200 edge detail

advertisement

Described below is a method of construction to utilise the

INSULSLAB form of waffle slab foundation in conditions

where the foundation is supported at shallow depth directly by

the underlying soils. For piled foundations using INSULSLAB

similar methods apply.

Whilst accepting that individual interpretation and innovation

may well give rise to alternative methods to suit site specific

conditions, it is felt that what is described, will clearly and

accurately achieve the end product.

Severely sloping sites will introduce individual conditions to

be addressed which can be readily accounted for by referring

to Insulslab technical, however for the purposes of this

exercise we have assumed a relatively level site.

1

101

650

3450

395

395

3450

Insulslab SFRC Foundation Installation

Methodology.

650

250

250

600

1. Excavate to reduce general level to suit site layout

drawings, by others.

S.O.P

2. Set the plot out as normal, ensuring that you have a

completed 'CONSTRUCTION ISSUE' drawing showing the

Insulslab foundation layout and the standard details drawing.

S.O.P

3. Excavate to reduce general level to a depth of 600 mm

below top of slab level over the pod area and 675mm under

edge beams and party walls. Sub-base should be prepared

using methods 2, 3 or 4 from table 6/4 of the Specification of

Highway Works Volume 1 Series 600 Earthworks and in

accordance with NHBC recommendations. Additional fill may

also be necessary to ensure that all topsoil, degradable

material and soft spots are removed.

4. Position, excavate & install all services and drainage

entries. The accuracy of this operation is paramount, as

correction of inaccuracies is very difficult.

5

101

3450

1

101

1

101

5. Place granular hardcore and compact to a level 550mm

below top of slab level. Compaction with a Wacker plate or

trench roller to the hardcore in the trenches or a

larger twin drummed roller to the whole of the formation area

is acceptable. Tolerances on top of the finished sub-base

should be within +10/-20 mm with an average of -5 mm.

6. Install 100 thick insulation under all edge / internal beams.

Provide "hyrib" at beam

/ beam intersections to

first pour (Typical)

7. Set up and install the first stage edge shutter on top of the

horizontal edge insulation to the perimeter of the plot

DOWHUQDWLYHO\DQ³DOOLQRQH³HGJHVKXWWHUFDQEHXVHGIRU

monolithic pour)

8. Fill in between the Edge and internal insulation with

granular hardcore and compact.

375

9. Install a minimum 1200g dpm, or gas membrane as

required by the site investigation, to whole area extending

300 to 500mm beyond the edge of the shutter.

10. Starting from one corner of un-cut pods, the pods must be

placed to the prescribed layout, completing all full pods

before installing the cut-pods as required. Widened internal

beams should be separate by spacers in order to minimise

risk of movement.

11. Hyrib is to be installed and fixed in position across face of

internal ribs/beams in order to contain initial pour to edge

beam.

3175

12. Timber bracing is required from the top of the pod to the

shutter in corner locations and every perimeter pod during

concreting to ensure no lateral movement occurs. These are

removed when the concrete reaches the top of the pods.

Reinforcement to be cast into the first stage pour to provide a

shear connection between the two pours.

13. The concrete is to be placed to the outer toe section first

of the two stage pour, prior to installing the remaining

concrete to the full height in the usual manner. (The concrete

can either be pumped or placed directly)

14. Once set, the lower shutter can be stripped and installed

to form the second shutter. The foundation is then ready for

the internal ribs, slab, beams and remaining external beam to

be completed. Sacrificial bar or blocks may be introduced to

support the second stage pour shutter.

S.O.P

600

S.O.P

15. When the placement is completed, level carefully and

finish by bull float or skip float in order to improve flatness and

to hide visible fibres under the superficial mortar. If required

the slab may be finished by power, bull or skip floated.

THIS DRAWING IS COPYRIGHT AND MUST NOT BE REPRODUCED

WHOLLY OR IN PART WITHOUT PRIOR PERMISSION.

2012. GHW CONSULTING ENGINEERS LTD. / INSULSLAB SIG

General Notes.

1. Insulslab foundation to be placed on minimum 150mm

Type 2 granular material to be compacted in accordance with

the specification.

All soft spots to be excavated to competent formation and

back filled with compacted Type 2 granular material.

2. All works to be undertaken in accordance with the

recommendations contained within the geotechnical report

and NHBC Standards. Where trees are present, ground

conditions may require the placing of an additional hardcore

bed under the whole area to overcome the influence of

trees/shrinkable soils in accordance with the NHBC Standards

Chapter 4.2 and 4.5.

3. For depths of sub-base required beneath edge beams refer

to sections.

4. The Insulslab pods have a load bearing requirement and

are protected by a patent. Online technical data and ordering

information can be found on the website www.insulslab.com

5. Slab to be cured under a spray application of curing /

sealing solution, Permaban Pro-Seal or similar.

6. Where ground levels have been adjusted to suit site set-out

requirements, it has been assumed that infill / regrade

material has been suitabilty engineered and consolidated in

order to achieve a minimum ground bearing capacity of

50kN/m2

7. For all general details and sections see drawing No. 100.

8. For on site setting out of units, orientation / handing and

co-ordination, see Architects detail drawings and relevant site

setting out drawings by others.

9. For all finished ground levels and slab levels, see

Architects / Set-out drawings by others.

10. For setting out of all services, drainage and utilities see

Architects and specialists detail drawings.

Specification for Concrete and Fibres.

1. The concrete mix shall follow the recommendations as

noted in the ArcelorMittal Sheffield Ltd. BBA Certification 12 /

4894 product sheet 2 "ArcelorMittal - Insulslab foundation

system for housing applications using SFRC" page 3, Table 1

Concrete Specifications along with the following mix design

guide lines. These are to be considered together and neither

is to be considered complete without the other.

2. Concrete mix design shall be based on the use of 20mm

aggregate. Other aggregate sizes or blends may be used on

further review by ArcelorMittal in conjunction with the

readymix supplier and only formal written confirmation from

ArcelorMittal. The proportions will depend on the gradation of

the local materials.

3. The concrete grade to be a C30 / 37 - C35 with a maximum

water cement ratio of 0.55 using super-plasticiser. All

admixtures used should be from the same manufacturer and

used as per manufacturers instructions.

4. Permitted cement type shall be Portland cement or blends

of up to 20% replacement using GGBS or PFA. This

corresponds to the following cement types to BS EN 197-1:

CEM I, CEM II/A-S OR CEM II/A-V. Minimum cement quantity

WREHNJPñ

5. The slump shall be between 180 and 230mm (S4 type

EN206 / BS8500) at the time of delivery. The addition of

water on site is prohibited, except where the additional water

is allowable water remaining from the original batch target.

Any water added to the concrete shall be recorded on the

delivery ticket.

6. The fines content shall be aproximately 50% by weight of

the total aggregate content. Total fines content shall be

450kg/m3 fines graded at or below 200ȝ Please refer to the

required sieve curve analysis for optimum aggregate

gradation to be used when investigating the suitability of the

given mix.

6WHHOILEUHVWREH+('RVDJHUDWHLVNJPñ

NOTE:

LAYOUT SHOWN IS INDICATIVE AND SUBJECT

TO CONFIRMATION AND CO-ORDINATION WITH

ARCHITECTS DRAWINGS AND SPECIALISTS

LINE LOADS

P1

DM

Preliminary - Costing

00.00.00

BY

To be confirmed.

Extent of any underbuild

Gas regime

TBC

TBC

REV

Gas membrane

Gas Venting

AMENDMENTS

DATE

PRELIMINARY

16. Apply a spray application of curing & sealing membrane

such as Permaban Permaseal or similar approved.

17. Strike the shutter and place aside for re-use.

Foundation Plan

(Housetype Example)

S.O.P Denotes 'Setting Out Point' of Pod Units

18. The DPM is then lapped up the outside vertical face of the

toe. The horizontal and inside vertical face of the toe is

painted with two coats of RIW LAC or similar.

19. The vertical insulation is then placed against the outside

face of the toe and backfilled against.

20. The contractor shall record and retain on site, all concrete

mix delivery tickets for onward submission to the statutory

body for their approval.

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

NOTE:

Where ground levels have been raised / adjusted,

it is assumed that a suitable engineered material

has been laid and consolidated in order to achieve

a minimum ground bearing pressure 50kN/m 2

Hatched areas

denotes pour one

of two stage pour see plan & sections

Hatched areas

denote insulslab

pods cut on site

to suit.

THIS DRAWING IS FOR COSTING

PURPOSES ONLY AND MUST NOT

BE USED FOR CONSTRUCTION

FOR CONSTRUCTION DETAIL INFORMATION

CONTACT GHW CONSULTING ENGINEERS Ltd.

New Development

12-2999

Insulslab Foundation Layout

Example Housetype

DM

AW

A1 - 1:25

A3 - 1:50

INS12-0000

AW

Nov 2012

01

P1

Described below is a method of construction to utilise the

INSULSLAB form of waffle slab foundation in conditions

where the foundation is supported at shallow depth directly by

the underlying soils. For piled foundations using INSULSLAB

similar methods apply.

Whilst accepting that individual interpretation and innovation

may well give rise to alternative methods to suit site specific

conditions, it is felt that what is described, will clearly and

accurately achieve the end product.

Severely sloping sites will introduce individual conditions to

be addressed which can be readily accounted for by referring

to Insulslab technical, however for the purposes of this

exercise we have assumed a relatively level site.

1

101

650

3450

395

395

3450

Insulslab SFRC Foundation Installation

Methodology.

650

250

250

600

1. Excavate to reduce general level to suit site layout

drawings, by others.

S.O.P

2. Set the plot out as normal, ensuring that you have a

completed 'CONSTRUCTION ISSUE' drawing showing the

Insulslab foundation layout and the standard details drawing.

S.O.P

3. Excavate to reduce general level to a depth of 600 mm

below top of slab level over the pod area and 675mm under

edge beams and party walls. Sub-base should be prepared

using methods 2, 3 or 4 from table 6/4 of the Specification of

Highway Works Volume 1 Series 600 Earthworks and in

accordance with NHBC recommendations. Additional fill may

also be necessary to ensure that all topsoil, degradable

material and soft spots are removed.

4. Position, excavate & install all services and drainage

entries. The accuracy of this operation is paramount, as

correction of inaccuracies is very difficult.

5

101

3450

1

101

1

101

5. Place granular hardcore and compact to a level 550mm

below top of slab level. Compaction with a Wacker plate or

trench roller to the hardcore in the trenches or a

larger twin drummed roller to the whole of the formation area

is acceptable. Tolerances on top of the finished sub-base

should be within +10/-20 mm with an average of -5 mm.

6. Install 100 thick insulation under all edge / internal beams.

Provide "hyrib" at beam

/ beam intersections to

first pour (Typical)

7. Set up and install the first stage edge shutter on top of the

horizontal edge insulation to the perimeter of the plot

DOWHUQDWLYHO\DQ³DOOLQRQH³HGJHVKXWWHUFDQEHXVHGIRU

monolithic pour)

8. Fill in between the Edge and internal insulation with

granular hardcore and compact.

375

9. Install a minimum 1200g dpm, or gas membrane as

required by the site investigation, to whole area extending

300 to 500mm beyond the edge of the shutter.

10. Starting from one corner of un-cut pods, the pods must be

placed to the prescribed layout, completing all full pods

before installing the cut-pods as required. Widened internal

beams should be separate by spacers in order to minimise

risk of movement.

11. Hyrib is to be installed and fixed in position across face of

internal ribs/beams in order to contain initial pour to edge

beam.

3175

12. Timber bracing is required from the top of the pod to the

shutter in corner locations and every perimeter pod during

concreting to ensure no lateral movement occurs. These are

removed when the concrete reaches the top of the pods.

Reinforcement to be cast into the first stage pour to provide a

shear connection between the two pours.

13. The concrete is to be placed to the outer toe section first

of the two stage pour, prior to installing the remaining

concrete to the full height in the usual manner. (The concrete

can either be pumped or placed directly)

14. Once set, the lower shutter can be stripped and installed

to form the second shutter. The foundation is then ready for

the internal ribs, slab, beams and remaining external beam to

be completed. Sacrificial bar or blocks may be introduced to

support the second stage pour shutter.

S.O.P

600

S.O.P

15. When the placement is completed, level carefully and

finish by bull float or skip float in order to improve flatness and

to hide visible fibres under the superficial mortar. If required

the slab may be finished by power, bull or skip floated.

THIS DRAWING IS COPYRIGHT AND MUST NOT BE REPRODUCED

WHOLLY OR IN PART WITHOUT PRIOR PERMISSION.

2012. GHW CONSULTING ENGINEERS LTD. / INSULSLAB SIG

General Notes.

1. Insulslab foundation to be placed on minimum 150mm

Type 2 granular material to be compacted in accordance with

the specification.

All soft spots to be excavated to competent formation and

back filled with compacted Type 2 granular material.

2. All works to be undertaken in accordance with the

recommendations contained within the geotechnical report

and NHBC Standards. Where trees are present, ground

conditions may require the placing of an additional hardcore

bed under the whole area to overcome the influence of

trees/shrinkable soils in accordance with the NHBC Standards

Chapter 4.2 and 4.5.

3. For depths of sub-base required beneath edge beams refer

to sections.

4. The Insulslab pods have a load bearing requirement and

are protected by a patent. Online technical data and ordering

information can be found on the website www.insulslab.com

5. Slab to be cured under a spray application of curing /

sealing solution, Permaban Pro-Seal or similar.

6. Where ground levels have been adjusted to suit site set-out

requirements, it has been assumed that infill / regrade

material has been suitabilty engineered and consolidated in

order to achieve a minimum ground bearing capacity of

50kN/m2

7. For all general details and sections see drawing No. 100.

8. For on site setting out of units, orientation / handing and

co-ordination, see Architects detail drawings and relevant site

setting out drawings by others.

9. For all finished ground levels and slab levels, see

Architects / Set-out drawings by others.

10. For setting out of all services, drainage and utilities see

Architects and specialists detail drawings.

Specification for Concrete and Fibres.

1. The concrete mix shall follow the recommendations as

noted in the ArcelorMittal Sheffield Ltd. BBA Certification 12 /

4894 product sheet 2 "ArcelorMittal - Insulslab foundation

system for housing applications using SFRC" page 3, Table 1

Concrete Specifications along with the following mix design

guide lines. These are to be considered together and neither

is to be considered complete without the other.

2. Concrete mix design shall be based on the use of 20mm

aggregate. Other aggregate sizes or blends may be used on

further review by ArcelorMittal in conjunction with the

readymix supplier and only formal written confirmation from

ArcelorMittal. The proportions will depend on the gradation of

the local materials.

3. The concrete grade to be a C30 / 37 - C35 with a maximum

water cement ratio of 0.55 using super-plasticiser. All

admixtures used should be from the same manufacturer and

used as per manufacturers instructions.

4. Permitted cement type shall be Portland cement or blends

of up to 20% replacement using GGBS or PFA. This

corresponds to the following cement types to BS EN 197-1:

CEM I, CEM II/A-S OR CEM II/A-V. Minimum cement quantity

WREHNJPñ

5. The slump shall be between 180 and 230mm (S4 type

EN206 / BS8500) at the time of delivery. The addition of

water on site is prohibited, except where the additional water

is allowable water remaining from the original batch target.

Any water added to the concrete shall be recorded on the

delivery ticket.

6. The fines content shall be aproximately 50% by weight of

the total aggregate content. Total fines content shall be

450kg/m3 fines graded at or below 200ȝ Please refer to the

required sieve curve analysis for optimum aggregate

gradation to be used when investigating the suitability of the

given mix.

6WHHOILEUHVWREH+('RVDJHUDWHLVNJPñ

NOTE:

LAYOUT SHOWN IS INDICATIVE AND SUBJECT

TO CONFIRMATION AND CO-ORDINATION WITH

ARCHITECTS DRAWINGS AND SPECIALISTS

LINE LOADS

P1

DM

Preliminary - Costing

00.00.00

BY

To be confirmed.

Extent of any underbuild

Gas regime

TBC

TBC

REV

Gas membrane

Gas Venting

AMENDMENTS

DATE

PRELIMINARY

16. Apply a spray application of curing & sealing membrane

such as Permaban Permaseal or similar approved.

17. Strike the shutter and place aside for re-use.

Foundation Plan

(Housetype Example)

S.O.P Denotes 'Setting Out Point' of Pod Units

375

4120

18. The DPM is then lapped up the outside vertical face of the

toe. The horizontal and inside vertical face of the toe is

painted with two coats of RIW LAC or similar.

19. The vertical insulation is then placed against the outside

face of the toe and backfilled against.

20. The contractor shall record and retain on site, all concrete

mix delivery tickets for onward submission to the statutory

body for their approval.

4120

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

375

www.insulslab.com

3863

NOTE:

Where ground levels have been raised / adjusted,

it is assumed that a suitable engineered material

has been laid and consolidated in order to achieve

a minimum ground bearing pressure 50kN/m 2

3588

See drawing /51 for reinforcement details

Max Pile Load = 360kN

Hatched areas

denotes pour one

of two stage pour see plan & sections

Hatched areas

denote insulslab

pods cut on site

to suit.

THIS DRAWING IS FOR COSTING

PURPOSES ONLY AND MUST NOT

BE USED FOR CONSTRUCTION

FOR CONSTRUCTION DETAIL INFORMATION

CONTACT GHW CONSULTING ENGINEERS Ltd.

New Development

12-2999

Insulslab Foundation Layout

Example Housetype

DM

AW

A1 - 1:25

A3 - 1:50

INS12-0000

AW

Nov 2012

01

P1

THIS DRAWING IS COPYRIGHT AND MUST NOT BE REPRODUCED

WHOLLY OR IN PART WITHOUT PRIOR PERMISSION.

2012. GHW CONSULTING ENGINEERS LTD. / INSULSLAB SIG

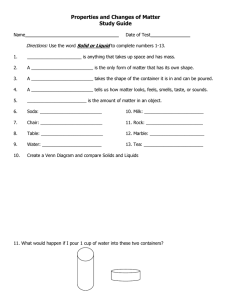

General Notes.

1. For notes refer to drg /01

REINFORCED CONCRETE NOTES

1. FOR CONCRETE NOTES REFER TO GA DRAWING.

2. CONCRETE COVER:

GROUND BEAMS - 30 TOP, SIDES AS SHOWN, 75 BTM

2H16-B

3H16-B

2H12-T

3H16-B

2H12-T

2H16-B

27H10-300 LINKS

COVER TO REINFORCEMENT IS TO BE ACHIEVED AND

MAINTAINED BY USE OF PROPRIETORY ACCESSORIES

IN ACCORDANCE WITH BS 7973.

5. WHERE APPLICABLE, REBAR LAP LENGTHS ARE NOT

TO BE LESS THAN 40 x BAR DIA. WHERE ONE BAR LAPS

WITH ANOTHER OF A DIFFERENT DIAMETER, THEN USE

THE LAP LENGTH FOR THE SMALLER BAR. PREWELDED

MESH LAP LENGTHS ARE TO BE NOT LESS THAN

400mm.

2H16-B

3H16-B

2H12-T

6. CONCRETE SURFACE FINISHES ARE TO BE IN

ACCORDANCE WITH THE SPECIFICATION.

3H16-B

2H12-T

3H16-B

2H12-T

7. LAYER ABBREVIATIONS (WHERE USED)

13H10-300 LINKS

BTM

TOP

B1

B2

T1

T2

NF1

NF2

FF1

FF2

EF

EW

STG

ABR

- BOTTOM FACE

- TOP FACE

- OUTERMOST LAYER IN BTM

- SUBSEQUENT LAYER IN BTM

- OUTERMOST LAYER IN TOP

- SUBSEQUENT LAYER IN TOP

- OUTERMOST LAYER IN NEAR FACE

- SUBSEQUENT LAYER IN NEAR FACE

- OUTERMOST LAYER IN FAR FACE

- SUBSEQUENT LAYER IN FAR FACE

- EACH FACE

- EACH WAY

- STAGGERED

- ALTERNATE BARS REVERSED

27H10-300 LINKS

3H16-B

2H12-T

09. THIS DRAWING IS TO BE READ IN CONJUNCTION

WITH GHW Drg. No. 01, IN ADDITION TO OTHER

DRAWINGS REFERENCED THEREIN.

2H16-B

3H16-B

2H12-T

3H16-B

2H12-T

27H10-300 LINKS

2H16-B

8. REBARS TO BE PRE-FIXED BY THE DRAWING

NUMBER.

10. REINFORCEMENT NOMENCLATURE:

5H40-01-150-T1 ABR

COMMENT

LOCATION OF BARS

BAR CENTRES (mm)

BAR MARK

BAR DIAMETER (mm)

TYPE OF STEEL

NUMBER OF BARS

27H10-300 LINKS

3H16-B

2H12-T

12H10-300 LINKS

3H16-B

2H12-T

3H16-B

2H12-T

NOTE:

LAYOUT SHOWN IS INDICATIVE AND SUBJECT

TO CONFIRMATION AND CO-ORDINATION WITH

ARCHITECTS DRAWINGS AND SPECIALISTS

LINE LOADS

P1

DM

Preliminary - Costing

00.00.00

REV

BY

2H16-B

AMENDMENTS

DATE

2H16-B

3H16-B

2H12-T

27H10-300 LINKS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

50

H12

H12

H10

H12

H10 Lin

Link

k

75

REMOVE LIP

ON PODS

ADJACENT

BEAMS

75 MIN

H12

REMOVE LIP

ON PODS

ADJACENT

BEAMS

75

75 MIN COVER

75 MIN COVER

LINK POSITIONED

CENTRALLY ON

BEAM

30

www.insulslab.com

LINK POSITIONED

50 OFF TOE FACE

30

3H16-B

2H12-T

2H16-B

PRELIMINARY

No. OFF AND SIZE OF BARS TO BTM

OF BEAMS VARIES - REFER TO PLAN

Typical Edge

Beam Section

Typical Internal

Beam Section

Scale 1:10

Scale 1:10

NOTE:

Where ground levels have been raised / adjusted,

it is assumed that a suitable engineered material

has been laid and consolidated in order to achieve

a minimum ground bearing pressure 50kN/m 2

Hatched areas

denotes pour one

of two stage pour see plan & sections

Hatched areas

denote insulslab

pods cut on site

to suit.

THIS DRAWING IS FOR COSTING

PURPOSES ONLY AND MUST NOT

BE USED FOR CONSTRUCTION

FOR CONSTRUCTION DETAIL INFORMATION

CONTACT GHW CONSULTING ENGINEERS Ltd.

New Development

12-2999

Reinforcement details for

Example Housetype

DM

AW

A1 - 1:25

A3 - 1:50

INS12-0000

AW

Nov 2012

51

P1

75 MIN / 150 MAX SIDE

COVER TO Z BAR

H12 'Z' BARS AT 250crs MAX. PUSHED INTO FIRST POUR.

CONTRACTOR TO ENSURE STABILITY DURING CONSTRUCTION

30-50 COVER

SLAB LEVEL

100

SLAB

225

POUR 2

75 MIN

CAVITY INSULATION

AND DPC IN

ACCORDANCE WITH

ARCH DETAILS

TEMPORARY BLOCK TO

ENSURE CORRECT COVER

300

BEAM

LOWER SECTION OF

BEAM CAST FIRST

INSULSLAB 'HYRIB' STANDARD OR

EXTENDED BEAM CLOSER FIXED

ACROSS FACE OF INTERNAL BEAMS /

RIBS TO CONTAIN FIRST STAGE POUR

50

50 INSULSLAB

CB INSULATION

225

POUR 1

INSULSLAB POD

ROCKER PIPE IN

ACCORDANCE WITH

NHBC GUIDELINES

50 MIN

100

MIN

250

VARIES - SEE PLAN

75

OPTIONALLY INSTALL 225 HARDCORE

TO BUILDING FOOTPRINT

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

1050 FOR FULL POD

TYPICAL EDGE DETAIL AT SERVICE ENTRY POINTS

(SECTION 1)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

150

225 MIN

TO EDGE

BEAM

150 COMPACTED SUB-BASE WITH BLINDED

CLOSED SURFACE AT MEMBRANE

150

2 COATS OF RIW LAC

OR SIMILAR 3RD PARTY

ACCREDITED LIQUID

DPM INSTALLED AS PER

MANUFACTUERS

RECOMMENDATIONS

DPM

TUCKED

INTO

FIRST

POUR

TYPICAL EDGE DETAIL

INS 12-0

200

P1

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

DPM DETAIL (WHERE GAS

MEMBRANE REFER TO

PLOT SPECIFIC DRGS)

75 MIN / 150 MAX SIDE

COVER TO Z BAR

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

50 INSULSLAB

CB INSULATION

350

POD

INSULSLAB POD

LOWER SECTION OF

BEAM CAST FIRST

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

150

225

POUR 1

TO SUIT SITE LEVELS

POUR 2

100

SLAB

H12 'Z' BARS AT 250crs MAX. CONTRACTOR TO

ENSURE STABILITY DURING CONSTRUCTION

225 MIN

TO EDGE

BEAM

100 INSULSLAB

ACD INSULATION

100 INSULSLAB ACD

HORIZONTAL EDGE

INSULATION

250

100 MIN

VARIES - SEE PLAN

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

(SECTION 3 - ALSO REFER TO /102)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

TYPICAL EDGE DETAIL

AT DEEPENED EDGE

BEAM/UNDERBUILD

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

202

P1

MONAFLOOR BRIDGESTOP

SYSTEM, INSTALLED IN

ACCORDANCE WITH

MANUFACTURERS DETAILS

INSULSLAB

POD

150

INSULSLAB

POD

350

BEAM

100

SLAB

SLAB LEVEL

100

MIN

100 INSULSLAB ACD

HORIZONTAL EDGE

INSULATION

100

MIN

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

TYPICAL DETAIL AT INTERNAL/PARTY WALLS

(SECTION 5)

TYPICAL DETAIL AT

INTERNAL/PARTY LOAD

BEARING WALLS

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

203

P1

MONAFLOOR BRIDGESTOP

SYSTEM, INSTALLED IN

ACCORDANCE WITH

MANUFACTURERS DETAILS

AS PLAN

100

SLAB

SLAB LEVEL

INSULSLAB

POD

150

INSULSLAB

POD

350

BEAM

DAY JOINT

LOWER SECTION OF

BEAM CAST FIRST

100 INSULSLAB

ACD INSULATION

100 MIN

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

100 MIN

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL DETAIL AT CHANGE IN

SLAB LEVEL AT PARTY WALLS

(SECTION 6)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

CHANGE IN SLAB LEVEL

AT PARTY WALL BEAMS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

204

P1

100

SLAB

OPTIONAL DAY JOINT

BEAM

CAST GARAGE FLOOR LEVEL

PRIOR TO MAIN HOUSE

TEMP BARS FIXED INTO STAGE 1

POUR AT 450crs TO PROVIDE

RESTRAINT TO FORMER. CUT DOWN

TO FFL FOLLOWING CONSTRUCTION

SLAB LEVEL

AS PLAN

INSULSLAB

POD

350

POD

INSULSLAB

POD

LOWER SECTION OF

BEAM CAST FIRST

150

SLAB

TIMBER FORMER TIED TO

REINFORCEMENT TO FORM

STEP IN SLAB TO REMAIN TRUE

AND ALLIGNED AT ALL TIMES

100 INSULSLAB

ACD INSULATION

100 MIN

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

100 MIN

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL DETAIL AT CHANGE IN SLAB

LEVEL TO GARAGE - 150 STEP MAX

(SECTION 7)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

TYPICAL CHANGE IN

SLAB LEVEL ADJACENT

GARAGE

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

205

P1

SPACING

INSULSLAB

POD

75 MIN TYPE 1

SLAB LEVEL

TYPICAL VIBRO PLAN

75 COMPACTED SUB-BASE WITH

BLINDED CLOSED SURFACE AT

MEMBRANE ON VIBRO PILING MAT

OR ENG. FILL DESIGNED BY OTHERS

PILING MAT/

ENGINEERED

GROUND

2000 MAX

9,%5272%(,167$//('72N1Pð81'(5

EXTERNAL AND INTERNAL BEAMS ONLY. SLAB

IS DESIGNED TO SPAN BETWEEN BEAMS.

DETAIL SHOWING REDUCED HARDCORE

ON VIBRO OR ENGINEERED GROUND

TYPICAL EDGE DETAIL

FOR VIBRO OR

ENGINEERED FILL SITES

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

210

P1

125 TO PILE

TYPICAL

150 MAX DUCT

THROUGH EDGE BEAMS

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

PILE REINFORCEMENT TO BE

RETAINED TO ACHIEVE FULL

ANCHORAGE LENGTH INTO PILE CAP

100

SLAB

SLAB LEVEL

225

POUR 2

INSULSLAB 'HYRIB' STANDARD OR

EXTENDED BEAM CLOSER FIXED

ACROSS FACE OF INTERNAL BEAMS /

RIBS TO CONTAIN FIRST STAGE POUR

ROCKER PIPE IN

ACCORDANCE WITH

NHBC GUIDELINES

50 MIN

100 MIN

250

VARIES - SEE PLAN

75 MIN COMPACTED SUB-BASE

WITH BLINDED CLOSED SURFACE

AT MEMBRANE ON PILING MAT

DESIGNED BY OTHERS

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

1050 FOR FULL POD

TYPICAL EDGE DETAIL AT SERVICE ENTRY POINTS

(SECTION 1)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

75 50

225

POUR 1

225 MIN

TO EDGE

BEAM

50 INSULSLAB

CB INSULATION

LOWER SECTION OF

BEAM CAST FIRST

300

BEAM

INSULSLAB POD

150

2 COATS OF RIW LAC

OR SIMILAR 3RD PARTY

ACCREDITED LIQUID

DPM INSTALLED AS PER

MANUFACTUERS

RECOMMENDATIONS

PILING MAT

75 MIN

REFER SEPARATE DRG FOR

REINFORCEMENT DETAILS

DPM

TUCKED

INTO

FIRST

POUR

TYPICAL EDGE DETAIL

INS 12-0

220

P1

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

DPM DETAIL (WHERE GAS

MEMBRANE REFER TO

PLOT SPECIFIC DRGS)

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

225 MIN

TO EDGE

BEAM

50 INSULSLAB

CB INSULATION

350

POD

INSULSLAB POD

LOWER SECTION OF

BEAM CAST FIRST

100 INSULSLAB ACD

HORIZONTAL EDGE

INSULATION

250

75

225

POUR 1

TO SUIT SITE LEVELS

POUR 2

100

SLAB

REFER SEPARATE DRG FOR

REINFORCEMENT DETAILS

100 INSULSLAB

ACD INSULATION

75 MIN COMPACTED SUB-BASE

WITH BLINDED CLOSED SURFACE

AT MEMBRANE ON PILING MAT

DESIGNED BY OTHERS

100 MIN

VARIES - SEE PLAN

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

(SECTION 3 - ALSO REFER /103)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

TYPICAL EDGE DETAIL

AT DEEPENED EDGE

BEAM/UNDERBUILD

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

222

P1

MONAFLOOR BRIDGESTOP

SYSTEM, INSTALLED IN

ACCORDANCE WITH

MANUFACTURERS DETAILS

INSULSLAB

POD

100 MIN

INSULSLAB

POD

350

BEAM

100

SLAB

SLAB LEVEL

100 MIN

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL DETAIL AT INTERNAL/PARTY WALLS

(SECTION 5)

TYPICAL DETAIL AT

INTERNAL/PARTY LOAD

BEARING WALLS

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

223

P1

MONAFLOOR BRIDGESTOP

SYSTEM, INSTALLED IN

ACCORDANCE WITH

MANUFACTURERS DETAILS

IF DAY JOINT REQUIRED

USE H12 'Z' BARS AT 250crs

MAX. CONTRACTOR TO

ENSURE STABILITY

DURING CONSTRUCTION

AS PLAN

100

SLAB

SLAB LEVEL

100 MIN

LOWER SECTION OF

BEAM CAST FIRST

100 INSULSLAB

ACD INSULATION

100 MIN

PILING MAT

INSULSLAB

POD

75

INSULSLAB

POD

350

BEAM

DAY JOINT

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL DETAIL AT CHANGE IN

SLAB LEVEL AT PARTY WALLS

(SECTION 6)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

CHANGE IN SLAB LEVEL

AT PARTY WALL BEAMS

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

224

P1

100

SLAB

LOWER SECTION OF

BEAM CAST FIRST

75

INSULSLAB

POD

350

POD

INSULSLAB

POD

100 INSULSLAB

ACD INSULATION

100 MIN

100 MIN

PILING MAT

CAST GARAGE FLOOR LEVEL

PRIOR TO MAIN HOUSE

TEMP BARS FIXED INTO STAGE 1

POUR AT 450crs TO PROVIDE

RESTRAINT TO FORMER. CUT DOWN

TO FFL FOLLOWING CONSTRUCTION

SLAB LEVEL

AS PLAN

TIMBER FORMER TIED TO

REINFORCEMENT TO FORM

STEP IN SLAB TO REMAIN TRUE

AND ALLIGNED AT ALL TIMES

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL DETAIL AT CHANGE IN SLAB

LEVEL TO GARAGE - 150 STEP MAX

(SECTION 7)

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

TYPICAL CHANGE IN

SLAB LEVEL ADJACENT

GARAGE

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

225

P1

75 MIN / 150 MAX SIDE

COVER TO Z BAR

H12 'Z' BARS AT 250crs MAX. CONTRACTOR TO

ENSURE STABILITY DURING CONSTRUCTION

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

100

SLAB

450dp MAIN SLAB

POUR 3

WALL TIES AT 900crs

HORIZONTAL AND 450crs

VERTICAL (TYPE TBC BY

PROJECT ENGINEER) TO

BE SHOT FIRED WITH

HILTI DS-27 OR FIXED

USING HPS-1R 6/25x50

HAMMER SCREW

FIXINGS OR SIMILAR

APPROVED TO SFRC.

TEMPORARY BLOCK TO TOP OF

POD TO ENSURE CORRECT COVER

5

INSULSLAB POD

DETAIL BETWEEN POURS

TO SUIT SITE LEVELS

POUR 2

150

CONST JOINT

CONST

JOINTS AS

REQUIRED

1

100 INSULSLAB ACD INSULATION

4

CONST JOINT

1. INSTALL TEMPORARY FORMWORK

2. BACKFILL WITH GEN0 LEAN MIX

3. CAST POUR 1 IN SFRC

4. CAST POUR 2 IN SFRC

5. CAST MAIN SLAB IN SFRC

LEAN MIX CONCRETE TO

FORM SHUTTER TO

INSULATION/DOWNSTAND

3

225

POUR 1

50 INSULSLAB

CB INSULATION

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

TEMPORARY FORMWORK

2

225 MIN

TO EDGE

BEAM

ROUGH TAMP

FINISH BETWEEN

POURS

DAY

JOINT

350

POD

2 COATS OF RIW LAC

OR SIMILAR 3RD PARTY

ACCREDITED LIQUID

DPM INSTALLED AS PER

MANUFACTUERS

RECOMMENDATIONS

250 MINIMUM

EMBEDMENT

OF H12 TIE

BAR INTO

EACH POUR

30-50 COVER

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

250

VARIES - SEE PLAN

TYPICAL RAFT DETAILS

AT UNDERBUILD

100

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

OPTION 1

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

240

P1

75 MIN / 150 MAX SIDE

COVER TO U BAR

WALL TIES

AS OPTION 1

250 MINIMUM

EMBEDMENT

OF H12 TIE

BAR INTO

EACH POUR

100

SLAB

30-50 COVER

ROUGH TAMP

FINISH BETWEEN

POURS

5

DAY

JOINT

350

POD

TEMPORARY BLOCK TO TOP OF

POD TO ENSURE CORRECT COVER

POUR 3

450dp MAIN SLAB

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

INSULSLAB POD

DETAIL BETWEEN POURS

TO SUIT SITE LEVELS

POUR 2

150

CONST JOINT

100 INSULSLAB

ACD INSULATION

4

2

225

POUR 1

3

SUITABLE WELL COMPACTED

BACKFILL TO WORKING SPACE

10N BLOCKWORK WITH

MORTAR DESIGNATION

(iii) TO PROVIDE

TEMPORARY SHUTTER

CONST JOINT

1

1. CAST POUR 1 IN SFRC

2. BUILD BLOCKWORK OR SIMILAR

SUIT POUR 2 HEIGHT AND INSTALL

INSULATION

3. BACKFILL WITH SUITABLE WELL

COMPACTED FILL

4. CAST POUR 2 IN SFRC

5. CAST MAIN SLAB IN SFRC

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

225 MIN

TO EDGE

BEAM

50 INSULSLAB

CB INSULATION

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

2

TYPICAL RAFT DETAILS

AT UNDERBUILD

OPTION 2

250

VARIES - SEE PLAN

50

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

OPTION 2

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

241

P1

75 MIN / 150 MAX SIDE

COVER TO Z BAR

H12 'Z' BARS AT 250crs MAX. CONTRACTOR TO

ENSURE STABILITY DURING CONSTRUCTION

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

WALL TIES AT 900crs

HORIZONTAL AND 450crs

VERTICAL (TYPE TBC BY

PROJECT ENGINEER) TO

BE SHOT FIRED WITH

HILTI DS-27 OR FIXED

USING HPS-1R 6/25x50

HAMMER SCREW

FIXINGS OR SIMILAR

APPROVED TO SFRC.

100

SLAB

30-50 COVER

INSULSLAB POD

DAY

JOINT

350

POD

5

DETAIL BETWEEN POURS

TO SUIT SITE LEVELS

POUR 2

150

CONST JOINT

CONST

JOINTS AS

REQUIRED

1

100 INSULSLAB ACD INSULATION

4

CONST JOINT

1. INSTALL TEMPORARY FORMWORK

2. BACKFILL WITH GEN0 LEAN MIX

3. CAST POUR 1 IN SFRC

4. CAST POUR 2 IN SFRC

5. CAST MAIN SLAB IN SFRC

LEAN MIX CONCRETE TO

FORM SHUTTER TO

INSULATION/DOWNSTAND

3

225

POUR 1

50 INSULSLAB

CB INSULATION

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

TEMPORARY FORMWORK

2

225 MIN

TO EDGE

BEAM

ROUGH TAMP

FINISH BETWEEN

POURS

TEMPORARY BLOCK TO TOP OF

POD TO ENSURE CORRECT COVER

POUR 3

450dp MAIN SLAB

2 COATS OF RIW LAC

OR SIMILAR 3RD PARTY

ACCREDITED LIQUID

DPM INSTALLED AS PER

MANUFACTUERS

RECOMMENDATIONS

250 MINIMUM

EMBEDMENT

OF H12 TIE

BAR INTO

EACH POUR

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

100 INSULSLAB ACD

HORIZONTAL EDGE INSULATION

TYPICAL PILE DETAILS

AT UNDERBUILD

OPTION 1

250

VARIES - SEE PLAN

100

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

OPTION 1

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

242

P1

75 MIN / 150 MAX SIDE

COVER TO U BAR

CAVITY INSULATION AND

DPC IN ACCORDANCE

WITH ARCH DETAILS

100

SLAB

30-50 COVER

450dp MAIN SLAB

POUR 3

ROUGH TAMP

FINISH BETWEEN

POURS

5

350

POD

TEMPORARY BLOCK TO TOP OF

POD TO ENSURE CORRECT COVER

DAY

JOINT

INSULSLAB POD

DETAIL BETWEEN POURS

CONST JOINT

TO SUIT SITE LEVELS

POUR 2

150

WALL TIES

AS OPTION 1

250 MINIMUM

EMBEDMENT

OF H12 TIE

BAR INTO

EACH POUR

100 INSULSLAB

ACD INSULATION

4

2

225

POUR 1

3

SUITABLE WELL COMPACTED

BACKFILL TO WORKING SPACE

10N BLOCKWORK WITH

MORTAR DESIGNATION

(iii) TO PROVIDE

TEMPORARY SHUTTER

CONST JOINT

1

1. CAST POUR 1 IN SFRC

2. BUILD BLOCKWORK OR SIMILAR TO

SUIT POUR 2 HEIGHT AND INSTALL

INSULATION

3. BACKFILL WITH SUITABLE WELL

COMPACTED FILL

4. CAST POUR 2 IN SFRC

5. CAST MAIN SLAB IN SFRC

HATCHED AREAS

DENOTES POUR ONE

OF TWO STAGE POUR SEE PLAN & SECTIONS

225 MIN

TO EDGE

BEAM

50 INSULSLAB

CB INSULATION

150 COMPACTED SUB-BASE

WITH BLINDED CLOSED

SURFACE AT MEMBRANE

2

R

F

P

TYPICAL PILE DETAILS

AT UNDERBUILD

OPTION 2

250

VARIES - SEE PLAN

50

TYPICAL EDGE DETAIL AT DEEPENED EDGE BEAM

OPTION 2

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

243

P1

THIS DRAWING IS COPYRIGHT AND MUST NOT BE REPRODUCED

WHOLLY OR IN PART WITHOUT PRIOR PERMISSION.

2012. GHW CONSULTING ENGINEERS LTD. / INSULSLAB SIG

225

300

450

100

Slab Level

225

250

Cellcore HX S

grade 13/18

under slab.

Plasticity Depth

90

Low

Medium 160

225

High

100

100

100

Cellcore HX B

grade 13/18 under

edge beams.

Plasticity Depth

Low

85

Medium

155

High

220

Typical Edge Detail Two Stage Pour

100 Insulslab ACD

horizontal insulation

Cellcore HX B

grade 13/18 under

internal beams.

Plasticity Depth

Low

85

Medium

155

High

220

50

100 Insulslab ACD

horizontal insulation

Slab Level

Typical Internal Beam Detail

TYPICAL DETAIL OF

VOID FORMER UNDER

INSULSLAB PILED

FOUNDATION

Insulslab Technical.

Tel: 0121 781 7379

e-mail: insulslab@ghwconsulting.co.uk

Insulslab Sales.

Tel: 0844 5766 726

e-mail: sales@insulslab.com

www.insulslab.com

INS 12-0

244

P1