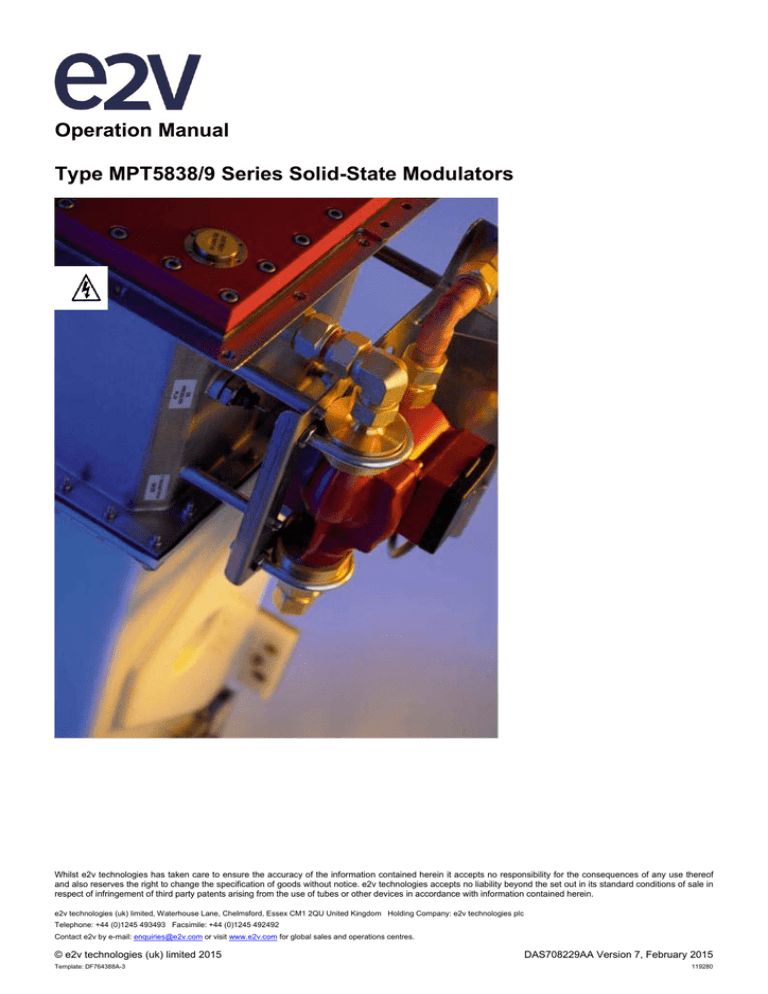

Operation Manual Type MPT5838/9 Series Solid-State

advertisement