Arc Flash/Blast for Qualified Persons

advertisement

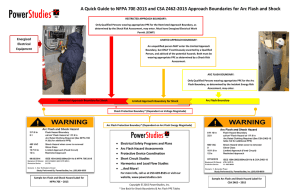

3/21/2014 Addressing Arc Flash Hazards Without Breaking the Bank Safety Day 2014 Waubonsee Community College Addressing Arc Flash Hazards Without Breaking the Bank - Module No. 3 Live electrical work should be done using insulated tools 1 3/21/2014 This presentation is based on OSHA 29 CFR 1910 Subpart S legal requirements for facility electrical systems and work practices including but not limited to: 29 CFR1910.332 Training 29 CFR1910.333 Selection and use of work practices 29 CFR1910.334 Use of equipment 29 CFR1910.335 Safeguards for personnel protection In addition the program references NFPA 70E “Standard for Electrical Safety in the Workplace”, 2009 Edition Arc Flash/Blast for Qualified Persons An arc flash/blast occurs when current flows between two conductors through air, e.g.: – Tool slips and makes contact with conductors energized at different potential – Insulation fails Arc flash • The flash may be 35,000 °F • Three inches of # 10 copper may vaporize to 1 ft³ in volume 2 3/21/2014 Arc Flash/Blast for Qualified Persons Arc energy released is determined by • Voltage • Arc resistance • Available shortcircuit current, and • Time needed for overcurrent device to open Vapors released by the arc are conductive and sustain the arc through its duration Heat energy absorbed by persons or objects in the area are stated as calories of heat energy per square centimeter or cal/cm2 Arc Flash for Qualified Persons Arc flash results • Death • Serious injuries – Burning – even vaporizing the skin – Blindness and other damage to the eyes – Deafness – Internal injuries Flash burns – arc flash incident • Disastrous fires • Damage and destruction of equipment • Extensive downtime 3 3/21/2014 Arc Flash for Qualified Persons Severe burns or death may be caused by • Clothing that ignites instantly • Continues to burn long after the arc has subsided • Enclosed spaces and panel doors that don’t open fully increase the danger Proper PPE is essential Employees’ hands and faces are often 6 – 12 inches from the arc Arc Flash for Qualified Persons The fabrics or materials of arc flash PPE are tested and rated for resistance to arc flash energy Rating reflects the maximum heat energy resistance of a material during an incident • Prior to “breakopen” (formation of openings or holes) from heating or • At the onset a seconddegree skin burn. Arc rating label identifies this level and lists it in cal/cm2 COMPLIANCE TO ASTM 1506 NFPA 70E OSHA 1910.335 ARC RATING 4 CAL/CM2 Size 16 - 33 4 3/21/2014 Arc Blast for Qualified Persons Single phase-to-phase fault on a 480V system with 20,000 amps of available fault current • Releases energy equivalent to 1.5 pounds of TNT • Resulting devastation is comparable. • Arcs often cause serious injuries or death Arc Blast for Qualified Persons Arc blast results • 140 Decibel sound pressure may rupture eardrums • Air pressure > 2000 psf • Forces on the chest may be 1000 lbs – Puncture the lungs – Break bones • Whiplash resulting in brain damage 5 3/21/2014 Arc Blast for Qualified Persons Exposure to arc flash without protection by – Distance – Safety procedures – Protective equipment The solution in most cases is to work with or around electrical circuits that are • guarded or • de-energized, locked and tagged out Arc Blast for Qualified Persons Work on or around energized electrical circuits or equipment is permitted only – At less than 50 volts – Not feasible, e.g.: • Electrical testing (checking for voltage) • Trouble shooting – Where there is a greater hazard, e.g.: immediately necessary to save a life 6 3/21/2014 Arc Flash/Blast for Qualified Persons Some reported incident causes • Accidental contact with energized parts • Tools dropped on energized parts • Improper work procedures • Tracking across insulation surfaces • Mechanical breakdown, loose connections, and insulation failure • Corrosion of equipment parts and contacts • Contamination, such as dust on insulating surfaces • Wiring errors • Inadequate short circuit ratings Arc Blast for Qualified Persons What should we do? Comply with OSHA legal mandates for plant electrical • Equipment and installations • Electrical safetyrelated work practices This also requires • Electrical safety program and procedures • Recognized and respected approach limits for exposed energized parts and circuits • Hazard/Risk category classifications • Appropriate personal protective equipment 7 3/21/2014 Electrical Safety Program The employer should develop a written electrical safety program based on NFPA 70E Activities must be based on – Voltages involved – Determination and understanding of energy levels – Identification of the condition of circuits NFPA 70E Article 110.7 and the NFPA 70E Handbook give the details Arc Flash/Blast for Qualified Persons • Regular maintenance inspection can identify many potential arc flash issues • Checking for heating of system components and wiring is important • If available, infrared photography may be very useful In-use equipment 8 3/21/2014 Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 1. An arc flash/blast occurs when current flows between two conductors through ___________. A. Water B. An electrician C. Ground D. Air 2. The temperature at the terminals in an arc flash/blast can be as high as ___________. A. The surface of the sun B. 18,000 °F C. Almost hot enough to melt copper D. As high as 35,000 °F Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 1. An arc flash/blast occurs when current flows between two conductors through ___________. A. Water B. An electrician C. Ground D. Air 2. The temperature at the terminals in an arc flash/blast can be as high as ___________. A. The surface of the sun B. 18,000 °F C. Almost hot enough to melt copper D. As high as 35,000 °F 9 3/21/2014 Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 3. The expansion of copper in an arc flash/blast is equivalent to three inches of # 10 copper vaporizing to _________. A. 1 cubic foot in volume B. 1 cubic inch in volume C. 1 cubic yard in volume D. Enough to fill a small room 4. Heat energy absorbed by persons or objects in the area are stated as ___________. A. Joules of heat energy per cubic meter B. Calories of heat energy per pound of body weight C. Calories of heat energy per square centimeter D. Perspiration threshold Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 3. The expansion of copper in an arc flash/blast is equivalent to three inches of # 10 copper vaporizing to _________. A. 1 cubic foot in volume B. 1 cubic inch in volume C. 1 cubic yard in volume D. Enough to fill a small room 4. Heat energy absorbed by persons or objects in the area are stated as ___________. A. Joules of heat energy per cubic meter B. Calories of heat energy per pound of body weight C. Calories of heat energy per square centimeter D. Perspiration threshold 10 3/21/2014 Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 5. The employer should develop a written electrical safety program with activities based on __________________. A. Voltages, energy levels and condition of circuits B. Test results, insulated means and oversight C. Production schedules D. All of the above Module 3 Unit 3 - 1 Arc Flash/Blast for Qualified Persons Practice Quiz 5. The employer should develop a written electrical safety program with activities based on __________________. A. Voltages, energy levels and condition of circuits B. Test results, insulated means and oversight C. Production schedules D. All of the above 11 3/21/2014 Keys to Understanding NFPA 70E Keys to Understanding NFPA 70E – In this unit, we will describe and explain several terms useful in understanding NFPA 70E . These concepts will help in preventing electrical accidents and help in implementing a successful electrical safety program. These key terms are: –Limits of Approach and Boundaries –Hazard/Risk Categories –Arc Ratings –Personal Protective Equipment and Clothing 12 3/21/2014 Keys to understanding NFPA 70E Preventing electrical accidents and implementing a successful electrical safety program involves – Compliance with OSHA’s legal electrical work practices requirements – Implementing and following a proven effective safety guidance like NFPA 70E, Standard for Electrical Safety in the Workplace 2009 – NFPA 70E is nationally recognized as an appropriate guidance Keys to understanding NFPA 70E Limits of Approach and Boundaries Safe approach distances from exposed energized electrical conductors or circuit parts. They are described and categorized in NFPA 70E and are based on the level of electrical arc flash and shock hazard. Hazard/Risk Categories A rating system for the relative electrical hazard of tasks Arc Ratings Values identify the level of performance of PPE in an electrical arc discharge 13 3/21/2014 Limits of Approach and Boundaries • Arc flash boundaries are determined by arc flash energy (incident energy) available to contact the employee(s) • Incident energy is measured in calories per square centimeter (cal/cm2). It is determined by: – System Voltage – Available short-circuit current – Time needed for overcurrent device to open Flash Protection Boundary Boundary within which an unprotected person would receive at least a 2nd degree burn from an arc flash – “blister boundary” Default distance of 4 foot minimum for equipment up to 600 V (provided system capacity does not exceed 100 kA cycles) – Increased for higher voltages – Crossing this boundary requires wearing appropriate PPE – Qualified persons only – Unqualified must be Default accompanied Flash NFPA 70E – Article 100, 130.3 (A) (1) Protection Boundary 14 3/21/2014 Default Flash Protection Boundary Minimum 4 foot flash protection boundary is based on – Bolted fault current of 50 kA – Clearing time of 2 cycles (0.033 sec.) and – Other general equipment information Utility power supply provides higher incident energy at the plant service entrance See NFPA 70E Article 130.3 (A) (1) Don’t work inside or on this energized utility supply switchgear panel Shock Approach Boundaries to Energized Electrical Conductors For exposed energized conductors and parts • Shock Protection Boundaries include the following boundaries for the given task: – Limited – Restricted – Prohibited SHOCK HAZARD • Options for determining the location of shock approach boundaries include: – Detailed analysis and calculations – Distances identified for various voltages as shown in NFPA 70E Table 130.2(C) 15 3/21/2014 Excerpt - Table 130.2(C) Approach Boundaries For Shock Protection Distance from energized conductor or part to employee Limited Approach Boundary1 Nominal System, Voltage Range, Phase to Phase2 Exposed Movable Conductor3 Exposed Fixed Circuit Part Restricted Approach Boundary1; Prohibited Approach Boundary1 Includes Inadvertent Movement Adder Less than 50 Not specified Not specified Not specified 50 to 300 10 ft 0 in. 3 ft 6 in. Avoid contact Avoid contact 301 to 750 10 ft 0 in. 3 ft 6 in. 1 ft 0 in. 0 ft 1 in. 50 to 300 volts Not specified 301 to 750 volts – 3 for feet 6 regarding inches Limited – 3 feet See the6complete inches Table 130.2 inLimited NFPA 70E 2009 details voltage higher than 750 volts Restricted – 1 foot Restricted – Avoid Contact Prohibited – 1 inch or more Prohibited – Avoid Contact Note: For Arc Flash Protection Boundary, see 130.3(A). 751 to 15 kV 1 See definition in Article 100 and text in 130.2(D)(2) and Annex C for elaboration. 2 For single-phase systems, select the range that is equal to the system’s maximum phase-to-ground voltage multiplied by 1.732. 3 A condition in which the distance between the conductor and a person is not under the control of the person. The term is normally applied to overhead line conductors supported by poles. Provide as Handout Approach Boundaries for Shock Protection – Table 130.2 (C) 50 to 300 volts Limited – 3 feet 6 inches Restricted – Avoid Contact Prohibited – Avoid Contact 301 to 750 volts Limited – 3 feet 6 inches Restricted – 1 foot Prohibited – 1 inch or more Limited Restricted Prohibited Shock Approach Boundaries Fixed Parts 16 3/21/2014 Prohibited approach boundary Any point on an exposed energized conductor Prohibited space Restricted approach boundary Restricted space 17 3/21/2014 Limited approach boundary Limited space Flash Exposure Area Flash Protection Boundary 18 3/21/2014 Approach Boundaries Arc flash protection boundary Limited approach boundary Prohibited Space Restricted space Restricted approach boundary Limited Approach Boundary Work inside the limited approach boundary is for QPs only For most exposed energized 480 VAC parts = 3 feet 6 inches Unqualified persons must be – Accompanied by a QP – Advised of risk of shock and electrocution – Advised of the location of the exposed energized conductors NFPA 70E Article 130.2 (D) (1), (2) 19 3/21/2014 Limited Approach Boundary Unqualified persons – Management, supervisors and QPs must ensure safety e.g.: – Barriers – Warnings – Signs or barricades – The person must be informed and know of how to avoid the hazards NFPA 70E Article 130.2 (D) (1), (2) Unqualified persons are Not qualified for never permitted within the electrical Task restricted approach boundary Restricted Approach Boundary Crossed only by qualified person Requires shock protection techniques and equipment – Properly rated PPE – Training – Documented work plan approved by management Prohibited Space QP must keep all uninsulated parts of body out of “Prohibited Space” NFPA 70E Article 130.2 (C) (1), (2) 20 3/21/2014 Prohibited Approach Boundary • Crossed only by qualified person • Requires same protection as if making contact with live parts • To cross into “Prohibited Space” must have specific training • Documented plan justifying need to perform this work NFPA 70E Article 130.1 (B) Prohibited Approach Boundary Working within the prohibited approach boundary around energized electrical equipment –Requires an “Energized Electrical Work Permit” –Considered the same as making contact with the energized parts –Only 1 inch from 480 volt parts –Too close for comfort without safety precautions and protection NFPA 70E Article 130.1 (B) Energized Work Permit Task Reason for Live Work Precautions PPE Management Signature 21 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 1. The flash protection boundary is defined as ____________. A. The distance required for the flash to operate properly on an infrared thermography camera B. The boundary within which an unprotected person would receive at least 2nd degree burns C. The boundary within which an electrician can work without fear of arc flash D. The boundary within which live work is approved 2. Crossing the flash protection boundary requires __________. A. Rayon undergarments B. Steel-toed shoes C. At a minimum, sunglasses to protect the eyes D. Appropriate PPE to protect against arc flash/blast and shock Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 1. The flash protection boundary is defined as ____________. A. The distance required for the flash to operate properly on an infrared thermography camera B. The boundary within which an unprotected person would receive at least 2nd degree burns C. The boundary within which an electrician can work without fear of arc flash D. The boundary within which live work is approved 2. Crossing the flash protection boundary requires __________. A. Rayon undergarments B. Steel-toed shoes C. At a minimum, sunglasses to protect the eyes D. Appropriate PPE to protect against arc flash/blast and shock 22 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 3. The default distance for the flash protection boundary is __________ for equipment up to 600 V. A. Two feet B. No further than the restricted approach boundary C. Four feet D. Whatever is deemed appropriate by the qualified person 4. Shock protection boundaries include the ______________ approach boundaries. A. Limited, restricted and prohibited B. Arc flash, prohibited and ultimate C. Limited, recognized and exclusive D. Recognized, restricted and common sense Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 3. The default distance for the flash protection boundary is __________ for equipment up to 600 V. A. Two feet B. No further than the restricted approach boundary C. Four feet D. Whatever is deemed appropriate by the qualified person 4. Shock protection boundaries include the ______________ approach boundaries. A. Limited, restricted and prohibited B. Arc flash, prohibited and ultimate C. Limited, recognized and exclusive D. Recognized, restricted and common sense 23 3/21/2014 Hazard/Risk Categories Hazard/Risk Rating system ranking Category the relative electrical hazard of tasks 0 Rated 0 through 4 for low 1 or little risk to relatively 2 high risk Each category is assigned 2* a corresponding 3 minimum arc thermal 4 performance value Minimum Rating (Cal/cm2) N/A 4 8 8 25 40 Category 2 is supplemented by category 2* to assure protection of the neck, sides and back of the head Hazard/Risk Categories Rated Categories are associated with specific tasks in Table 130.7 (C) (9) Identify appropriate levels of PPE Tables 130.7 (C) (8) to (11) are meant to be used together. They identify: – Standard specifications for PPE – Task Hazard/Risk Category – Type and kind of PPE appropriate to the task –Tables must be used within the limitations of the Notes for Tables 130.7 (C) (9) and (10) Provide (C)(8) through (C)(11)as Handouts 24 3/21/2014 Table 130.7 (C) (9) >240 and up to 600 volts 25 3/21/2014 Table 130.7 (C) (9) Table 130.7 (C) (9) Fast acting devices can significantly reduce – Hazard/risk category – Energy released in an event Application of the table is limited by: – Available short circuit current and – Maximum fault clearing time These values must be determined to utilize the table Overcurrent opening time affects the available arc flash intensity. 26 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 5. Hazard/Risk categories rank the hazards of electrical tasks from _________________. A. 0 for low-risk to 4 for high-risk B. 0 for no-risk to 4 for excellent-risk C. 1 for tasks that require no protection to 10 for tasks that require a licensed electrician D. Low to high depending on the experience level of the qualified person actually performing the work Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 5. Hazard/Risk categories rank the hazards of electrical tasks from _________________. A. 0 for low-risk to 4 for high-risk B. 0 for no-risk to 4 for excellent-risk C. 1 for tasks that require no protection to 10 for tasks that require a licensed electrician D. Low to high depending on the experience level of the qualified person actually performing the work 27 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 6. Insertion and removal of starter buckets from an energized 480 V motor control center is a hazard/risk category of ____. A. 2* B. 4 C. Requires only supervisor’s approval D. 3 7. Voltage testing on a 480 V panelboard with insulated case circuit breakers requires. A. Rubber insulating gloves and normal tools B. Normal tools only C. Insulated tools only D. Insulated tools and rubber gloves Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 6. Insertion and removal of starter buckets from an energized 480 V motor control center is a hazard/risk category of ____. A. 2* B. 4 C. Requires only supervisor’s approval D. 3 7. Voltage testing on a 480 V panelboard with insulated case circuit breakers requires. A. Rubber insulating gloves and normal tools B. Normal tools only C. Insulated tools only D. Insulated tools and rubber gloves 28 3/21/2014 Determining the Energy of Possible Arc Flash An arc flash hazard determination of the available incident energy requires knowledge of – the bolted fault current, – duration of faults, and – other general equipment information Operating equipment Arc Flash Hazard Analysis Detailed arc flash hazard analysis is not required where all of the following conditions exist: – Circuit rated at 240 volts or less – Circuit is supplied by one transformer – Transformer supplying circuit is rated less NFPA 70E Article 130.3 Exception No. 1 than 125 kVA 29 3/21/2014 Arc Flash Hazard Analysis In lieu of detailed incident energy analysis The 130.7 (C) (9) to (11) tables on hazard/ risk categories and PPE may be used Improper maintenance can increase overcurrent opening time and incident energy. For more see • NFPA 70E Chapter 2 on electrical maintenance • NFPA 70E hand book and Safety Program book NFPA 70E Article 130.3 Exception No. 2 Hazard/Risk Categories and Arc Rating Identifying the hazard/ risk category of a task is important. It enables decisions to made about necessary : – Protective clothing and personal protective equipment – Precautions – Procedures 30 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 8. An arc flash hazard determination of the available incident energy requires knowledge of _____________________. A. The closing time of related circuits B. The bolted fault current and the duration of the faults C. How long the task is expected to take D. The distance to the nearest branch disconnect switch 9. Improper maintenance can _____________ overcurrent opening time and incident energy. A. Limit B. Decrease C. Eliminate D. Increase Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 8. An arc flash hazard determination of the available incident energy requires knowledge of _____________________. A. The closing time of related circuits B. The bolted fault current and the duration of the faults C. How long the task is expected to take D. The distance to the nearest branch disconnect switch 9. Improper maintenance can _____________ overcurrent opening time and incident energy. A. Limit B. Decrease C. Eliminate D. Increase 31 3/21/2014 Hazard/Risk Categories and Arc Rating Protective clothing and other protective gear to be worn by personnel working on energized circuitry is identified and described relating to each hazard/risk category in Tables 130.7 (C) (10) and (C) (11) of NFPA 70E. Hazard/Risk Categories and Arc Rating Arc rated clothing for the various hazard/ risk categories is described in Table 1307 (C) (11) Avoid work-wear made with cotton/ polyester blends 32 3/21/2014 Work Wear for Hazard/Risk Category 0 Long sleeve shirt and long pants • Non-melting (per ASTM F 1506) or • Untreated Natural Fiber – wool, silk or cotton • Safety glasses or goggles depending on the environment • Hearing protection (ear canal inserts) • Leather gloves over insulating gloves where required (e.g.: gloves are optional for circuit breaker operation with covers off – 240 volts and below) • Leather work shoes Work-Wear for Hazard/Risk Category 1 Flame Resistant Clothing Minimum arc-rating of 4 • Compliant with ASTM F 1506 • Long-sleeve shirt and long pants or arc-rated coverall • Arc-rated jacket, parka, or rainwear if needed Leather work shoes as needed 33 3/21/2014 Work-Wear for Hazard/Risk Category 1 Equipment • Hard Hat • Leather gloves over insulating gloves • Safety glasses or goggles • Hearing protection (ear canal inserts) • Arc-rated face shield or • Arc flash hood - 4 CAL/CM2 Work-Wear for Hazard/Risk Category 2 Flame Resistant Clothing • Compliant with ASTM F 1506 • Long-sleeve shirt and long pants or arc-rated coverall • Arc-rated jacket, parka, or rainwear if needed 34 3/21/2014 Work-Wear for Hazard/Risk Category 2 Equipment • • • • • • • Hard Hat Leather gloves over insulating gloves Safety glasses or goggles Hearing protection (ear canal inserts) Arc-rated face shield or Arc flash hood Leather work shoes as needed Work-Wear for Hazard/Risk Category 2 * Same as Category 2 except An arc flash suit hood with a minimum arc rating of 8 must be used for head protection OR Face shield and balaclava (sock hood) with a minimum arc rating of 8 A balaclava covers the face, head and neck except for the eye and nose areas. 35 3/21/2014 Electrical work - Cautions Never perform electrical tasks on energized equipment or circuits exceeding 480 Volts, or of a hazard/risk category of 3 or 4 (See Table 130.7 (C) (9) without all of the following: –Detailed electrical hazard analysis –Documented specific procedure –Written Energized Work Permit –Task qualified personnel –Appropriate PPE Hazard/Risk Categories and Arc Rating Field marking of equipment Label must show the available incident energy OR required level of PPE Circuit components - as installed - will determine the incident energy and the level of hazard Marking of equipment as installed is required NFPA 70E Article 130.3 (C) 36 3/21/2014 Hazard/Risk Categories and Arc Rating Working inside the Limited Approach Boundary requires the use of insulated Tools and Equipment. See Table 130.7 (C) (9) for tasks that require insulated and insulating hand tools. NFPA 70 E Article 130.7 (D) Hazard/Risk Categories and Arc Rating Insulated tools and equipment must be: • Rated for the voltages on which they are used. • Designed and constructed for the use environment • Inspected prior to each use for the following: – Condition of insulation – Damage that may limit tool performance – Defects that increase the Not an insulated tool potential for an incident NFPA 70 E Article 130.7 (D) 37 3/21/2014 Hazard/Risk Categories and Arc Rating There are similar requirements for the use of other insulated equipment when necessary – Fuse or Fuse Holding Equipment – Ropes and Handlines – Fiberglass-Reinforced Plastic Rods – Portable Ladders – Protective Shields – Rubber Insulating Equipment – Voltage-Rated Plastic Guard Equipment – Physical or Mechanical Barriers Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 10. An arc flash rated face shield or hood is required for all live work at hazard/risk category of __________ and higher. A. 1 B. 2 C. 2* D. 0* 11. Working inside the Limited Approach Boundary requires the use of ____________________. A. A letter of acknowledgement from OSHA or the NFPA B. The assistance of a non-qualified person C. Insulated tools and equipment D. Increased awareness and scrutiny of relevant codes 38 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 10. An arc flash rated face shield or hood is required for all live work at hazard/risk category of __________ and higher. A. 1 B. 2 C. 2* D. 0* 11. Working inside the Limited Approach Boundary requires the use of ____________________. A. A letter of acknowledgement from OSHA or the NFPA B. The assistance of a non-qualified person C. Insulated tools and equipment D. Increased awareness and scrutiny of relevant codes Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 12. A hazard/risk category of ‘1’ requires clothing with a minimum arc thermal performance rating of at least ______. A. Optional for PPE B. Minimum 40 cal/cm² C. Minimum 4 cal/cm² D. Minimum 8 cal/cm² 39 3/21/2014 Module 3 Unit 3 - 2 Keys to Understanding NFPA 70E Practice Quiz 12. A hazard/risk category of ‘1’ requires clothing with a minimum arc thermal performance rating of at least ______. A. Optional for PPE B. Minimum 40 cal/cm² C. Minimum 4 cal/cm² D. Minimum 8 cal/cm² Electrical Safety Program - Procedures Example of a fundamental task and procedure is proper positioning when branch electrical connections are made and broken – Requires discipline – Well recognized Stand away from the panel! 40 3/21/2014 Module 3 Unit 3 – 4 Safe Procedures for Electrical Work Practice Quiz 3. As part of the electrical procedure planning process, equipment requiring electrical work must be marked to indicate ________________. A. The date and time of the scheduled work B. The Manufacturer, Model No. and Serial No. C. The available incident energy or required level of PPE D. The name or number of the employee who will do the work 4. Procedures must be ________________. A. Job and task specific for the plant B. Filed with NADCA and OSHA C. Generic and apply to many different kinds of equipment and electrical work D. Ignored if you need to improvise Module 3 Unit 3 – 4 Safe Procedures for Electrical Work Practice Quiz 3. As part of the electrical procedure planning process, equipment requiring electrical work must be marked to indicate ________________. A. The date and time of the scheduled work B. The Manufacturer, Model No. and Serial No. C.The available incident energy or required level of PPE D. The name or number of the employee who will do the work 4. Procedures must be ________________. A.Job and task specific for the plant B. Filed with NADCA and OSHA C. Generic and apply to many different kinds of equipment and electrical work D. Ignored if you need to improvise 41 3/21/2014 Electrical Safety Program - Principles (1) Inspect and evaluate electrical equipment (2) Maintain equipment insulation and enclosure integrity (3) Plan every job and document first-time procedures (4) Deenergize, if possible (5) Anticipate unexpected events (6) Identify and minimize hazards (7) Protect employees from – shock, – burn, blast, and – Any other hazards (8) Use the right tools for the job (9) Assess people’s abilities (10) Audit these principles NFPA 70E Article 110.7 (C) Annex E.1 Thank You For Attending! – Final Questions? 42