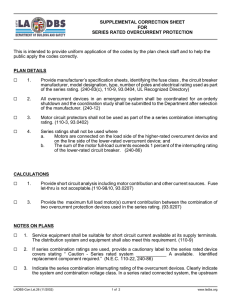

Overcurrent Protection · CPI

advertisement