8800DB0408

October 2004

Raleigh, NC, USA

Data Bulletin

Altivar® Adjustable Speed Drives

Energy Savings for Pumps

Restricted to Company Personnel

INTRODUCTION

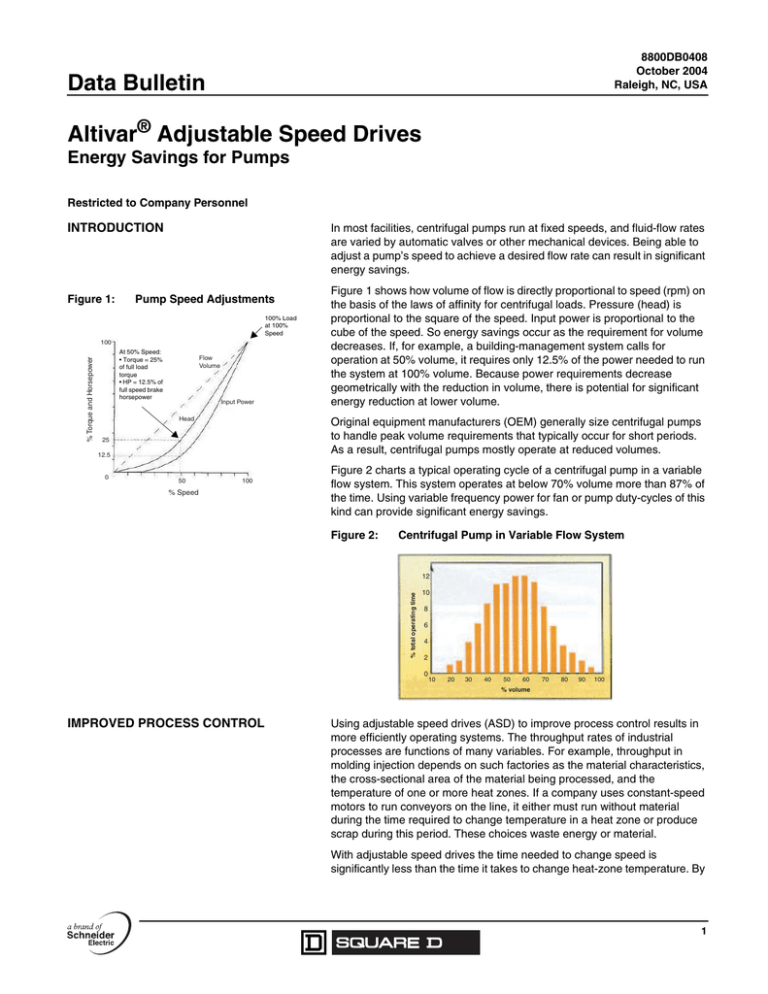

Figure 1:

In most facilities, centrifugal pumps run at fixed speeds, and fluid-flow rates

are varied by automatic valves or other mechanical devices. Being able to

adjust a pump’s speed to achieve a desired flow rate can result in significant

energy savings.

Pump Speed Adjustments

100% Load

at 100%

Speed

% Torque and Horsepower

100

At 50% Speed:

• Torque = 25%

of full load

torque

• HP = 12.5% of

full speed brake

horsepower

Flow

Volume

Input Power

Head

Original equipment manufacturers (OEM) generally size centrifugal pumps

to handle peak volume requirements that typically occur for short periods.

As a result, centrifugal pumps mostly operate at reduced volumes.

25

12.5

0

50

Figure 1 shows how volume of flow is directly proportional to speed (rpm) on

the basis of the laws of affinity for centrifugal loads. Pressure (head) is

proportional to the square of the speed. Input power is proportional to the

cube of the speed. So energy savings occur as the requirement for volume

decreases. If, for example, a building-management system calls for

operation at 50% volume, it requires only 12.5% of the power needed to run

the system at 100% volume. Because power requirements decrease

geometrically with the reduction in volume, there is potential for significant

energy reduction at lower volume.

100

% Speed

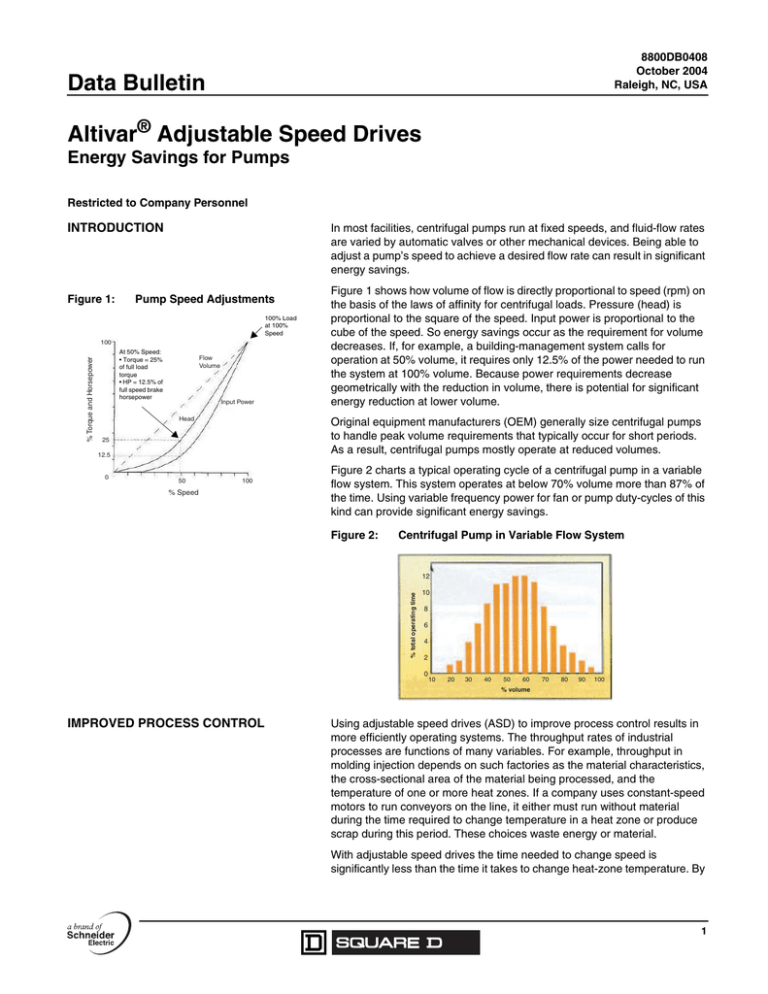

Figure 2 charts a typical operating cycle of a centrifugal pump in a variable

flow system. This system operates at below 70% volume more than 87% of

the time. Using variable frequency power for fan or pump duty-cycles of this

kind can provide significant energy savings.

Figure 2:

Centrifugal Pump in Variable Flow System

% total operating time

12

10

8

6

4

2

0

10

20

30

40

50

60

70

80

90

100

% volume

IMPROVED PROCESS CONTROL

Using adjustable speed drives (ASD) to improve process control results in

more efficiently operating systems. The throughput rates of industrial

processes are functions of many variables. For example, throughput in

molding injection depends on such factories as the material characteristics,

the cross-sectional area of the material being processed, and the

temperature of one or more heat zones. If a company uses constant-speed

motors to run conveyors on the line, it either must run without material

during the time required to change temperature in a heat zone or produce

scrap during this period. These choices waste energy or material.

With adjustable speed drives the time needed to change speed is

significantly less than the time it takes to change heat-zone temperature. By

1

Altivar® Adjustable Speed Drives

Energy Savings for Pumps

8800DB0408

October 2004

adjusting the material flow continuously to match the heat zone conditions,

a company can operate continuously. The results are less energy use and

less scrap.

REDUCED MECHANICAL STRESS:

SOFT STARTING

While most engineers select adjustable speed drives for energy savings and

process improvements, these drives also reduce mechanical stress on

process systems through reduced voltage starting. Starting a motor on line

power increases stress on the mechanical system causing belts to slip and

squeal, high pressure develops in pipes and ducts, and chains jump.

Reduced-voltage and reduced-frequency starting decreases this

mechanical stress. Adjustable speed drives vary the output voltage along

with output frequency to control a motor's torque and speed. This control

results in a soft start as the motor's speed accelerates based on a preprogrammed rate. Acceleration time in most adjustable speed drives can be

varied from 5 to 360 seconds. In short, variable-speed drives inherently offer

soft starts.

IMPROVED ELECTRICAL SYSTEM

POWER FACTORS

OEMs are concerned about how adjustable speed drives affect their

facility's power factor because many utility companies penalize facilities with

poor power factors. Figure 3 shows a typical power factor triangle.

Figure 3:

The size of a building's power distribution system is represented in kVA. The

useful work performed by motors and other electrical equipment wired to the

power system is measured in kW. It's useful to think of power factor as the

measure of a device's efficiency in converting power consumed (kVA) to

useful work (kW). Cos Θ represents the power factor. See Θ (or inverse

cos Θ) gives the angular displacement in the power factor triangle.

Typical Power Factor Triangle

kW

Power factor = cos θ = ____

kVA

kVA

kVAr

θ

kW

Schneider Electric USA

8001 Highway 64 East

Knightdale, NC 27545 USA

1-888-SquareD (1-888-778-2733)

www.us.SquareD.com

To function, all induction machines, including motors or active current,

require magnetizing power. A machine's kW and power factor determine the

magnetizing power (the vertical segment of the power factor triangle),

labeled kVAr (kilovolt-ampere reactive).

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 2004 Schneider Electric All Rights Reserved