Industrial

Catalogue

www.lumacell.com

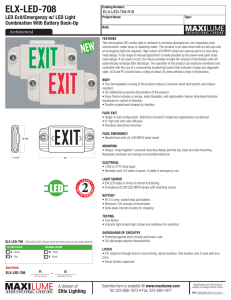

CATALOG

Special Collection

3. Products Table of Contents ............................................ 11

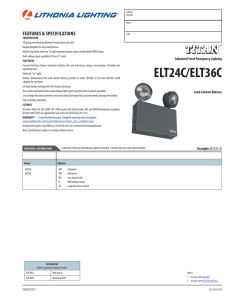

4. Exit Signs ........................................................................ 15

5. Remotes.......................................................................... 37

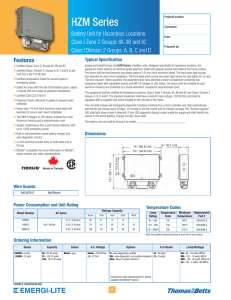

6. Battery Units .................................................................. 51

7. DC Systems, Options & Acessories .............................. 59

INDEX

2. IP Rating ........................................................................ 10

Special Collection

1. Hazardous Locations - C.E.C. Classifications ................ 06

Hazardous Locations — C.E.C. Classifications

C.E.C. Code Changes

Classes

In 1998, the Canadian Electrical

Code® (C.E.C.) adopted the

International Electrotechnical

Commission's (IEC) “Three Zone

Area” Classification System for

Class I hazardous locations. The

Zone System is an alternate

classification for Class I

hazardous locations and was

adopted to promote

harmonization with international

standards.

The Canadian Electrical Code

(C.E.C.), Part I, Section 18 Hazardous Locations, identifies three

classes of hazardous locations:

• Class I - Gas and Vapour

Environments

• Class II - Dust Environments

• Class III - Fibers and Flyings

Environments

The Division System for Class I

hazardous locations continues to

be used for existing facilities and

is expected to remain in use at

least for the next few editions of

the C.E.C. For this reason, this

catalogue's certification

information for Class I hazardous

locations includes both the pre1998 Division System and the

new I.E.C. Zone System.

The following pages provide an

overview of C.E.C. hazardous

location classifications.

The 1998 revisions to the C.E.C.

affect only Class I - Gas and

Vapour Environments.

Hazardous location is defined by the

C.E.C. as premises, buildings or parts

thereof in which there exists the

hazard of fire or explosion due to

highly flammable gases and/or

flammable, volatile liquid mixtures that

are manufactured, used or stored in

other than the original containers.

This definition can also be extended

to include combustible dust and

easily ignitable fibers that are likely

to be present in sufficient quantities

to produce an explosive mixture.

Class I — Gas and Vapour Environments

Locations which are deemed

hazardous due to the presence of

gases or vapours that are present

in the air in a sufficient quantity to

produce explosive or ignitable

mixtures.

Locations identified as Class I

require that enclosures and

connectors be explosion-proof.

Class I hazardous locations are

further subdivided into :

• Divisions (pre-1998 version of the

C.E.C.), or

• Zones (I.E.C. Classification - 1998

C.E.C.)

The Division System may still be

used for the maintenance and repair

of existing facilities. All new

construction must use the I.E.C.

Zone Classification.

Divisions

• Division 1 — a Class I location

where the hazardous atmosphere

is expected to be present during

normal operations on a

continuous, intermittent or

periodic basis.

• Division 2 — a Class I location in

which volatile flammable liquids or

gases are handled, processed or

used but in which they would

normally be confined within closed

containers or closed systems from

which they can escape only in the

event of an accidental rupture or

breakdown of the containers or

systems.

6

Hazardous Locations — C.E.C. Classifications

Class I — (continued)

• Zone 0 — Class I locations in

which explosive gas atmospheres

are present continuously or are

present for long periods.

• Zone 1 — Class I locations in

which:

i. explosive gas atmospheres are

likely to occur in normal

operation; or

ii. explosive gas atmospheres may

exist frequently because of

repair or maintenance

operations or because of

leakage; or

iii. the location is adjacent to a

Class I, Zone 0 location, from

which explosive gas

atmospheres could be

communicated.

• Zone 2 — Class I locations in

which:

iv. explosive gas atmospheres are

not likely to occur in normal

operation and if they do occur

they will exist for a short time

only; or

v. flammable volatile liquids,

flammable gases or vapours are

handled, processed, or used,

but in which liquids, gases or

vapours are normally confined

within closed containers or

closed systems from which they

can escape only as a result of

accidental rupture or

breakdown of the containers or

systems or the abnormal

operation of the equipment by

which the liquids or gases are

handled, processed or used; or

vi. explosive gas atmospheres are

normally prevented by adequate

ventilation by which may occur

as a result of failure or abnormal

ope-ration of the ventilation

system; or

vii. the location is adjacent to a Class

I, Zone 1 location from which

explosive gas atmospheres could

be communicated, unless such

communication is prevented by

adequate positive-pressure

ventilation from a source of clean

air, and effective safeguards

against ventilation failure are

provided.

Hazardous Locations

Zones

Area Classification — Divisions vs. Zones

Intermittent Hazard

Zone 1

Division 1

Class I Equipment

Electrical equipment that is

approved for use in Class I

Hazardous Location Areas (HLAs) is

referred to as explosion-proof or

flame-proof. This designation means

that the equipment has been

designed and manufactured to

ensure that it will not become a

source of ignition when used in a

Class I, Gas and Vapour HLA.

All explosion proof equipment is

clearly identified by either:

Division 2

• a «Class I Location» marking

(Division System); or

• a «Type of protection “d”» marking

(IEC Zone System).

Gas Group Designations

Two systems of groupings for gases

are included in the 1998 C.E.C: the

pre-1998 Division Gas Groups

consisting of Groups A, B, C and D;

and the IEC System consisting of

Groups IIA, IIB and IIC.

Both systems are accepted by the

C.E.C.

7

Continuous Hazard

Zone 0

Hazard Under

Abnormal Conditions

Zone 2

Hazardous Locations — C.E.C. Classifications

Class I — (continued)

Comparison of Hazardous Location Gas Group Designations

From Most Restrictive to Least Restrictive

Typical Gas

Hazard

Division Gas

Groups

1998 CEC and IEC

Gas Groups

Acetylene

Hydrogen

Ethylene

Propane

A

B

C

D

IIC

Division Gas Groups

IIB

IIA

I.E.C. Zone Gas Groups

• Group A

acetylene

• Group B

butadiene, ethylene oxide,

hydrogen, manufactured gases

containing more than 30%

hydrogen (by volume),

propylene oxide.

• Group C

acetaldehyde, cyclopropane,

diethyl, ether, thylene,

unsymmetrical dimethyl

hydrazine (UDMH 1, 1-dimethyl

hydrazine).

• Group D

acetone, acrylonitrile, alcohol,

ammonia, benzene, benzine,

benzol, butane, 1-butanol,

2-butanol, butyl acetate,

isobutyl acetate, ethane,

ethanol, ethyl acetate, ethylene

dichloride, gasoline, heptanes,

hexanes, isoprene, methane,

methanol, 3-methyl-1-butanol,

methyl ethyl ketone, 2-methyl1-propanol,

2-methyl-2-propanol, naphtha,

natural gas, petroleum naphtha,

octanes, pentanes, 1-pentanol,

propane, 1-propanol, 2propanol, propylene, styrene,

toluene, vinyl acetate, vinyl

chloride, xylenes

• Group IIC

acetylene, butadiene, propylene

oxide, carbon disulphide,

hydrogen or other gases or

vapour of equivalent hazard

• Group IIB

cyclopropane, diethyl ether,

ethylene, ethylene oxide,

hydrogen sulfide,

unsymmetrical dimethyl

hydrazine (UDMH) or other

gases or vapour of equivalent

hazard

• Group IIA

acetaldehyde, acetone,

acrylonitrile, alcohol, ammonia,

benzine, benzol, butane,

ethylene dichloride, gasoline,

hexane, isoprene, lacquer

solvent vapours, naptha, natural

gas, propane, propylene,

styrene, vinyl acetate, vinyl

chloride, xylenes or other gases

or vapour of equivalent hazard

8

Hazardous Locations — C.E.C. Classifications

Comparison of Division and I.E.C. Zone Systems

Class 1

Gases

and

Vapours

Division

System

I.E.C.

Zone System

Zone 0

Zone 0 locations are a small percentage of all

hazardous locations.

Zone 1

While the wiring practices and acceptable products

differ, Class I, Division 1 locations encompass both

Zones 0 and 1.

Zone 2

Zone 2 and Division 2 are essentially the same.

Division 1

Division 2

Notes

Class II — Dust Environments

Locations which are deemed hazardous

due to the presence of combustible or

electrical conducting dusts.

Class II locations normally require

that enclosures and connectors be

dust tight.

Class II — Divisions

Class II locations are further divided in two divisions as follows:

• Division 1 — In which

combustible dust is or may be in

suspension in air continuously,

intermittently or periodically under

normal operating conditions.

• Division 2 — In which combustible

dust may be in suspension in the air

as a result of infrequent

malfunctioning.

Class II — Group Designations

The Canadian Electrical Code

(C.E.C.), Part 1 Section 18 Hazardous Locations defines

various groups which have been

established for the purpose of

testing and approval.

similarly hazardous

characteristics.

• Group F — Comprising

atmospheres containing carbon

black, coal or coke dust.

• Group E — Comprising

atmospheres containing metal

dust including aluminum,

magnesium, and their commercial

alloys, and other metals of

• Group G — Comprising

atmospheres containing flour,

starch or grain dust, and other

dusts of similarly hazardous

characteristics.

Class III — Fibers and Flyings Environments

Locations which are deemed

hazardous due to the presence of

easily ignitable fibers or

flyings, but in which such fibers

or flyings are not likely to be in

suspension in the air in sufficient

quantities to produce ignitable

mixtures.

Class III locations normally require

that enclosures and connectors be

constructed to minimize the entry of

fibers or flyings.

Class III — Divisions

9

Class III locations are further divided in two divisions as follows:

• Division 1 —In which readily

• Division 2 — In which readily

ignitable fibres or materials

ignitable fibres other than those in

producing combustible flying are

process of manufacture are stored

handled, manufactured or used.

or handled.

IP Rating

lthough IP is mainly a European

rating system, it is referred to

more and more in North America,

especially for lighting fixtures

needing a wet location label.

A

The first number of an IP rating

represents the degree of protection

against penetration of solids and the

second number, the degree of

protection against penetration of

water. So, for example, a wall

sconce that is rated IP65 is

completely protected against

penetration of dust particles and

against jets of water.

Degree of protection

FIRST IDENTIFICATION

NUMBER

Degree of protection against

penetration of solids.

SECOND IDENTIFICATION

NUMBER

Degree of protection against

penetration of water.

0

Not Protected

0

Not Protected

1

Protected against

penetration of solids larger

than 2”

1

Protected against vertical

fall of water drops

2

2

Protected against

penetration of solids larger

than 1/2”

Protected against the fall of

water at a maximum angle

of 15”

3

Protected against rain

3

Protected against

penetration of solids larger

than 3/32”

4

Protected against splashes

5

Protected against

penetration of solids larger

than 1/32”

Protected against jets of

water

6

Protected against waves

7

Protected against the

effects of immersion

8

Protected against the

effects of prolonged

immersion

4

5

Protected against

penetration of dust

6

Completely protected

against penetration of dust

10

CATALOG

Products

Products

RG12S-E Series

page 16

High Capacity Combo Unit

The RG12S-E series combines an efficient exit sign with a high capacity battery unit. This

simplifies typical installations and helps save on wires runs. Energize either many remote

fixtures off of one “combo” or, a few high power fixtures mounted directly on the unit.

LER-HZ Series

page 18

Hazardous Location Exit Sign Class I Zone 2

Extremely resistant to water, strong impacts, vibrations and variations in temperature,

the LER-HSZ is ideally suited for areas whith the risk of presence of flammable gases,

vapors or liquids able to create an explosive gas atmosfere.

LERE-XP Series

page 20

Hazardous Location Exit Sign Class I, II, III

The LERE-XP Series of remote exit signs are designed to cover emergency lighting

applications for the entire spectrum of hazardous locations, where inflammable gases,

vapors, liquids, dust particles or fabrics tissues are permanently present or are likely to exist.

LEREOB12L Series

page 22

NEMA-3R Certified Bilingual Exit Sign

The LEREOB12L Series exit sign is specifically designed for industrial applications

requiring protection against adverse environmental conditions. This exit sign is ideally

suited for high abuse areas, wet locations, dust- and oil-tight applications.

LTEU Series

page 24

Power-Free Exit Sign

The LTEU Series exit sign is completely self-luminous, requiring no electrical source, and

is ideally suited for applications where electrical installation is hazardous or prohibitively

expensive such as historical buildings, mines and industrial facilities.

3LER3000 Series

page 26

NEMA-4X Certified Combo Unit

A complete emergency lighting solution, these products are designed for use in a wide

range of commercial and industrial environments where humidity, dust, water infiltration

and the risk of vandalism are specification criteria.

LER3000 Series

page 28

NEMA-4X Certified Exit Sign

A complete emergency lighting solution, these products are designed for use in a wide

range of commercial and industrial environments where humidity, dust, water infiltration

and the risk of vandalism are specification criteria.

RG-X Series

page 30

Hazardous Locations Unit and Combo, Class I, II, III

Extremely resistant to water, strong impacts, vibrations and variations in temperature,

the LER-HSZ is ideally suited for areas whith the risk of presence of flammable gases,

vapors or liquids able to create an explosive gas atmosfere.

3LERHZ Series

page 32

Combination Unit for Class I Zone 2 Hazardous Locations

The 3LERHZ Series of combination units (unit equipment and exit sign) are designed

specifically for installation in hazardous locations and other high-abuse, industrial

environment.

12

Products

page 36

MQM-HZ Series

Remote Fixture for Hazardous Locations Class I Zone 2

The MQM-HZ Series of remote fixtures has been designed specifically for

installation in hazardous locations and other and high-abuse, industrial

environments.

page 38

MQM-NX Series

Remote Fixture - Water Proof NEMA-4X Series

A complete emergency lighting solution, these products are designed for use in a wide

range of commercial and industrial environments where humidity, dust, water infiltration

and the risk of vandalism are specification criteria.

page 40

Saf-T-Ray Series

Vandal Resistant Wall Mount Remote Head

The Saf-T-RayTM wall sconce unit was designed and engineered with durability and

sophistication in mind. Its low-profile aesthetic design will provide an attractive

alternative to the typical two-headed standard emergency lighting unit.

page 42

RS10XP Series

Remote Lighting Fixtures for Hazardous Location Class I, II, III

The RS10XP Series of remote emergency lighting heads is designed to cover emergency lighting

applications for the entire spectrum of hazardous locations, where inflammable gases, vapors,

liquids, dust particles or fabrics, tissues are permanently present or are likely to exist.

page 44

RS-WP Series

Remote Fixture - Water Proof Series

PAR 36, surface-mounted industrial remote fixtures. Available in single, double or triple

head fixtures. Durable thermoplastic construction suitable for industrial or high abuse

areas.

page 45

RS-WPRB Series

Water Proof Series

Sealed beam, PAR 36, surface-mounted, rubber coated industrial remote fixture.

page 45

MT-W4T Series

Water Proof Series

NEMA-4X listed, surface-mounted, square industrial remote fixture. Available with

tungsten or quartz lamps in single or double head configurations. Gray fiberglass base

and clear polycarbonate lens.

page 46

RS10/RS20/RS30T Series

Surface Mounted Series

PAR36, surface-mounted, large remote fixtures. Single, double or triple head. Positive

aim swivel. Available in factory white (standard) and black.

page 47

RSQB/RSQBD/RSQB2 Series

Surface Mounted Series

13

Cubic, vandal-resistant surface-mounted fixture. Single, double or twin cube with center

body. Available in factory white (standard) and black with frosted polycarbonate cube.

Products

RGS-DT Series

page 50

NEMA-12 Cassified, 6, 12 and 24 Volts Battery Units

The RGS-DT Series battery units are specifically designed for use in industrial facilities

where equipment is exposed to dust, water, oil or corrosive substances.

RG-NX Series

page 52

NEMA-4X Certified Battery Unit

A complete emergency lighting solution, these products are designed for use in a wide

range of commercial and industrial environments where humidity, dust, water infiltration

and the risk of vandalism are specification criteria.

RG-HZ Series

page 54

Battery Unit for Hazardous Locations Class I Zone 2

The RG-HZ Series of battery units are designed specifically for installation in hazardous

locations and other high-abuse, industrial environments. Extremely resistant to water,

high impacts, vibrations and variations in temperature.

IPLTM Series

page 56

IP65 Linear Fluorescent Fixture

The IPLTM Series of fluorescent fixtures by Lumacell are offered as normally on standard

linear fluorescent fixtures. When used with one of our fluorescent inverters, the IPLTM is

converted to a self-powered emergency lighting unit.

LUMA Source Series

page 62

120 VDC Central Single Source

In an existing or new installation where exit signs and emergency lighting

may be supplied by a single 120VDC source using a common negative

wire and a switched positive.

DC Central Systems

page 64

Fully Automatic Charger

Lumacell’s Central DC Systems are utilized where a large number of remote heads or

standard 120 Volt incandescent fixtures. The systems offer the advantage of a central

location for maintenance with full supervision of all operating functions.

Zone Sensing VSR Series

page 68

The VSR (Voltage Sensing Relay) option activates all of the emergency

lighting if only one, multiple or all zones become de-energized through

either a power failure or lighting circuit breaker tripping.

Nexus System

page 70

The NEXUS project started in Australia. Following many successful installations “down

under”,Thomas & Betts decided to adapt NEXUS to North American norms and

specifications, as this system is a truly useful maintenance tool for property owners and

managers.

14

CATALOG

Exit Signs

RG12S-E

Series

High Capacity Combo Unit

Up to 360 watts of Remote Capacity

Features

• High quality steel enclosure with corrosion resistant undercoating

• Fully C860 approved “Exit” legend illuminated with ALINGAP LEDs

• Available in 12 volts, 110, 144, 250 and 360 watts

• Standard 120/347Vac input

• Optional Auto-test charger (available with 110 watts only)

• Long life, maintenance free lead acid battery

• Sealed dust-proof transfer relay

• Solid state pulse type charger standard

Typical Specification

The RG12S-E series

combines an efficient exit

sign with a high capacity

battery unit. This simplifies

typical installations and

helps save on wires runs.

Energize either many

remote fixtures off of one

“combo” or, a few high

power fixtures mounted

directly on the unit

Supply and install a unit that

combines an illuminated LED exit

sign with an emergency light battery

unit. The housing and faceplate shall

be constructed of steel. The

faceplate shall come standard with

knock out chevrons. The light source

for the exit sign shall be LED. The

LED lamps shall provide illumination

in normal and emergency operation.

Red LEDs shall be of ALINGAP*

technology. The charger board, the

battery and the LEDs shall be

contained in a single housing. A

diffuser optimized for LEDs shall be

mounted behind the legend to

provide the 6” high by 3/4” stroke

letters with even illumination.

The unit shall include a test switch

and high charge pilot light. The

equipment shall be designed to

furnish exit illumination from the

normal AC source. When a power

failure occurs, the exit sign along

with the emergency heads shall

illuminate for a minimum of 30

minutes. The power available for

emergency lights shall be at least

110 watts or as otherwise specified.

The heads shall require no tools to

aim and shall be as specified. The

exit sign shall be CSA-C860-07

approved.

The equipment shall be Lumacell

Model – RG12S_________________.

Dimensions

10 1/4”

[26.0cm]

16 1/8”

[41.0cm]

16 1/8”

[41.0cm]

13 7/8”

[35.3cm]

5 1/2”

[13.8cm]

13 7/8”

[35.4cm]

10 1/4”

[26.1cm]

5 1/2”

[13.8cm]

16 1/8”

[41.1cm]

B CABINET

(110W and 144W)

23 1/8”

[58.8cm]

5 1/2”

[13.8cm]

C CABINET

(250W and 360W)

5 3/8”

[13.8cm]

16

EXAMPLE:

RG12S110

Series

RG12S110 =

12V-110watts

E

2

Lettering # of Heads

E=

EXIT

MT9W

B

ZC

AT

Head Style and Wattage

Colour*

Voltage

Options

MT9W =

mini tungsten, 12V - 9watt, wedge base

RG12S144 =

12V-144watts

1=

one head

MT18W =

mini tungsten, 12V - 18watt, wedge base

RG12S250 =

12V-250watts

2=

two heads

MQ8W =

mini halogen, 12V - 8watt, quartz bi-pin

RG12S360 =

12V-360watts

3=

three heads

MQ12W =

mini halogen,12V -12watt, quartz bi-pin

Blank =

Blank =

AT =

factory white 120/347VAC autotest (110w only)

B=

Black

ZC =

277VAC

Blank =

No options

Series

Blank =

no heads

RG12S-E

Ordering Information

MM12W =

mini halogen,12V - 12watt, MR16

MM20W =

mini halogen, 12V - 20watt, MR16

LH9W =

large tungsten ,12V - 9watt, wedge base

LH18W =

large tungsten, 12V - 18watt, wedge base

LH25W =

large tungsten,12V - 25watt, DCB

LQ12W =

large halogen,12V - 12watt, quartz bi-pin

LQ20W =

large halogen, 12V - 20watt, quartz bi-pin

LQ55W =

large halogen,12V - 55watt, quartz bi-pin

SB12W =

large tungsten,12V - 9watt, sealed beam

SB18W =

large tungsten,12V - 18watt, sealed beam

SB25W =

large tungsten, 12V - 25watt, sealed beam

SQ8W =

large halogen,12V - 8watt, quartz sealed beam

SQ12W =

large halogen,12V - 12watt, quartz sealed beam

D12W =

Deco head DR130, 12V - 12watt, MR16

B Cabinet for

110w or

144w and C

Cabinet for

250w or

360w

D20W =

Deco head DR130, 12V - 20watt, MR16

D35W =

Deco head DR130, 12V - 35watt, MR16

D50W =

Deco head DR130, 12V - 50watt, MR16

* Other colours

availble on

demand.

Consult your

sales

representative.

17

*ALINGAP (AlInGaP): Aluminum, Indium, Gallium and Phosphorus. ALINGAP LED

offers a higher light efficacy, with the Lumen/Watt ratio 300% to 500% higher than

the traditional GaAs LED.

AlInGaP Exit signs are designed for 10 years+ of CSA/UL photometric compliance.

AlInGaP LEDs show an annual light loss rate 10 times lowers than the average light

loss of standard GaAs LEDs.

LER-HZ

Series

HAZARDOUS LOCATION LED EXIT SIGN

Class I, Zone 2 - compliant LED exit sign

Features

The LER-HZ Series of Exit

signs has been designed

specifically for installation in

hazardous locations and

other high-abuse, industrial

environments. Extremely

resistant to water, high

impacts, vibrations and

variations in temperature,

the LER-HZ Series is ideally

suited for areas with the risk

of presence of flammable

gases, vapors or liquids

able to create an explosive

gas atmosphere.

• Certified Class I Division2, Groups A, B, C and D as per CSA C22.2

No.137-M1981, Class I, Zone 2, Groups IIC, IIB and IIA

• Temperature Code: T6 (maximum 85ºC as per Canadian Electrical

Code, Part I and CSA C22.2 No.137-M1981)

• Certified CSA C860-07

• Suitable for cold-weather: -20ºC (self-powered model, “CW” option)

and -40ºC (AC-only and AC-DC models)

• Input voltages: 120 to 347Vac universal AC-input; 6 to 48Vdc universal

DC-input

• High impact thermoplastic frame, with built-in gasket to prevent

water infiltration

• Sealed faceplate of heavy-duty, vandal-resistant polycarbonate

• Tamper-resistant, hermetically sealed magnetic test switch

• Self-test / self-diagnostic circuitry is standard on self-powered

models

• Sealed, maintenance-free, Nickel-Cadmium batteries

• Batteries recharge as per CSA requirements and provide 90 minutes

of emergency operation

• Long-life, energy-efficient ALINGAP red LED light source

• Energy efficient – consumes less than 3 watts in AC or DC mode

Typical Specification

Supply and install Lumacell LER-HZ

Series LED exit signs. The equipment

shall operate with universal two-wire

AC input voltage from 120Vac to

347Vac at less than 3 watts and

universal two-wire DC input voltage

from 6Vdc to 48Vdc at less than 2

watts for single and double face

signs. Designed specifically for hostile

environments, the equipment frame

shall be of industrial grade high

impact thermoplastic with a gasket

around lenses and canopy. The

faceplate(s) shall be constructed of

heavy-duty vandal-resistant

polycarbonate and feature an even

illuminated legend. The light source

shall be light emitting diodes (LED).

Red LED technology shall be

ALINGAP. An LED-sensitive diffuser

shall be mounted behind the legend

to provide the 6” high by 3/4” stroke

letters with even illumination.

The equipment shall be certified for

Hazardous Locations: Class I Division

2 Groups A, B, C and D with a

temperature code T6 (Maximum

85ºC). The equipment shall be

designed specifically for high abuse

areas, wet location, and cold weather

(-20°C) applications. The self-powered

model shall stay illuminated during

emergency operation for at least 90

minutes upon AC failure and shall

include a magnetic test switch and

self-testing / self-diagnostic functions.

The equipment shall automatically

self test for 5 minutes every 30 days,

30 minutes every 60 days and 90

minutes annually. A “Service

required” lamp shall be located near

the test switch and flash when a fault

is detected. A two-LED diagnostic

display shall be located inside the

equipment and shall identify the

eventual source of failure (battery,

charger circuitry, or LED lamps).

The exit sign shall be CSA-C860-07

approved.

The exit sign shall be Lumacell

Model – _______________________.

18

LER-HZ

Dimensions

4 3/8”

(11 cm)

2 1/4”

(5.7 cm)

Series

13 1/2”

(34.2 cm)

9 1/8”

(23.2 cm)

13 1/4”

(33.6 cm)

3 1/2”

(8.9 cm)

Power Consumption

Model

AC Specs

AC/DC red

AC/DC green

Self-powered red

Self-powered green

120 to 347Vac

120 to 347Vac

120 to 347Vac

120 to 347Vac

DC Specs

Less than 3W

Less than 3W

Less than 3W

Less than 3W

6 to 48Vdc

6 to 48Vdc

NiCad battery

NiCad battery

Less than 2W

Less than 2W

Min. 90 minutes

Min. 90 minutes

Ordering information

EXAMPLE:

LERHZ

500

SG

SPD

GN

Series

Faces/Mounting

Colour

Voltage

Options

LERHZ =

EXIT

hazardous

location

500 =

single face, ceiling or wall

mount

600 =

double face, ceiling mount only

SG =

grey/grey

Blank =

universal120-347Vac, 6-48Vdc

SPD =

120-347Vac, self-powered c/w diagnostic

(non audible)

VACDC2 =

120Vac, 120Vdc 2 wire (AC only)

NEX =

Nexus System Interface*

Blank =

no option

GN =

green letters

CW =

cold weather*

19

*Nexus option with self-powered models only

*(-20ºC for selfpowered, -40ºC

for AC/DC)

LERE-XP

Series

Hazardous Location

Exit Signs

RSTP

Series

Transfer

Panels

CSA certified for use in hazardous locations

Class I, Zone 1, Groups IIC, IIB and IIA for Severity Code 1 products

Class I, Zone 1, Groups IIB and IIA for Severity Code 2 products

Class I, Zone 2, Groups IIC, IIB and IIA for Severity Code 3 products

Features

REW-XP Series Exit Signs

The LERE-XP Series of

remote exit signs are

designed to cover

emergency lighting

applications for the entire

spectrum of hazardous

locations, where

inflammable gases, vapors,

liquids, dust particles or

fabrics tissues are

permanently present or are

likely to exist. The LERE-XP

remote exit signs can be

connected to the RSTP

transfer panel (see below),

the RG-X Series of battery

equipment, or the Lumacell

DC system.

• CSA Certified for use in hazardous locations:

• Class I, Divisions 1 and 2, Groups A, B, C, D

• Class II, Divisions 1 and 2, Groups E, F, G

• Class III, Divisions 1 and 2

• Die-cast aluminum body with gray epoxy powder coat finish

• Exit housing and faceplate made of industrial-grade 14-gauge steel

and finished in gray enamel

• Faceplate features universal knockout chevrons

• Two-wire input circuit for both AC and DC inputs

• Available in 6, 12, 24 and 120Vac/dc

• LED lamp with ALINGAP LEDs; consumes less than 5 Watts in AC

and DC mode

• New, easy-to-build catalogue number based on the Lumacell Severity

Codes

• CSA certified, meets or exceeds C860-07 requirements

RSTP Series Transfer Panel

• Available with hazardous location housing (Class I, II and III) or

NEMA-1 housing (for use outside the hazardous location area)

• Standard AC input: 120Vac, optional 277Vac, 347Vac; standard DC

input: 6, 12 or 24Vdc

• Two-wire output with permanently present AC/DC low voltage

• Output power: 25W, can drive up to five (5) units of the LERE-XP

remote exit series

• Also available as self-powered exit sign, battery unit and combo unit;

see RG-X catalogue sheet

Typical Specification

LERE-XP Series Remote Exit Sign:

Supply and install the Lumacell

LERE-XP Series remote exit sign.

The exit housing shall be industrial

grade 14-gauge steel and finished in

gray enamel. The faceplate will be

constructed of heavy-duty

14-gauge steel and feature universal

knockout chevrons and the red letters

shall not be less than 6” (150 mm) in

height with a 3/4” (19 mm) stroke.

The sign shall come complete with a

____Volt LED lamp, and function from

one voltage source only, in AC and DC

current. The LED Lamp shall use

ALINGAP LEDs and shall consume less

than 5 watts in either AC or DC current.

The exit sign shall be CSA-C860-07

approved.

The exit sign shall be suitable for

Class ___, Division ___, Group ____.

The exit sign shall be Lumacell

Model - ________________________.

RSTP Series Transfer Panel:

Supply and install the Lumacell

RSTP Series transfer panel for

hazardous location remote exit

signs. The unit shall have two

voltage inputs: ____ Vac and ____

Vdc and shall be able to maintain

an output of ____Volts 25 watts for

the permanent supply of a total of

four remote LED exit signs.

The transfer panel shall be suitable

for Class ___, Division ___,Group ___

or for a NEMA 1 environment.

The unit shall be Lumacell Model __________________.

20

CEILING MOUNT

PENDANT MOUNT

8 3/8”

[21.3cm]

147/8” [37.7cm]

6”

[15.3cm]

33” [83.9cm]

6”

[15.3cm]

173/8” [44.2cm]

123/8” [31.4cm]

9” [22.9cm]

91/4” [23.5cm]

8” [20.3cm]

10”

[25.4cm]

14

107/8” [27.5cm]

S2, S3 and S4

10 / ”

[26.0cm]

281/2” [72.3cm]

6”

[15.3cm]

Severity Class S1,

6”

[15.3cm]

121/4” [31.2cm]

123/8” [31.4cm]

133/8” [34.1cm]

33/8” [8.4cm]

31/2” [9.0cm]

111/4” [28.7cm]

107/8” [27.5cm]

19 / ” [50.50cm]

34

10 / ” [27.5cm]

3 1/8”

[7.8cm]

78

SEVERITY S3, S4

123/8” [31.4cm]

303/4”

[78.0cm]

121/4” [5.7cm]

Before ordering, identify the environment of your application: Class___, Division___,

Group___. Refer to the following chart for the Severity Code to use in your catalogue

number:___________________ .

For temperature information, please

Severity

Environment

look at the table below:

Code

Cl. I, Div. 1, Gr. A, B

Cl. I, Div. 1, Gr. C, D

CI. I, Div. 2, Gr. A, B, C, D

Cl. II, Div. 1 & 2, Gr. E, F, G

Cl. III, Div. 1 & 2

S1

S2

S3

S4

Series

12 3/8”

[31.4cm]

4” [10.1cm]

& RSTP

4 1/8”

[10.4cm]

303/8”

[77.1cm]

8 1 /2”

[21.5cm]

95/8” [24.5cm]

241/4” [61.5cm]

7 1/8”

[18.1cm]

14 / ” [37.7cm]

78

12 3/8”

[31.4cm]

6”

[15.3cm]

5 1 /4 ”

[13.3cm]

No Severity Rating

Series

SEVERITY S1, S2

DOUBLE PENDANT MOUNT

LERE-XP

Dimensions

Certification Guide for LERE-XP Series Exit Signs (40°C ambient)

Severity Code

S1

S2

S3

S4

Temperature Code

T6

T6

T3C

T3C (EGF)

Max 85°C

Max 85°C

Max 160°C

Max 160°C

CSA/UL rating

Ordering Information

EXAMPLE:

LERE1X

-L12

S1

W

Series

Voltage

Lamp Type

Severity Code

Mounting

LERE1X =

exit single face C860 LED

LERE2X =

exit double face C860 LED

-L6 = 6 volts

-L12 = 12 volts

-L24 = 24 volts

-L120 = 120 volts

Blank = L.E.D. less

than 5 watts

S1 = see chart

S2 = see chart

S3 = see chart

S4 = see chart

C = ceiling

P = pendant

W = wall

RSTP

120

12

25

Series

A.C. Voltage

D.C. Voltage

Load Wattage

Housing

RSTP = transfer panel

120 = 120Vac

347 = 347Vac

6 = 6 volts

12 = 12 volts

24 = 24 volts

25 = 25 watts

Blank = NEMA 1

XP = hazardous

location

Transfer Panel

21

EXAMPLE:

LEREOB12L

Series

NEMA-3R Certified Bilingual Exit Sign

Features

The LEREOB12L Series exit

sign is specifically designed

for industrial applications

requiring protection against

adverse environmental

conditions. This exit sign is

ideally suited for high abuse

areas and wet locations

applications.

• Certified NEMA-3R

• Gasketed fiberglass housing designed specifically for industrial

applications

• Gray finish is standard

• Sealed, vandal-resistant polycarbonate faceplate

• Long-life, even illumination of “EXIT SORTIE” legend provided by

energy efficient, ALINGAP technology LED light source consuming

less than 3 watts per face (standard AC/DC model)

• Wall or ceiling mounting; wall or ceiling brackets available for easy

installation

• Normal AC and emergency DC operation – 120 to 347 volts AC input;

6 to 24 DC input

• CSA certified, meets or exceeds C860-01 and NRCAN/C860-01

requirements

• The self-powered version is also CSA C22.2 No. 141 certified

Typical Specifications

Supply and install Lumacell

LEREOB12L Bilingual Led exit sign.

The equipment shall operate with

universal two-wire AC input voltage

from 120 Vac to 347 Vac a less than

3 Watts per face and universal twowire DC input voltage from 6 Vdc to

24 Vdc at less than 3 Watts per face.

The housing shall be of gray

fiberglass, gasketed, specially

designed for industrial environment.

The sealed front cover shall be

constructed of heavy-duty vandalresistant transparent polycarbonate

of 4mm thickness and shall be bent

around the back box for increased

rigidity. The front cover will feature

an even illuminated legend with the

text ”EXIT” and “SORTIE” positioned

one on top of the other. The light

source shall be the new ALINGAP

technology red LED. The equipment

shall be suitable for wall or ceiling

mount and be designed specifically

for high abuse areas, wet locations,

dust and oil-tight applications. The

equipment in a self-powered

configuration shall stay illuminated

during emergency operation for at

least 60 minutes upon AC failure.

The equipment shall be NEMA-3R,

C-860 and NRCan approved.

The equipment shall be Lumacell

Model - _______________________ .

Power Consumption

Model

AC Specs*

AC/DC red

120 to 347 Vac

Self-powered red 120 to 347 Vac

DC Specs*

Less than 3W 6 to 24 Vdc

Less than 3W

Less than 6W NiCad battery

Min. 60 min.

Note: The values of power consumption are for single-face model (max. 6W / bilingual legend).

Note: For the certification guide and temperature codes, please refer to

both pages from the LERE-XP Series of exit signs and the RS10XP Series

of remote lighting fixtures or consult factory.

22

2”

[5.1cm]

po

24 1/8“ [61.4 cm]

po

4”

[10.2 cm]

po

EXAMPLE:

LEREO1W4T

B12L

UNIV

Model

Lettering

Voltage

LEREO1W4T =

single face NEMA-3R, exit/sortie

LEREO2W4T =

double face NEMA-3R, exit/sortie

LSRSO1W4T =

single face NEMA-3R, sortie/exit

LSRSO2W4T =

double face NEMA-3R, sortie/exit

B12L = bilingual

UNIV = 120 to 347

Vac, 6 to 24 Vdc

SP = self-powered

120 to 347 Vac

Series

Ordering Information

23

Double face

Simple face

15“ [38.1 cm]

po

LEREOB12L

Dimensions

LT E U

Series

Power Free Exit Sign

Self-luminous, independent operation exit sign

Features

• Illumination provided by borosilicate glass tubes, internally coated

with zinc sulphide phosphor and filled with tritium gas

• Minimum brightness at time of manufacture is 0.132 foot-lambert

(0.452 cd/m2)

• Decorative, slim-line heavy-duty ABS housing

• Rugged, impact-resistant polycarbonate face

• Spark free construction

• Simple installation – universal direction capability, comes complete

with universal mounting hardware

The LTEU Series exit sign is

completely self-luminous,

requiring no electrical

source, and is ideally suited

for applications where

electrical installation is

hazardous or prohibitively

expensive such as historical

buildings, mines and

industrial facilities. The

LTEU Series can also be

used for all classes and

divisions of explosion-proof

environments such as oil

refineries, pulp and paper

mills, chemical plants and

grain elevators.

• Stands up to extreme temperatures in outdoor or indoor applications

• Standard 12-year life expectancy. 15- or 20-year life expectancies

available as an option

Typical Specification

Supply and install Lumacell LTEU

Series self-luminous exit signs.

The exit shall be constructed of a

thermoplastic housing and be

corrosion proof. The sealed housing

will incorporate no loose or

removable parts allowing for easy

installation. The standard expected

life shall be 12 years with a minimum

guaranteed life of 10 years. The

Wire Guards

460.0079

460.0027

460.0028

Dimensions

Wall Mount

End Mount

Ceiling Mount

standard mounting brackets will allow

for either end/ceiling or wall mount.

Standard signs shall be supplied with

red face, grey frame and white letters

that are 6” high by 3/4” stroke. The

initial average minimum brightness

shall be .132 foot-lambert

(0.452cd/m2)

The Exit shall be Lumacell Model ________________________________.

24

LT E U

EXAMPLE:

1

Series

Faceplates/Mounting

Housing Colour

Life Years

Options

LTEU = exit

LTB3LE/S = exit/sorti

LTB3LS/E = sortie/exit

1 = single face,

universal mount

2 = double face,

universal mount

Blank = grey

WH = white

B = black

Blank = 12 years

15 = 15 years

20 = 20 years

SW = special wording

GN = green background Contact

factory for disposal procedures.

Series

LTEU

25

Ordering Information

3LER3000

Series

Combo Unit

NEMA-4X Certified Combo Unit

Features

Standard

• NEMA-4X Certified for wall or ceiling mount

• High efficiency MR16 halogen lamps up to 12V, 12W or 12V, 5W white

LED, MR16 emergency lights

• Uniform Alingap technology LED illuminated legend

• Comes standard with non-audible advanced diagnostic charger

board, 10 minute time delay and lamp disconnect

• Audible warning and time delay functions can be enabled or disabled

NEMA-4X

• Micro-controller diagnostic system tests, detects and indicates

battery, charger circuitry, LEDs or MR16 lamp failures

Innovative, field-adjustable

lamp head assembly

Choice of MR16 halogen

lamps up to 12V, 12W

or high-efficiency, 5-Watt,

MR16 LED lamps

Long life, energy efficient

ALINGAP technology

red LED illuminated EXIT

legend

Can be wall or ceiling

mounted

Double face available

Suitable for cold weather

applications -40˚C (CW

option — available in 6V only)

• Sealed, maintenance-free nickel cadmium battery

• Non-intrusive magnetic test switch

• Choice of grey, factory white or black housing and face

• NSF Certified for food processing plants

• CSA Certified, meets or exceeds C860-07 requirements

• CSA C22.2 No. 141 Certified

Optional

• Double face

• Cold weather (-40°C; 6Volt Unit)

• No heads (for more remote capacity)

• Fire alarm activated flasher

• Flasher/buzzer (AC power failure)

• Flasher (AC power failure)

Dimensions

3 7/8˝

(9.9cm)

3 1/2˝

(8.7cm)

SINGLE FACE

12 5/8˝

(32.1cm)

9 1/4˝

(23.4cm)

DOUBLE FACE

13 1/4˝

(33.6cm)

26

capacity, the charger will shut-off and

thereafter periodically pulse charge to top

off the battery. This pulse-type charger

promotes long battery life and reduces the

potential for grid corrosion. Its charge

voltage is factory set to ± 1% tolerance

and temperature compensated. The

charger has the functions of Lockout and

Brownout Circuits, and Low Voltage

Disconnection. It protects the unit from

over-current, short-circuit, and reverse

polarity. The unit shall self-test for 1 minute

every 30 days, 10 minutes on the 6th month

and 30 minutes every 12 months. The unit

shall be capable of full recharge in

compliance with CSA specifications. The

unit shall be furnished with a magnetic test

switch. A “Service Required” lamp shall be

located near the test switch and flash when

a fault is detected. A four-LED diagnostic

display shall be located inside the

equipment and shall identify the source of

failure (battery, charger circuitry, or lamps).

The exit sign shall be CSA-C860-07

approved.

The unit shall be Lumacell Model ______________________________________

Series

Supply and install Lumacell 3LER3000

LED exit sign and power pack series. The

equipment shall operate under two

operating voltage, 120Vac or 347Vac. The

equipment frame shall be of industrial

grade polyvinyl chloride with a gasket

around lenses and canopy designed

specifically for hostile environments. The

unit shall be certified for NEMA-4X for wall

or ceiling mount and designed specially for

high abuse areas, wet location, and cold

weather (CW option). The faceplate(s) shall

be constructed of heavy-duty vandalresistant polycarbonate and features an

even illuminated legend. The legend light

source shall be light emitting diodes (LED).

Red LED techno-logy shall be ALINGAP.

Emergency lights shall be fully adjustable

and high efficiency MR16 lamps.

The Lumacell Advanced Diagnostic Microcontroller board shall supply the rated load

for a minimum of a 1/2 hour to 87,5% of

the rated battery voltage. The unit shall be

rated 120/347 V, 60 Hz and be CSA listed.

The unit shall have an output of ___ Volts.

The charger shall at first bulk recharge the

battery, then when the battery is at full

3LER3000

Typical Specification

Power Consumption

AC Specs

Model

3LER3

5LER3

DC Specs

120/347Vac Less than 10W

120/347Vac Less than 10W

6V-36W

12V-60W

Min. 30 minutes

Min. 30 minutes

Wire Guards

With heads

460.0078

460.0060

Without heads

Wall Mount

Ceiling Mount

460.0079

460.0028

Wall Mount

Ceiling Mount

Ordering Information

EXAMPLE:

Series

3LER3 =

6V-36W,

NEMA-4X

5LER3 =

12V-60W,

NEMA-4X

500

2

MI

WH

Faces # of Heads Lamp/Wattage Housing/Face Colour

500 =

single

face

600 =

double

face

Blank =

0 head

2=

two heads

MI =

MR16, 6V-6W

MJ =

MR16, 6V-10W

MK =

MR16, 12V-12W

L=

LED, 12V-5W

WH =

factory white/white

WB =

factory white/black BK =

black/black

BW =

black/white

GW =

grey/white

GB =

grey/black

SG =

grey/grey

CW

Voltage

Options

Blank =

120/347Vac

ZC =

120/277Vac

Blank = no options

*CW = cold weather (-40°C)

FA = flasher (fire alarm activated)

F/B = flasher/buzzer (AC power

failure)

FL = flasher (AC power failure)

GN = green letters

**NEX = Nexus System interface

* Available in 3LER3 only (add

10W of power consumption for

this option). Single face only

** Not available with

(W, FA, F/B, FL)

27

3LER3

LER3000

Series

Exit Sign

NEMA-4X Certified Exit Sign

Features

• Polymeric enclosure is fully gasketed around lens and canopy to

prevent water infiltration - NEMA-4X Certified

• Sealed faceplate of heavy-duty, vandal-resistant polycarbonate with

evenly illuminated legend

• Suitable for cold weather: -40°C for AC/DC models and -25°C for selfpowered (“CW” option)

• Tamper-resistant magnetic test switch

NEMA-4X

• Self-diagnostic circuitry standard on all self-powered models

Sealed heavy-duty, vandalresistant

polycarbonate faceplate

Suitable for cold weather 40˚C (AC/DC model)

and -25˚C on self-powered

model (CW option)

Long-life, energy-efficient

ALINGAP technology

red LED light source

Energy efficient –

consumes less than 3 watts

in AC or DC mode

• Sealed, maintenance-free, nickel cadmium batteries for superior

performance and long life

• Provides 90 minutes of emergency operation (consult factory for

longer operation)

• Long-life, energy-efficient ALINGAP red LED light source

• Energy efficient – consumes less than 3 watts in AC or DC mode

• Normal AC and emergency DC operation – 120 to 347 volts universal

AC 2 wire input; 6 to 48 volts universal DC

• Also available with power pack; see 3LER3000 combo unit

• NSF Certified for food processing plants

• CSA Certified, meets or exceeds C860-07 requirements

• The self-powered version is CSA C22.2 No. 141 Certified

Dimensions

13 1/4˝

(33.6cm)

3 1/2˝

(8.7cm)

3 7/8˝

(9.9cm)

9 1/4˝

(23.4cm)

DOUBLE FACE

SINGLE FACE

28

wet location, and cold weather (-25°C)

applications. The self-powered model shall

stay illuminated during emergency

operation for at least 90 minutes upon AC

failure and shall include a magnetic test

switch and self-testing and self-diagnostic

functions. The equipment shall

automatically self test for 5 minutes every

30 days, 30 minutes every 60 days and 90

minutes annually. A “Service Required”

lamp shall be located near the test switch

and flash when a fault is detected. A twoLED diagnostic display shall be located

inside the equipment and shall identify the

eventual source of failure (battery, charger

circuitry, or LED lamps).

Series

Supply and install Lumacell LER3000

Series LED exit signs. The equipment shall

operate with universal two-wire AC input

voltage from 120Vac to 347Vac at less

than 3 watts and universal two-wire DC

input voltage from 6Vdc to 48Vdc at less

than 2 watts for single and double face

signs. The equipment frame shall be of

industrial grade polyvinyl chloride with a

gasket around lenses and canopy

designed specifically for hostile

environments. The faceplate(s) shall be

constructed of heavy-duty vandal-resistant

polycarbonate and feature an even

illuminated legend. The light source shall

be light emitting diodes (LED). Red LED

technology shall be Alingap. An LEDsensitive diffuser shall be mounted behind

the legend to provide the 6” high by 3/4”

stroke letters with even illumination. The

exit shall be certified for NEMA-4X and

designed specifically for high abuse areas,

LER3000

Typical Specification

The exit sign shall be CSA-C860-07

approved.

The exit sign shall be Lumacell Model _____________________________________.

Power Consumption

AC Specs

Model

120 to 347Vac

AC/DC red

120 to 347Vac

AC/DC green

Self-powered red 120 to 347Vac

Self-powered green 120 to 347Vac

DC Specs

Less than 3W

Less than 3W

Less than 3W

Less than 3W

6 to 48Vdc

6 to 48Vdc

NiCad battery

NiCad battery

Less than 2W

Less than 2W

Min. 90 minutes

Min. 90 minutes

Wire Guards

With heads

460.0079

460.0027

460.0028

Wall Mount

End Mount

Ceiling Mount

Ordering Information

EXAMPLE:

500

WH

Series Faces/Mounting Housing/Faceplate Colour

LER3 =

C860

approved

500 = single face,

universal mount

600 = double face,

universal mount

WH = factory white/white

BK = black/black

BW = black/white

WB = factory white/black

GA = grey/grey

GW = grey/white

GB = grey/black

4X

Voltage

Options

Cabinet

Blank = universal

120-347Vac,

6-48Vdc

SPD = 120-347Vac,

self-powered c/w

diagnostics

(non-audible)

120VACDC2 =

120Vac, 120Vdc 2

wires (AC only)

Blank = no options

GN = green letters

FA = fire alarm activated

flasher

*FB = flasher/buzzer

CW = cold weather

(-25°C for self-powered, 40°C for AC/DC)

**NEX = Nexus System interface

4X = approved

NEMA-4X

* Self-powered models only

** Not available with

(FA, FB, CW)

29

LER3

RG-X

Series

Hazardous Location

Battery Units, Self-Powered Exit Signs, Combination Units

CSA certified for use in hazardous locations

Class I, Zone 1, Groups IIC, IIB and IIA for Severity Code 1 products

Class I, Zone 1, Groups IIB and IIA for Severity Code 2 products

Class I, Zone 2, Groups IIC, IIB and IIA for Severity Code 3 products

Features

The RG-X Series of battery

equipment is designed to

cover emergency lighting

applications for the entire

spectrum of hazardous

locations, where

inflammable gases, vapors,

liquids, dust particles or

fabrics tissues are

permanently present or are

likely to exist.

The RG-X Series combines

in one simple-to-order

catalogue family three

traditional emergency

lighting products with

battery back-up: battery

units with emergency lights,

self-powered exit signs, and

combination units with

emergency lights and exit

sign. The equipment is also

available with additional

emergency power capacity

to drive remote heads and

exit signs.

• CSA Certified for use in hazardous locations:

• Class I, Divisions 1 and 2, Groups A, B, C, D

• Class II, Divisions 1 and 2, Groups E, F, G

• Class III, Divisions 1 and 2

• Die-cast aluminum body with gray epoxy powder coat finish; clear,

impact and heat resistant prismatic glass globe

• Long-life, maintenance-free lead-calcium battery

• Battery charger is current limited, temperature compensated, shortcircuit proof and reverse polarity protected

• Emergency heads with one or twin lamp design

• Self-powered exit (combo) includes a transfer circuit to drive four

remote LED-based exit signs

• Exit sign uses a LED lamp with ALINGAP LEDs

• Exit sign is CSA certified, meets or exceeds C860-07 requirements

• The self-powered version is also CSA C22.2 No. 141 certified

• Easy-to-build catalogue number based on the Lumacell Severity

Codes

• Also available as remote exit signs and remote fixtures; refer to the

LERE-XP and RS10XP catalogue sheets

Typical Specification

30

Supply and install the Lumacell RG-X

Series of hazardous location battery

equipment. The battery unit housing will

be constructed of die cast aluminum

with gray epoxy powder coat finish. The

equipment shall be rated for 120, 277 or

347 volts, 60 Hz input and be CSA listed.

The equipment shall have an output of

____ volts and ___ watts and shall supply

the rated load for a minimum of a 1/2

hour to 87,5% of the rated battery

voltage. The battery shall be a long-life,

maintenance-free lead-calcium type. The

charger shall be fully computer tested

and have its charge voltage set in the

factory to ± 1% tolerance. The charger

shall be current limited, temperature

compensated, short-circuit proof and

reverse polarity protected. The charger

shall be furnished with an electronic

lockout circuit, which will connect the

battery when the AC circuit is activated,

and an electronic brownout circuit, which

will activate the emergency heads when

the utility power dips below 75% of

nominal voltage.

Where required the equipment shall come

complete with ____ heads, each of them

equipped with ___ lamp(s) of ____ watts.

The head housing shall be die-cast

aluminum with gray epoxy powder coat

finish. The lenses shall be a clear, impact

and heat resistant prismatic glass globe.

The head shall be factory sealed, with no

need for external seals.

Where required the equipment shall come

complete with one exit sign and will

include a transfer circuit to maintain the

exit sign permanently lighting in both

normal and emergency operation. The exit

housing shall be industrial grade 14-gauge

steel and finished in gray enamel. The

faceplate will be constructed of heavyduty 14-gauge steel and feature universal

knockout chevrons and the red letters

shall not be less than 6” (150 mm) in

height with a 3/4” (19 mm) stroke. The

sign shall include a LED lamp with

ALINGAP LEDs and shall consume less

than 5 watts in either AC or battery mode.

The equipment shall be suitable for

Class ___ Division ___ Group ____.

The exit sign shall be CSA-C860-07

approved.

The equipment shall be the Lumacell

Model - ________________________.

63/8” [16.3cm]

227/8” [58.1cm]

195/8” [49.9cm]

227/8” [58.0cm]

9 5/8”

[24.4cm]

195/8” [48.9cm]

207/8”

[53.0cm]

143/8” [36.6cm]

273/4” [70.5cm]

6 1 /4 ”

[20.8cm]

211/4” [53.9cm]

233/8” [59.2cm]

201/8” [51.0cm]

18

233/8” [59.2cm]

10”

[25.4cm]

131/8”

[33.4cm]

20 / ” [51.0cm]

LARGE CABINET

181/4”

[46.5cm]

Series

SMALL CABINET

103/8”

[26.4cm]

RG-X

Dimensions

Before ordering, identify the

environment of your application:

Class___, Division___, Group___. Refer

to the following chart for the Severity

Code to use in your catalogue

number:________________________ .

Environment

Severity Code

Cl. I, Div. 1, Gr. A, B

S1

Cl. I, Div. 1, Gr. C, D

S2

CI. I, Div. 2, Gr. A, B, C, D

S3

Cl. II, Div. 1 & 2, Gr. E, F, G

S4

Cl. III, Div. 1 & 2

143/8” [36.6cm]

305/8” [77.8cm]

233/4” [60.4cm]

The temperature code of complete

equipament is given by the type of

emergency head or Exit Sign installed.

For temperature information, please

look at the table below:

Temperature Codes for LERE-XP

Series Exit Signs (40°C ambient)

Severity Code

Temperature

Code

CSA/UL

rating

S1

S2

S3

S4

T3C

T6

T6

T3C

(EGF)

Max Max

Max Max

85°C 85°C 160°C 160°C

Ordering Information

EXAMPLE:

6

36

X

Series

D.C.

Voltage

Capacity/

Cabinet Size

Housing

6=

6 volts

36 = 36 watts [S]*

72 = 72 watts [S]*

108 = 108 watts [L]*

72 = 72 watts [S]*

144 = 144 watts [L]*

200 = 200 watts [L]*

144 = 144 watts [L]*

288 = 288 watts [L]*

RG

12 =

12 volts

24 =

24 volts

* Cabinet size is not

part of the ordering

information. Housing

X=

hazardous

location

Faces

A1

12W

Head

Style

Lamps

Blank =

-0 = no

12W = halogen,

no exit sign

heads

6V, 12V - 12 watts,

RE1 =

A1 = single

quartz bi-pin

single face

remote, 1

20W = halogen,

exit sign

lamp

12V, 24V - 20 watts,

C860,

A2 = single

quartz bi-pin

L.E.D.

remote, 2

RE2 =

lamps

double face A3 = douexit sign

ble remote, Note: for other lamp

C860,

1 lamp

options, please

L.E.D.

contact factory.

S3

TD

Severity

A.C.

Options

Code

Voltage

S1 =

see chart

S2 =

see chart

S3 =

see chart

S4 =

see chart

Blank =

120Vac

ZC =

277Vac

input

ZD =

347Vac

input

Blank =

no options

TD =

time delay

TP =

transfer

panel

31

RG

3LERHZ

Series

Combination Unit for hazardous

locations Location

Features

The 3LERHZ Series of

combination units

(unit equipment and exit

sign) are designed

specifically for installation in

hazardous locations and

other high-abuse, industrial

environment. Extremely

resistant to water, high

impacts, vibrations and

variations in temperature,

the 3LERHZ Series is ideally

suited for areas with the risk

flammable gases, vapors or

liquids that can create an

explosive atmosphere.

Equipped with long-life and

efficient light sources

(ALINGAP LEDs, MR16

halogen lamps) the

equipment offers impressive

illumination performance on

the path of egress.

• Certified Class I Division 2, Groups A, B, C and D as per CSA C22.2

No.137-M19811, Class I, Zone 2, Groups IIC, IIB and IIA

• Certified temperature Codes for several types of emergency lamps

• Certified CSA C22.2 No141

• Certified CSA C860-07

• Polymeric frame, with built-in gasket to prevent water infiltration

• Heavy-duty 1/8-inch thick aluminum back plate with key-holes for

secure wall-mount installation

• Sealed faceplate of heavy-duty, vandal-resistant polycarbonate

• Exit sign module illuminated by long-life, energy-efficient ALINGAP

red LEDs

• Two MR16 halogen lamps, shielded by a cast aluminum housing and

a polycarbonate cover

• Sealed, maintenance-free, Lead-Calcium or Nickel-Cadmium

batteries

• Remote load capacity

• Comes standard with self-test / self-diagnostic functions

• Comes standard with industrial-grade, die-cast Aluminum electrical

box

• ½-inch electrical conduit entry on both sides and at the top

Typical Specification

Supply and install Lumacell 3LERHZ

Series combination of unit equipment

and LED exit sign. Designed specifically

for hostile environments, the equipment

frame shall be of industrial grade

polymeric material with gaskets around

both sides of the frame contour. The

back plate shall be made of 1/8-inch

thick aluminum sheet and shall include

knock-outs for installation on an

electrical box and four keyholes for

alternative installation on a wall surface.

The faceplate shall be constructed of

heavy-duty vandal-resistant

polycarbonate and feature a uniformly

illuminated legend. The light source

shall be light emitting diodes (LED). Red

LED technology shall be ALINGAP. An

LED-sensitive diffuser shall be mounted

behind the legend to provide the 6” high

by 3/4” stroke letters with even

illumination. When specified, the

equipment shall have attached a lower

compartment containing two emergency

lights with adjustable swivels and longlife MR-16 halogen lamps of ___ V and

___ W. The lamps shall be shielded by

cast aluminum housing and protected by

a shock-absorbent, transparent

polycarbonate cover.

The equipment shall be certified for

Hazardous Locations: Class I Division 2

Groups A, B, C and D. The standard AC

input voltage shall be: 120/347Vac. The

equipment shall be equipped with a

magnetic test switch located behind the

face plate and two LED pilot lights: ACon and “Service required”. The unit shall

include self-testing / self-diagnostic

functions monitored by a microcontroller and shall automatically self

test for one minute every 30 days, 10

minutes in the 6th month and 30 minutes

annually. The “Service required” LED

shall light when a fault is detected. A

four-LED diagnostic display located

inside the equipment shall identify the

source of the failure (battery, charger

circuitry, or lamp load). The exit sign

module shall be CSA-C860-07

approved. The combination unit shall be

Lumacell Model –

_______________________.

32

3LERHZ

Dimensions

3 1 /2 ”

[8.9cm]

141/2” [36.8cm]

61/4” [15.6cm]

Series

125/8” [32.1cm]

133/4” [34.9cm]

Power Consumption and Unit Rating

Model

AC Specs

3LERHZ 120/347 Vac 0.15 / 0.06 Amp

3LERHZN 120/347 Vac 0.15 / 0.06 Amp

5LERHZN 120/347 Vac 0.30 / 0.10 Amp

30 min.

36

36

60

Wattage Capacity

1 hr. 1.5 hrs. 2 hrs. 4 hrs.

21

15

12

30

20

15

40

30

20

10

Temperature Codes

Lamp Rating

6V 10W

12V 12W

12V 20W

Temperature Code

T3C

T3A

T2D

Max. Temperature Replacement part #

160 °C

580.0079

180 °C

580.0080

215 °C

580.0068

Note: Use qualified replacement lamps to avoid risk of over-heating

Ordering Information

EXAMPLE:

2

MJ

GG

Series

# of Heads

Lamp/Wattage

Housing/Face

Color

3LERHZ=

6V - 36W, lead acid

3LERHZN =

6V - 36W, NiCad

5LERHZ =

12V - 60W NiCad

Blank =

no heads

2=

2 heads

MJ =

MR16, 6V - 10W

MK =

MR16, 12V - 12W

MW =

MR16 12v- 20 w IR

GG = grey/grey

AT

Voltage

Letters

Color

Blank =

120/347vac

ZC =

120/277vac

Blank =

red letters

G=

green letters

Options

AT =

autotest audible

ATN =

auto Test, nonaudible

NEX =

nexus system

interface

33

3LERHZ

CATALOG

Remotes

MQM-HZ

Series

HAZARDOUS LOCATION Compliant Remote Fixture

Class I, Division 2, Groups A, B, C and D

Class I, Zone 2, Groups IIC, IIB and IIA

Features

The MQM-HZ Series of

remote fixtures has been

designed specifically for

installation in hazardous

locations and other and

high-abuse, industrial

environments. Extremely

resistant to water, high

impacts, vibrations and

variations in temperature,

the MQM-HZ Series is

suited for areas with the risk

of presence of flammable

gases, vapors or liquids

able to create an explosive

gas atmosphere. Besides

their superior endurance,

the fixtures have

outstanding lighting

performance, with a centerto-center egress

illumination up to 70-foot

long and 3-foot wide.

• Certified Class I Division 2, Groups A, B, C and D as per CSA C22.2

No. 9 and No.137-M1981, Class I, Zone 2, Groups IIC, IIB and IIA

• Temperature Codes: T3B (10W and 12W MR16 lamps) and T2C (20W

MR16 lamps), as per Canadian Electrical Code, Part I and CSA C22.2

No.137-M1981)

• Extreme operational temperature range: -40ºC to +40ºC.

• Choice of single- or double-lamp models

• High-efficacy MR16 halogen lamps of 10W, 12W and 20W (see

specification table)

• Input voltage: 6V, 12V, 24V or 120V

• Fully gasketed die-cast aluminum back plate

• Clear polycarbonate cover, UV and impact resistant

• Easy installation on a 4-inch octagonal box (included in the package)

• Comes standard with tamper-proof screws and bit

Typical Specification

shall be listed to CSA C22.2 No. 9

and CSA C22.2 No.137-M1981. The

fixture shall be rated with a

temperature code for the selected

lamps as in the table below.

Each lamp in the fixture shall be able

to be oriented without tools and

should be equipped with high

efficiency MR16 halogen lamp(s) of

___ Volts ___ Watts. The remote

fixtures will provide illumination in

emergency operation and shall

receive their DC power from the

Lumacell battery unit Model________________________ .

The fixture shall be certified for use

The fixture shall be Lumacell Model

in hazardous locations Class I,

Division 2, Groups A, B, C and D and – _______________________.

Supply and install Lumacell MQMHZ Series Model - ________________

remote emergency lighting fixture.

The fixture shall have a single- or

double-lamp configuration (as

specified) and shall include a fully

gasketed die-cast aluminum back

plate and a clear heavy-duty UV

resistant polycarbonate cover. The

fixture shall come standard with a 4inch octagonal box, stainless steel

tamper-proof screws and dedicated

screwdriver bit.

Power Consumption

Lamp type Input Voltage Power (each of 2 lamps)

10 Watts

MR16

6 Volts

12 Watts

MR16

12, 24 Volts

20 Watts

MR16

12, 24, 120 Volts

Temperature code

T3B (Max 165ºC)

T3B (Max 165ºC)

T2C (Max 230ºC)

36

5.7/8”

[14.9cm]

7.1/8”

REMOTE

FIXTURE

[18.1 cm]

2.1/8”

[5.4cm]

4.5/8”

[11.7cm]

Series

4” JUNCTION BOX

3.3/4”

[9.5cm]

JUNCTION

BOX

MQM-HZ

Dimensions

Ordering information

MQM1HZ

12V20WH

SG

Series

Lamp/Wattage

Colour

MQM1HZ =

single lamp

MQM2HZ =

double lamp

6V10W = 6V - 10 Watts, MR16

12V12W = 12V - 12 Watts, MR16

12V20WH = 12V - 20 Watts, MR16-High output

24V12W = 24V - 12 Watts, MR16

24V20W = 24V - 20 Watts, MR16

120V20W = 120V - 20 Watts, GU10

SG = grey

37

EXAMPLE:

MQM-NX

Series

Remote Fixture

NEMA-4X Certified Battery Unit

Features

• Delivers unsurpassed pathway illumination – 70 feet, center-to-center

(with 12V 20W lamp)

• Fully gasketed cast aluminum back plate with clear polycarbonate

cover – NEMA-4X Certified

NEMA-4X

• UV and impact resistant cover

• Choice of three colours: factory white, black or grey

Choice of single or double

head models

• Choice of single or double head models

• Available in 6, 12 and 24 Volt models with various wattages

Fully gasketed cast

aluminum back

plate with clear UV

resistant

polycarbonate cover

Choice of MR16 halogen

lamps up to 24V, 20W or

high-efficiency, 5-Watt,

MR16 LED lamps

• High efficiency MR16 lamps up to 20W

• Easy installation on four-inch octagonal box

• Easy lamp replacement

• Comes standard with tamper-proof screws and bit

• NSF Certified for food processing plants

• CSA Certified to C22.2 No. 9

Typical Specification

Supply and install Lumacell MQM NX

Series Model - _________________ remote

emergency lighting fixtures. These remote

fixtures will consist of either single or double

lamp configurations according to the

design. These fixtures shall be fully

gasketed with a die cast aluminum back

plate and a clear heavy-duty UV resistant

polycarbonate light cover. Units shall be

NEMA-4X certified and specifically designed

for high abuse areas, wet and cold weather

locations. The standard unit will come with

stainless steel tamper-proof screws and bit.

The remote fixture shall be certified to CSA

C22.2 No. 9 and NSF Certified for use in

food processing plants.

The head(s) shall be fully adjustable

without tools and should be equipped with

high efficiency MR16 halogen lamp(s) of

___ volts ___ watts.

The remote fixtures will provide

illumination in emergency operation and

receive their DC power from Lumacell

battery unit Model- ___________________ .

38

7 1/8˝

[18.1cm]

3 3/4˝

[9.5cm]

MQM-NX

Dimensions

Series

4 5/8˝

[11.7cm]

Ordering Information

MQM1NX

6V6W

Series

Lamp/Wattage

Colour

MQM1NX =

single, NEMA-4X

MQM2NX =

double, NEMA-4X

6V6W = 6V-6 watts, MR16

6V10W = 6V-10 watts, MR16

12V12W = 12V-12 watts, MR16

12V20W = 12V-20 watts, MR16

24V20W = 24V-20 watts, MR16

24V12W = 24V-20 watts, MR16

L = 12V-5 watts, LED

Blank = factory

white

BK = black

SG = grey

39

EXAMPLE:

S a f - T- R a y

Series

Wall Mount Remote Head

Robust, vandal resistant,

versatile wall mount fixture

Features

•

•

•

•

•

•

The Saf-T-RayTM wall

sconce unit was designed

and engineered with

durability and

sophistication in mind.

Its low-profile aesthetic

design will provide an

attractive alternative to

the typical two-headed

standard emergency

lighting unit.

The Saf-T-RayTM is

suitable for outdoor and

indoor use, in a wide

range of applications

where aesthetics cannot

be compromised.

Compact wall sconce unit for indoor and outdoor use