Design of an All-In-One Embedded Flight Control System

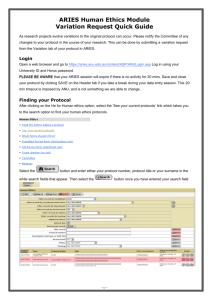

advertisement