ANCHOR SYSTEMS

advertisement

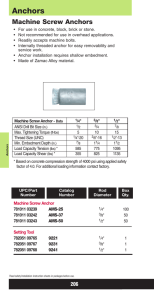

AN-00 AN-00 ANCHOR SYSTEMS Product & Application Guide Home Office B-Line Systems, Inc. 509 W. Monroe St. Highland, IL 62249-0326 618-654-2184 618-654-1917 Fax Regional Distritution Centers B-Line Systems, Inc. 6655 Corners Industrial Court Norcross, GA 30092-3604 Additional B-Line Facilities B-Line Systems, Inc. 2017 25th Avenue Franklin Park, IL 60131-3592 B-Line Systems, Inc. 13755 Stead Blvd. Reno, NV 89506-0260 B-Line Systems, Inc. 21000 East 32nd Parkway Aurora, CO 80011 B-Line Systems, Inc. 4900 Marshall Street Sherman, TX 75090-2076 B-Line Systems, Canada 2149 Winston Park Drive Oakville, Ontario L6H 6J8 Please visit our websit at w w w.b-line.com SYSTEMS THAT MAKE SENSE 15300 Printed in U.S.A. ©2000 B-Line Systems, Inc. ® ELECTRICAL TELECOMMUNICATIONS MECHANICAL SYSTEMS THAT MAKE SENSE INDEX INTRODUCTION Catalog Number Series B-Line Systems Inc. is a leading manufacturer and fabricator of steel and aluminum products which are used in support equipment for industrial, commercial, utility and OEM installations. B-Line is proud of the exacting standards of research, design, engineering and manufacturing that go into each and every product. With the introduction of anchors, our customers have access to the most complete support system offered including; strut systems, cable tray, pipe hangers, vibration control devices, slotted angle, spring steel fasteners and fiberglass strut and cable tray. Many B-Line products are listed by Underwriters Laboratories, Inc. and approved by Factory Mutual Laboratories. All B-Line products are manufactured to meet or exceed industry standards set for their design and manufacturing. This catalog is designed to be helpful to contractors in the application and selection of anchors and support products for construction and manufacture. If a unique application requires a special product not included in this catalog, B-Line engineering personnel are ready to furnish design consultation and realistic cost estimates. In addition, sales representatives with engineering know-how are located throughout the United States and abroad for your convenience. ACS Page ..................................................................... 14 & 15 ADE .......................................................................... ADI ............................................................................ 11 8 ADN .......................................................................... 22 AHD .......................................................................... 28 AHW .................................................................... 26 & 27 AJC-RH & AJC-WH ............................................................ 19 AJN-RH & AJN-WH ........................................................... 20 AJS-RH & AJS-WH ............................................................ 19 AJT-RH & AJT-WH ............................................................ 20 ........................................................... 19 ALA .......................................................................... 13 ALS ........................................................................... 12 AJW-RH & AJW-WH AMS ........................................................................... ANN .......................................................................... 23 APC .......................................................................... 32 APD .......................................................................... 30 APS ........................................................................... 31 APT ........................................................................... 29 ARC-RH & ARC-SW ARS-RH & ARS-SW ........................................................... 16 ............................................................ 17 ARW-RH & ARW-SW ASA 9 .......................................................... ....................................................................... 18 6&7 ASB ........................................................................... 21 ASE ........................................................................... 10 ATB ........................................................................... 24 ATH .......................................................................... 25 AWA ....................................................................... AZD .......................................................................... 4&5 30 CATALOG NUMBERING SYSTEM ASA - 50 - 225 HN Prefix ACS - Concrete Screw ADE - Double Expansion ADI - Drop-In ADN - Drive Nail AHD - Hollow Wall Drive-In AHW - Hollow Wall AJC - Jr. Rapid Rod™-Concrete AJN - Jr. Rapid Rod™-Drive Nail AJS - Jr. Rapid Rod™-Steel AJT - Jr. Rapid Rod™-Toggles AJW - Jr. Rapid Rod™-Wood ALA - Lead Anchor ALS - Lag Shield AMS - Machine Screw ANN - Nylon Nail-In APC - Conical Anchors APD - Plastic Walldriller® APS - Plastic Screw APT - Plastic Toggle ARC - Rapid Rod™-Concrete ARS - Rapid Rod™-Steel ARW - Rapid Rod™-Wood ASA - Sleeve Anchor ASB - Split Bolt ASE - Single Expansion ATB - Toggle Bolt AWA - Wedge Anchor AZD - Zinc Walldriller® Screw Diameter Length Suffix 4 #4 50 1/2 F - Flat 6 #6 62 5/8 H - Hex 8 #8 75 3/4 L - Long 10 #10 87 7/8 K - Kit 12 1/8 100 1 18 3/16 125 11/4 R - Round 25 1/4 137 13/8 S - Short 31 5/16 150 11/2 T - Tool 37 3/8 162 15/8 AN - Acorn Nut 50 1/2 175 13/4 FQ - Flat Quadrex 62 5/8 187 17/8 G5 - Grade 5 75 3/4 200 2 HN - Hex Nut 87 7/8 225 21/4 RH - Rod Hanger 100 1 250 21/2 RQ - Round Quadrex 125 11/4 275 23/4 SL - Short Long 150 11/2 300 3 M - Mushroom WH - Wire Hanger XL - Extra Long XS - Extra Short Note: The Rapid Rod™ and Jr. Rapid Rod™ numbering systems has been revised and do not follow the screw diameter and length information shown in the above chart. Refer to pages 16 -20. 1 TABLE OF CONTENTS Description Description Page Wedge Anchors AWA Series .......................... Page Expansion Anchors, Double ADE Series 4&5 ............................. Sleeve Anchors ASA Series .......................... Lag Shields ALS Series 6&7 .............................. 8 Machine Screw Anchors AMS Series 12 ............................. 13 Concrete Screw ACS Series ............................... 9 Expansion Anchors, Single ASE Series ............................. ............................. Lead Anchors ALA Series Drop-In Anchors ADI Series 2 11 10 ...................... 14 & 15 Rapid Rod™ Hangers ARC, ARW, ARS, AJC, AJN, AJS, AJT & AJW Series & Accessories . . . . . . . . . . . . . . . . . . . . . . . 16 - 20 TABLE OF CONTENTS Description Page Page Hollow Wall Anchors AHW Series Split Bolt Anchors ASB Series ............................. Description 21 ....................... 26 & 27 Hollow Wall Drive-In Anchors AHD Series Drive Nail Anchors ADN Series ............................. ............................. 22 ............................. Plastic Toggles APT Series ............................. Nylon Nail-In Anchors ANN Series 23 ............................. 30 Plastic Screw Anchors APS Series 24 Toggle Heads ATH Series ............................. 29 Walldriller® APZ & AZD Series ............................. Toggle Bolts ATB Series 28 ............................. 31 Conical Anchors 25 ............................. 32 3 WEDGE ANCHORS Features ® • • • • For use in concrete, stone No layout or hole spotting required Heavy-duty anchor All wedge anchors are supplied with stainless steel clips for long lasting installations • Available in zinc plated steel or stainless steel • Special sizes also available • Grade 5, mechanically galvanized steel and 316 stainless steel also available Loading Data Anchor Size Grade 2 & Grade 5 with Minimum Embedment Minimum Allowable Allowable Embedment Pull-out Shear Depth Load* Load* in. mm 1/4”-20 11/8” lbs. kN 3/8”-16 13/4” 1/2”-13 (28.6) 470 (1.8) 385 (38.1) 1090 (3.0) 1280 21/4” (57.1) 1535 (5.1) 5/8”-11 23/4” (69.8) 2117 3/4”-10 33/8” (82.6) 7/8”-9 4” 1”-8 41/2” 11/4”-7 51/2” *Tested in 4,500 Psi in. mm (1.3) 3” (3.7) 25/8” 2090 (8.0) (8.6) 2687 3175 (14.3) (101.6) 4687 (114.3) 5750 (139.7) (28MPa) 8750 lbs. kN (76.2) 903 (3.9) (66.8) 1490 (6.5) 31/2” (88.9) 2917 (12.8) (14.8) 43/8” (111.1) 3975 (17.5) 5437 (23.9) 51/2” (139.7) 4875 (21.4) (20.8) 7500 (33.0) 51/2” (139.7) 6000 (26.4) (25.5) 9825 (43.2) 6” (152.4) 7200 (31.7) (69.8) 61/4” (158.8) 10900 (47.9) (38.5) lbs. 15875 kN Grade 5 with Deep Embedment Deep Allowable Embedment Pull-out Depth Load* concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole deeper than bolt embedment (min 4.5 dia.). Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Add washer and thread nut flush with top of bolt. Drive bolt into hole through item to be fastened. 4. To set, hand tighten nut and then tighten three or four turns with wrench. Conforms to Federal Specifications FF-S-325, Group II, Type 4, Class 1 for concrete expansion shields. See ICBO report #2350 for allowable tension and shear loads. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 4 WEDGE ANCHORS Catalog Number Thread Size AWA-25-200WH AWA-25-175 AWA-25-225 AWA-25-325 AWA-37-225 AWA-37-275 AWA-37-300 AWA-37-375 AWA-37-500 AWA-50-275 AWA-50-375 AWA-50-425 AWA-50-550 AWA-50-700 AWA-62-350 AWA-62-450 AWA-62-500 AWA-62-600 AWA-62-700 AWA-62-850 AWA-75-425 AWA-75-475 AWA-75-550 AWA-75-625 AWA-75-700 AWA-75-850 AWA-75-1000 AWA-87-600 AWA-87-800 AWA-87-1000 AWA-100-600 AWA-100-900 AWA-100-1200 AWA-125-900 AWA-125-1200 AWA-25-175SS AWA-25-225SS AWA-25-325SS AWA-37-225SS AWA-37-275SS AWA-37-300SS AWA-37-375SS AWA-37-500SS AWA-50-275SS AWA-50-375SS AWA-50-425SS 1/4"-20 Overall Length Stainless Steel Grade 2- Zinc Plated in. 1/4"-20 1/4"-20 1/4"-20 3/8"-16 3/8"-16 3/8"-16 3/8"-16 3/8"-16 1/2"-13 1/2"-13 1/2"-13 1/2"-13 1/2"-13 5/8"-11 5/8"-11 5/8"-11 5/8"-11 5/8"-11 5/8"-11 3/4"-10 3/4"-10 3/4"-10 3/4"-10 3/4"-10 3/4"-10 3/4"-10 7/8”-9 7/8”-9 7/8”-9 1”-8 1”-8 1”-8 11/4"-7 11/4"-7 1/4"-20 1/4"-20 1/4"-20 3/8"-16 3/8"-16 3/8"-16 3/8"-16 3/8"-16 1/2”-13 1/2”-13 1/2”-13 2" 13/4" 21/4" 31/4" 21/4" 23/4" 3" 33/4" 5" 23/4" 33/4" 41/4" 51/2" 7" 31/2" 41/2" 5" 6" 7" 81/2" 41/4" 43/4" 51/2" 61/4" 7" 81/2" 10” 6" 8" 10" 6" 9" 12" 9" 12" 13/4" 21/4" 31/4" 21/4" 23/4" 3" 33/4" 5" 23/4" 33/4" 41/4" Max. Mat'l. Thickness to be Anchored Minimum Embedment Depth Drill Hole Diameter mm in. mm in. (51) 9/32" (7) 11/8" (44) 3/8" (9) (57) 7/8" (22) (82) 17/8" 3/8" 7/8" 11/8" 17/8" 31/8" 1/8" 1" 11/2" 23/4" 41/4" 1/8" 7/8" 15/8" 25/8" 35/8" 51/8" 1/4" 3/4" 11/2" 21/4" 3" 41/2" 6" (47) 1/4” (6) (9) 3/8” (10) 3/8” (10) 3/8” (10) (47) 3/8” (10) (79) 3/8” (10) (3) 1/2” (13) (25) 1/2” (13) 1/2” (13) (13) (108) 1/2” 1/2” (3) 5/8” (16) (22) 5/8” (16) (41) 5/8” (16) 5/8” (16) (92) 5/8” (16) (130) 5/8” (16) (6) 3/4” (19) (19) 3/4” (19) (22) 3/4” (19) 3/4” (19) (66) 3/4” (19) (92) 3/4” (19) (130) 3/4” (19) (35) 7/8” (19) 7/8” (22) (136) 7/8” (22) (13) 1” 1” 1” 11/4” 11/4” 1/4” 1/4” 1/4” 3/8” 3/8” 3/8” 3/8” 3/8” 1/2” 1/2” 1/2” (25) (57) (70) (76) (95) (127) (70) (95) (108) (140) (178) (89) (114) (127) (152) (178) (216) (108) (120) (140) (159) (178) (216) (254) (152) (203) (254) (152) (228) (305) (228) (305) (44) (57) (82) (57) (70) (76) (95) (127) (70) 13/8" 4" 53/8" 1/2" 31/2" 61/2" 21/4" 51/4" 3/8" 7/8" 17/8" 3/8" 11/8" 11/8" 17/8" 31/8" 1/8" 11/8" mm in. mm (28) 1/4” (6) 1/4” (6) 1/4” (6) (28) (22) (28) (38) 11/2" 21/4" (38) (57) (70) (66) (41) (101) (89) 23/4" 31/4" 4 41/2" (70) (82) (102) (114) (165) (57) (133) 51/2" (140) 11/8" (28) (9) (22) (47) (9) (28) (28) 11/2" (38) (47) (79) (3) (95) 1" (25) (108) 11/2" (38) 21/4" (57) AWA-25-200WH Wire Hanger Anchor (13) (25) (25) (32) (32) (6) (6) (6) (9) (9) (9) (9) (9) (13) (13) (13) Note: Additional stainless steel sizes are available upon request. UL Listed and FM Approved for 3/8”-16 - 3/4”-10 thread sizes. 5 SLEEVE ANCHORS Features • • • • • • For use in concrete, block, brick, stone One piece assembly No layout or hole spotting required Available in zinc plated steel or 304 stainless steel Extenders for extra length Head styles available: acorn, hex nut, flat head, round head, wire hanger and rod hanger ® Type Catalog Number Size Body Dia. x Length in. ASA-25-62AN ASA-25-137AN* ASA-25-225AN* ASA-31-150HN* ASA-31-250HN* ASA-37-187HN* ASA-37-300HN* ASA-50-225HN* Hex ASA-50-300HN* Nut ASA-50-400HN ASA-50-600HN ASA-62-225HN ASA-62-300HN ASA-62-425HN ASA-62-600HN ASA-75-250HN ASA-75-425HN ASA-75-625HN ASA-25-150FQ ASA-25-225FQ ASA-25-312FQ ASA-25-400FQ Flat ASA-31-250FQ Quadrex† ASA-31-350FQ ASA-37-275FQ ASA-37-400FQ ASA-37-500FQ ASA-37-600FQ ASA-25-125RQ ASA-25-200RQ Round ASA-25-275RQ Quadrex† ASA-37-250RQ ASA-37-375RQ ASA-37-475RQ Wire Hanger ASA-31-175WH ASA-37-187RH37 †† Rod ASA-50-225RH37 †† Hanger ASA-62-225RH50 ††† Acorn Nut 1/4” 5/8” x x 13/8” 1/4” x 21/4” 5/16” x 11/2” 5/16” x 21/2” 3/8” x 17/8” 3/8” x 3” 1/2” x 21/4” 1/2” x 3” 1/2” x 4” 1/2” x 6” 5/8” x 21/4” 5/8” x 3” 5/8” x 41/4” 5/8” x 6” 3/4” x 21/2” 3/4” x 41/4” 3/4” x 61/4” 1/4” x 11/2” 1/4” x 21/4” 1/4” x 31/8” 1/4” x 4” 5/16” x 21/2” 5/16” x 31/2” 3/8” x 23/4” 3/8” x 4” 3/8” x 5” 3/8” x 6” 1/4” x 11/4” 1/4” x 2” 1/4” x 23/4” 3/8” x 21/2” 3/8” x 33/4” 3/8” x 43/4” 5/16” x 13/4” 3/8” x 17/8” 1/2” x 21/4” 5/8” x 21/4” 1/4” Thread Size Drill/Hole Diameter mm in. mm (6 x 16) #10-24 #10-24 #10-24 1/4”-20 1/4”-20 5/16”-18 5/16”-18 3/8”-16 3/8”-16 3/8”-16 3/8”-16 1/2”-13 1/2”-13 1/2”-13 1/2”-13 5/8”-11 5/8”-11 5/8”-11 #10-24 #10-24 #10-24 #10-24 1/4”-20 1/4”-20 5/16”-18 5/16”-18 5/16”-18 5/16”-18 #10-24 #10-24 #10-24 5/16”-18 5/16”-18 5/16”-18 1/4”-20 5/16”-18 3/8”-16 1/2”-13 1/4” (6) 1/4” (6) 1/4” (6) 5/16” (8) (6 x 35) (6 x 57) (8 x 38) (8 x 64) (10 x 48) (10 x 76) (13 x 57) (13 x 76) (13 x 102) (13 x 152) (16 x 57) (16 x 76) (16 x 108) (16 x 152) (19 x 64) (19 x 108) (19 x 159) (6 x 38) (6 x 57) (6 x 79) (6 x 102) (8 x 64) (8 x 89) (10 x 70) (10 x 102) (10 x 127) (10 x 152) (6 x 32) (6 x 51) (6 x 70) (10 x 64) (10 x 95) (10 x 121) (8 x 44) (10 x 48) (13 x 57) (16 x 57) 5/16” (8) 3/8” (10) 3/8” (10) 1/2” (13) 1/2” (13) 1/2” (13) 1/2” (13) 5/8” (16) 5/8” (16) 5/8” (16) 5/8” (16) 3/4” (19) 3/4” (19) 3/4” (19) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 5/16” (8) 5/16” (8) 3/8” (10) 3/8” (10) 3/8” (10) 3/8” (10) 1/4” (6) 1/4” (6) 1/4” (6) 3/8” (10) 3/8” (10) 3/8” (10) 5/16” (8) 3/8” (10) 1/2” (13) 5/8” (16) Acorn Nut Hex Nut Flat Quadrex Round Quadrex Wire Hanger Rod Hanger * Also stocked in stainless steel. To order drop suffix and add SS to end of catalog number (ie. ASA-37-187SS). † Quadrex is a combination Phillips and Robertson screwdriver slot. Additional stainless steel sizes available upon request. †† For 3/8”-16 threaded rod. ††† For 1/2”-13 threaded rod. 6 SLEEVE ANCHORS Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole deeper than anchor length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. With top nut flush with top of stud, insert the anchor through the item to be fastened and tap it into the hole until nut and washers seat. Catalog Number Minimum Allowable Allowable Embedment Pull Out Load* Shear Load* in. mm lbs. kN lbs. kN ASA-25-62AN 1” (25) 300 (1.3) 210 (0.9) ASA-25-137AN 1” ASA-25-225AN 1” (25) 300 (1.3) 210 (0.9) (25) 300 (1.3) 210 (0.9) ASA-31-150HN ASA-31-250HN 1” (25) 435 (1.9) 365 (1.6) 1” (25) 435 (1.9) 365 (1.6) ASA-37-187HN 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-300HN 11/4” (32) 675 (2.9) 570 (2.5) ASA-50-225HN 11/2” (38) 1100 (4.8) 1100 (4.8) ASA-50-300HN 11/2” (38) 1100 (4.8) 1100 (4.8) ASA-50-400HN 11/2” (38) 1100 (4.8) 1100 (4.8) ASA-50-600HN 11/2” (38) 1100 (4.8) 1100 (4.8) ASA-62-225HN 2” (51) 1545 (6.8) 1790 (7.8) ASA-62-300HN 2” (51) 1545 (6.8) 1790 (7.8) ASA-62-425HN 2” (51) 1545 (6.8) 1790 (7.8) ASA-62-600HN 2” (51) 1545 (6.8) 1790 (7.8) ASA-75-250HN 21/2” (64) 1990 (8.7) 2640 (11.6) ASA-75-425HN 21/2” (64) 1990 (8.7) 2640 (11.6) ASA-75-625HN 21/2” (64) 1990 (8.7) 2640 (11.6) ASA-25-150FQ 1” (25) 300 (1.3) 210 (0.9) ASA-25-225FQ 1” (25) 300 (1.3) 210 (0.9) ASA-25-312FQ 1” (25) 300 (1.3) 210 (0.9) ASA-25-400FQ 1” (25) 300 (1.3) 210 (0.9) ASA-31-250FQ 1” (25) 435 (1.9) 365 (1.6) ASA-31-350FQ 1” (25) 435 (1.9) 365 (1.6) ASA-37-275FQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-400FQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-500FQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-600FQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-25-125RQ 1” (25) 300 (1.3) 210 (0.9) ASA-25-200RQ 1” (25) 300 (1.3) 210 (0.9) ASA-25-275RQ 1” (25) 300 (1.3) 210 (0.9) ASA-37-250RQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-375RQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-37-475RQ 11/4” (32) 675 (2.9) 570 (2.5) ASA-31-175WH 1” (25) 435 (1.9) 365 (1.6) 11/4” (32) 610 (2.7) 570 (2.5) ASA-50-225RH37 11/2” (38) 610 (2.7) 1100 (4.8) ASA-62-225RH50 (51) 1130 (5.0) 1100 (4.8) ASA-37-187RH37 2” 4. To set, hand tighten and then turn 3 or 4 turns with wrench. * Tested in 3500PSI (24MPa) concrete Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 7 DROP-IN ANCHORS Features • • • • • • • • • • For use in concrete, stone Use with machine screw, bolt or threaded rod Made of zinc plated steel Layout or hole spotting required Internal plug, pre-assembled Screw engagement minimum 2/3 of thread depth Setting tool included with each box of 100 pieces For flush mounted installations One piece pre-assembled construction Stainless steel also available Catalog Number Thread Size ADI-25 ADI-37 ADI-50 ADI-62 ADI-75 1/4”-20 3/8”-16 1/2”-13 5/8”-11 3/4”-10 Catalog Number ADI-25 ADI-37 ADI-50 ADI-62 ADI-75 Length Anchor Length in. mm in. mm in. mm (25) 7/16” (11) 3/8” (10) (40) 5/8” (16) 1/2” (13) (51) 13/16” (21) 5/8” (16) (64) 13/16” 13/16” (30) 7/8” (22) (30) 1” (25) (79) Allowable Allowable Setting Tool Pull-out Load* Shear Load* Catalog Number in. mm lbs. (25) 635 1170 1883 2434 2754 (40) (51) (64) (79) (20.7 MPa) Drill/Hole Diameter 1” 19/16” 2” 21/2” 31/8” 1” 19/16” 2” 21/2” 33/16” * Tested in 3000 PSI Thread Depth kN (2.8) (5.1) (8.2) (10.7) (12.1) lbs. 478 1054 1903 3403 5178 kN (2.1) (4.6) (8.3) (14.9) (22.7) ADI-25T ADI-37T ADI-50T ADI-62T ADI-75T ADI-xxT Setting Tool concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the body diameter. Drill hole deeper than anchor length. Do not use core bits. Maintain accurate hole size. 2. Clean Hole of debris. 3. Drop in anchor, slotted end first. 4. To set, drive setting tool into anchor until shoulder of tool is flush with top of anchor. 5.Select proper bolt length. (Thread engagement must be minimum of 2/3 of anchor threads). Install bolt and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 8 MACHINE SCREW ANCHORS Features • • • • • • • • • Catalog Number Thread Size Drill/Hole Diameter in. AMS-6 AMS-8 AMS-10 AMS-25 AMS-31 AMS-37 AMS-50 * Tested in 3500 PSI #6-32 #8-32 #10-24 1/4”-20 5/16”-18 3/8”-16 1/2”-13 ( 24.1 MPa) For use in concrete, stone, brick, block Accepts standard machine screws and bolts Caulk in type anchor One piece construction Made of lead and Zamac #3 alloy Rustproof Setting tool included in each box of 100 anchors Screw engagement minimum 2/3 of thread depth Layout or hole spotting required Min. Hole Depth Allowable Allowable Pull Out Load* Shear Load* mm in. mm lbs. kN 5/16” (8) 1/2” (13) (8) 1/2” (13) 3/8” (10) 5/8” (16) 1/2” (13) 7/8” (22) 5/8” (16) (19) 7/8” (22) 1” 11/4” 11/2” (25) 3/4” 115 197 242 550 775 1375 1577 (0.5) 5/16” (32) (38) (0.8) (1.0) (2.4) (3.4) (6.0) (6.9) lbs. 147 175 297 525 600 1075 1250 kN (0.5) (0.7) (1.3) (2.3) (2.6) (4.7) (5.5) concrete Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter. Drill hole to depth shown in chart. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Insert anchor with cone down. 4. Place setting tool on top of anchor and strike with hammer. 5. Locate fixture over anchor. Install bolt and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 9 SINGLE EXPANSION ANCHORS Features • • • • • • • For use in concrete, block, brick, stone Use with machine screw or bolt Made of Zamac #3 alloy Layout or hole spotting required Rustproof Non-caulking, expands as bolt is tightened Screw engagement minimum 2/3 of thread depth Catalog Number ASE-25 ASE-31 ASE-37 ASE-50 ASE-62 ASE-75 * Tested in 3100 PSI Thread Size 1/4”-20 5/16”-18 3/8”-16 1/2”-13 5/8”-11 3/4”-10 (25.5 MPa) Length Drill/Hole Diameter Allowable Allowable Pull Out Load* Shear Load* in. mm in. mm lbs. kN lbs. 15/6” 11/2” 11/2” 2” 25/8” 23/4” (33) 1/2” (13) 5/8” (16) (38) 5/8” (16) (51) 7/8” (22) (67) 1” 11/4” (25) 440 520 577 900 1495 2227 (1.9) (38) 530 800 950 2025 3000 3800 (70) (32) (2.3) (2.5) (3.9) (6.5) (9.7) kN (2.3) (3.5) (4.1) (8.9) (13.2) (16.7) concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole deeper than shield length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 4. Locate fixture over anchor. Install bolt and tighten. 3. Insert anchor, thread end down. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 10 DOUBLE EXPANSION ANCHORS Features • • • • • • • • • Catalog Number Thread Size ADE-25 ADE-31 ADE-37 ADE-50 ADE-62 ADE-75 1/4”-20 * Tested in 3700 PSI Length 5/16”-18 3/8”-16 1/2”-13 5/8”-11 3/4”-10 (25.5 MPa) For use in concrete, brick, stone Use with machine screw or bolt Made of Zamac #3 alloy Layout or hole spotting required Heavy-duty anchor Dual expansion develops greater contact with walls of hole Screw engagement minimum of 2/3 of anchor threads Non-caulking, expands as bolt is tightened Rustproof Drill/Hole Diameter Allowable Allowable Pull Out Load* Shear Load* in. mm in. mm lbs. 15/16” 11/2” 11/2” 2” 25/8” 23/4” (33) 1/2” (13) (38) 5/8” (16) (38) 5/8” (16) (51) 7/8” (22) (67) 1” 1 1 /4” (25) 497 562 1002 1220 1550 2412 (70) (32) kN (2.2) (2.4) (4.4) (5.3) (6.8) (10.6) lbs. 662 892 1085 2197 3325 3940 kN (2.9) (3.9) (4.7) (9.6) (14.6) (17.3) concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole deeper than shield length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Insert anchor, thread end down. 4. Locate fixture over anchor. Install bolt and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 11 LAG SHIELDS Features • • • • • • • For use in mortar joint, concrete Use with lag bolt Made of Zamac #3 alloy Layout or hole spotting required Rustproof Short series for hard masonry Long series for soft masonry Catalog Number Lag Screw Diameter Long Short in. ALS-25-S ALS-31-S ALS-37-S ALS-50-S ALS-25-L ALS-31-L ALS-37-L ALS-50-L mm 1/4” (6) 5/16” (8) 3/8” (10) 1/2” (13) 1/4” (6) 5/16” (8) 3/8” (10) 1/2” (13) * Tested in 3000PSI (20.7 MPa) Length in. 1” 11/4” 13/4” 2” 11/2” 13/4” 21/2” 3” Drill/Hole Diameter Allowable Pull Out Load* mm in. mm lbs. kN (25) 1/2” (13) 1/2” (13) (44) 5/8” (16) (51) 3/4” (19) (38) 1/2” (13) (44) 1/2” (13) (64) 5/8” (16) (76) 3/4” (19) 125 200 300 500 150 300 500 750 (0.5) (32) (0.8) (1.3) (2.2) (0.6) (1.3) (2.2) (3.3) concrete Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter, Drill hole deeper than shield length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Insert shield into hole. 4. Locate fixture over anchor. Install bolt and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 12 LEAD ANCHORS Features • • • • • • • Catalog Number ALA-6-75 ALA-6-100 ALA-6-150 ALA-10-75 ALA-10-100 ALA-10-150 ALA-16-100 ALA-16-150 Screw Size #6 & #6 & #6 & #10,#12 #10,#12 #10,#12 #16 & #16 & * Tested in 4,000 PSI Anchor Length #8 #8 #8 & #14 & #14 & #14 #18 #18 (27.5 MPa) For use in concrete, block, brick Use with sheet metal screw or wood screw Made of lead alloy Layout or hole spotting required Not recommended for vibratory or shock loads Rustproof Length of screw required depends on thickness of material being anchored Drill/Hole Diameter Allowable Pull Out Load* in. mm in. mm lbs. kN 3/4” (19) 1/4” (6) 37 50 62 50 75 150 125 250 (0.1) 1” (25) 1/4” (6) 11/2” (38) 1/4” (6) 3/4” (19) 5/16” (8) 1” 11/2” 1” 11/2” (25) 5/16” (8) (38) 5/16” (8) (25) 3/8” (10) (38) 3/8” (10) (0.2) (0.2) (0.2) (0.3) (0.6) (0.5) (1.1) concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole same depth as anchor length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Tap lead anchor into hole. 4. Locate fixture over anchor. Install screw and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 13 CONCRETE SCREWS Features • • • • • • • For use in concrete, block, brick Blue fluorocarbon coating for corrosion resistance. Pilot hole required Threads notched to reduce installation torque Self tapping threads Removable One drill bit per 100 screws Head Type Catalog Number Size in. Hex Head Flat Head Installation Tool 14 Pilot Hole Diameter mm ACS-18-125H ACS-18-175H ACS-18-225H ACS-18-275H ACS-18-325H ACS-18-375H ACS-18-400H 3/16” ACS-25-125H ACS-25-175H ACS-25-225H ACS-25-275H ACS-25-325H ACS-25-375H ACS-25-400H 1/4” (6 x 32) 1/4” (6 x 44) ACS-18-125F ACS-18-175F ACS-18-225F ACS-18-275F ACS-18-325F ACS-18-375F ACS-18-400F 3/16” ACS-25-125F ACS-25-175F ACS-25-225F ACS-25-275F ACS-25-325F ACS-25-375F ACS-25-400F ACS-25-500F ACS-25-600F 1/4” (6 x 32) 1/4” (6 x 44) ACS-T in. mm 5/32” (4) 3/16” (5) 5/32” (4) 3/16” (5) 11/4” x (5 x 32) x 13/4” (5 x 44) 3/16” x 21/4” (5 x 57) 3/16” x 23/4” (5 x 70) 3/16” x 31/4” (5 x 82) 3/16” x 33/4” (5 x 95) 3/16” x 4” (5 x 102) 3/16” x 11/4” x 13/4” 1/4” x 21/4” 1/4” x 23/4” 1/4” x 31/4” 1/4” x 33/4” 1/4” x 4” (6 x 57) (6 x 70) (6 x 82) (6 x 95) (6 x 102) x 11/4” (5 x 32) x 13/4” (5 x 44) 3/16” x 21/4” (5 x 57) 3/16” x 23/4” (5 x 70) 3/16” x 31/4” (5 x 82) 3/16” x 33/4” (5 x 95) 3/16” x 4” (5 x 102) 3/16” x 11/4” x 13/4” 1/4” x 21/4” 1/4” x 23/4” 1/4” x 31/4” 1/4” x 33/4” 1/4” x 4” 1/4” x 5” 1/4” x 6” (6 x 57) (6 x 70) (6 x 82) (6 x 95) (6 x 102) (6 x 127) (6 x 152) CONCRETE SCREWS Screw Diameter in. 3/16” 1/4” Embedment Depth mm in. (25) (5) 1” 11/4” 11/2” 13/4” 1” 11/4” 11/2” 13/4” (25) (6) * Tested in 4000 PSI mm (32) (38) (44) (32) (38) (44) (27.6 MPa) Allowable Pull-out Load* Allowable Shear Load* lbs. kN lbs. kN 100 150 220 280 (0.4) 210 210 220 255 (0.9) 200 310 400 510 (0.9) 390 415 420 540 (1.7) (0.6) (0.9) (1.2) (1.3) (1.7) (2.2) (0.9) (0.9) (1.1) (1.8) (1.8) (2.3) concrete. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same diameter as the pilot hole diameter shown in the chart. Drill the hole deeper than the screw length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Insert screw through fixture and use a drill or screw gun to drive screw in until head seats against surface. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 15 RAPID ROD™ HANGERS (CONCRETE) Features • • • • • • • For use in concrete Self tapping Pilot hole required For hanging 1/4”-20 and 3/8”-16 threaded rods Installation tool available Sidewinder™ (SW) available for side mounting applications Made of zinc plated steel RH SW Concrete Catalog Number Screw Thread Size & Length in. ARC-1-RH25 ARC-1-RH37 ARC-1-SW37 ARR-T ASW-T mm Drill/Hole Diameter in. 5/16” 1/4” x 11/2” (8 x 38) 5/16” x 11/2” (8 x 38) 1/4” 5/16” x 11/2” (8 x 38) 1/4” Standard Rapid Rod™ Tool Hanging Allowable Rod Size Pull-Out Load mm (6) 1/4”-20 (6) 3/8”-16 (6) 3/8”-16 Allowable Shear Load lbs. kN lbs. kN 702 702 -- (3.1) --512 --- (3.1) -- (2.3) Sidewinder™ Tool Loads based on 2000 PSI (13.8 MPa) concrete. Drill bit included in each box of 100. Installation 1. Use a carbide bit (ANSI B94.12-1977) the same diameter as the pilot hole diameter shown in the chart. Drill the hole deeper than the screw length. Do not use core bits. Maintain accurate hole size. 4. Thread rod into hanger. 2. Clean hole of debris. Sidewinder™ mounting 3. Drive the rod hanger screw into the hole using a screw gun and the ARR-T nut driver. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 16 RAPID ROD™ HANGERS (STEEL) Features • • • • • • • • • • RH SW Steel (For steel up to 3/16” (5mm) Catalog Number thick) Screw Thread Size & Length in. ARS-1-RH25 ARS-5-RH25 ARS-10-RH25 ARS-15-RH25 ARS-20-RH25 ARS-1-RH25L ARS-1-RH37 ARS-5-RH37 ARS-10-RH37 ARS-15-RH37 ARS-20-RH37 ARS-1-RH37L D D ARS-1-RH37HD** D ARS-1-SW37 — ARS-1-SW37L* †† ARS-5-SW37L* †† ARS-1-SW37HD** † ARR-T ASW-T 1/4” x 1” x 11/2” 1/4” x 2” 1/4” x 21/2” 1/4” x 3” 1/4” x 1” 1/4” x 1” 1/4” x 11/2” 1/4” x 2” 1/4” x 21/2” 1/4” x 3” 1/4” x 1” #12 x 11/2” 1/4” x 2” 1/4” x 1” 1/4” x 11/2” #12 x 11/2” 1/4” For use in steel Self drilling and tapping For hanging 1/4”-20 and 3/8”-16 threaded rods No pilot hole required Installation tool available Standard version self drilling up to 1/4” thick steel Heavy duty (HD) version self drilling up to 1/2” thick steel Sidewinder™ (SW) available for side mounting applications Made of zinc plated steel Locknut (L) version provided with nut Hanging Allowable Pull-Out Load Rod Size 12 Ga. Steel 14 Ga. Steel mm Allowable Shear Load lbs. kN lbs. kN lbs. kN 1/4”-20 386 (1.7) 286 (1.2) -- -- 1/4”-20 386 (1.7) 286 (1.2) -- -- 3/8”-16 386 (1.7) 286 (1.2) -- -- (6 x 25) 3/8”-16 3/8”-16 (6 x 25) 3/8”-16 (6 x 38) 3/8”-16 (5 x 38) 3/8”-16 --369 475 593 827 -- (6 x 51) 407 228 ----- (1.8) 3/8”-16 462 381 ----- (2.0) (5 x 38) (6 x 25) (6 x 38) (6 x 51) (6 x 64) (6 x 76) (6 x 25) (6 x 25) (6 x 38) (6 x 51) (6 x 64) (6 x 76) (1.7) ----- (1.0) ----- -(1.6) (2.1) (2.6) (3.7) Rapid Rod™ Tool Sidewinder™ Tool *Allowable shear load in 20 ga. (0.9mm) steel. **HD for steel up to 1/2” (13mm) thick. D FM approved for hanging up to and including 4” (100mm) nominal pipe. DD FM approved for hanging up to and including 21/2” (64mm) nominal pipe. Not recommended for less than 16 ga. (1.4mm) steel. † Recommend retainer nut for steel less than 1/4” (6mm) thick. †† UL Listed. Installation 1. Using a screw gun and the ARR-T Nut Driver, drive the rod hanger in until head seats against surface. 2. Thread rod into hanger. Sidewinder™ mounting Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. 17 RAPID ROD™ HANGERS (WOOD) Features • • • • • • • For use in wood Self drilling and tapping For hanging 1/4"-20, 3/8"-16 and 1/2"-13 threaded rods No pilot hole required Installation tool available Sidewinder™ (SW) available for side mounting applications Made of zinc plated steel RH SW Wood Catalog Number Screw Thread Size & Length in. ARW-1-RH25 ARW-5-RH25 ARW-10-RH25 ARW-1-RH37 ARW-5-RH37 ∆ ARW-10-RH37 ∆∆ ARW-1-RH50 ARW-5-RH50 ARW-10-RH50 ARW-1-SW37 † ARR-T ASW-T Hanging Allowable Pull-Out Rod Size Load In Wood* Allowable Shear Load mm lbs. kN lbs. kN x 1" (6 x 25) 1/4" x 2" 1/4"-20 (6 x 51) 1/4" x 3" (6 x 76) 1/4" x 1" (6 x 25) 1/4" x 2" 3/8"-16 (6 x 51) 1/4" x 3" (6 x 76) 1/4" x 3" (6 x 76) 1/4" x 4" (6 x 102) 1/2"-13 1/4" x 6" (6 x 152) 1/4" x 2" 3/8"-16 (6 x 51) Standard Rapid Rod™ Tool Sidewinder™ Tool 167 440 515 167 440 515 515 545 557 -- (.75) ---------431 -- 1/4" (1.9) (2.3) (.75) (1.9) (2.3) (2.3) (2.4) (2.5) -- --------(1.9) Not recommended for laminate beams. Use ARS steel screw for this application. *Tested with entire screw embedded in Douglas Fir. ∆ FM approved for hanging up to and including 21/2" (64mm) nominal pipe. ∆∆ FM approved for hanging up to and including 4" (100mm) nominal pipe. Installation 1. Using a screw gun and the ARR-T Nut Driver, drive the rod hanger in until head seats against surface. 2. Thread rod into hanger. Sidewinder™ mounting Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. 18 JUNIOR RAPID ROD™ HANGERS Features • • • Three types for use in concrete, steel, or wood Installation tool available Concrete type is self tapping but requires a pilot hole Steel type is self drilling and tapping and requires no pilot hole Wood type is self drilling and tapping and requires no pilot hole Made of zinc plated steel Concrete Wood Steel • Concrete Catalog Number Screw Thread Size & Length in. 1/4” AJC-1-WH AJC-1-RH25 AJR-T Drill/Hole Diameter mm 11/2” x (6 x 38) x 11/2” (6 x 38) Junior Rapid Rod™ Tool 1/4” * Tested in 2000 PSI (13.8 MPa) in. Hanging Allowable Rod Size Pull-Out Load mm 3/16” (5) -- 3/16” (5) 1/4”-20 lbs. kN 255 255 (1.1) (1.1) concrete. Steel Catalog Number Screw Thread Size & Length in. mm (5 x 25) -#10 x 1” 1/4”-20 #10 x 1” (5 x 25) 1/4”-20 #10 x 11/2” (5 x 38) Junior Rapid Rod™ Tool AJS-1-WH AJS-1-RH25 AJS-5-RH25 † AJR-T * Tested in .080 † UL Listed. Hanging Rod Size (2mm) Allowable Pull-Out Load lbs. kN 157 157 157 (.7) (.7) (.7) purlin thickness. Wood Catalog Number Screw Thread Size & Length in. AJW-1-WH † AJW-1-RH25 AJW-5-RH25 † AJR-T Hanging Rod Size Allowable Pull-Out Load mm lbs. kN #10 x 2” (5 x 51) -1/4”-20 #10 x 1” (5 x 25) 1/4”-20 #10 x 2” (5 x 51) Junior Rapid Rod™ Tool 225 225 225 (1.0) (1.0) (1.0) * Tested in 2 x 4 Douglas Fir. † UL Listed. For Installation Instructions: See page 16 for concrete • See page 17 for steel • See page 18 for wood Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. 19 JUNIOR RAPID ROD™ HANGERS Features • • Installation tool available Made of zinc plated steel Toggle Bolt Drive Nail Toggle Bolt Catalog Number Screw Thread Size & Length in. AJT-1-WH † AJT-1-RH25 † Drill/Hole Diameter mm 25/8” #10 x #10 x 25/8” Hanging Allowable Rod Size Pull-Out Load in. mm (5 x 66) 1/2” (13) -- (5 x 66) 1/2” (13) 1/4”-20 lbs. kN 37 37 (.16) (.16) * Tested in 5/8” (16mm) thick sheetrock. For installation instructions see page 24. † UL Listed. Drive Nail Catalog Number AJN-1-WH † AJN-1-RH25 † Screw Thread Size & Length Hanging Rod Size in. mm #10 x 21/2” #10 x 21/2” (5 x 64) -- (5 x 64) 1/4”-20 Allowable Pull-Out Load lbs. kN 50 50 (.22) (.22) * Tested in 2 x 4 Douglas Fir. To install, drive hanger directly into wood stud with a hammer. † UL Listed. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. 20 SPLIT BOLT ANCHORS Features • • • • • • • Head Type Flat Round Catalog Number For use in concrete, stone One piece, pre-expanded anchor No layout or hole spotting required Made of high grade zinc plated steel For heavy duty permanent installation Three head styles available: round, flat and tie-wire Minimum embedment is 11/8” (28mm) Size Diameter in. mm ASB-25-150F ASB-25-200F ASB-25-250F ASB-25-300F ASB-25-350F ASB-25-400F 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) ASB-25-125R ASB-25-150R ASB-25-200R ASB-25-250R 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) Load Data (11/8” Installation Concrete Strength psi MPa 2755 4120 4985 (19.0) (28.4) (34.4) (28mm) Length in. 11/2” 2” 21/2” 3” 31/2” 4” 11/4” 11/2” 2” 21/2” mm Drill/Hole Diameter in. mm (38) (51) (64) (76) (89) 1/4” (6) (102) (32) (38) (51) (64) Embedment) Allowable Allowable Pull-Out Load Shear Load lbs. 205 282 339 1. Using 1/4” diameter carbide bit (ANSI B94.12-1977), drill hole at least 1/4” (6mm) deeper than bolt embedment (min. 11/8” (28mm). kN (0.9) (1.2) (1.7) lbs. 413 - kN (1.8) - 3. To set, drive anchor into hole through fixture until fixture is firmly anchored. 2. Clean hole of debris. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 21 DRIVE NAIL ANCHORS Features • • • • • For concrete, brick or stone Not recommended for vibratory or shock loads One piece assembly No layout or hole spotting Made of Zamac #3 Alloy (body portion) pre-assembled with zinc plated steel or Type 301 stainless steel nail Nail Type Catalog Number Anchor Diameter in. Zinc Plated Steel Stainless Steel * Tested in 4985 PSI (34.3 MPa) concrete. ADN-18-87 ADN-25-75 ADN-25-100 ADN-25-125 ADN-25-150 ADN-25-200 3/16” 1/4” ADN-25-100SS ADN-25-125SS ADN-25-150SS ADN-25-200SS Catalog Number ADN-18-87 ADN-25-75 ADN-25-100 ADN-25-125 ADN-25-150 ADN-25-200 ADN-25-100SS ADN-25-125SS ADN-25-150SS ADN-25-200SS mm Length (from under head) in. mm (5) 7/8” (6) 3/4” 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) Hole Diameter in. mm (22) 3/16” (5) (19) 1/4” (6) 1” 11/4” 11/2” 2” (25) 1/4” (6) (32) 1/4” (6) (38) 1/4” (6) (51) 1/4” (6) 1” 11/4” 11/2” 2” (25) 1/4” (6) (32) 1/4” (6) (38) 1/4” (6) (51) 1/4” (6) Allowable Pull Allowable Out Load* Shear Load* Embedment Depth lbs. kN lbs. kN in. mm 257 265 289 300 409 431 (1.1) 257 290 328 340 380 415 (1.1) 3/4” (19) (1.3) 5/8” (16) (1.4) 7/8” (22) (1.5) (28) (1.8) 11/8” 13/8” 17/8” (1.4) 7/8” (22) (1.5) 11/8” 13/8” 17/8” (28) 289 300 409 431 (1.1) (1.2) (1.3) (1.8) (1.9) (1.2) (1.3) (1.8) (1.9) 328 340 380 415 (1.6) (1.6) (1.8) (35) (48) (35) (48) Installation 1. Use a carbide bit (ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole at least 1/4” (6mm) deeper than anchor embedment [min 3/4” (19mm)]. 2. Clean hole of debris. 3. Tap anchor into hole until body head is tight against fixture. 4. To set drive nail until flush with head. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 22 NYLON NAIL-IN ANCHORS Features • • • • • • • Catalog Number Head Type Anchor/Hole Body Length Allowable Allowable Diameter (from under head) Pull Out Load Shear Load in. ANN-18-100M ANN-25-75M ANN-25-100M ANN-25-150M ANN-25-200M ANN-25-300M ANN-25-400M ANN-18-100R ANN-18-150R ANN-25-100R ANN-25-150R ANN-25-200R ANN-18-100F ANN-18-150F ANN-25-100F ANN-25-150F ANN-25-200F Mushroom Round Flat For use in concrete, block, brick, drywall One piece assembly No layout or hole spotting required Light duty anchor Removable Made of nylon with zinc plated steel nail Three head styles available: mushroom, round and flat mm 3/16” (5) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 1/4” (6) 3/16” (5) 3/16” (5) 1/4” (6) 1/4” (6) 1/4” (6) 3/16” (5) 3/16” (6) 1/4” (6) 1/4” (6) 1/4” (6) in. 1” 3/4” 1” 11/2” 2” 3” 4” mm lbs. kN lbs. kN 62 47 58 72 80 82 86 (0.2) 132 162 197 207 212 227 230 (0.2) 60 76 63 75 80 (0.2) 150 172 182 202 212 (0.6) 80 70 63 75 80 (0.3) 157 172 182 202 212 (0.7) (25) (19) (25) (38) (51) (76) (102) 1” 11/2” 1” 11/2” 2” (25) 1” 11/2” 1” 11/2” 2” (25) (38) (25) (38) (51) (38) (25) (38) (51) (0.2) (0.2) (0.3) (0.3) (0.3) (0.3) (0.3) (0.2) (0.3) (0.3) (0.3) (0.3) (0.3) (0.3) (0.7) (0.8) (0.9) (0.9) (1.0) (1.0) (0.7) (0.8) (0.9) (0.9) (0.7) (0.8) (0.8) (0.9) Installation 1. Use a carbide bit ( ANSI B94.12-1977) the same size as the hole diameter shown in the chart. Drill hole 1/4” (6mm) deeper than body length. Do not use core bits. Maintain accurate hole size. 2. Clean hole of debris. 3. Insert anchor through the material to be fastened and into drilled hole. 4. Tap with hammer until nail seats against head. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 23 TOGGLE BOLTS Features • For use in any type of hollow construction; drywall, block, etc. • Made of zinc plated steel • Fully threaded machine screw included • Combination Phillips and slotted head Catalog Number Head Type Thread Size Length in. #8-32 #8-32 #8-32 2” 3” 4” #10-24 #10-24 3” 4” ATB-25-300M ATB-25-400M 1/4”-20 1/4”-20 3” 4” ATB-18-200R ATB-18-300R ATB-18-400R ATB-18-500R ATB-18-600R #10-24 #10-24 #10-24 #10-24 #10-24 2” 3” 4” 5” 6” ATB-25-300R ATB-25-400R ATB-25-500R ATB-25-600R 1/4”-20 ATB-12-200M ATB-12-300M ATB-12-400M ATB-18-300M ATB-18-400M Mushroom 1/4”-20 1/4”-20 1/4”-20 Round Head ATB-31-300R ATB-31-400R ATB-31-500R ATB-31-600R 5/16”-18 ATB-37-300R ATB-37-400R ATB-37-500R ATB-37-600R 3/8”-16 * Tested in 3500 PSI 5/16”-18 5/16”-18 5/16”-18 3/8”-16 3/8”-16 3/8”-16 (24.1 MPa) 3” 4” 5” 6” 3” 4” 5” 6” 3” 4” 5” 6” Drill/Hole Diameter mm in. mm (51) 3/8” (10) (76) 3/8” (10) (102) 3/8” (10) (76) 1/2” (13) (102) 1/2” (13) (76) 5/8” (16) (102) 5/8” (16) (51) 1/2” (13) (76) 1/2” (13) (102) 1/2” (13) (127) 1/2” (13) (152) 1/2” (13) (76) 5/8” (16) (102) 5/8” (16) (127) 5/8” (16) (152) 5/8” (16) (76) 7/8” (22) (102) 7/8” (22) (127) 7/8” (22) (152) 7/8” (22) (76) 7/8” (22) (102) 7/8” (22) (127) 7/8” (22) (152) 7/8” (22) Allowable Pull Out Load in Concrete* in 1/2” Drywall lbs. kN lbs. kN 30 (0.1) 60 (0.2) 33 (0.1) 107 (0.4) 36 (0.1) 225 (1.0) 33 (0.1) 107 (0.4) 36 (0.1) 225 (1.0) 40 (0.1) 257 (1.1) 43 (0.2) 272 (1.2) concrete. Installation 1. Drill hole using drill bit the same sizes as the hole diameter shown in the chart. 2. Insert bolt through the item to be fastened. 3. Thread toggle head onto bolt. 4. Insert toggle head into drilled hole and tighten screw. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary. 24 TOGGLE HEADS Features • • • • Catalog Number ATH-12 ATH-18 ATH-25 ATH-31 ATH-37 * Tested in 3500 PSI Thread Size #6-40 #10-24 1/4”-20 5/16”-18 3/8”-16 (24.1 MPa) For use in any type of hollow construction: drywall, block, etc. Threaded for use with standard machine screws Toggle head is spring loaded Bolt not included Fully Opened Width Allowable Pull-Out Load Drill/Hole Diameter in 1/2” Drywall in Concrete* in. mm in. mm lbs. kN lbs. kN 13/4” 21/4” 21/4” 23/4” 31/4” (44) 3/8” (10) (13) (57) 5/8” (16) (70) 7/8” (22) (82) 1” (25) 60 107 225 257 272 (0.2) 1/2” 30 33 36 40 43 (0.1) (57) (0.1) (0.1) (0.1) (0.1) (0.4) (1.0) (1.1) (1.2) concrete. Installation 1. Drill hole using drill bit the same size as the hole diameter shown in chart. 2. Insert bolt through the item to be fastened. 3. Thread toggle head onto bolt. 4. Insert toggle head into drilled hole and tighten screw. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary. 25 HOLLOW WALL ANCHORS Features • • • • • For use in drywall, plaster, paneling Complete pre-assembled anchor, no other fastener needed Made of zinc plated steel Slotted hex head or flat head screws also available Remove screw as often as needed Catalog Number Screw Size AHW-12XS AHW-12S AHW-12L AHW-12SL AHW-12XL AHW-18S AHW-18L AHW-18XL AHW-25S AHW-25L AHW-25XL AHW-T Anchor Length Hole Diameter Wall Thickness in mm in mm in mm in #6 x 1” #6 x 11/2” #6 x 2” #6 x 2” #6 x 21/2” #10 x 21/4” #10 x 23/4” #10 x 31/2” 1/4” x 21/4” 1/4” x 23/4” 1/4” x 31/2” (4 x 25) 3/4” (19) 5/16” (8) 1/16”-1/4” (2-6) (4 x 38) 11/4” 15/8” 13/4” 21/4” 21/16” 21/2” 31/8” 21/16” 21/2” 31/8” (32) 1/4” (6) 1/8”-1/2” (3-13) (41) 1/4” (6) (6) 5/8”-7/8” 1/8”-13/16” (16-22) (44) 1/4” (57) 1/4” (6) (32-38) (52) 3/8” (10) (64) 3/8” (10) (79) (10) (52) 3/8” 7/16” (64) 7/16” (11) (79) 7/16” (11) 11/4”-11/2” 1/8”-5/8” 5/8”-13/16” 11/4”-21/4” 1/8”-5/8” 5/8”-13/16” 11/4”-13/4” (4 x 51) (4 x 51) (4 x 64) (5 x 57) (5 x 70) (5 x 89) (6 x 57) (6 x 70) (6 x 89) (11) mm (3-21) (3-16) (16-30) (32-44) (3-16) (16-30) (32-44) Installation Tool Installation 1. Drill hole using drill bit the same size as the hole diameter shown in the chart. 2. Gently tap anchor until cap prongs are embedded in wall and cap is snug against surface. 3. Turn screw clockwise, pressing firmly to prevent anchor from rotating. As the screw turns, the anchor legs spread and grip the inside of the wall. 5. Turn screw counter clockwise to remove screw. Anchor remains. 6. Hold fixture in position, replace screw and tighten. Installation is complete. 4. Tighten screw until a definite increase in resistance is felt. Anchor is fully expanded. Note: A saftey factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 26 HOLLOW WALL ANCHORS Catalog Number AHW-12XS AHW-12S In Plywood AHW-12L AHW-12SL AHW-12XL AHW18S AHW-18L AHW-18XL AHW-25S AHW-25L AHW-25XL Catalog Number Material Thickness AHW-12S AHW-12L In Drywall AHW-12SL AHW-12XL AHW18S AHW-18L AHW-18XL AHW-25S AHW-25L AHW-25XL Allowable Pull Out Load Allowable Shear Load in. mm in-lbs Nm lbs. N lbs. N 1/8” (3) (0.56) (6) (6) 1/2” (13) 5/8” (16) 7/8” (22) 1/4” (6) 5/8” (16) 11/4” 1/4” 5/8” 5/8” 11/8” 11/4” 1/4” 5/8” 5/8” 11/8” 11/4” (32) 25 112 87 107 112 112 88 112 112 137 157 160 182 191 150 212 225 250 305 (111) 1/4” 27 31 16 75 107 112 16 112 125 16 118 125 151 165 16 125 140 182 191 (122) 1/4” 5 5 4 4 5 5 4 4 5 6 6 6 6 6 10 10 10 10 15 (6) (16) (16) (28) (32) (6) (16) (16) (28) (32) Material Thickness in. AHW-12XS Torque in-lbs -4 4 5 5 4 4 5 6 6 6 6 6 10 10 10 10 15 -- -(6) 1/2” (13) 5/8” (16) 7/8” (22) 1/4” (6) 5/8” (16) 11/4” 1/4” 5/8” 5/8” 11/8” 11/4” 1/4” 5/8” 5/8” 11/8” 11/4” (32) (6) (16) (16) (28) (32) (6) (16) (16) (28) (32) (0.45) (0.45) (0.56) (0.56) (0.45) (0.45) (0.56) (0.68) (0.68) (0.68) (0.68) (0.68) (1.13) (1.13) (1.13) (1.13) (1.70) Torque mm 1/4” (0.56) (138) (72) (333) (477) (500) (72) (500) (55) (72) (527) (555) (672) (733) (72) (555) (622) (800) (850) (500) (388) (472) (500) (500) (394) (500) (500) (611) (705) (712) (811) (850) (666) (944) (1000) (1111) (1355) Allowable Pull Out Load Allowable Shear Load Nm lbs. N lbs. -- -6 22 32 36 6 33 65 6 33 33 67 75 6 35 38 41 50 -- -47 41 51 68 50 52 80 57 75 76 121 122 60 75 82 137 143 (0.45) (0.45) (0.56) (0.56) (0.45) (0.45) (0.56) (0.68) (0.68) (0.68) (0.68) (0.68) (1.13) (1.13) (1.13) (1.13) (1.70) (27) (100) (144) (161) (27) (150) (289) (27) (150) (150) (289) (333) (27) (155) (172) (183) (222) N -(211) (183) (227) (305) (222) (233) (355) (255) (333) (339) (539) (544) (266) (333) (366) (611) (639) Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary. 27 HOLLOW WALL DRIVE-IN ANCHORS Features • • • • • • • For use in drywall, plaster, paneling Complete pre-assembled anchor, no other fastener needed Made of zinc plated steel Combination Phillips and slotted pan head Slotted hex head or flat head screws also available Remove screw as often as needed No drilling required In Drywall Catalog Number Thread Size Overall Length Wall Thickness in. mm in. mm in. mm AHD-12XS AHD-12S AHD-12L AHD-12SL AHW-T #6 x 3/8” #6 x 3/4” #6 x 211/32” #6 x 211/32” Installation tool (4 x 35) 3/4” (19) 1/16” - 1/4” (2 - 6) (4 x 44) 11/4” 13/4” 13/4” (32) (44) 1/8” - 1/2” 5/8” - 7/8” (16 - 32) (44) 1/8” - 13/16” (3 - 21) Catalog Number Material Thickness AHD-12XS AHD-12S AHD-12L ADH-12SL (4 x 60) (4 x 60) Torque Allowable Pull-Out Load (3 - 13) Allowable Shear Load in. mm in-lbs Nm lbs. N lbs. N 3/8” 5/8” 7/8” 5/8” - 4 5 5 4 - 6 32 36 21 - 22 51 68 43 - (10) (16) (22) (16) (0.45) (0.56) (0.56) (0.45) (27) (144) (161) (94) (100) (227) (305) (194) Installation 1. Drive anchor in until cap prongs are imbedded in wall and cap is snug against surface. 2. Turn screw clockwise, pressing firmly to prevent anchor from rotating. As the screw turns, the anchor legs spread and grip the inside of the wall. 4. Turn screw counter-clockwise to remove screw. Anchor remains. 5. Hold fixture in position, replace screw and tighten. Installation is complete. 3. Tighten screw until a definite increase in resistance is felt. Anchor is fully expanded. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary. 28 PLASTIC TOGGLES Features • • • • • Catalog Number APT-37 APT-50 APT-62 For use in drywall, block, concrete Made of polyethylene Accepts #8, #10 &#12 sheet metal or wood screws Concave folding for easier installation Kits are supplied with combination slot, pan head, Type AB tapping screws Wall Thickness Drill/Hole Diameter in. mm in. mm 0” - 3/8” (0 - 10) 3/8” (10) 3/8” - 1/2” (10 - 13) 3/8” (10) 1/2” - 5/8” (13 - 16) 3/8” (10) Screw Size in. #8,#10, &#12 mm (4,5,&6) Kits Catalog Number Wall Thickness in. APT-37K APT-50K APT-62K Installation 1. Drill hole deeper than anchor length in solid material using drill bit the same size as the hole diameter shown in the chart. Drill/Hole Diameter mm in. mm (0 - 10) 3/8” (10) 3/8” - 1/2” (10 - 13) 3/8” (10) 1/2” - 5/8” (13 - 16) 3/8” (10) 0” - 3/8” Screw Size in. #8 x 11/4” mm (4 x 32) •Kits include 50 anchors and screws. 2. Pinch wings together and insert toggle into hole. 3. Tap toggle in until flush with wall. 4. Insert screw through item to be mounted and into toggle and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 29 WALLDRILLER® Features • • • • For use in drywall Accepts all types of self-tapping and sheet metal screws Kits are supplied with combination slot, pan head, Type AB tapping screws No pre-drilling required, anchor screws into drywall Catalog Number APD-8 AZD-8 Screw Size in Material mm #8 to #10 #6 to #8 (4 to 5) (4 to 5) Plastic Zinc Kits Catalog Number APD-8K AZD-8K Screw Size in #8 x 11/4” #8 x 11/4” Material mm (4 to 38) (4 to 38) Plastic Zinc •Kits include 50 anchors and screws. Installation 1. Insert phillips screwdriver into anchor. 2. Push the pointed end of the anchor into the drywall and twist screwdriver clockwise, driving the anchor in until the head seats against dry wall. 3. Insert screw through object to be anchored and drive screw into the anchor. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 30 PLASTIC SCREW ANCHORS Features • • • • • Catalog Number Screw Size Anchor Length in. APS-4-87 APS-8-125 APS-12-150 Can be used in concrete, brick, drywall Lateral ribs increase pull-out strength Special polyethelene for increased flexibility Double expansion points provide four points of contact for greater strength Kits are supplied with combination slot, pan head type AB tapping screws #4, #6, &#8 #8, #10, &#12 #12, #14, &#16 Drill/Hole Diameter Allowable Pull Out Load† mm in. mm lbs. kN 7/8” (22) 3/16” (5) (32) 1/4” (6) (38) 5/16” (8) 50 100 150 (0.2) 11/4” 11/2” (0.4) (0.6) † Tested in 3,000 psi (20.7 MPa) concrete. Catalog No. APS-4-87K APS-8-125K APS-12-150K Master Cartons Catalog No. Quantity Kits Screw Size in. mm. #6 x 11/4 #10 x 11/2 #12 x 11/2 (4 x 32) (5 x 38) APS-4-87MC APS-8-125MC APS-12-150MC 75,000 pcs. 25,000 pcs. 20,000 pcs. (6 x 38) Kits include 100 anchors, 100 screws and a drill bit. Installation 1. Drill hole deeper than anchor length using a drill bit the same size as the hole diameter shown in the chart. 2. Push anchor into hole. 3. Locate fixture over anchor, install screw and tighten. Note: A safety factor of 4.0 has been applied to the allowable loads shown in the chart. These values are based on average test loads and are to be used as a guide only. Actual results may vary depending on such factors as concrete strength, concrete curing time, embedment depth and proper installation. 31 CONICAL ANCHORS Features • • Can be used in concrete, brick, drywall Kits are supplied with combination slot, pan head type AB tapping screws Catalog Number APC-6-75 APC-10-100 APC-14-137 Screw Size Anchor Length #6, & #8 #10 & #12 #14 & #16 Drill/Hole Diameter in. mm in. mm 3/4” (19) 3/16” (5) 1” 3 1 /8” (25) 1/4” (6) (35) 5/16” (8) Kits Catalog No. APC-6-75K APC-10-100K APC-14-137K Screw Size in. mm. #6 x 1 #10 x 1 #14 x 11/2 (4 x 25) (5 x 25) (6 x 38) Kits include 100 anchors, 100 screws and a drill bit. Installation 1. Drill hole deeper than anchor length using a drill bit the same size as the hole diameter shown in the chart. 32 2. Push anchor into hole. 3. Locate fixture over anchor, install screw and tighten. INDEX INTRODUCTION Catalog Number Series B-Line Systems Inc. is a leading manufacturer and fabricator of steel and aluminum products which are used in support equipment for industrial, commercial, utility and OEM installations. B-Line is proud of the exacting standards of research, design, engineering and manufacturing that go into each and every product. With the introduction of anchors, our customers have access to the most complete support system offered including; strut systems, cable tray, pipe hangers, vibration control devices, slotted angle, spring steel fasteners and fiberglass strut and cable tray. Many B-Line products are listed by Underwriters Laboratories, Inc. and approved by Factory Mutual Laboratories. All B-Line products are manufactured to meet or exceed industry standards set for their design and manufacturing. This catalog is designed to be helpful to contractors in the application and selection of anchors and support products for construction and manufacture. If a unique application requires a special product not included in this catalog, B-Line engineering personnel are ready to furnish design consultation and realistic cost estimates. In addition, sales representatives with engineering know-how are located throughout the United States and abroad for your convenience. ACS Page ..................................................................... 14 & 15 ADE .......................................................................... ADI ............................................................................ 11 8 ADN .......................................................................... 22 AHD .......................................................................... 28 AHW .................................................................... 26 & 27 AJC-RH & AJC-WH ............................................................ 19 AJN-RH & AJN-WH ........................................................... 20 AJS-RH & AJS-WH ............................................................ 19 AJT-RH & AJT-WH ............................................................ 20 ........................................................... 19 ALA .......................................................................... 13 ALS ........................................................................... 12 AJW-RH & AJW-WH AMS ........................................................................... ANN .......................................................................... 23 APC .......................................................................... 32 APD .......................................................................... 30 APS ........................................................................... 31 APT ........................................................................... 29 ARC-RH & ARC-SW ARS-RH & ARS-SW ........................................................... 16 ............................................................ 17 ARW-RH & ARW-SW ASA 9 .......................................................... ....................................................................... 18 6&7 ASB ........................................................................... 21 ASE ........................................................................... 10 ATB ........................................................................... 24 ATH .......................................................................... 25 AWA ....................................................................... AZD .......................................................................... 4&5 30 AN-00 AN-00 ANCHOR SYSTEMS Product & Application Guide Home Office B-Line Systems, Inc. 509 W. Monroe St. Highland, IL 62249-0326 618-654-2184 618-654-1917 Fax Regional Distritution Centers B-Line Systems, Inc. 6655 Corners Industrial Court Norcross, GA 30092-3604 Additional B-Line Facilities B-Line Systems, Inc. 2017 25th Avenue Franklin Park, IL 60131-3592 B-Line Systems, Inc. 13755 Stead Blvd. Reno, NV 89506-0260 B-Line Systems, Inc. 21000 East 32nd Parkway Aurora, CO 80011 B-Line Systems, Inc. 4900 Marshall Street Sherman, TX 75090-2076 B-Line Systems, Canada 2149 Winston Park Drive Oakville, Ontario L6H 6J8 Please visit our website at w w w.b-line.com SYSTEMS THAT MAKE SENSE 15300 Printed in U.S.A. ©2000 B-Line Systems, Inc. ® ELECTRICAL TELECOMMUNICATIONS MECHANICAL SYSTEMS THAT MAKE SENSE