cooling Air Exhaust 12 Cab Console in Process Cab Console Completed 13 Accessory Equipment ¾ Equipped with a variable speed 3 phase 240-480 VAC electric motor driven Atlas-Copco model rotary screw air compressor. ¾ The Equipment blower provides 15,000 cfm cooling air for the traction motors, DC Choppers, DC Rectifier, Low Voltage Power Supply and Electric Cabinet Pressurization. ¾ The Low Voltage Power Supply Converts 240-480 VAC to 64-74 VDC for battery charging and low voltage control. ¾ A DC to AC inverter is provided to convert 64-74 VDC to 115 VAC for RV type heating, ventilation and air conditioning (HVAC) power as well as 24 VDC for Low Voltage GenSet Control. ¾ Equipped with standard 26L air brake. ¾ NYAB electronic air brake is optional. Air Compressor and Equipment Blower 14 RV Type HVAC ORIGINAL MP15 DC CORE LOCOMOTIVE 15 16 17