Electrical Work

Safety Program

Thousands of workers are unnecessarily injured each

year by electrical shock or burned by electrical arcs.

The frequency and severity of these types of injuries

can be significantly reduced by developing and

implementing an electrical work safety program that

complies with the guidelines established in NFPA 70E®.

These programs should include the following topics.

Program Elements

An overall electrical safety program directs the activity

appropriate for the voltage, energy level and circuit

conditions. It should provide an awareness of the

potential electrical hazards to employees who work in

an environment influenced by the presence of electrical

energy. An electrical safety program should identify:

• Principles and controls upon which it is based

• Hazard/risk evaluation to determine if electrical hazards

exist for live parts operating at 50 volts or more

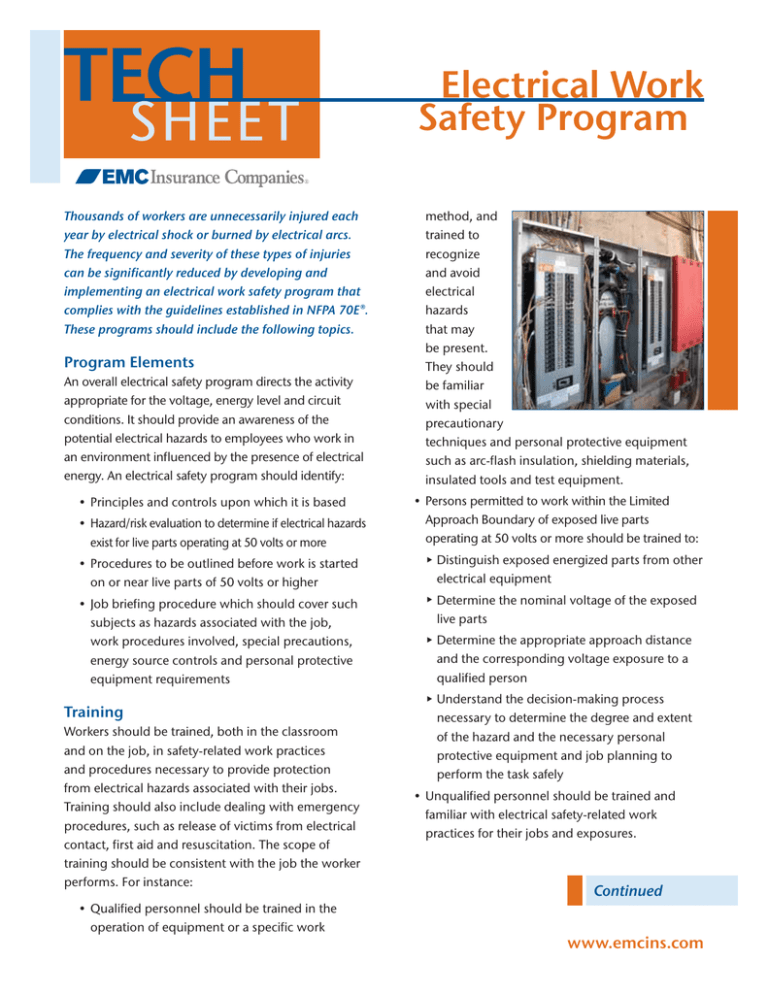

method, and

trained to

recognize

and avoid

electrical

hazards

that may

be present.

They should

be familiar

with special

precautionary

techniques and personal protective equipment

such as arc-flash insulation, shielding materials,

insulated tools and test equipment.

• Persons permitted to work within the Limited

Approach Boundary of exposed live parts

operating at 50 volts or more should be trained to:

• Procedures to be outlined before work is started

on or near live parts of 50 volts or higher

f

Distinguish exposed energized parts from other

electrical equipment

• Job briefing procedure which should cover such

subjects as hazards associated with the job,

work procedures involved, special precautions,

energy source controls and personal protective

equipment requirements

f

Determine the nominal voltage of the exposed

live parts

f

Determine the appropriate approach distance

and the corresponding voltage exposure to a

qualified person

f

Understand the decision-making process

necessary to determine the degree and extent

of the hazard and the necessary personal

protective equipment and job planning to

perform the task safely

Training

Workers should be trained, both in the classroom

and on the job, in safety-related work practices

and procedures necessary to provide protection

from electrical hazards associated with their jobs.

Training should also include dealing with emergency

procedures, such as release of victims from electrical

contact, first aid and resuscitation. The scope of

training should be consistent with the job the worker

performs. For instance:

• Qualified personnel should be trained in the

operation of equipment or a specific work

• Unqualified personnel should be trained and

familiar with electrical safety-related work

practices for their jobs and exposures.

Continued

www.emcins.com

Electrical Work

Safety Program

Safe Work Practices for Electrical

Conductors or Circuit Parts

Safety-related work practices should protect workers

from hazards while they are working near exposed

electrical conductors or circuit parts that could

become energized. The following safe work practices

should be followed by all organizations:

• An employee could be exposed to live parts

which should be placed into an electrically safe

work condition before an employee works on

or near these parts, according to NFPA 70E®

Article 120, unless the work on the energized

components can be justified according to NFPA

70E® Article 130.

• Only qualified persons should be permitted to

work on electrical conductors or circuits that have

not been placed into a safe work condition.

• When working on electrical conductors and

circuits of 50 volts or higher that are not in an

electrically safe condition, an electrical hazard

analysis should be completed to develop

procedures that will protect the worker from arc

flash and contact with live parts.

• Appropriate safety-related work practices should

be determined, using both shock hazard analysis

and flash hazard analysis, before any person

approaches exposed live parts within the Limited

Approach Boundary.

• Unqualified persons should not be permitted

to enter spaces that are accessible to qualified

employees, according to NFPA 70E® Article 400.16.

• Only qualified persons with sole control should

be permitted to bypass an electrical safety

interlock, and then only temporarily while that

qualified person is working on the equipment.

For Additional Information

Occupational Safety & Health Administration:

www.osha.gov – Safety/Health Topics

EMC Insurance Companies: www.emcins.com

• Loss Prevention Information Manual

f

Electrical Safety

f

Lockout/Tagout

• Tech Sheets

f

Electrical Hazards

f

Lockout/ Tagout Program

• An Energized Electrical Work Permit should

be completed prior to entering the Limited

Approach Boundary.

Home Office: 717 Mulberry • Des Moines, IA 50309 • 800-447-2295 • www.emcins.com

Disclaimer: This material is designed and intended for general information purposes only, and is not intended, nor shall be construed or relied upon, as specific legal advice.

©Copyright Employers Mutual Casualty Company 2011. All rights reserved. Image ©2011 JupiterImages Corporation.

6167 (12-11)