keystone - Headwaters Construction Materials

advertisement

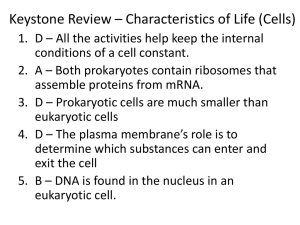

COMPAC COMPAC • Residential • Commercial • Governmental • D.O.T. KEYSTONE® Classic Keystone, Natural Appeal Product Specs COMPACIII COMPACIII KEYSTONE® Approximately 65-70 lbs KEYSTONE®8"h x 18"w x 12"d Compac IIITri-plane Victorian Straight Split Cap Unit Universal Cap 4"h x 18/12"w x 10.5" d 50 lbs Keystone Compac units are made of high-strength, low absorption concrete for long lasting structures. All structural units are interconnected using high strength fiberglass pins for strong shear connection. The connecting pins allow for ease of unit alignment and a secure positive mechanical connection with soil reinforcement materials. Keystone’s patented pin system is the critical difference providing the safety and security of a structural retaining wall solution. Compac Specifications COMPRESSIVE STRENGTH: ABSORPTION: REFERENCE STANDARDS: Minimum 3000 psi 8% ASTM C-1372 Fiberglass Pin Specifications FLEXURAL STRENGTH: Minimum 128,000 psi SHORT BEAM SHEAR STRENGTH: Minimum 6400 psi REFERENCE STANDARDS: ASTM D-4476, ASTM D-4475 Keystone Fiberglass Pins *Note: Unit colors, dimensions, weight, and availability varies by manufacturer. It makes the. difference Pin Keystone Connection 2 Keystone Compac www.keystonewalls.com Step 1 Install the Base Course. Place the first course of Keystone units end to end (with face of wall corners touching) on the prepared base. The receiving pin holes should face upward, as shown. Make sure each unit is level. Leveling the first course is critical for accurate and acceptable results. Keystone recommends minimum embedment depth for below grade placement of Keystone units on a ratio of 1" (25mm) below grade for each 8" (200mm) of wall height above grade or one unit, whichever is greater. Step 4 Step 3 Prepare the Base Leveling Pad. After selecting the location and length of the wall, excavate the base trench to the designed width and depth. Start the leveling pad at the lowest elevation along the wall alignment. Step up in 6 or 8" (150-200mm) increments with the base as required at elevation change in the foundation. Level the prepared base with 6" (150mm) of well-compacted granular fill (gravel, road base, or ½" to ¾" [10-20mm] crushed stone). Compact to 95% Standard Proctor or greater. Do not use PEA GRAVEL or SAND for leveling pad. Step 2 Installation Instructions, Features and Benefits Insert the Fiberglass Pins. Place the appropriate fiberglass pins (straight or shouldered) into the holes of each Keystone unit as required. Once placed, the pins create an automatic setback for the additional courses. According to wall requirements and design, place pins in the front holes for near vertical (1⁄8" or [3mm]) setback and the rear holes for 1¼" (32mm) setback per course. Install Fill & Compaction. Once the pins have been installed, provide ½"-¾" (10-20mm) crushed stone drainage fill behind the units to a minimum distance behind the tail of one foot (300mm). Fill all open spaces between units and open cavities/cores with the same drainage material. Proceed to place backfill in maximum 6-8” (150200mm) layers and compact to 95% Standard Proctor with the appropriate compaction equipment. Drainage and Geogrid Reinforcement may be required components on your project. Please consult your Sales Professional regarding these products. Features & Benefits Ease of Installation •T apered sides offer ease in constructing radii. •S horter tail design, makes for easier handling in the field. •T riangular pin connection hole allows for installer-friendly construction adjustments. Aesthetics •V ariety of colors complement any landscape. Step 6 Step 5 • Natural stone appeal. www.keystonewalls.com Install Additional Courses. Place the next course of Keystone units over the fiberglass pins, fitting the pins into the receiving pin hole or channel recess of the units above. Push the units toward the face of the wall until they make full contact with the pins. If pins do not connect properly with channel, place drainage fill in the cores to provide interlock with unit below. Continue backfilling and building to desired top elevation. Capping the Wall. Complete your wall with the appropriate Keystone capping units. With units dry and clean, use construction adhesive (Keystone KapSeal™) on the top surface of the last course before applying cap units. Backfill and compact to finish grade. Design Versatility and Performance •2 0% lighter weight than the Compac II units, reducing costs while maintaining structural integrity. •N ear vertical or battered setback options available. • Higher unit-to-unit shear resistance. • Increased vertical drainage through face units. •O pen cores allow for gravel interlock across block interfaces. • Improves connection strength between face units and geogrid. Keystone Compac 3 For more than 25 years, Keystone Retaining Wall Systems LLC has set the worldwide standard for excellence and innovation within the segmental retaining wall industry. With cutting-edge design, performance and aesthetics, Keystone has always been a product of the passion and focus of the industry’s top network of professionals. Together with premier manufacturers, product developers, engineers and sales professionals, we proudly ensure that Keystone products and services offer the best site solutions for governmental, commercial/industrial, recreational, public works and residential applications. Distributed By: We reserve the right to improve our products and make changes in the specifications and design without notice. The information contained herein has been compiled by KEYSTONE and to the best of our knowledge, accurately represents the KEYSTONE product use in the applications which are illustrated. Final determination of the suitability for the use contemplated and its manner of use are the sole responsibility of the user. Keystone Retaining Wall Systems LLC • A Contech Company 4444 West 78th Street • Minneapolis, MN 55435 (952) 897-1040 • www.keystonewalls.com ©2012 Keystone Retaining Wall Systems LLC