S.C.A.D.A.– Supervisory Control and Data Acquisition

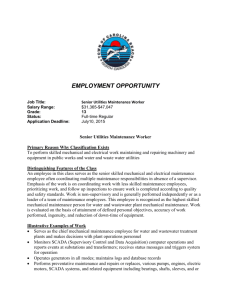

advertisement

S URCE Volume 25 • Number 3 Summer 2011 S.C.A.D.A.– Supervisory Control and Data Acquisition Issues, Solutions & the Future Many Are Honored at 2011 Spring Conference Awards CA-NV Section Volunteers Receive 2011 Publications Awards from AWWA CA-NV Section AWWA Descends on Washington, D.C. C A L I F O R N I A • N E VA D A S E C T I O N A W W A Taking Your SCADA System to the Next Level By Philip Gaberdiel, Westin Engineering S upervisory Control and Data Acquisition (SCADA) Systems have become common elements of a utility’s technology infrastructure. Many utilities implemented their first systems in the 1980’s when the availability of low-cost federal loans and grants aligned with the emerging maturity of computer technology to make the implementation of a SCADA system a responsible investment for public water/wastewater utilities. The early systems replaced hard-wired circuits and relay logic with digital components. These first generation systems were typically comprised of specialized hardware and custom software. Although rudimentary by today’s standards, these early systems (when they worked) provided operational efficiencies by allowing a plant operator in a central control room to monitor and control process equipment. When applied to geographically distributed applications, such as water distribution and wastewater collection, these efficiencies were often quite substantial. Evolution of SCADA The manner in which utilities use their SCADA systems has also evolved over the years. Automatic control algorithms, which make process adjustments based on parameters measured by field instrumentation, are commonplace. These control strategies sequence pump starts/stops, control the speed of variable speed drives, adjust chemical dosages and blower speeds, and perform scores of other process adjustments that had previously been performed manually by plant staff. Automation of these processes not only ensures more consistent procedures but also helps to lower overall chemical usage and to reduce energy consumption. Implementing automation can also relieve plant staff from performing routine process adjustments, allowing them to focus more on overall optimization, responding to abnormal operating conditions, and ensuring proper equipment operation. In addition to process automation, utilities are now beginning to utilize the power of their SCADA system to support more advanced applications. For instance, system-wide optimization strategies can enable utilities to dramatically reduce the energy costs associated with the distribution of treated water. By integrating their SCADA system with their computerized maintenance management system (CMMS), Utilities can adopt predictive maintenance practices to reduce the costs and improve Continued on next page Over the years, as computer technology has evolved and service areas have expanded, most utilities have upgraded or replaced their SCADA systems a number of times. It is not unusual for a utility to be on their third or fourth generation SCADA system. The power and sophistication of today’s SCADA systems are much greater than previous generation systems while at the same time overall system costs have gone down. Today’s SCADA systems are built on open system components utilizing many of the same hardware and software components found in the other technology systems being used by the utility. www.ca-nv-awwa.org 25 Next Level, Continued the effectiveness of their maintenance program. By utilizing an Operational Data Management System (ODMS), utilities can leverage historical operational data to plan for system expansion and upgrades and can provide utility management with dashboards that present Key Performance Indicators in a real-time fashion. Why Can’t My SCADA System Do That? As the utility industry has begun to fully appreciate the importance and value of SCADA systems, many utilities are frustrated because their existing systems will not allow them to take advantage of these advanced applications. Many systems have evolved in a piece-meal fashion with little standardization of components or implementation techniques. Low bid procurement methods can sometimes force implementers to cut corners by reducing training, documentation, and using substandard components. SCADA Warning Signs In addition, without an effective SCADA Governance program, a utility can allow a solid SCADA System implementation to become difficult to support and virtually impossible to expand or enhance. Without regular upgrades and patches, software applications become outdated and unsupportable. Without consistent change management, maintenance staff is unsure of the most current program version making software modifications risky. Developing a SCADA Master Plan If you find that your current SCADA System is not providing the full value expected, engaging an outside consultant to develop a SCADA Master Plan should be the first step in addressing the issue. By taking a proactive approach, you can set a vision for the upgrades and improvements needed and then set in motion a process for achieving that vision. The process of developing a SCADA Master Plan is comprised of five straightforward steps, shown graphically on page 25. Project Initiation: To initiate the project, the utility should establish a Core Team. The Core Team should consist of three to five staff members who: (1) have detailed knowledge 26 SOURCE summer 2011 Without regular upgrades and patches, software applications become outdated and unsupportable. of the existing SCADA System components; (2) can collectively represent the interests of the utility in defining the requirements for upgrades and improvements to the existing SCADA System; and (3) can dedicate the necessary time to actively participate in the master planning activities. Ideally, the Core Team will continue to participate in the planning and execution of the follow-on projects identified by the Master Plan. In addition to the Core Team, the utility should designate an Executive Steering Committee to provide management oversight and direction to the master planning process. This Committee should include the key utility managers who will help to ensure that the overall goals of the Master Plan are aligned with the Strategic Business Plans of the organization. Current State: It is important to fully understand the current state of the existing SCADA System before developing plans for improvement. This process should begin with a review of design documentation for the existing system. These documents typically include System Block Diagrams, Network Block Diagrams, Communication System Block Diagrams, Record (As-Built) Drawings, Operations and Maintenance (O&M) Manuals, SCADA and I&C Standards, Process Control Narratives, etc. Alternatives Analysis: This step consists of conducting a detailed analysis of functional alternatives for meeting the system requirements addressed by the longer-term projects. These projects can be relatively large in scope, complexity, and cost, and a detailed review of functional alterna- tives is warranted. For some aspects of the planned system improvements, little to no additional analysis will be required since the utility has already established standards, either formal or de facto. There will be other areas that will require additional analysis. For these items, a set of functional alternatives to be analyzed along with a set of criteria for evaluating the merits of each functional alternative should be developed. These criteria will typically include functionality, implementation and support costs, implementation approach, maintainability, expandability, etc. An analysis should be developed for each selected alternative using the evaluation criteria, and a recommended alternative for each area of consideration selected. SCADA Master Plan: The next step is developing the SCADA system master plan itself. The master plan will provide a background section that summarizes the requirements definition and alternative analysis processes. The document will then outline a set of projects that implement the recommended SCADA system improvements. For each project, a conceptual scope of work, implementation schedule, and budgetary cost opinion should be provided. In order to be adopted and fully implemented, it is important that the master plan define a long-term vision for the utility’s SCADA system, not just the next system upgrade. In addition, the plan must consist of pragmatic, practical steps that provide measurable operational benefit to the utility not a collection of esoteric initiatives, which are not likely to be feasible. A SCADA master plan typically contains the following sections: • Executive Overview; • Overview of Current State; • Summary of Functional Requirements; • Recommended Alternatives; • Description of Short-term Projects; and • Description of Longer-term Projects. Conclusion Progressive utilities recognize their SCADA system as a critical component of their system infrastructure. In addition to the mission-critical role of process control, SCADA systems are beginning to be used to for higher-level applications such as predictive maintenance, system-wide optimization schemes, and the long-term planning of capital investments. But some organizations have SCADA systems that will not currently support these types of advanced applications. Proprietary and/ or obsolete components complicate the task of system upgrades or expansion. Inaccurate and incomplete documentation makes system maintenance costly and time-consuming. Utility staff is so busy trying to keep the existing system running, it is difficult to make plans for system improvements. By developing a SCADA system master plan, a utility can set the groundwork for a phased approach for migrating to a SCADA system based on industry best practices. Over the span of the SCADA system improvement program, the utility will begin to reap the benefits For some aspects of the planned system improvements, little to no additional analysis will be required since the utility has already established standards, either formal or de facto SCADA System in an evergreen state, which will continue to meet their needs for many years to come. S Philip Gaberdiel has more than 30 years of engineering experience in the planning and design and implementation of control systems for municipal water and wastewater facilities. His experience includes developing SCADA master plans, managing control system design projects, and performing technical duties including evaluation, design, specification, construction management, commissioning, startup of new and replacement systems, and analysis of existing control systems. Philip is National SCADA Practice Director for Westin Engineering, Inc. He can be reached by email at phil.gaberdiel@ we-inc.com. of their investment in technology. And, by reviewing and updating the plan on a regular basis, the utility can keep their www.ca-nv-awwa.org 27