Roosevelt Hall Interior Specs - The City University of New York

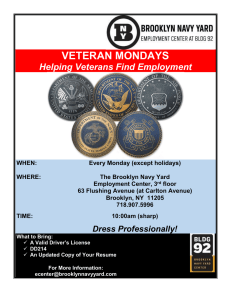

advertisement