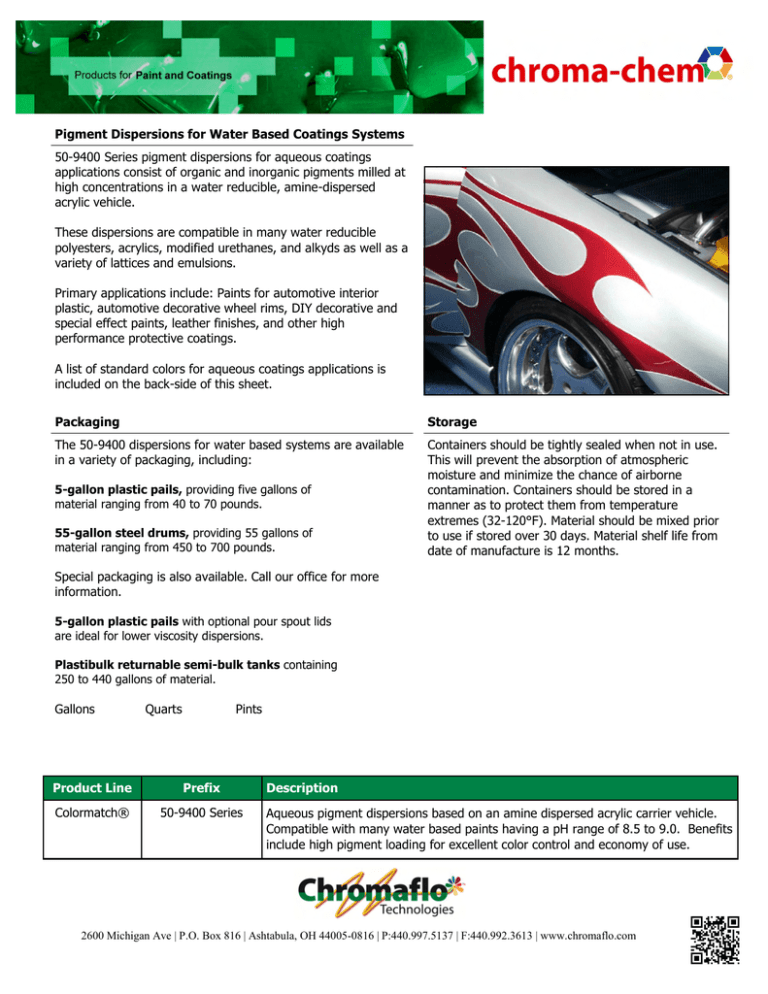

Product Line Prefix Description Colormatch® 50

advertisement