ENGINEERED SOLUTIONS

Collector Pans

A Versatile System

Contech Collector Pans

Economical, Efficient Containment

of Liquid Pollutants

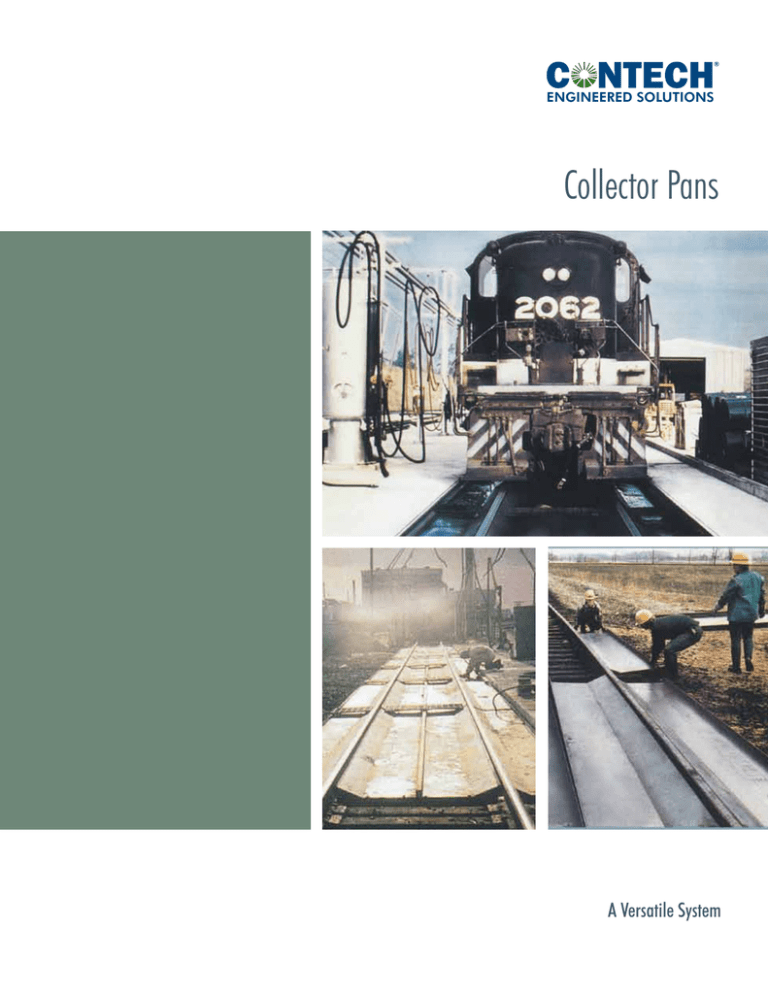

Contech Collector Pans are a modular

system of steel pans and drains easily

installed on existing or new tracks to

catch wastes such as spilled or leaking

fuel, oils and greases and other

pollutants.

Their effectiveness has been proven

in hundreds of installations for

both railroads an industry. Typical

applications are along fueling stations,

ready tracks, tank car loading and

unloading areas, washing facilities

- anywhere that oils, chemicals and

other pollutants cna drip from standing

cars and find their way into sewers and

streams.

Pans are installed to cover the area

completely between and immediately

outside the rails. Cross drains are

installed at right tangles to the track

between the ties to carry wastes and

rainwater into under drains and on to

treatment and disposal facilities.

Three Adaptable Designs

Type 1 Collector Pans are designed

for and are generally used at fueling

areas. They also have been used at

washing facilities and industrial tracks

with heavy waste loads.

Type 2 and Type 2-Modified Pans are

simplified versions of the Type 1 Pan.

They are designed for ready tracks or

other areas with less waste. They have

proven excellent for fueling areas with

existing or new concrete platforms.

Because they use fewer parts, both

Type 2 and Type 2-Modified Pans

are less expensive than Type 1 Pans.

However, Type 1 Pans provide a tighter

barrier against spills and are best

suited for critical control areas. Type 2

Contech Type 2 Collector Pans on ready tracks. The grating over the cross drain allows personnel

to easily walk from side to side.

Pans offer more adaptability where

curves, platforms and turnouts are

involved.

Long Service Life, No

Obsolescence

The strong and flexible steel

construction of Contech Collector Pans

helps avoid the cracking and resulting

leaks that are possible with non-steel

pans. And should an accident damage

a Contech Collector Pan, its modular

construction means that only the

damaged section need be replaced at

minimum cost.

Contech Collector Pans are also

completely reusable. Yard layouts and

the locations of fueling facilities and

ready tracks change. Unlike concrete

structures, Contech Collector Pans can

be easily relocated at small cost.

In addition, Contech Collector

Pans are easily removed for track

maintenance simply by removing a few

bolts. When reinstalled later, they still

perform like new.

Components are also available in

galvanized or stainless steel. Type 1

and 2 are galvanized in accordance

with ASTM A123, except minimum

coating weight shall be 2 Oz/Sq. Ft.,

total both sides. Type 2-Modified when

specified galvanized is manufactured

from pregalvanized steel conforming

to ASTM A446 with a minimum 2 Oz/

Sq. Ft. coating, total both sides.

Easy Field Installation with

Minimal Downtime

Contech Collector Pans are engineered

to be simple in design, rugged for

handling ease, and easy to install. No

special installation skills are needed.

A competent foreman, a welder,

and four or five unskilled laborers

can easily install a Type 1 or Type 2

Collector Pan system. A welder is not

needed for Type 2-Modified Pans if rail

joints are welded.

Installation involves only a minimal

amount of track down-time. Contrast

this with a comparable installation of

concrete aprons. The concrete requires

extra weeks of expensive, wasted time.

Contech Collector Pans

Modular Construction is Key to

Versatility

While certain dimensions of Contech

Collector Pans are standard, a wide

range of module combinations can be

made to meet specific requirements.

For example:

• Contech Pans can be used on

tracks with a descending grade

as easily as on a level track and

often they are more economical.

• On installations around curves,

Type 2 Pans can be furnished

pre-formed to fit most curves

and simple field modifications

will meet practically and field

condition.

• If desired, pans can be installed

between the concrete platforms

on each fueling track.

• Underdrains can be included as

part of your Contech Collector

Pans system, and our plastic

pipe has proven effective for

this purpose. Joints are oil-tight,

flow characteristics are excellent.

Manholes and catch basins are

also used on many installations.

• Contech Collector Pans are

easily fitted around rail joints

by field cutting with a torch

to the approximate outline of

the joint bars and bolts. We

strongly recommend that rail

joints be welded through all pan

installations.

• Tie movements does not affect

the performance of Contech

Collector Pans. The pans are

not rigidly attached to the ties

but “float” on them. With Type

1 Pans, the aprons, attached

to the rails, hold the pans in

place. Type 2 Pans are bolted

On this installation, concrete platforms were poured with a nosing angle on the edge. A zee

flashing angle is welded to the angle, protecting against oil leaksage.

tightly to anchor angles under

the rails, holding the pans down

and securely against the rail

web. Type 2-Modified Pans are

fastened directly to the channelshaped cross drains with selfdrilling screws.

• Type 1 and Type 2 Collector

Pans are appropriate for use on

signaled track.

Your Contech Representative can

provide additional information.

14’-0”

Type 1

11’x4”

Type 1

9’-10”

Type 2

10’-0” Type 2

Modified

14’-0”

11’x4”

9’-10”

10’-0”

Module length-center to center 19’-0”

of cross drains

19’-0”

19’-0”

39’x6” (varies)

Pan length-actual

18’-5”

18’-5”

18’-5”

19’-1 7/8 "

Width of crosswalk

2’-0”

2’-0”

2’-0”

1’-6 ¾”

O.D. of cross drain downspout 5 ½”

5 ½”

5 ½”

4”

Pan Gage

7

7

7

12

Nominal thickness

(0.179”) (0.179”) (0.179”) (0.105”)

Module Data

Width-out to out of pan

flanges

On this installation, concrete platforms were

poured with a nosing angle on the edge. A

zee flashing angle is welded to the angle,

protecting against oil leaksage.

An Answer to Your Site Development Problems

Type 1 Design (CP1)

Standard units

11’-4” or 14’-0” wide

CROSS

DRAIN

END PLATE

FIELD WELD

AS REQ’D

11’-4” OR 14’-0” WIDE PAN UNIT

5’-8” FOR 11’-4” UNIT

7’-0” FOR 14’-0” UNIT

WELD CENTER FLASHING TO

1 PAN ONLY, ALWAYS ON

SAME SIDE OF CENTERLINE

CENTER FLASHING

SIDE GRATING

TRACK

RAIL APRON

CENTER FLASHING

GUIDE ANGLE

TACK WELD

CENTER GRATING

SIDE GRATING

GRATING

TRASH

RACK

1” ± DROP

DOWN SPOUT

ANCHOR ANGLE

5’- 4 ½” FOR 11’- 4”

6’- 8 ½” FOR 14’-0” UNIT

Type 2 Design (CP2)

Standard unit

9’-10” wide

CROSS DRAIN

5/8” X 1 ¼” H.H. BOLT, NUT

AND LOCK WASHER(TYPICAL)

TRACK

AND PANS

2’-3 ½” ANCHOR

ANGLE

STANDARD TIE

SWITCH TIES APPROX. 5’-3” CENTERS

9’-10” PAN UNIT

TRACK

CENTER FLASHING

CROSS

DRAIN

END PLATE

FIELD WELD

AS REQ’D

CENTER GRATING

SIDE GRATING

COLLECTOR PAN

WELD CENTER FLASHING TO

1 PAN ONLY, ALWAYS ON

SAME SIDE OF CENTERLINE.

SIDE GRATING

GRATING

TRASH

RACK

1” DROP

DOWN SPOUT

TRACK

AND PANS

CROSS DRAIN

TIE

3” X 1 5/8” ANCHOR ANGLE. ATTACHED

TO PANS WITH 5/8” X 1 ¼” HH BOLTS,

NUTS AND LOCK WASHERS.

4’ - 7 ½”

Type 2-Modified Design (CP2M)

Standard unit » 10’-0” wide

Not available for tracks

with signal circuits

10’ WIDE (120”) OTHER WIDTHS AVAILABLE UPON REQUEST

TRACK

THESE SCREWS AT

LAP JOINTS ONLY

PAN #1

PAN #2

PAN #1

CROSS DRAIN

TIE

DOWN SPOUT

4” O.D.

½” SQUARE PABR X 1 ½”

LONG, SHOP ATTACHED TO

GRATING (4 PLACES PER GRATE)

PAN #2

½” OPEN SPACE

ALLOWS SAND AND SILT

GRATING (FULL DEPTH TO FLOW THROUGH

NOT SHOWN FOR

CLARITY)

TRACK

Type 1 & Type 2 Design

Type 2-Modified Design

24” GRATING

CROSS DRAIN

FIELD WELD

2 ½” TYPICAL

PAN

12 SCREWS AT THIS

JOINT (TYPICAL)

19 ¼”

18 ¾ GRIP STRUT

GRATING

2 ½” DEEP, 14 GAGE GALV.

GRIP STRUT GRATING

GRATING SUPPORT

ANGLE

PAN

CROSS DRAIN

TIE

TIE

TIE

23 ¼” ±

ANCHOR ANGLES

CROSS DRAIN

DOWN SPOUT

(1’ LONG)

NOTHING IN THIS CATALOG SHOULD BE CONSTRUED AS AN EXPRESSED

WARRANTY OR AN IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. SEE THE CONTECH STANDARD CONDITIONS

OF SALE (VIEWABLE AT WWW.CONTECHES.COM/COS) FOR MORE

INFORMATION.

CollectorPansBro PDF 6/14 MC

RECYCLED

PAPER

Visit our web site: www.ContechES.com

800.338.1122

ENGINEERED SOLUTIONS

©2014 Contech Engineered Solutions LLC

All rights reserved. Printed in USA.