Straumann® CARES® Guide.

CARES Visual 8.8.

How to use the S­traumann® CARES® Guide.

1 Indication > Material

You know the treatment indication and are looking for a suitable S­traumann CARES

material. First, go to the appropriate indication section: 'Tooth-borne applications' or

'Implant-borne applications' The S­traumann CARES Guide shows you which materials

are available for each indication. In the 'Leading material offering' section, you can

find detailed information on each individual S­traumann CARES material.

Crown

Lava™ Ultimate

zerion®

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

VITA TriLuxe

polycon® ae

polycon® cast

2 Material > Indication

You are already familiar with a certain S­traumann CARES material, but don't know

what indications you can use it for. Start in the 'Leading material offering' section

and the S­traumann CARES Guide will show you the available indications for each

S­traumann CARES material.

IPS e.max® CAD

Veneer

Inlay

Onlay

Crown

Coping

CARES®

X-Stream™

Partial Crown

4/3

16

4/3

polycon® ae

16

1/1

polycon® cast

16

4/4

Resin Nano Ceramic

3M™ ESPE™ Lava™ Ultimate Restorative

Ceramic

Zirconium-dioxide for CARES Abutment

IPS e.max® CAD – MO

IPS e.max® CAD – LT

IPS e.max® CAD – HT

IPS Empress® CAD – Multi and LT

IPS Empress® CAD – HT

VITA Mark II

VITA TriLuxe

Metal

ticon®

Titanium for CARES Abutment

Titanium for CARES SRBB

TAN for CARES Abutment*

coron®

Polymers

Strongly recommended application

Possible application Acrylic burn-out

Veneerable inlay for the materials zerion®, ticon®, coron® and polycon® ae.

2

Availability of the maximum bridge elements can vary from country to country.

* Availability can vary from country to country

1

S­traumann CARES Bars

16

Specials

S­traumann® CARES® Abutment

Maximum number of pontics in the

anterior/posterior region

1/1

Inlay/Maryland bridge

3

Inlay/Onlay1

zerion® HT

Veneer

4/2

Crown

16

Partial Crown

zerion® LT

Coping

Maximum number of bridge elements2

Bridges

Telescopic crown

Single-tooth

restorations

S­traumann CARES Screw-retained Bridge

Implantborne

Tooth-borne

Broad range of applications.

Tooth-borne applications

Veneer

Inlay

Onlay

Partial Crown

Crown

Bridge framework

Maryland bridge

Inlay bridge

Full-contour

bridge

Telescopic crown

Implant-borne applications

CARES®

Abutment

CARES Screwretained Bridge

Cares Bars

CARES® X-Stream™ – The one-step prosthetic solution: 1 scan, 1 design, 1 delivery

CARES

X-Stream

Coping

Tooth-borne applications.

S­traumann® CARES® tooth-borne restorations are used to restore natural teeth or

are placed on abutments. The applications provide treatment flexibility so that the

needs of each individual patient can be met.

Veneer

Inlay

Onlay

Partial Crown

Crown

Coping

Bridge

framework

Maryland

bridge

Inlay bridge

Full-contour

bridge

Telescopic

crown

Tooth preparation.

For successful results, observe the general tooth preparation guidelines below.

Also observe the additional tooth preparation guidelines, which apply specifically

to 3M™ ESPE™ Lava™ Ultimate Restorative, zerion®, IPS e.max® CAD, IPS Empress®

CAD, VITA Mark II, VITA TriLuxe, ticon®, coron® and polycon® ae – see the relevant

material-specific preparation guidelines.

incorrect

correct

Preparing the surfaces

incorrect

correct

Remove sufficient hard tooth material under fissures

Block out with a dentine-adhesive build-up filling

correct

incorrect

Preparing the margins

correct

incorrect

Do not prepare in a gutter shape

incorrect

correct

Do not leave any sharp transitions

Form transitions correctly toward oral/vestibular

Veneer.

3M™ ESPE™ Lava™ Ultimate Restorative Veneer

ѹѹ Broad range of ceramic materials for esthetic and efficient restorations

ѹѹ High precision and very thin veneers possible

ѹѹ Innovative materials for minimally invasive patient treatment

Available in these S­traumann® CARES® materials:

Resin Nano Ceramic

Lava™ Ultimate

Ceramic

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

VITA TriLuxe

Inlay and onlay.

IPS Empress® CAD Inlay

ѹѹ Broad range of ceramic materials for esthetic and efficient restorations

ѹѹ Easy handling

Available in these S­traumann® CARES® materials:

Resin Nano Ceramic

Metal

Polymers

Lava™ Ultimate

ticon®1

polycon® ae1

coron®1

polycon® cast

Ceramic

zerion® LT 1

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

1

Veneerable inlay

Partial Crown.

IPS e.max® CAD Partial Crown

ѹѹ Broad range of ceramic materials for esthetic and efficient restorations

ѹѹ Reliable materials for minimally invasive patient treatment

ѹѹ Flexibility in patient treatment

Available in these S­traumann® CARES® materials:

Resin Nano Ceramic

Lava™ Ultimate

Ceramic

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

VITA TriLuxe

Crown.

VITA Mark II Crown

ѹѹ Broad range of materials for full-contour restorations

ѹѹ Flexibility in patient treatment

Available in these S­traumann® CARES® materials:

Resin Nano Ceramic

Metal

Polymers

Lava™ Ultimate

ticon®

polycon® ae

coron®

polycon® cast

Ceramic

zerion® HT

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

VITA TriLuxe

Coping.

coron® Coping

ѹѹ Broad range of materials

ѹѹ Flexibility in patient treatment

Available in these S­traumann® CARES® materials:

Ceramic

Metal

Polymers

zerion® LT

ticon®

polycon® ae

zerion® HT

coron

polycon® cast

IPS e.max® CAD

Bridges.

zerion® LT Bridge framework

ѹѹ Excellent treatment flexibility

ѹѹ Highly stable bridge frameworks for up to 16 elements

ѹѹ Full-contour bridges with zerion® HT up to 3 bridge elements

Available in these S­traumann® CARES® materials:

Ceramic

Metal

Polymers

zerion LT

ticon®

polycon® ae

zerion HT

coron®

polycon® cast

Telescopic crown.

coron® Telescopic crown

Available in these S­traumann® CARES® materials:

Ceramic

Metal

Polymers

zerion® LT

ticon®

polycon® cast

coron

Implant-borne applications.

S­

traumann® implants and abutments complement each other in a precisely

harmonized system combining excellent quality and flexibility. Our products are

designed to deliver the esthetic results your patients demand with the time-tested

reliability you count on.

S­traumann screw-retained abutments and S­traumann implants are engineered to

be used together to ensure a harmony of design (shapes and features), tolerances,

surface qualities and materials used.

CARES®

Abutment

CARES Screwretained Bridge

Cares Bars

S­traumann® CARES® Abutments.

Customized shape and emergence profile

S­traumann CARES Abutments are designed to offer patient-specific emergence

profiles and an anatomic shape to support optimal soft tissue management.

Control over the cement gap

S­traumann CARES Abutments help clearing excess cement because the cement

margin can be ideally placed for each individual restoration.

Optimized insertion path

Flexible design parameters allow for angulation corrections and adjustments, which

can simplify the insertion of the final restoration.

Optimum convenience during restoration processes

S­traumann CARES Abutments provide precision, time and cost savings throughout

the restoration process.

S­traumann® CARES® Zirconium-dioxide Abutment

ѹѹ Full-ceramic abutment designed for excellent esthetics

ѹѹ Excellent material properties designed for high

precision and reliability

ѹѹ Maximum design flexibility (within design

specifications) for efficiency

Zirconium for CARES

Abutment

S­traumann CARES Titanium Abutment

ѹѹ Excellent material properties designed for high

precision and reliability

ѹѹ Maximum flexibility (within design specifications)

for efficiency

Titanium for CARES

Abutment

S­traumann CARES TAN Abutment 1

ѹѹ A biocompatible titanium alloy for direct veneering

ѹѹ Excellent material properties designed for increased

design flexibility

TAN for CARES

Abutment

1

Pending FDA 510K clearance

S­traumann® CARES® Screw-retained Bridge.

Direct connection to the implant

No additional abutment required (reduces complexity and costs)

No cementing (reduced risk of periimplantitis due to residual cement)

Abutment level connection

ѹѹ Align the insertion axis of highly divergent implants

ѹѹ Reduce soft tissue injuries when removing the framework for maintenance

Easy maintenance

The framework can be unscrewed for maintenance, if necessary

Product characteristics

ѹѹ 2 to 16 elements1

ѹѹ Placement on 2 to 16 interfaces

ѹѹ Tissue Level implant platforms

ѹѹ Bone Level implant platforms

ѹѹ Combination of Tissue Level and Bone Level platforms

ѹѹ Straumann Screw-retained Abutment

ѹѹ Delivered with machine-smoothed surface

1

Maximum number of anterior pontics: 4

Maximum number of posterior pontics: 3

Maximum number of free-end pontics: 1 per end

S­traumann® CARES® Screw-retained Bridges are available for tissue

level, bone level, mixed tissue level and bone level cases and the

S­traumann Screw-retained Abutment.

S­traumann CARES Screw-retained Bridges are screwed directly to the

S­traumann implant or the Straumann Screw-retained Abutment.

Available in these S­traumann CARES materials:

Metal

Titanium for CARES SRBB

coron®

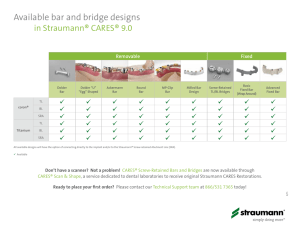

S­traumann® Cares® Bars.

Direct connection to the implant

No additional abutment required (reduces complexity and costs)

No cementing (no risk of periimplantitis due to residual cement)

Abutment level connection

ѹѹ Align the insertion axis of highly divergent implants

ѹѹ Reduce soft tissue injuries when removing the framework for maintenance

Easy maintenance

The framework can be unscrewed for maintenance, if necessary

Product characteristics

ѹѹ Placement on 2 to 10 interfaces

ѹѹ Tissue Level implant platforms

ѹѹ Bone Level implant platforms

ѹѹ Combination of Tissue Level and Bone Level platforms

ѹѹ Straumann Screw-retained Abutment

ѹѹ Free-end extension possible

ѹѹ Bars are delivered polished

Dolder® Bar U-Shape (Standard and Mini)

Dolder® Bar Egg-Shaped (Standard and Mini)

MP Clip® Bar Ø 1.8 mm

Ackermann Bar®, Ø 1.9 mm

Round Bar, Ø 1.8 mm

Milled Bar*

Locator® Bar

Abutment

Available in these S­traumann® CARES® materials:

Metal

coron®

Titanium for CARES SRBB

* Availability can vary from country to country

0 – 6°

S­traumann® CARES® X-Stream™ –

The one-step prosthetic solution: 1 scan, 1 design, 1 delivery.

CARES X-Stream provides a single-tooth full prosthetic solution to restore

Staumann implants. With only one scan and design procedure, all required prosthetic

components (e.g. abutment and its relevant crown) are manufactured in a

Straumann-validated environment and arrive together in one packaged delivery

with an excellent fit of the components. This optimization of the necessary processing

steps reduces turnaround time and related costs considerably.

CARES

X-Stream

Efficiency – the key to competitiveness

ѹѹ Higher productivity thanks to simultaneous design, order and delivery of the

prosthetic components required for a patient's case

ѹѹ Increased efficiency due to the highly precise prosthetics ensuring excellent fit

between components

ѹѹ Validated long-term performance with the original Straumann® implantabutment connection

ѹѹ Consistent and re-producible quality with controlled design and milling

environment

Now available – Straumann® Variobase™ Abutment

The Straumann Variobase™ Abutment is a strong foundation for flexible

prosthetic restorations thanks to its minimal body size combined with an optimal

force distribution1. It is available within the CARES® X-Stream™ solution with multiple

restorative options, such as

CARES® customized coping

ѹѹ Efficient hybrid abutment solutions

CARES customized

coping

CARES® customized full-contour crown

ѹѹ Cost effective prosthetic restorations

CARES customized

full-contour crown

CARES X-Stream™ Restorative Options:

Full-contour crown or coping

zerion®

IPS e.max® CAD

3M™ ESPE™

(Zirconium

(LithiumLava™

5

dioxide available

disilicate

Ultimate

(Resin Nano

in 13 shades)

available in

Ceramic available

45 shades)

in 12 shades)

coron®

(Cobalt

Chromium)

ticon®

(Titanium)

polycon® ae

(PMMA

available in

5 shades)

CARES Abutment,

Zirconium dioxide2

CARES Abutment,

Titanium3

Straumann®

Variobase™

Abutment4

NEW

Patent pending for the engaging mechanism between the Straumann® CARES Variobase

Not available for the Soft Tissue Level NNC and WN Platforms; all copings or crowns are available without

screw channel holes

3

Not available for the Soft Tissue Level NNC Platform; all copings or crowns are available without screw channel holes

4

Not available for the Soft Tissue Level NN Platform; all copings or crowns are available with or without screw channel holes

5

Only available for full-contour crowns

1

2

Leading material offering.

Lava™ Ultimate

zerion®

Zirconium for CARES®

Abutment

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

VITA TriLuxe

ticon®

coron®

Titanium for CARES

Abutment

TAN for CARES

Abutment

polycon® ae

polycon® cast

Titanium for CARES

SRBB

Additional information on 3M™ ESPE™ LAVA™ Ultimate Restorative

Preparation guidelines

A traditional design is recommended for inlays and onlays. Do not prepare any undercuts. Bevel the cavity walls 5 – 6 degrees to

the longitudinal axis of the preparation. Round all inner edges and angles. The incisal/occlusal reduction is carried out with 1.5 to

2 mm clearance with centric occlusion and all excursion movements.

For veneers, the standard reduction is 0.6 mm on the labial surface and 0.4 mm in the gingiva, as the enamel is thinner there. The

reduction in the incisal, labial-lingual angle is 0.5 to 1.5 mm. Leave the preparation margins in the enamel. The margins for veneers should pass above the gingiva. In addition, they should extend far enough into the approximal area so that the margins are

not visible, and also should not have any approximal-gingival undercuts.

For crowns and partial crowns, an axial reduction of 1.2 to 1.5 mm with a taper angle of 5 – 6 degrees is performed. The incisal/

occlusal reduction is carried out with 1.5 to 2 mm clearance with centric occlusion and all excursion movements. Shoulders must

extend at least 1.0 mm to lingual in the approximal contact area. Non-beveled shoulder border lines are recommended.

Available colors

High translucency (HT) is available in the following colors: A1, A2, A3, B1.

Low translucency (HT) is available in the following colors: A1, A2, A3, A3,5, B1, C2, D2, Bleach.

Specifications

Material

Resin Nano Ceramic

Density [g/cm3]

2.1

Flexural strength [MPa]

204 ± 19

3M™ ESPE™ Lava™ Ultimate Restorative.

(Resin Nano Ceramic, manufactured by 3M)

3M™ ESPE™ Lava™ Ultimate Restorative is a nanoceramic artificial resin containing

approximately 80 % (by weight) nanoceramic particles, which strengthen a highly

cross-linked polymer matrix.

Product characteristics

ѹѹ

ѹѹ

ѹѹ

ѹѹ

Designed for durability and reliability

Brilliant esthetics with long-lasting shine

High efficiency thanks to easy adjustment and polishing

Tooth-preserving and abrasion - and impact-resistant, thus enabling

maintenance of the functional balance

ѹѹ Available in 8 LT (low translucency) and 4 HT (high translucency) colors

Processing options

ѹѹ

ѹѹ

ѹѹ

ѹѹ

Attachment options

Do not fire

Can be used without further processing

Polishing possible

Coloring/characterization possible

ѹѹ Adhesive cementation

Available applications

Veneer

Inlay

Onlay

Partial Crown

Crown

CARES®

X-Stream™

Additional information on zerion®

Preparation guidelines

The preparation must be free of sharp angles and edges.

The shoulder preparation must have rounded inner edges and/or grooves.

The preparation must have anchorage surfaces for conventional and/or self-adhesive cementing.

Available colors

zerion® LT is available for frameworks in 9 colors:

white, light 1, light 2, light 3, light 4, medium 1, medium 2, medium 3, dark

zerion® HT is available for full-contour restorations and bridge frameworks with a maximum of three elements in

4 colors: pure, light, medium, intense

Chemical composition

Specifications

Elements

Percentage

Material

Y-TZP-A

ZrO2 + HfO2 + Y2O3

≥ 99 %

Density [g/cm3]

≥ 6.05

Y 2 O3

> 4.5 – ≤ 6 %

Flexural strength (3-point bend) [MPa]

≥ 800

HfO2

≤ 5 %

CTE (20 – 500 °C) [K-1]

10.5 x 10 -6

Al2O3

> 0.05 – ≤ 0.5 %

Other oxides

≤ 0.5 %

zerion®.

(zirconium-dioxide ceramic)

Zerion is a high-performance ceramic suitable for a broad spectrum of applications.

Product characteristics

ѹѹ Broad range of applications, from frameworks to full anatomic restorations,

for high flexibility

ѹѹ Highly stable frameworks designed for a predictable prosthetic result1

ѹѹ Available in 9 LT (low translucency) and 4 HT (high translucency) colors

Processing options

Attachment options

ѹѹ Veneering required for zerion® LT

ѹѹ Polishing required for zerion® HT

ѹѹ Adhesive cementation

ѹѹ Conventional cementation

Available applications for zerion LT

Inlay2

Coping

Bridge

framework

Maryland

bridge

Inlay bridge

Telescopic

crown

Available applications for zerion HT

Crown

1

2

Coping

Full-contour

bridge

CARES®

X-Stream™

Up to 4 pontics in the anterior region and up to 2 pontics in the posterior region for zerion LT

Veneerable inlay

Additional information on IPS e.max® CAD

Preparation guidelines

The preparation must have anchorage surfaces for conventional and/or self-adhesive cementing.

For inlays, onlays and partial crowns, the static and dynamic antagonist contacts have to be taken into account and the

preparation margin must not lie on the centric antagonist contacts.

In the case of veneers, the preparation should lie in the enamel if possible, and the incisal preparation margins should not

lie in the region of static or dynamic enamel contacts.

Available colors

High translucency (HT) is available in the following colors: A1, A2, A3, A3,5, A4, B1, B2, B3, B4, C1, C2, C3, C4, D2, D3, D4, BL1, BL2, BL3, BL4.

Low translucency (LT) is available in the following colors: A1, A2, A3, A3,5, A4, B1, B2, B3, B4, C1, C2, C3, C4, D2, D3, D4, BL1, BL2, BL3, BL4.

Medium opacity (MO) is available in the following colors: MO 0, MO 1, MO 2, MO 3, MO 4.

Chemical composition

Specifications

After crystallization

Elements

Percentage

Material

Lithium-disilicate glass-ceramic

SiO2

57 – 80 %

Flexural strength [MPa]

≥ 360

LiO2

11 – 19 %

Fracture toughness [MPa m0,5]

≥2

K 2O

0 – 13 %

Chemical solubility [µm/cm2]

≤ 50

P 2O 5

0 – 11 %

CTE (100 – 500 °C) [K-1]

10.5 ± 0.5 x 10 -6

ZrO2

0 – 8 %

ZnO

0 – 8 %

Others + col-

0 – 12 %

oring oxides

IPS e.max® CAD.

(lithium-disilicate glass-ceramic, manufactured by Ivoclar Vivadent AG)

State before crystallization

IPS e.max® CAD is a lithium-disilicate glass-ceramic material that is suitable for

manufacturing high-strength esthetic single-tooth restorations.

Product characteristics

ѹѹ

ѹѹ

ѹѹ

ѹѹ

All-ceramic restorations for efficient esthetics

Versatility for easy handling

High-strength product designed for reliable restorations

Available in 5 MO (medium opacity), 20 LT (low translucency) and 20 HT

(high translucency) colors

Processing options

Attachment options

ѹѹ Crystallization firing required

ѹѹ Veneerable

ѹѹ Adhesive cementation

ѹѹ Self-adhesive cementation for crowns

ѹѹ Conventional cementation for crowns

Available applications

Veneer

Inlay

Onlay

Partial Crown

Crown

Coping

CARES®

X-Stream™

Additional information on IPS Empress® CAD

Preparation guidelines

The preparation must be free of sharp angles and edges, and the shoulder preparation must have rounded inner edges

and/or grooves.

For inlays, onlays and partial crowns, the static and dynamic antagonist contacts have to be taken into account and the

preparation margin must not lie on the centric antagonist contacts.

In the case of veneers, the preparation should lie in the enamel if possible, and the incisal preparation margins should not

lie in the region of static or dynamic enamel contacts.

Available colors

High translucency (HT) is available in the following colors: A1, A2, A3, A3,5, B1, B2, B3, C2, D3.

Low translucency (LT) is available in the following colors: A1, A2, A3, A3,5, B1, B2, B3, C2, D3, BL1, BL2, BL3, BL4.

Multi is available in the following A- to D- and bleach (BL-) colors: A1, A2, A3, A3,5, B1, BL1, BL3.

Chemical composition

Specifications

Elements

Percentage

Material

Leucite glass-ceramic

SiO2

60 – 65 %

Density [g/cm3]

2.5 ± 0.1

Al2O3

16 – 20 %

Vickers hardness HV

6200 ± 250

K 2O

10 – 14 %

Flexural strength [MPa]

160 ± 20

Na2O

3.5 – 6.5 %

Fracture toughness [MPa m0,5]

1.3 ± 0.1

Other oxides

0.5 – 7 %

Chemical solubility [μg/cm2]

25

Pigments

0.2 – 1 %

Modulus of elasticity [GPa]

62 ± 8

CTE (100 – 500 °C) [10 -6 K-1]

17.5 x 0.25

IPS Empress® CAD.

(leucite glass-ceramic, manufactured by Ivoclar Vivadent AG)

Product characteristics

ѹѹ

ѹѹ

ѹѹ

ѹѹ

All-ceramic restorations for natural esthetics

Simplicity for easy handling

Tried-and-tested product for precisely predictable restorations

Available in 7 Multi, 13 LT (low translucency) and 9 HT (high translucency) colors

Processing options

Attachment options

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ Adhesive cementation

Can be used without further processing

Polishing possible

Glazing possible

Coloring/characterization possible

Veneerable

Available applications

Veneer

Inlay

Onlay

Partial Crown

Crown

Additional information on VITA Mark II

Tooth preparation guidelines

The teeth need to be cooled sufficiently during preparation and must not be overheated by excessive pressure during grinding.

Only use instruments with a good cutting performance.

Rough preparation must be carried out before final preparation.

The pulp must be protected against damage caused by grinding.

Subgingival preparation margins must be avoided.

The preparation must meet the following requirements:

Tooth-specific preparation

The upper and lower tooth axes are aligned with each other.

The required residual thickness of the dentine layer of 0.7 – 1.0 mm is ensured in all areas.

Preparation information for anterior and posterior crowns:

A groove or shoulder with a rounded inner edge must be prepared. The aim is to achieve a continuous gradation of 1 mm

in depth.

The vertical preparation angle must be at least 3°.

All transitions from the axial to the occlusal or incisal surfaces must be rounded.

Subgingival preparation margins should generally be avoided.

Preparation guidelines for veneers

Avoid an approximal 'gutter-shaped' preparation.

Available colors

VITA Mark II is available in the following colors: 0M1C, 1M1C, 1M2C, 2M1C, 2M2C, 2M3C, 3M1C, 3M2C, 3M3C, 4M2C, A1C, A2C, A3C,

in accordance with the VITA color system.

Chemical composition

Elements

Specifications

Percentage

Material

Fine-structure feldspar

SiO2

56 – 64 %

Al2O3

20 – 23 %

Density [g/cm3]

2.44 ± 0.01

K 2O

6 – 8 %

Flexural strength [MPa]

154 ± 15

Na2O

6 – 9 %

CTE (25 – 500 °C) [10 -6 K-1]

9.4 ± 0.1

CaO

0.3 – 0.6 %

Transformation range [°C]

780 – 790

TiO2

0.0 – 0.1 %

Chemical solubility (ISO 6872) with emphasis on glazing substance [μg/cm2]

≈30

ceramic

VITA Mark II.

(feldspar ceramic, manufactured by VITA Zahnfabrik H. Rauter GmbH & Co. KG)

VITA Mark II restorations by S­traumann offer maximum flexibility and a broad variety

of applications so that each patient's individual needs can be met.

Product characteristics

ѹѹ

ѹѹ

ѹѹ

ѹѹ

Broad range of colors for natural esthetics

Versatility for easy handling

High-quality material designed for precisely predictable results

Available in 13 colors

Processing options

Attachment options

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ Adhesive cementation

ѹѹ Self-adhesive cementation for crowns

Can be used without further processing

Polishing possible

Glazing possible

Coloring/characterization possible

Veneerable

Available applications

Veneer

Inlay

Onlay

Partial Crown

Crown

Additional information on VITA TriLuxe

Tooth preparation guidelines

The teeth need to be cooled sufficiently during preparation and must not be overheated by excessive pressure during grinding.

Instruments with a good cutting performance must be used.

Rough preparation must be carried out before final preparation.

The pulp must be protected against damage caused by grinding.

Subgingival preparation margins must be avoided.

The preparation must meet the following requirements:

Tooth-specific preparation

The upper and lower tooth axes are aligned with each other.

The required residual thickness of the dentine layer of 0.7 – 1.0 mm is ensured in all areas.

Preparation information for anterior and posterior crowns:

A groove or shoulder with a rounded inner edge must be prepared. The aim is to achieve a continuous gradation of 1 mm

in depth.

The vertical preparation angle must be at least 3°.

All transitions from the axial to the occlusal or incisal surfaces must be rounded.

Subgingival preparation margins should generally be avoided.

Preparation guidelines for veneers

Avoid an approximal 'gutter-shaped' preparation.

Available colors

VITA TriLuxe is available in three multilayer colors: 1M2C, 2M2C, 3M2C, in accordance with VITA color system.

Chemical composition

Specifications

Elements

Percentage

Material

SiO2

56 – 64 %

Fine-structure feldspar

Al2O3

20 – 23 %

Density [g/cm ]

K 2O

6 – 8 %

Flexural strength [MPa]

154 ± 15

Na2O

6 – 9 %

CTE (25–500 °C) [10 -6 K-1]

9.4 ± 0.1

CaO

0.3 – 0.6 %

Transformation range [°C]

780 – 790

TiO2

0.0 – 0.1 %

Chemical solubility (ISO 6872) with

emphasis on glazing substance [μg/cm2]

≈30

ceramic

3

2.44 ± 0.01

VITA TriLuxe.

(feldspar ceramic, manufactured by VITA Zahnfabrik H. Rauter GmbH & Co. KG)

VITA TriLuxe restorations by S­traumann are made of a multi-layer fine-structure

feldspar ceramic that replicates the characteristic structure of teeth with neck,

dentine and enamel. They enable high-quality esthetic fabrication of single-tooth

restorations.

Product characteristics

ѹѹ

ѹѹ

ѹѹ

ѹѹ

Broad range of colors for natural-looking esthetics

Versatility for easy handling

High-quality material developed for predictable results

Available in 3 colors

Processing options

Attachment options

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ

ѹѹ Adhesive cementation

ѹѹ Self-adhesive cementation for crowns

Can be used without further processing

Polishing possible

Glazing possible

Coloring/characterization possible

Veneerable

Available applications

Veneer

Partial Crown

Crown

Additional information on ticon®

Preparation guidelines

The preparation must be free of sharp angles and edges.

The shoulder preparation must have rounded inner edges and/or grooves.

The preparation must have anchorage surfaces for conventional cementing.

Chemical composition

Specifications

Elements

Percentage

Color

Silver

Ti

Balance

Material

Grade 2 titanium

O

≤ 0.25 %

Yield strength Rp0,2 [MPa]

≥ 275

Fe

≤ 0.3 %

Tensile strength Rm [MPa]

≤ 345

N

≤ 0.03 %

Elongation at break A 5 [%]

≥ 20

C

≤ 0.08 %

CTE (25 – 500 °C) [K-1]

9.6 x 10 -6

H

≤ 0.015 %

ticon®.

(titanium)

The titanium alloy ticon is an ideal alternative to noble casting alloys and is suitable for a broad

range of applications: from single copings up to one-piece full-arch restorations.

Product characteristics

ѹѹ Milled frameworks1 for great reliability and precision

ѹѹ Veneering comparable to noble casting alloys for easy processing

ѹѹ Ideal alternative to noble casting alloys

Processing options

Attachment options

ѹѹ Polishing possible

ѹѹ Veneerable

ѹѹ Conventional cementation

Available applications

Inlay2

1

2

Crown

Coping

Bridge framework

Maryland

bridge

Up to 4 pontics in the anterior region & up to 3 pontics in the posterior region

Veneerable inlay

Inlay bridge

Telescopic

crown

CARES®

X-Stream™

Additional information on coron®

Preparation guidelines

The preparation must be free of sharp angles and edges.

The shoulder preparation must have rounded inner edges and/or grooves.

The preparation must have anchorage surfaces for conventional cementing.

Use suitable dental technology veneering techniques for S­traumann® CARES® Screw-retained Bridges.

Chemical composition

Specifications

After thermal treat-

Balance

Color

Silver gray

Cr

28 %

Material

NPM alloy

W

8.5 %

Yield strength Rp0,2 [MPa]

≥ 360

Si

1.65 %

Elongation at break

≥2

Additional elements

below 1 %

Mn, N, Nb, Fe

A 5 [%]

Elements

Percentage

Co

ment

CTE (25 – 500 °C) [K-1]

14.3 x 10-6

coron®.

(cobalt-chromium alloy)

The cobalt-chromium alloy coron is suitable for a broad range of applications: from conventional

full anatomic restorations and single and multi-unit frameworks to screw-retained bars and bridges.

Product characteristics

ѹѹ Milled frameworks for consistent high quality

ѹѹ Broad range of applications for high flexibility

ѹѹ Veneering comparable to noble casting alloys for easy processing

Processing options

Attachment options

ѹѹ Polishing possible

ѹѹ Veneerable

ѹѹ Conventional cementation

Available applications

Inlay1

Crown

CARES® Screw- Cares Bars

retained Bridge

1

Veneerable inlay

Coping

CARES

X-Stream™

Bridge framework

Maryland

bridge

Inlay bridge

Telescopic

crown

Additional information on polycon® ae

Preparation guidelines

The preparation must be free of sharp angles and edges.

The shoulder preparation must have rounded inner edges and/or grooves.

The preparation must have anchorage surfaces for conventional cementing.

Available colors

ѹѹ The S­traumann® CARES® polycon® ae is available in 5 colors: A1, A2, A3, B1, B2.

Chemical composition

Specifications

Elements

Percentage

Material

PMMA

Polymethyl methacrylate

> 98 %

Flexural strength [MPa]

≥ 50

Water absorption [μg/mm3]

≤ 40

Water solubility [μg/mm ]

≤ 7.5

(PMMA)

Methyl methacrylate

< 1 %

Dibenzoyl peroxide

< 1 %

Pigments

< 0.5 %

3

polycon® ae.

(PMMA-based acrylate resin)

The IPN1 resin polycon ae offers biocompatibility, color stability and excellent compound

stability with non-ceramic veneering materials. It can be used for full anatomic temporary crowns

and bridges in the anterior and posterior region.

Product characteristics

ѹѹ Specially designed for full anatomic temporary restorations and high efficiency

ѹѹ Outstanding connection stability for easy handling

ѹѹ Available in 5 colors

Processing options

Attachment options

ѹѹ Can be used without further processing

ѹѹ Polishing possible

ѹѹ Veneerable

ѹѹ Temporary cementing

Available applications

Inlay2

Crown

Coping

Bridge framework

Maryland

bridge

Inlay bridge

CARES®

X-Stream™

IPN = Highly cross-linked Interpenetrated Polymer Network

A PMMA-based acrylate resin with significantly greater strength and considerably better abrasion values due to

molecular cross-linking.

2

Veneerable inlay

1

Additional information on polycon® cast

Chemical composition

Specifications

Elements

Percentage

Color

Colorless

Polymethyl methacrylate

> 98 %

Material

PMMA

(PMMA)

Methyl methacrylate

< 1 %

Dibenzoyl peroxide

< 1 %

Pigments

< 0.5 %

polycon® cast.

(filler-free burn-out acrylate)1

Polycon cast is a filler-free acrylic glass that represents an alternative to standard crown and bridge

waxing in the casting technique. The resin PMMA, which can be burned out without residue, can

be used instead of modeling wax. Polycon cast can be used in veneering and full cast techniques.

Product characteristics

ѹѹ Specially designed for standard waxing of crowns and bridges

(can be burned out without residue)

Available applications

Inlay2

1

2

Crown

Coping

Bridge

framework

Maryland

bridge

Inlay bridge

Telescopic

crown

Polycon cast must not be tried out in the patient's mouth to test the fit. Polycon cast is not a medical product!

Veneerable inlay

Further information.

Processing steps.

Build-up/supplementation

Layering

Coloring/characterization

Glazing

Polishing

Crystallization

None

Depending on the indication, material and selected technique, various processing steps can

be followed in order to achieve the final restoration.

Resin Nano Ceramic

3M™ ESPE™ Lava™ Ultimate Restorative

Ceramic

zerion® LT

zerion® HT

IPS e.max® CAD – MO

IPS e.max® CAD – HT / LT

IPS Empress® CAD – Multi / HT / LT

VITA Mark II

VITA TriLuxe

Metal

ticon®

coron®

Polymers

polycon® ae

polycon® cast

n. a.

Necessary processing step and/or technique

Possible processing step and/or technique

(Note: depending on the material selected, some steps can be combined.)

Use suitable dental technology veneering techniques for CARES® Screw-retained Bridges.

a) Crystallization

This processing step is only required (and also indispensable) for IPS e.max® CAD restorations

by S­traumann® CARES®. The flexural strength of the supplied IPS e.max® CAD restorations by

S­traumann CARES is 130 ± 30 MPa. To achieve its final flexural strength of 360 ± 60 Mpa and its

final optical characteristics (color, translucency and brightness), the IPS e.max® CAD restorations

by S­traumann CARES must undergo crystallization firing in a furnace at 840 – 850 °C for

approximately 21 to 30 minutes. Further information on crystallization, compatible ovens, firing

programs etc. can be found in the instructions for use.

b) Polishing

In this processing technique, the supplied full anatomic restoration is only polished.

c) Glazing

In this processing technique, the glazing substance is applied to the supplied full anatomic

restoration and then the restoration is glaze-fired. For IPS e.max® CAD restorations by S­traumann

CARES, the crystallization and glaze firing can be carried out in one step.

d) Coloring

In this processing technique, the color is applied to the supplied full anatomic restoration. Depending

on the material, the restoration is either polished or glazed before undergoing color and glaze firing.

For IPS e.max® CAD restorations by S­traumann CARES, the crystallization, color and glaze firing can

be carried out in one step.

e) Layering technique

In this processing technique, various layering materials are fired onto the supplied

framework. All commercially available veneering materials that are intended for veneering with

the selected material and are suitable for the selected material's CTE value can be used. The

veneering material manufacturers' processing instructions must be observed. Before application

of the layering technique, the restoration must be cleaned with a steam jet.

f) Build-up or application

This processing step applies exclusively to S­traumann CARES restorations made of 3M™ ESPE™

Lava™ Ultimate Restorative. It enables the restoration to be adapted by means of an additive

technique. In this processing technique, a light-curing methacrylate-based filling material is applied

to the supplied full anatomic restoration and then light-cured and polished.

Processing techniques.

Depending on the processing technique and indication, the following recommendation can

be given with regard to the selection of materials.

Bridge

Coping

Veneerable inlay

Layering

Bridge

Crown

Partial Crown

Veneer

Cut-back

Bridge

Crown

Partial Crown

Veneer

Inlay / Onlay

Full contour

Resin Nano Ceramic

3M™ ESPE™ Lava™ Ultimate Restorative

Ceramic

zerion® LT

zerion® HT

IPS e.max® CAD – HT

IPS e.max® CAD – LT

IPS e.max® CAD – MO

2

IPS Empress® CAD – HT

IPS Empress® CAD – LT

1

IPS Empress® CAD – Multi

VITA Mark II

1

VITA TriLuxe

1

Metal

ticon®

coron®

Polymers

polycon® ae

polycon® cast

Recommended

Possible

1

For anterior crowns only 2

For anterior crowns and premolars only

Cementing.

Conventional

1

1

Resin Nano Ceramic

3M™ ESPE™ Lava™ Ultimate Restorative

Ceramic

zerion® LT

zerion® HT

IPS e.max® CAD

IPS Empress® CAD

VITA Mark II

1

VITA TriLuxe

1

Metal

ticon®

coron®

Polymers

polycon® ae

polycon® cast

For crowns only

1

n. a.

Temporary

Self-adhesive

Adhesive

Depending on the indication and selected material, the tooth-borne prosthetic restorations

by S­traumann® CARES® can be fitted using adhesive, self-adhesive or conventional cementing

(see table below).

Measuring points for minimum thicknesses.

Inlay Onlay

OnlayTeilkrone

TeilkroneVeneer

Veneer

Krone

Krone

CustomizedCus

Ab

Onlay

Partial Crown

Cusp height

Fissure

depth

Inlay

Inlay

Cusp height

Fissure

depth

Fissure depth

Circular

Gingiva

Steg Brücke

Brücke

verschraubter

verschraubter

Steg

verschraubte

Steg

verschrau

Brücke

Steg

Veneer

Isthmus

width

Steg

Isthmus

width

Isthmus

width

Steg Brücke

verschraubter

Brücke

Steg

verschraubter

verschraubte

Steg

Brücke verschraubte

Brüc

Steg Brücke

verschraubter

Steg

verschraubte

Brücke

Incisally applied veneer

Incisal

Incisal

Circular

Circular

Gingiva

Gingiva

Steg

Steg Brücke

Brücke

verschraubter

Steg

verschraubter

Steg

verschraubte

Steg

Brückeverschraubte

Brücke

verschraubter

BrückeSteg

v

Anterior crown

Posterior crown

Inlay

Inlay OnlayTeilkrone

OnlayTeilkroneVeneer

TeilkroneVeneerKroneVeneer

Customized

Krone

AbutmentsCustomized

Ka

Inlay Onlay

Krone

Customized

Abutments

Incisal

Incisal

Circular

Circular

Gingiva

Gingiva

Bridge construction

Inlay Inlay-Brücke

Inlay Inlay-Brücke

Onlay

Onlay

Teilkrone

Inlay

Teilkrone

Veneer

Onlay

Veneer

Krone

Teilkrone

Krone

Customized

Veneer

Customized

Abutments Abutments

KroneKa

Inlay-Brücke

Maryland-Brücke

Maryland-Brücke

Primärkrone

Primärkrone

Geschiebelement

Geschiebe

Maryland-Brücke

Primärkrone

Geschiebelement

Incisal/occlusal

Circular

rschraubte

Brücke Brücke

verschraubter Steg

verschraubte Brücke

Connector minimum

cross-section

Inlay-Brücke

Inlay-Brücke Maryland-Brücke

Maryland-Brücke

Inlay-Brücke Primärkrone

Primärkrone

Maryland-BrückeGeschiebelement

Geschiebelement

Primärkrone

rücke

oneCustomizedVeneer

Abutments

Krone

Kappe

Customized

Variobase

Abutments

Kappe

Variobase

Minimum thickness guidelines for full contour.

Maximum number of pontics

in the anterior/posterior region

0,6

12

1/1

Circular (mm)

Connector minimum crosssection

Bridge in anterior

and posterior

region

Incisal / Occlusal (mm)

Gingiva (mm)

Circular (mm)

Posterior

crown

Occlusal (mm)

Gingiva (mm)

Circular (mm)

Anterior

crown

Incisal (mm)

Isthmus width (mm)

Fissure depth (mm)

Cusp height (mm)

Circular (mm)

Partial Crown

Gingiva (mm)

Incisal (mm)

Circular (mm)

Incisal

overlapped

veneer

Gingiva (mm)

Incisal (mm)

Circular (mm)

Veneer

Gingiva (mm)

Isthmus width (mm)

Fissure depth (mm)

Cusp height (mm)

Inlay/

Onlay

Resin Nano Ceramic

3M™ ESPE™ Lava™

1,5

Ultimate Restorative

0,4 0,6 0,5 0,4 0,6 1,5 1,0

1,5

1,5

1,0

1,5

1,0

Ceramic

zerion® HT

0,6

IPS e.max® CAD – HT

1,0

0,6

IPS e.max® CAD – LT

IPS Empress® CAD – HT

2,0

1,5

IPS Empress® CAD – LT and Multi

VITA Mark II

VITA TriLuxe

2,0 1,5

1,5

0,6

0,7

0,7

0,5

0,6

0,6

0,7 1,0

1,0

0,5

1,5

1,0 1,5 2,0

1,0

2,0

0,6

1,5 1,2 1,0 1,5

1,5 1,0

1,5

2,0 1,5 1,0 2,0 1,5 1,0

1,5

1,5

1,0

2,0

1,0

Metal

ticon®

0,4

0,4

0,4

5

4/3

coron®

0,3

0,3

0,3

5

4/3

polycon® ae

0,6

0,6

0,6

9

1/1

polycon® cast

0,25

0,25

0,25

5

4/4

Polymers

Minimum thickness guidelines for cut-back.

1,0

anterior/posterior region

1,5

Maximum number of pontics in the

0,5

Connector minimum cross-section

0,4

Bridge

Wall thickness (mm)

1,2

Occlusal (mm)

1,0

Circular (mm)

0,5

1,3

Posterior

crown

Gingiva (mm)

0,6

Incisal (mm)

1,5

Circular (mm)

Circular (mm)

1,0

Gingiva (mm)

Gingiva (mm)

0,4

Anterior

crown

Cusp height (mm)

Incisal (mm)

Partial

Crown

0,6

Gingiva (mm)

Circular (mm)

Veneer1

Ceramic

IPS e.max® CAD – HT and LT

IPS Empress® CAD – HT and Multi

IPS Empress® CAD – LT

VITA Mark II and TriLuxe

0,3

1,5

1,02

1,0

Metal

ticon®

0,4

0,4

0,4

5

4/3

coron®

0,3

0,3

0,3

5

4/3

polycon® ae

0,6

0,6

0,6

9

1/1

polycon® cast

0,25

0,25

0,25

5

4/4

Polymers

1

2

Includes incisally applied veneer

1,3 mm for molars

Minimum thickness guidelines for

veneerable frameworks.

Maximum number of pontics in the

anterior/posterior region

Wall thickness (mm)

CARES® Vario­

base™ Abutment

Connector minimum cross-section

Connector (mm)

Wall thickness (mm)

Posterior and

anterior region

9

4/2

0,4

Ceramic

zerion® LT for frameworks

0,5

zerion® HT

0,6

9

1/1

IPS e.max® CAD – MO (up to the premolar)

0,81

n. a.

n. a.

ticon®

0,4

5

4/3

coron®

0,3

5

4/3

polycon® ae

0,6

9

1/1

polycon® cast

0,25

5

4/4

Metal

Polymers

1

1,0 mm occlusal for premolar

0,5

Guarantee.

Quality from S­traumann is a given, which is why we offer our customers the S­traumann® Guarantee1.

This ensures the rapid and efficient replacement of all system components, and provides you with

the security of knowing that you can rely on S­traumann at all times.

S­traumann Products covered by the S­traumann Guarantee

Implant

Abutment attached

to an implant1

Tooth- and implantborne restoration

5-year

guarantee

period

–

Replacement with

equivalent ceramic

abutment2

Replacement with

equivalent ceramic

restoration3

10-year

guarantee

period

–

Replacement with

equivalent metal

abutment2

Replacement with

equivalent metal or

resin nano ceramic

restoration3

Lifetime

guarantee

period

Replacement with

equivalent implant

and equivalent abutment, if necessary

–

–

1

In accordance with the S­traumann Guarantee brochure

2

Including S­traumann CARES® Screw-retained Bridges and Bars. Excluding consumable products and retentive

products such as ball anchors.

3

Including S­traumann CARES copings, full-contour crowns and bridges.

EXCLUDING all other products offered by S­traumann, particularly S­traumann CARES inlays, onlays, veneers,

partial crowns and S­traumann CARES Guided Surgery products.

© Straumann USA, LLC 2014. All rights reserved.

Straumann® and/or other trademarks and logos from Straumann® that are mentioned herein are the trademarks

or registered trademarks of Straumann Holding AG and/or its affiliates. All rights reserved.

5/14

Straumann North American Headquarters

Straumann USA, LLC

60 Minuteman Road

Andover, MA 01810

Phone 800/448 8168 (US) 800/363 4024 (CA)

Fax

978/747 2490

www.straumann.us www.straumann.ca

NAMLIT 1002

International Headquarters

Institut Straumann AG

Peter Merian-Weg 12

CH-4002 Basel, Switzerland

Phone +41 (0)61 965 11 11

Fax

+41 (0)61 965 11 01