BUILDING PRODUCTS

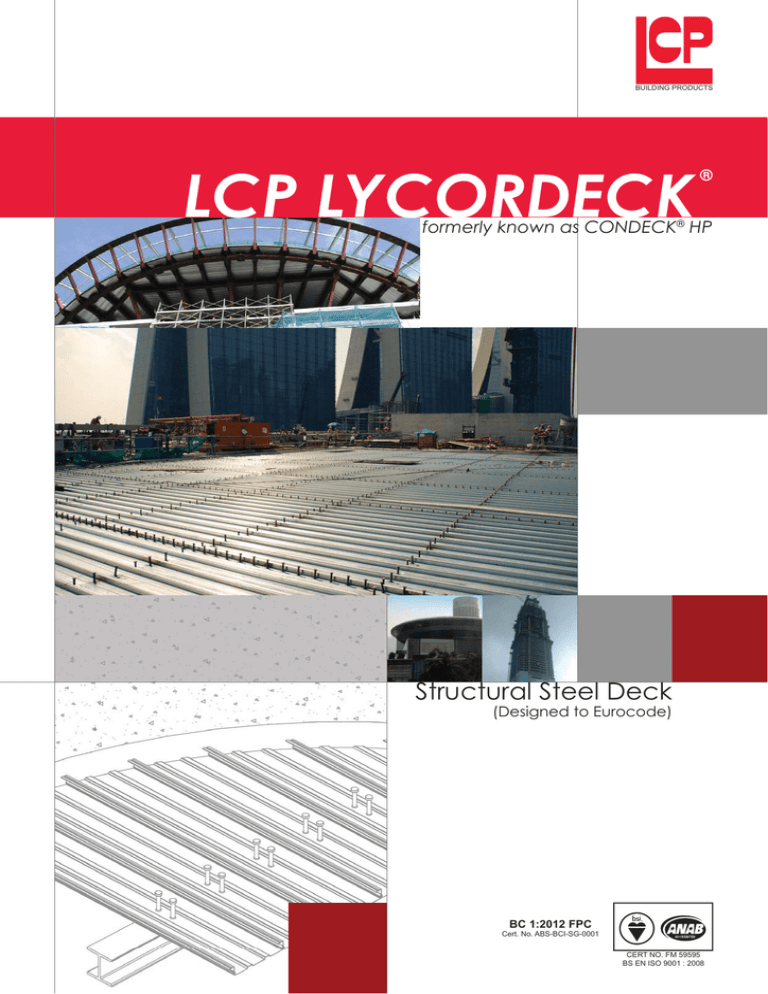

LCP LYCORDECK

®

formerly known as CONDECK® HP

Structural Steel Deck

(Designed to Eurocode)

BC 1:2012 FPC

Cert. No. ABS-BCI-SG-0001

CERT NO. FM 59595

BS EN ISO 9001 : 2008

L C P

L Y C O R D E C K®

FEATURE

LCP LYCORDECK® (formerly known as CONDECK® HP)

Steel Decking is designed to be used in composite

construction and save reinforcing material and

construction time.

All relevant and latest Eurocodes were used to ensure

that the LCP LYCORDECK® Steel Decking performs at the

highest level in accordance with the latest Singapore

requirements.

INTRODUCING UPDATED LCP LYCORDECK® STEEL DECKING

LCP LYCORDECK® will still feature:

With a constant need to keep abreast of international

standards to meet industry needs and building

authority requirements, LCPBP has engaged a local

academic institution to conduct full-scale tests to

ascertain that its design adheres to the Eurocodes.

Hence, with this update, we launch the steel decking

as LCPoLYCORDECK® to keep in line with our brand of

building products trusted by many of our clients.

Superior span performance – for greater span

capacity.

The steel decking will still retain the advantages derived

from its unique characteristics, i.e. the closed rib profile,

which sets it apart from its competitors.

Improved fire resistance periods – for even more cost

effective slabs.

Substantially reduced side lap fasteners – reduced

installation time.

Facility for ceiling system suspension – for quicker

ceiling installation if required.

PROPERTIES

LCP LYCORDECK® - Mass/Thickness Table

Thickness

Material Mass

BMT

(mm)

TCT

(mm)

kg/m2

kg/m

0.75

0.78

9.89

2.97

1.00

1.03

13.07

3.92

1.20

1.23

15.61

4.69

1

Special request options:

1. 1.2mm Base Metal Thickness.

2. Heavier galvanised coatings.

3. Colorbond coating to LCPoLYCORDECK®

Steel Decking soffit.

Please contact LCPBP for Technical Specification.

L C P

L Y C O R D E C K®

SECTION PROPERTIES

Ycg

Section Properties (per metre witdth)

Total

I Value Caculating

Section

Deflection

Properties

Ultimate

Web

Shear

Crushing

Capacity Resistance

BMT

Mass

Cross

Section

Area Ap

Ycg

mm

kg/m2

mm2

mm

I

106mm4

Isingle

106mm4

Icont

106mm4

Mp

kNm

Mn

kNm

Pv

kNm

Pw

kNm

0.75

9.89

1211

15.1

0.511

0.436

0.357

5.68

6.99

55.2

45.4

Ultimate Moment

Capacities

1.00

13.07

1620

15.2

0.666

0.590

0.483

7.83

9.11

98.2

73.6

1.20

15.61

1944

15.2

0.794

0.697

0.599

9.23

10.85

139.1

99.9

Ycg - Distance from base of rib to centre of gravity of panel

Mp - Ultimate moment capacity of positive moment regions

I

Mn - Ultimate moment capacity of negative moment

regions

- Second moment of area of section

Isingle - Second moment of area for computing rib deflection

of single spans

Icont - Second moment of area for computing rib deflection

of continuous spans

Pv

- Ultimate shear capacity

Pw - Ultimate web crushing resistance

2

L C P

L Y C O R D E C K®

UNPROPPED SPAN TABLES

Designers can use these tables to determine the required unpropped span.

Please note, the slab will still need to be checked for composite and if necessary fire resistance design.

The design parameters considered are 166mm (internal) and 146mm (end) wide beams.

LCP LYCORDECK® Unpropped Formwork Span (mm)

0.75 mm BMT

1.0 mm BMT

1.2 mm BMT

Slab

Thickness

(mm)

Single

Span

Double

Span

Triple

Span

Single

Span

Double

Span

Triple

Span

Single

Span

Double

Span

Triple

Span

100

2684

2959

3003

3009

3535

3447

3160

3756

3674

105

2646

2900

2947

2972

3482

3405

3121

3701

3630

110

2610

2845

2893

2936

3430

3364

3084

3648

3588

115

2575

2791

2842

2902

3381

3326

3049

3597

3547

120

2542

2741

2792

2869

3333

3289

3015

3548

3509

125

2510

2692

2745

2838

3287

3254

2982

3501

3472

130

2479

2646

2699

2808

3242

3220

2951

3455

3436

135

2450

2601

2656

2779

3199

3188

2922

3410

3402

150

2368

2478

2534

2700

3076

3098

2839

3286

3307

175

2249

2302

2359

2586

2877

2936

2720

3102

3158

200

2147

2154

2211

2489

2707

2769

2619

2926

2992

225

2059

2028

2084

2405

2561

2624

2531

2774

2841

250

1982

1919

1974

2332

2433

2497

2455

2641

2709

275

1914

1824

1877

2267

2321

2384

2370

2524

2591

300

1853

1740

1791

2283

2221

2206

2293

2419

2486

Note: Concrete density adopted is 2400kg/m . The spanning capacity can be enhanced by adopting LCP LYCORDECK®

(Super) 3rd Rib accessory, consult LCPBP Technical Department.

2

3

L C P

L Y C O R D E C K®

ENHANCED SPANNING

The exclusive LCP LYCORDECK® (Super) 3rd Rib

accessory, developed by LCPBP, is fastened along the

side of the end span ribs to significantly reduce end

span deflection under wet concrete. This effectively

eliminates the design limits imposed by end spans.

LCPoLYCORDECK® (Super) 3rd Rib accessory can be

used to increase unpropped end spans.

SUPER 3rd RIB

LCP LYCORDECK® (Super) 3rd Rib accessory increases the

spanning performance of LCP LYCORDECK® composite

decking in several ways.

Besides reducing lateral rib distortion and tray deflection,

it increases the stiffness of the composite slab and

increases the deck spans. With greater deck spans

come a reduction in the amount of propping required.

This accessory is simple to install and is only required on

decking end spans.

TESTING PROGRAMME

Design data for LCP LYCORDECK® composite decking are based on thorough testing

of performance in formwork, composite and fire design modes.

Full-scale and pilot tests were carried out by the School of Civil and Environmental

Engineering (CEE), Nanyang Technological University (NTU) and Building Research

Association of New Zealand (BRANZ).

The tests conducted on LCP LYCORDECK® with reference to Eurocode 4 include:

Shear and bending resistance of LCP LYCORDECK® at ambient temperature.

An experimental study of heat transfer through LCP LYCORDECK® composite

slabs to evaluate temperature distributions across the thickness of the slab.

LCP LYCORDECK® composite slab under loading in fire situation.

Construction Stage

EUROCODE

BRITISH STANDARD

Working personnel with small site equipment, Qca:qca,k = 0.75 kN/m

[Considered in Actions (1) and (2)]

2

Construction load

Load bearing element, Qcc:qcc,k = 0.5 kN/m2 [Considered in Action (3)]

4.5/span kN/m2

Weight of fresh concrete for design thickness, Qcf: qcf,k = project requirements [Spans < 3m]

[Considered in Actions (2) and (3)]

{Refer to BS5950: Part 4: 1994}

{Refer to SS EN-1991-1-6:2009, 4.11.2, Table 4.2 for definition of Actions}

Permanent: 1.35

Partial Safety Factor Variable: 1.5

Composite Stage

1.5 kN/m2

[Spans ≥ 3m]

Dead load: 1.4

Construction load: 1.6

{Refer to SS EN-1990:2008}

{Refer to BS5950: Part 4: 1994}

EUROCODE

BRITISH STANDARD

Partial safety factors for reinforcing steel

Persistent &

Transient design

situation

ys=1.15

ym=1.05

{Refer to SS EN 1992-1-1:2004}

{Refer to BS8110: Part 1: 1997}

4

L C P

L Y C O R D E C K®

KEY ADVANTAGES AT DIFFERENT STAGES

Construction stage

Ease of installation

Labour savings during installation

Time savings during installation

No need for rib-end closures

Composite stage

Reduced steel reinforcement

Resistance to deflection

Flexible placement of shear studs

Maintains sound and vibration insulation

Fire Emergency stage

Embedded ribs act as Fire Emergency Reinforcement

(F.E.R.)

Unrestricted placement of fire reinforcement

ADVANTAGES IN CONSTRUCTION STAGE

Ease of installation

The 300mm sheet width of LCP LYCORDECK® composite

decking makes it easy to carry, simple to cut and

trim and easier to fit to the floor layout with minimal

wastage. Its light weight allows two people to carry long

continuous lengths. Once in place the wide pan is easy

and safe to walk in.

Labour savings

LCP LYCORDECK® decking requires no timber formworks

and can be installed by semi-skilled labour under

supervision. The wide trays allow easy installation of

penetrations.

Time savings

The characteristic sheet interlocking of LCP LYCORDECK®

composite decking ensures quick, cost-effective

installation. The only fastening to attach the sheet to

the structure is minimal. Side lap fasteners are often not

required to connect the interlocking sheets.

No need for rib-end closures

The closed ribs of the LCPoLYCORDECK® does not require rib end closures or taping of joints therefore lowering installation

time and costs.

5

L C P

L Y C O R D E C K®

ADVANTAGES IN COMPOSITE STAGE

Reduced steel reinforcement

Generally, conventional positive reinforcement is not

required. LCP LYCORDECK® composite decking acts as

positive reinforcement to optimize strength and control

composite slab deflection.

Negative reinforcement may be reduced in many

continuous slabs by applying the partial shear

connection strength factor to take account of moment

redistribution

Resistance to deflection

Deflection of the completed composite slab is often the

governing design criterion. LCP LYCORDECK® composite

decking has excellent resistance to deflection due to

its ribs being fully enclosed in the concrete slab. The ribs

are embedded in the slab to provide maximum stiffness.

Flexible placement of shear studs

There are effectively no restrictions on the placement

of shear studs with LCP LYCORDECK® composite slab.

Therefore, flexibility in beam design provide engineers

with the opportunity to reduce the size of I-beams by

up to 20%.

Design virtually any stud configuration with 100mm,

200mm or 300mm centres.

10 stud/metre (single row) - nominal 100mm spacing

Maintains sound and vibration insulation

The LCP LYCORDECK® composite slab does not

compromise on sound insulation and vibration as it

is similar to a solid slab with the ribs being completely

encased in concrete with no voids.

6

L C P

L Y C O R D E C K®

ADVANTAGES IN FIRE EMERGENCY STAGE

Embedded ribs act as Fire Emergency Reinforcement (F.E.R.)

LCP LYCORDECK® composite decking has all of its profile

ribs embedded in finished concrete slab giving thermal

insulation comparable to a solid slab.

Compared with trapezoidal and re-entrant decks, there

are no gaps at the soffit of the slab for heat to penetrate.

This allows the ribs to remain cool and act as FER.

Based on the simplified FER design method for

LCPoLYCORDECK® composite decking, minimal or even

no additional reinforcement may be required.

Concrete

Unrestricted Placement of F.E.R.

Since the ribs of LCP LYCORDECK® are embedded in the

concrete, F.E.R. may be placed anywhere above the

ribs unlike trapezoidal or re-entrant decks where F.E.R.

placement is limited.

LCP LYCORDECK®

Fire emergency

reinforcement placed above

LCPoLYCORDECK® Steel

Decking ribs

OTHER ADVANTAGES

Flat Base

Skew Cut Savings

The flat base of LCP LYCORDECK is aesthetically

pleasing and if required, fireproofing or painting

LCPoLYCORDECK® soffit is straightforward.

®

7

The wastage from skew cutting of 300mm cover width

LCP LYCORDECK® is reduced as compared to skew

cutting a 600mm cover width decking sheet.

L C P

L Y C O R D E C K®

INSTALLATION PROCEDURES

LCP LYCORDECK®

Steel Decking

1

LCP LYCORDECK® is usually designed to support

weight of wet concrete plus a temporary

construction load without propping. However,

if temporary props are required, the temporary

continuous prop line must be able to carry the

relevant loads.

Centre

(from p - Centre Sp

a

roppin

g table n

)

Frame or supporting

structure

2

Place the first LCP LYCORDECK® panel with the

narrower male rib facing direction of laying. Align

this panel over the supports ensuring a minimum

overhang or end bearing of 50mm

Place on proceding panel

Allow LCP LYCORDECK®

Steel Decking to fall into

position

3

4

Panel should be secured immediately in outdoor

condition against wind uplift after placing over

supports. Heavy point loads during construction

should be distributed by means of timber planking.

Install side lap fasteners when required.

Steel reinforcement

fabrics

Place

the

shrinkage

and

temperature

reinforcement (fabric) such that minimum cover

(generally 20mm to 30mm cover from top of slab)

is satisfied

8

L C P

L Y C O R D E C K®

INSTALLATION PROCEDURES

Concrete

5

The concrete must be poured evenly to the

panel ends on the prepared clean deck, in the

direction of span of the decking. Heaping of wet

concrete must be avoided. Vibrator compaction

is recommended.

Steel reinforcement

fabrics

Edgeforma

6

Straps at

600mm Centres

Edgeforma is a lightweight, easy to use edge

form. Edgeforma is available in a range of

heights to suit different slab depths. The top

flange of the Edgeforma should be tied back to

LCPoLYCORDECK® steel decking ribs every 600mm

with galvanised strapping. For unsupported

deckings, edge fix Edgeformas at 300mm centres.

LCP LYCORDECK®

7

Concrete

Steel reinforcement

fabrics

LCP LYCORDECK® steel decking has provision for

suspended ceiling installation or support of building

services. A two part bracket is simply inserted into

the underside of any rib and held in place by the

suspension rod. The ceiling hanger is capable of

supporting a load of 2.5kN after the concrete is in

place.

Note: Side lap fasteners, installed through the vertical

web of the ribs - at no more than 500mm centers either

side of the hanger, are required if ceiling hanger is loaded

before the concrete pour. In this case, the maximum

capacity of the hanger is reduced to 0.6kN.

9

2 Part hanger

Ceiling rod

L C P

L Y C O R D E C K®

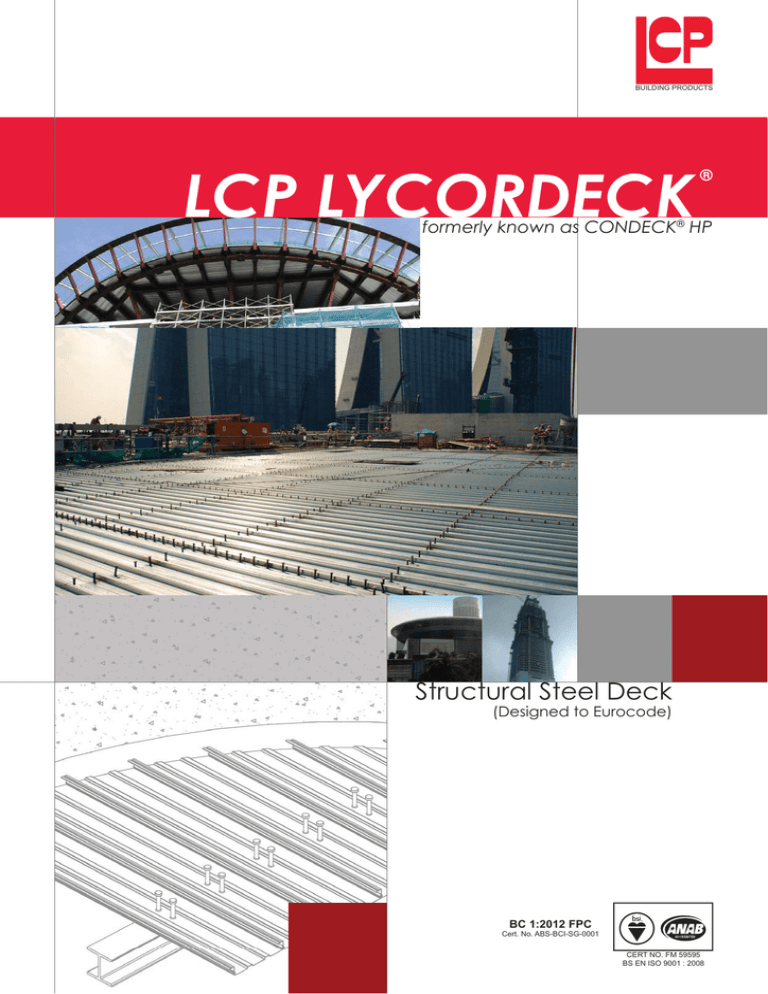

PROJECT REFERENCE

OUB Tower, Singapore

Naypyidaw Airport, Myanmar

ION Orchard, Singapore

Marina Bay Sands IR, Singapore

Times Square, Hong Kong

Supreme Court, Singapore

Changi Airport Terminal 3, Singapore

International Finance Centre, Hong Kong

Universal Studios, Singapore

10

IMPORTANT NOTE: The information published in this brochure is as far as possible accurate at the date of publication, however, prior

to application in a particular situation, LCP Building Products Pte. Ltd. recommends that you obtain qualified expert advice confirming

the suitability of product(s) in question for the application proposed. While LCP Building Products Pte. Ltd. accepts its legal obligations,

be aware however that to the extent permitted by law, LCP Building Products Pte. Ltd. disclaims all liability (including liability for

negligence) for all losses and damages resulting from the use of the information provided in this brochure.

CONDECK® HP is a registered trademark of Corporation Pty. Limited.

LCP BUILDING PRODUCTS PTE. LTD.

LCP BUILDING PRODUCTS PVT. LTD.

No. 6 Gul Circle, Singapore 629562

“Swathi Court”, Flat No. 4-B, 2nd Floor, Old

No. 22, New No. 43, Vijayaraghava Road,

T. Nagar, Chennai 600 017, India

CO. No. 200009173 C

BUILDING PRODUCTS

Tel: (65) 6865-1550

Email: lcp@lcp.sg

Fax: (65) 6861-4218

website: www.lcp.sg

(CO. No. U28112 TN2004 PTC053236)

Tel: +91 44 2815 4406/08

Fax: +91 44 2815 4407

Email: lcpindia@lcpgroup.asia

website: www.lcpindia.com

A member of LCP Group of Companies

Photographs of the premises displayed in

this Brochure are not to be construed as an

endorsement or recommendation by the owners

of the premises to LCP and its products.

LCP LYCORDECK® Brochure 01/15 ©2015 LCP

Building Products Pte. Ltd. All rights reserved.

LCP LYCORDECK® Brochure 01.2015 edition.