safety line - Keystone Shipping Co

advertisement

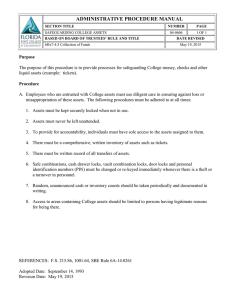

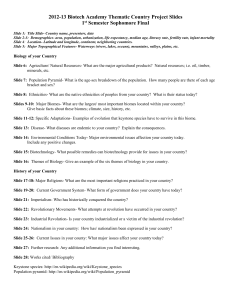

I s s ue 9 7 K e y s t o n e S h i p p i n g Co . S pr i ng 2 0 1 6 S AFETY L INE 2016 K EY STONE FLEET SEMINAR This February Keystone traveled to Traverse City, Michigan for our annual Keystone Fleet Seminar from February 29th through March 4th. With attendees ranging from our Key Lakes, tanker, and MARAD fleets we had a great cross section of talent. Everyone was actively engaged and participated in a variety of discussions. INSIDE THIS ISSUE: Keystone Fleet Seminar 1 NDRF Contract 1 Shipyard Safety 2,3 Near Miss Highlight 3 Extreme Heat 4 First Through the Locks 5 Making Sailors out of Soldiers 5 Keystone Spotlight 6 We want to thank our guest speakers for taking the time to join us, even our own Captain Rick Jordan gave a detailed yet entertaining presentation for us! We collected feedback while we were on site, but if you have ideas for what you would like to see please let us know! Our main focus this year was Keystone’s Safety Culture. We had numerous discussions on how the office and ships can work together in order to improve our already high standards. On the ships you will likely see some of these discussion points rolling out soon! We not only talked about safety, but looked at new projects that are in the works such as the MUNSON repowering and the rolling out of DocMap. President Don Kurz addressing the fleet at Keystone’s Opening Dinner for the 2016 Fleet Seminar on February 29, 2016. KEYSTONE AWARDED NDRF CONTRACTS On January 22, 2016 the U.S. Transportation Secretary Anthony Foxx announced that the DOT had awarded contracts for the management, maintenance, and operation of the 48 vessels which belong to the National Defense Reserve Fleet (NDRF). CAPE DIAMOND in Charleston, SC Keystone received the largest number of contracts at eleven vessels which take part in the DOT’s Ready Reserve Force. Contacts were extended for our Cape R vessels in Portsmouth, VA and for the Cape K vessels in New Orleans, LA. The Cape D’s are our newest addition to our MARAD fleet and include the CAPE DECISION, DOMINGO, DOUGLAS, DIAMOND, DUCATO, and you can’t forget the one E, our CAPE EDMONT! Keystone proudly welcomes the newest addition to our family, the Cape D’s positioned in Charleston, South Carolina! P age 2 I s s ue 9 7 SHIPYARD SAFETY With multiple vessels having gone on drydock and still more to go, it is important to be mindful of additional operations that will be taking place and the added precautions necessary to stay safe. “We wish to salute again in 2015 the extra safety efforts of our Shipyard Repair Superintendents, Masters, Chief Engineers, and Roving Safety Officers. Your hard work and safety vigilance paid off with stellar results. Well done!” -Capt. Tim O’Connor During dry dock many different operations are occurring at the same time. Heavy rigging is taking place beside hotwork, sandblasting, and installation of delicate instruments or cabinetry. There are not only the crew to be mindful of, but also there will be subcontractors on board. All of this additional activity leads to an increase in the potential for injuries. It is important to take the time to plan work activities at the beginning of each project in order to ensure safe work habits are being followed. The shipyard is a busy place to work in every day; so make your personal safety and that of your shipmates a priority in everything you do! USNS OBREGON at Drydock in Philadelphia Ship Repair—January 2016 SO WHAT IS THE HAZARD? Let us work our way around the vessel in order to observe a number of safe work habits to keep in mind for the dry-dock. PPE - PPE should be a part of every job! Make sure you are choosing the safe and appropriate choices for you and your crewmembers. Confined Space Entry - Always look for posted Marine Chemist Certificate or the Shipyard Safety Officer for an inspection form before entering a space. Cleaning - often requires scraping, pumping, or gas freeing (removing liquid residues) that can take place in spaces containing flammable or combustible liquids, gases, toxic or corrosive materials. Prepare each job by removing liquid residues, securing piping and pumping systems, and determining ventilation needs. Scaffolds, Ladders, and Access - before working with or around ensure that equipment is safely secured I N S I D E STO RY H E A D L I N E and supported, that they are level, safe access is provided, adequately decked and guard rails are in place. Fire Protection – make sure fire safety plans are compatible with shipyard and all employees on board are aware of the safety plan including subcontractors and shipyard staff. Surface Prep - includes removal of old paint, oil, scale, or rust where toxic S a f e ty L i n e cleaning solvents, chemical removers, mechanical removers or flammable and combustible liquids may be used. Make sure proper materials are used. P age 3 machinery, and deck machinery as injuries can occur due to unanticipated machinery movement or release of materials. General Working Conditions – housekeeping, lighting, slips, trips and falls, working alone, safety color codes for physical hazards and many other general safety rules must be maintained while in the yard to prevent accidents. Painting – paints and other preservative coatings contain many toxic and flammable materials such as hydrocarbon solvents, and epoxy resins. Take measures to prevent toxic inhalation, skin absorption, and for possible fire and explosion hazards. Electrical – potential for electrical shock hazard is greater during ship repairs due to temporary power cords and welding leads. Make sure before working energized equipment is guarded, deenergized, and appropriate PPE is used to prevent electrocution, burns or electrical shocks. Machinery & Piping Systems be aware of other projects taking place in boilers, piping systems, propulsion Seakay Spirit in Drydock in Freeport, Grand Bahamas—Jan.2016 Tools and Materials Handling - improper use and lack of maintenance can result in worker injuries. Hot Work - weld- S.S. DENEBOLA as she departs Boston Ship Repair - December 18, 2015 ing, cutting, burning, abrasive blasting, and other heat producing operations are all considered hot work and increases the risk of fire and explosion hazards. Always maintain a fire extinguisher or water hose near hot work activities as part of the firewatch. Know what you are doing and do it safely! Please remember that all crewmembers have the ―stop work‖ authority if something looks unsafe to them; so use it! NEAR MISS HIGHLIGHT Near Miss Reports provide useful issues to discuss and consider as you go about your tasks aboard our vessels and ashore. With our new Safety Line format the office is going to choose one or two near misses as appropriate to share with the entire fleet as our featured highlight. Keep sending in your near misses and maybe yours will appear in the next issue! Smoking Transformer Incident: When crewmember connected an appliance in his stateroom to a 220V-110V transformer, the transformer became hot and started smoking. opened and inspected a loose wire was discovered. Facts: Root Cause: The newly installed transformer was likely there for repair. Inadequate segregation and labeling of equipment is a safety hazard especially when new crew members come onboard. Lessons Learned: The transformer was newly installed in the room and had been found in the Electrical Shop. When the transformer was Ensure oversight that work areas are organized and labeled to ensure not using faulty equipment that is in for repair. Test equipment with unknown history prior to installation. When using new equipment have someone present in order to ensure it is properly working. This is a lesson for everyone to one make sure faulty goods are properly stowed or thrown out and two to make sure new crew members know their work areas for theirs and others safety. Make sure to test equipment with unknown history for your and your crew members’ safety! S a f e ty L i n e P age 4 OPERATING IN E XTREME H EAT Engineering and Administrative Controls Frequent water breaks First aid training for heat stroke or heat Potential Hazards Heat exhaustion Heat stroke exhaustion Dehydration Sunburn Eye injury from ultraviolet radiation Exploding pressurized containers Hot metal decks, handrails, ladders, machinery guards, etc. Personal Protective Equipment Work clothing that provides protection against hot surfaces and sunburn Additional salt in diet Buddy observation system Storage lockers for flammables Ventilation fans Eye protection with shaded lenses Be aware that this can happen at home as well as on the vessel! How to Use the Heat Index Across top locate predicted high temperature Down the left side locate predicted humidity Follow across and down to find the apparent temperature or ―What it feels like today‖ Heat Index of 90—100: Sun stroke, heat cramps, and heat exhaustion are possible with prolonged exposure and physical activity. Heat Index of 105—129: Sun stroke, heat cramps, and heat exhaustion likely. Heat stroke possibility with prolonged exposure and physical activity. Heat Index of 130 or higher: Heat stroke or sun stroke imminent. HEAT STROKE, K e ys t o n e S h i p p i n g C o . 1 Bala Plaza East Suite 600 Bala Cynwyd, PA 19004 TEL : 610-617-6800 If you have any suggestions or comments please submit them to Capt. T. O’Connor toconnor@keyship.com Summer is almost here so it is time to start thinking about the three kinds of heat related illnesses. Heat cramps, heat exhaustion, and heat strokes are all possible during hot weather. All heat related injuries need prompt medical attention! Heat cramps are muscle cramps usually occurring in the arms or legs, but also may be in the abdominal or chest muscles. Heat exhaustion signs include heavy sweating weakness, fast pulse, normal body temperature, headache, dizziness, nausea, and vomiting. First aid for heat exhaustion requires the worker to be moved to a cool place. Keep them lying down with their legs straight and elevated 8 to 12 inches. Apply cold packs, wet towels, or just wet their clothing in order to cool them down. E X HAU S TI O N , AN D Heat stroke is a true emergency! Signs and symptoms include high body temperature, unconsciousness, hot skin, rapid pulse and breathing, weakness, dizziness, and headache. Immediate first aid is required. Move the victim to a cool place and immediately cool the worker by any available means; use ice and water from a job site cooler for example. Keep the head and shoulders slightly elevated and make sure to monitor the airflow of the victim to ensure they are breathing. Prevention of heat illness is very important. Gradual adaptation to working in hot weather is a start. As the weather heats up take a few short breaks during the day and if possible schedule heavy work that has to be accomplished CRAMPS during cooler periods of the day. Dress sensibly and drink plenty of water! Keep a sharp eye out for potential heat injuries in coworkers as well. Practice prevention!! It is the name of the game and will keep you from becoming a victim of a heat related illness. Remember, these are serious medical emergencies. Call for professional help onboard the vessel immediately! S a f e ty L i n e P age 5 FIRST THROUGH THE LOCKS! It’s spring at the Soo; despite the frigid temperatures and snow when our vessels went through the Locks this year! and a ceremony was held onboard the Roger Blough on Thursday afternoon with Captain Mark Blatnik. March 25, 2016 the new shipping season for the Great Lakes kicked off with the opening of the Soo Locks. Both our vessels the Edwin H. Gott and the Roger Blough were the first ships through the locks this season. The Roger Blough was upbound in ballast heading to load up and the Gott was downbound. Raymond Bell, president of the Soo Locks Visitor's Center Association took a ride through the locks with Captain Tim Alfson on the Gott This is the third consecutive year that the Key Lakes Fleet has had a vessel open the Soo Locks. Not only is it our fleets third time, but this is the second year in a row that it was both the Gott and Blough! The opening of the Locks is like the opening day of baseball up on the Lakes and we are so proud of our vessels for holding onto that record. Captain Tim Alfson on the Edwin H. Gott Congratulations to all that helped in this achievement! Roger Blough was the first upbound vessel through the Soo Locks 2016 Edwin H. Gott was the first downbound vessel through the Soo Locks 2016 MAKING SAILORS OUT OF SOLDIERS ON THE USNS PLESS Embarked soldiers & marines going through Safety Orientation drill en-route. All were assigned to the USNS Maj Stephen Pless, in support of operation Pacific Pathways 2016. Exercises supported with strategic U.S. allies include: Cobra Gold (Thailand), Foal Eagle (Korea), & Balikatan, the Tagalog word for “Shoulder-to-Shoulder” (Philippines). "We strived to offer all MILDET to participate in various training modules onboard and en-route to destination ports of call so as to show them what routine shipboard life is all about. These included Marine Safety, Marine Fire Fighting, and basic Navigation training. Those participating took a keen interest in all, adding something to their daily routine onboard in a positive way." -Captain Brian Patten, USNS Maj. Stephen W. Pless S a f e ty L i n e P age 6 K e y s t o n e S n a p s h o ts OBREGON in Drydock with 3rd AE Jacob Brohawn, 3 AE Robert Bohovsky, and engine cadet Heather Lade Shoreside staff participating in a tabletop emergency drill exercise at our Pennsylvania office If you have any photos you would like to share please send them in! Capt. Mark Blatnik on the ROGER BLOUGH Capt. Rick Jordan presenting at the annual seminar Mate Don Parker, 2nd AE Bryan Kwiatkowski, & Ch Engineer Steve Thompson at annual seminar Port Engineer Robert Hodgdon, Capt. Adam Blackwell, Program Manager Andy Hake, and Port Captain David Carroll at annual seminar in Traverse City, Michigan SEAKAY SPIRIT coming out of Drydock