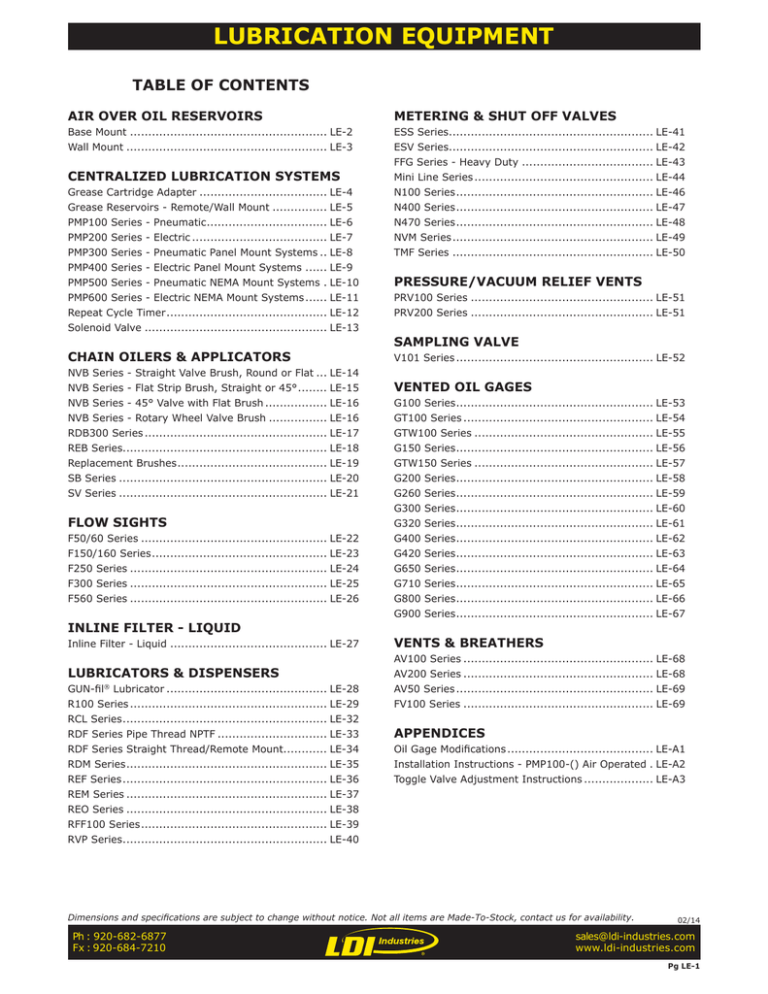

lubrication equipment

advertisement