Our energy working for you.

TM

Prime Power

Case History

Aitutaki, Cook Islands

Where:

Aitutaki, Cook Islands.

What:

Three C900 D5 generator sets, each

with a 820 kVA prime power rating,

a DMC200 digital master control system,

a low voltage paralleling switchboard,

a medium voltage 11 kV/3.3 kV

distribution switchboard, and associated

bulk fuel, exhaust and external radiator

systems.

Purpose:

To provide a reliable power supply to

the growing resort and hotel, and

business and community landscape.

Primary choice factors:

Cummins Power Generation’s ability to

provide a fully integrated and automatic

prime power system and deliver a

cutting-edge diesel power station.

Cummins Power Generation

powers a growing paradise in

the South Pacific.

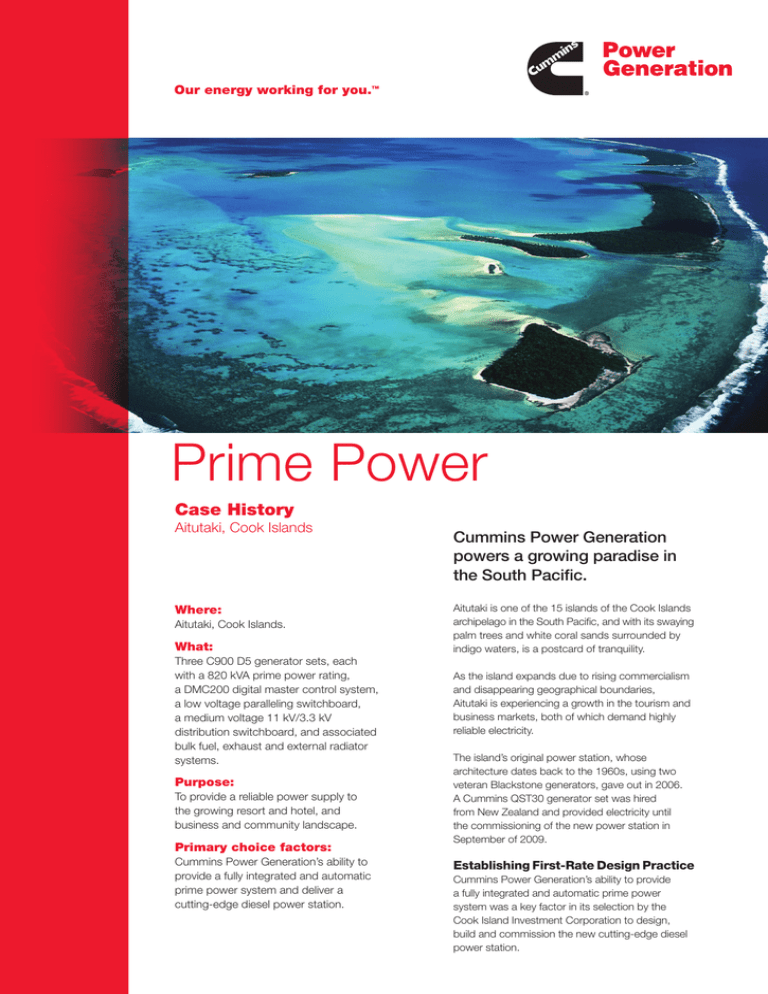

Aitutaki is one of the 15 islands of the Cook Islands

archipelago in the South Pacific, and with its swaying

palm trees and white coral sands surrounded by

indigo waters, is a postcard of tranquility.

As the island expands due to rising commercialism

and disappearing geographical boundaries,

Aitutaki is experiencing a growth in the tourism and

business markets, both of which demand highly

reliable electricity.

The island’s original power station, whose

architecture dates back to the 1960s, using two

veteran Blackstone generators, gave out in 2006.

A Cummins QST30 generator set was hired

from New Zealand and provided electricity until

the commissioning of the new power station in

September of 2009.

Establishing First-Rate Design Practice

Cummins Power Generation’s ability to provide

a fully integrated and automatic prime power

system was a key factor in its selection by the

Cook Island Investment Corporation to design,

build and commission the new cutting-edge diesel

power station.

Cummins Power Generation technician Craig Jenkinson headed up the

testing in Brisbane which was carried out over four days.

The island’s peak load requires two operating gensets, the third unit being

redundant, enabling servicing of the other two without power interruption.

Scott Lomate and the Cummins South Pacific’s prime and

remote power group established the best practice design

and over a number of meetings underpinned customer

confidence in Cummins’ expertise in prime power generation.

The power station was then dismantled and shipped to the

Cook Islands where installation became a simple matter

of bolting together components that had been assembled

previously, thus reducing on-site construction time.

“The old generators were fairly labour intensive to start and

operate compared with the new Cummins system that is fully

automatic and requires relatively little operator involvement,”

says Jeff Evans, Cummins South Pacific Power Generation

project manager.

Digital Master Control Model DMC200

The power station comprises of three Cummins C900 D5

generator sets, each with a 820 kVA prime power rating,

a Cummins DMC200 Digital Master Control system,

a low voltage paralleling switchboard, a medium voltage

11 kV/3.3 kV distribution switchboard, and associated bulk

fuel, exhaust and external radiator systems. These generator

sets are powered by 23-litre Cummins QSK23 engines.

The island’s peak load requires two operating generator sets,

enabling the third unit to provide a backup in the unlikely

event of a generator fault.

“We replicated the complete power station in

Brisbane so the customer could be completely

comfortable that we were delivering the system

we had promised…”

Reducing On-site Construction Time

The power station was fully assembled and tested at the

Cummins Brisbane branch prior to being shipped to the

Cook Islands – an exercise that gave the customer total

confidence in what they were getting.

Jeff Evans elaborates, “In view of the limited engineering

resources on Aitutaki, we decided to carry out full assembly,

performance testing and training for the customer at our

Brisbane facility.”

“We replicated the complete power station in Brisbane so

the customer could be completely comfortable that we were

delivering the system we had promised, and that all their

performance criteria had been met.”

“The testing and training was carried out over four days.

Testing included fully functional operation of the master control

system, including load demand call up/shut down, and load

shed capability, along with load testing of each generator unit.”

The model DMC200 Digital Master Control is fully designed

and built by Cummins and will synchronise the operation of

the diesel generator sets. The DMC200 is a microprocessor

based paralleling system designed to interface directly with

the generator set mounted PowerCommand controllers.

This control system provides enhanced reliability through a

distributed logic approach thereby enhancing uptime and

minimizing downtime or failure to start risks. Power for the

generator controls and master control unit is derived from

the generator starting batteries, and is backed up by an

independent battery system. The PowerCommand control

automatically tests starting battery power on every startup

thereby reducing the risk of failed batteries ... one of the

most common causes of generators failing to start.

The master control provides superior functionality around

load demand, load management and load prioritizing and

also includes a colour touchscreen HMI for easy operator

interface. The PowerCommand system automatically shares

loads amongst the gensets and also adds or sheds loads as

required by the available system capacity.

The Digital Master Control unit can be supplied fully

integrated into the generator paralleling switchgear package,

thereby reducing installation cost and risk or supplied loose

as a free standing unit.

For more information about integrated prime power systems,

contact our local Cummins Power Generation distributor or

visit www.cumminspower.com.

www.cumminspower.com

©2010 Cummins Power Generation Inc.

All right reserved. Cummins Power Generation

and Cummins are registered trademarks of

Cummins Inc. PowerCommand is a registered

trademark of Cummins Power Generation Inc.

“Our energy working for you.” is a trademark of

Cummins Power Generation. APCH-1004-10