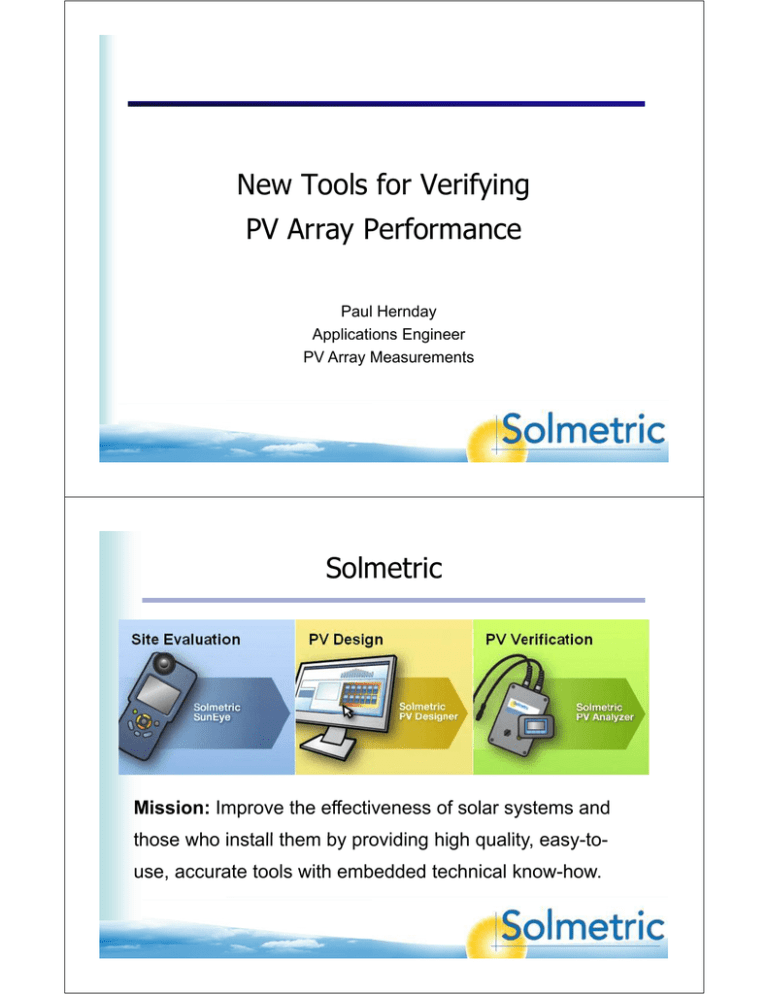

New Tools for Verifying f PV Array Performance Solmetric

advertisement

New Tools for Verifying PV Array Performance f Paul Hernday Applications pp Engineer g PV Array Measurements Solmetric Mission: Improve the effectiveness of solar systems and those who ho install them by b providing pro iding high q quality, alit eas easy-toto use, accurate tools with embedded technical know-how. Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays What is performance verification? Determination that measured performance meets a performance standard, to within a specified margin. Depending on the objective, the standard may be a reference PV string, a contracted performance specification, or a detailed array performance model. Objectives of performance verification • • • • • • • Expose problems earlier Troubleshoot more efficiently Get better commissioning data in less time Close out p projects j earlier ($$$ flows earlier)) Check the health of older PV arrays Localize problems to PV modules or inverter Provide data for PV module warranty claims Build better solar Improve financial & energy payback Cultivate public trust in PV Performance Verification Applications In the PV System Life Cycle Prelim. assessment Site survey Final design Startup Prelim. design Installation planning Commissioning C i i i Acceptance Proposal Installation Maintenance Contract Checkout Service Performance Verification Tools Inverter readout compared with system model DC measurements compared with PV model Basic I V curve measurements I-V t compared with PV model Comprehensive I V Solmetric PV Analyzer PVA-600 I V curve measurements I-V and on-board PV models Wireless to your notebook computer Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays Benefits of I-V Curve Measurement Compared p with DMM & Clampmeter p Testing g Max Power Point Current Power Isc (Clamp meter) Voltage g Voc (Multi-meter) • Full I-V curve More diagnostic value • Automated Fast & less chance of record record-keeping keeping mistakes Fill Factor Reduced ‘square-ness’ q of I-V curve can indicate aging, g g, defects Max Power Point Currentt Isc Imp Area A = Imp x Vmp Vmp Voc Voltage Fill Factor = Area B = Isc x Voc Area A Area B Series and Shunt Losses Contributors to reduced fill factor Max Power M P Point P i t Imp, Vmp Isc C Current Imp Shunt loss Series loss Voltage g Useful indicators: • Imp / Isc ( shunt loss) • Vmp / Voc ( series loss) Vmp Voc I-V measurement methods I sense V sense Load can be: •Electronic •Resistive •Capacitive Cu urrent Load L d requirements: i t • Voltage & current range • Power dissipation Voltage • ‘Sweep’ dynamics, esp sweep rate, which must be slower to accurately test high-efficiency modules Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays PV models For p predicting g PV arrayy performance p • Sandia National Labs PV Array Model – Most M t comprehensive h i (30+ parameters) t ) – ~400 modules modeled, more will flow starting ~ mid-2011 • 5-Parameter Model – Developed at U. Wisconsin, used by CEC for NSHP program , PV modules modeled at this time – ~1,700 • Simple Datasheet Model – Translates Pmax ((STC)) to actual irradiance & temperature p – User enters data sheet parameters These 3 methods are available in the Solar Advisor Model (SAM) from NREL and are embedded in the Solmetric PV Analyzer. Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays I-V measurement setup Example: measuring strings at a combiner box Steps to test a PV array at a combiner box PC setup (can be done in advance): • Select PV model p parameters (type ( yp & # of modules,, etc)) • Customize a directory (‘array tree’) for saving string data Hardware setup (onsite): 1 Locate 1. L t th the iirradiance di & temperature t t sensors 2. Open the combiner box’s DC disconnect 3. Lift the fuses to de-energize the buss bars 4. Connect test leads to the buss bars String measurement (per string): 1 Insert 1. I t a ffuse 2. Press “Measure” 3. Observe and save results Array tree for saving I-V data Same hierarchy as the PV system Measurement data from individual PV string tests Portland Habilitation Center PV System 860kW 7-inverter system y byy Dynalectric y Oregon g Testing at combiner boxes 860kW System y at Portland Habilitation Center,, byy Dynalectric y Oregon g Combiner Boxes (two per inverter) 860kW System y at Portland Habilitation Center,, byy Dynalectric y Oregon g Combiner Box 860kW System y at Portland Habilitation Center,, byy Dynalectric y Oregon g Testing individual PV strings 860kW System y at Portland Habilitation Center,, byy Dynalectric y Oregon g Max Power as % of Predicted Example Measured I-V & P-V curves Red dots are the model predictions p •Shaded area is the inverter’s MPPT voltage range •Model set to ‘array as sensor’ mode Performance analysis Evaluation of the ‘arrayy tree’ data Overlay plots of II-V V curves curves, raw and normalized Histograms Pmax, Fill factor, Imp/Isc, Vmp/V oc Isc, Voc, etc User-defined metrics Reports Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays PV module with 100 ohm shunt resistance Demonstration: Single PV module with external resistor PV module with 2.5 ohm added series resistance Troubleshooting example Comparison p of typical yp (blue) ( ) and atypical yp (red) ( ) I-V curves 8 7 Current - A 6 5 4 3 String 4B14 2 String 4B15 1 0 0 50 100 150 200 250 300 Voltage - V Troubleshooting example Problem isolated to failed module Irradiance changed between measurements 350 400 Field-aged thin film string Array-as-sensor mode Effect of shade on PV arrays PV Module with Bypass Diodes Example: p 72-cell module + Partial shading Inverter must identifyy and track the right g peak p Max Power (until the shade pattern changes!) Current Po ower Isc Voltage Voc Partially shaded residential array Single g string, g, along g lower edge g of roof Partially shaded residential array Single g string, g, along g lower edge g of roof Shading Pattern Effects Sub-cell shading Business card on 1 cell in a string g of 15,, 48-cell modules Shade 2 cells in the same cell-string Single module with 72 cells and 3 bypass diodes Shade 2 cells in adjacent cell-strings Single module with 72 cells and 3 bypass diodes Shade ‘taper’ along a cell-string Single g module with 72 cells and 3 bypass yp diodes Shade ‘taper’ across a cell-string Single g module with 72 cells and 3 bypass yp diodes Shadow of leafless tree branch Single g module with 72 cells and 3 bypass yp diodes Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays String access points Best choice depends p on system y layout y 2 1 3 DC Disco DC DC Combiner Disco 5 In e te Inverter Service Panel DC Disco 4 The challenges of string access #1: Electrical isolation • Easy when strings are individually fused • Difficult in small, non-fused (2-string) residential systems #2: Electrical connection • Commercial combiners typically provide enough space, but safety shields may make block alligator clip access to the buss bars • Difficult in un-fused residential systems if the source conductors run directly to inverter-integrated DC disconnect Recommendation: Every PV system should have means for isolating and connecting to string conductors for testing purposes, typically at the combiner box or the inverter inverter. Lifting conductors to isolate strings for measurement Topics • PV array performance verification • Current-Voltage (I-V) curve measurement • Array A a performance pe fo mance models • I-V test setup and process • Example I-V measurement results • Electrical access to strings for testing purposes • Thermography applied to PV arrays Thermography* applied to PV Example p applications: pp • Evaluate roof integrity (aerial imaging) • Evaluate temperature differences across an array • Identify hotter or cooler strings or modules (aerial imaging) • Identify hotter/cooler regions within a PV module Cells Ribbon bonds J boxes J-boxes * IR iimaging i and d ttemperature t measurementt Temperature variation across an array From D.L. King, et al, Photovoltaic Array Performance Model, Sandia, 2004 Aerial Thermography 860kW System y at Portland Habilitation Center,, byy Dynalectric y Image courtesy of Oregon Infrared http://www.oregoninfrared.com/ Conclusion • Verification of PV array DC performance is a best practice for PV system commissioning and ongoing maintenance. maintenance • I-V measurements compared with a detailed PV model gives the best insight into performance and aging characteristics of a PV array. • I-V testing is a natural troubleshooting tool for responding to performance alerts,, thermographic p g p surveys, y , and other indicators. • The automated nature of I-V measurements means more valuable data, in less time, with fewer errors. • The industry should adopt means, in inverters and combiner boxes, for isolating and connecting to string conductors, for testing purposes. New Tools for Verifying PV Array Performance f