SINGLE-PHASE CONVECTIVE HEAT TRANSFER IN

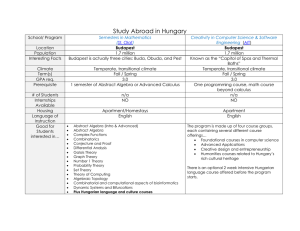

advertisement

SINGLE-PHASE CONVECTIVE HEAT TRANSFER IN MICROCHANNELS A State-of-the-Art Review by S. Kakaç, Y. Yener, W. Sun and T. Okutucu 14th INTERNATIONAL CONFERENCE ON THERMAL ENGINEERING AND THERMOGRAMMETRY (THERMO) June 22-24, 2005 Budapest, HUNGARY 14th THERMO OUTLINE Introduction Experimental Investigations, Analytical and Numerical Contributions June 22-24, 2005, Budapest, Hungary 14th THERMO INTRODUCTION June 22-24, 2005, Budapest, Hungary 14th THERMO In recent years various silicon-base systems having dimensions of the order of microns have been developed, such as • Micro-heat sinks • Micro-biochips • Micro-reactors • Micro-fuel cells June 22-24, 2005, Budapest, Hungary 14th THERMO Trend toward miniaturization Significantly the requirements for higher level of performance from cooling technology June 22-24, 2005, Budapest, Hungary 14th THERMO Existing heat flux levels > 100 W/cm2 Many ideas for effective cooling methods have been proposed, including a microchannel heat sink June 22-24, 2005, Budapest, Hungary 14th THERMO The microchannel heat sink was first introduced by Tuckerman and Pease* A microchannel heat sink is a structure with many microscale channels machined on the electrically inactive face of the microchip. *Tuckerman, D.B. and Pease, R. F., IEEE Electron Device Letter, 2 (1982), 126-129. *Tuckerman, D.B. and Pease, R. F., J. Electrochem. Soc., 129, (1982), C98. June 22-24, 2005, Budapest, Hungary 14th THERMO Tuckerman and Pease* demonstrated that • Water-cooled microchannels are capable of dissipating 790 W/cm2. • h for laminar flow > h for tubulent flow in macrochannels. ww=wc=57m & z=365m *Tuckerman, D.B. and Pease, R. F., J. Electrochem. Soc., 129 (1982), C98. June 22-24, 2005, Budapest, Hungary 14th THERMO Since the work of Tuckerman and Pease (1981, 1982), there has been an unprecedented upsurge in research to understand the fluid flow and heat transfer characteristics in microchannels for better design of various types of microsystems June 22-24, 2005, Budapest, Hungary 14th THERMO • Over the last two decades, experimental studies of friction factors and Nusselt numbers in microchannels have demonstrated that there is a great deal of discrepancies between the experimental data and the classical values, which are based on the continuum hypotheses. • Experimental data also appear to be inconsistent with one another. • Various reasons have been proposed to account for the differences. June 22-24, 2005, Budapest, Hungary 14th THERMO • One reason may be attributed to various surface conditions: Surface roughness Channel cross-section shape Surface hydrophilic property, etc. June 22-24, 2005, Budapest, Hungary 14th THERMO • Depending on the etching method and etching time, two kinds of microchannels, rectangular and trapezoidal having different aspect ratios are usually fabricated in silicon wafers. • Also, various surface roughness can be obtained depending on the concentration and temperature of etching solutions. •The surface hydrophilic property can easily be changed by decreasing or increasing the thickness of oxide layer on a silicon surface. June 22-24, 2005, Budapest, Hungary 14th THERMO EXPERIMENTAL INVESTIGATIONS, ANALYTICAL AND NUMERICAL CONTRIBUTIONS June 22-24, 2005, Budapest, Hungary 14th THERMO Wu and Little* measured friction factors and Nusselt numbers of gases flowing (both laminar and turbulent) in trapezoidal silicon/glass microchannels of widths 130 to 200 m and depths of 30 to 60 m. *Wu, P.Y. and Little, W.A., Cryogenics, 1983, V. 23(5), 273-277. *Wu, P.Y. and Little, W.A., Cryogenics, 1984, V. 24(8), 415-420. June 22-24, 2005, Budapest, Hungary 14th THERMO Wu and Little reported, • a transition from laminar to turbulent flow at Re ~ 400-900 • the surface roughness affected the values of friction factors even in the laminar flow regime, and • the frictional pressure drop for laminar flow was higher than the classical prediction. June 22-24, 2005, Budapest, Hungary 14th THERMO Wu and Little* also reported that Reduction in transition Re number Improved heat transfer *Wu, P.Y. and Little, W.A., Cryogenics, 1983, V. 23(5), 273-277. *Wu, P.Y. and Little, W.A., Cryogenics, 1984, V. 24(8), 415-420. June 22-24, 2005, Budapest, Hungary 14th THERMO Qu et al.* performed an experimental investigation on pressure drop and heat transfer of water in trapezoidal silicon microchannels with a hydraulic diameter ranging from 62 to 169 mm *Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 353-3656. Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 3925-3936. June 22-24, 2005, Budapest, Hungary 14th THERMO Qu et al.* found that the experimentally determined Nu number was much lower than that predicted by their numerical analysis. *Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 353-3656. Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 3925-3936. June 22-24, 2005, Budapest, Hungary 14th THERMO Qu et al* attributed the measured higher pressure drops and lower Nu numbers to the wall roughness, and proposed a roughness-viscosity model to interpret their experimental data. *Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 353-3656. Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 3925-3936. June 22-24, 2005, Budapest, Hungary 14th THERMO According to the roughness-viscosity model of Qu et al*, the increase in wall roughness causes the decrease in Nu number Contradictory to common sense *Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 353-3656. Qu, G.W., Mal, M. and Li, D.Q., Int. J. Heat Mass Transfer, 43 (2000), 3925-3936. June 22-24, 2005, Budapest, Hungary 14th THERMO In addition to surface roughness effects, the cross-sectional shape of the channel can have great influence on the fluid flow and heat transfer inside the non-circular microchannels June 22-24, 2005, Budapest, Hungary 14th THERMO Peng and Peterson* investigated PD and HT of water in rectangular microchannels of Dh = 0.133 - 0.367 and different geometric configurations. *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO The measurements of Peng and Peterson* indicated that the geometric configuration of the microchannel plate and individual microchannels had a great effect on the flow friction and the single-phase convective heat transfer, and that the effect on the laminar and turbulent convection was quite different. They also concluded that the shape of the channel plays a negligible role for both laminar and turbulent flow conditions. *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO Peng and Peterson* found that the laminar heat transfer does depend on the aspect ratio and the ratio of the hydraulic diameter to the center-to-center distance of the microchannels. *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO Peng and Peterson* found that the turbulent heat transfer was further a function of a new dimensionless variable, Z, such that Z=0.5 is the optimum configuration for turbulent heat transfer regardless of the aspect ratio. *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO *Peng, X.F. and Peterson, G.P., Int. J. Heat Mass Transfer, 39 (1996), 2599-2608. June 22-24, 2005, Budapest, Hungary 14th THERMO More recently, Wu and Cheng* carried out an experimental investigation on the laminar convective heat transfer and pressure drop of water in trapezoidal silicon microchannels having different • surface roughness, and • different geometric parameters, • surface hydrophilic properties. Cross-section of microchannels *Wu, H.Y. and Cheng, P., Int. J. Heat Mass Transfer, 46 (2003) 2547-2556 June 22-24, 2005, Budapest, Hungary 14th THERMO Wu and Cheng* found that the values of the laminar Nu number and apparent friction constant depend greatly on different geometric parameters: • Bottom-to-top width ratio, Wb/Wt • Height-to-top width ratio, H/Wt • Length-to-diameter ratio, L/Dh Cross-section of microchannels *Wu, H.Y. and Cheng, P., Int. J. Heat Mass Transfer, 46 (2003) 2547-2556 June 22-24, 2005, Budapest, Hungary 14th THERMO *Wu, H.Y. and Cheng, P., Int. J. Heat Mass Transfer, 46 (2003) 2547-2556 June 22-24, 2005, Budapest, Hungary 14th THERMO The Nu number and the apparent friction constant in trapezoidal microchannels having strong hydrophilic surfaces (thermal oxide surfaces) are larger than those having weak hydrophilic surfaces (silicon surfaces). *Wu, H.Y. and Cheng, P., Int. J. Heat Mass Transfer, 46 (2003) 2547-2556 June 22-24, 2005, Budapest, Hungary 14th THERMO Trapezoidal Wu and Cheng found that the Nu number and the apparent friction constant both increase with the increase in surface roughness. Triangular *Wu, H.Y. and Cheng, P., Int. J. Heat Mass Transfer, 46 (2003) 2547-2556 June 22-24, 2005, Budapest, Hungary 14th THERMO Surf. Geo. Hydphlc. Pars. Effect Effect June 22-24, 2005, Budapest, Hungary 14th THERMO Surf. Rough. Effect June 22-24, 2005, Budapest, Hungary 14th THERMO Although significant amount of experimental data is now available in the literature, momentum and heat transport phenomena in gas and liquid flows in the basic components of microdevices are still not well understood. The main difficulty in predicting the momentum and heat transport in micro-scales lies in formulating the appropriate governing equations. June 22-24, 2005, Budapest, Hungary 14th THERMO There are basically two distinct ways of modeling a flow field. Fluid is continuous and indefinitely divisible - Velocity, Fluid is collection of temperature, pressure, density, molecules – Deterministic etc. are all defined at every point or probabilistic modeling Fluid Modeling in space and time Molecular Models Continuum Models June 22-24, 2005, Budapest, Hungary 14th THERMO In considering the process of momentum exchange and heat transfer between a gas and a solid surface in microdomains (of characteristic length varying from 100 to 0.1 m), both macroscopic or continuum model, as well as the molecular or microscopic model should be considered. June 22-24, 2005, Budapest, Hungary 14th THERMO The distinction among the various regimes and corresponding describing models can be obtained by the so-called the Knudsen number. Kn L Mean free molecular path L = A characteristic flow dimension June 22-24, 2005, Budapest, Hungary 14th THERMO The limit Kn << 1 corresponds to the continuum limit. In the continuum limit, values of parameters at different points in the domain essentially represent averages of the microscopic behavior in the neighborhood of the point. This assumption eventually leads to the formulation of the Navier-Stokes and energy equations, which express the conservation of mass, momentum, and energy. However, these equations break down for finite values of the Kn number. June 22-24, 2005, Budapest, Hungary 14th THERMO Beskok and Karniadakis* proposed four flow regimes for gases. Kn Continuum flow Slip-flow regime (slightly rarefied) Transition regime (moderately rarefied) Free-molecular flow *Beskok, A. and Karniadakis, G.E., J. Thermo. & Heat Transfer, 8 (1994), 647-655. June 22-24, 2005, Budapest, Hungary 14th THERMO For Kn > 10, the fluid is considered a free-molecular flow. • In this regime, the only closed equation that is strictly applicable is the Boltzmann equation that involves the molecular velocities as the dependent parameters, instead of the macroscopic quantities. When 10-3 <Kn < 10, the gas is considered a rarefied. • A rarefied gas can neither be considered an absolutely continuous medium nor a free-molecular flow. June 22-24, 2005, Budapest, Hungary 14th THERMO The range 10-3 <Kn < 10 is further classified as, • Slip flow, 10-3 <Kn < 0.1 • Transition flow, 0.1 <Kn < 10 The local value of Kn number determines the degree of rarefaction and the degree of validity of the Continuum model June 22-24, 2005, Budapest, Hungary 14th THERMO In the slip flow regime, the gas adjacent to the surface no longer reaches the velocity and temperature of the surface. • The gas at the surface has a tangential velocity and it slips along the surface. • The temperature of the gas at the surface is finitely different from the temperature of the surface, and there is a jump in temperature between the surface and the adjacent gas. June 22-24, 2005, Budapest, Hungary 14th THERMO Experimental evidence indicates that in the slip-flow regime, velocity and temperature distributions in the flow field can be determined from the Navier-Stokes and the energy equations if velocity-slip and temperature-jump at the wall are taken into account via the slip boundary conditions. June 22-24, 2005, Budapest, Hungary 14th THERMO In the analytical and numerical studies reported in the literature, four important effects in microflows were considered. These are: • Compressibility effects, • Rarefaction effects, • Viscous heating effects, and • Thermal creep effects. June 22-24, 2005, Budapest, Hungary 14th THERMO • The thermal creep phenomenon is a rarefaction effect. For a rarefied gas flow it is possible to start the flow with tangential temperature gradients along the channel surface. In such a case, the gas molecules start creeping from cold to hot direction. • The viscous heating effects are due to the work done by viscous stresses, and they are important for microflows, especially in creating temperature gradients within the domain. June 22-24, 2005, Budapest, Hungary 14th THERMO Tunc and Bayazitoglu* studied convection for steady-state and hydrodynamically-developed laminar flow in microtubes with Barron et al. [4] uniform temperature and uniform heat flux boundary conditions. Velocity slip and temperature jump conditions at the tube wall and Ameel et al. [1] qw= Cont. viscous heating within the flow Tw= Cont. were included in their study. The effect of temperature jump. *Tunc, G. and Bayazitoglu, Y., Int. J. Heat Mass Transfer, 44 (2001), 2395-2403. June 22-24, 2005, Budapest, Hungary 14th THERMO The Brinkman number is defined by u m2 Br kT , where ΔT is the wall-fluid temperature difference. Br measures the importance of viscous heating relative to heat conduction June 22-24, 2005, Budapest, Hungary 14th THERMO Variation of NU number with Kn number, Tw=Const.* *Tunc, G. and Bayazitoglu, Y., Heat transfer in microtubes with viscous dissipation, Int. J. Heat Mass Transfer, 2001, 44, 2395-2403. June 22-24, 2005, Budapest, Hungary 14th THERMO Tw = Const. The effect of viscous heating* *Tunc, G. and Bayazitoglu, Y., Heat transfer in microtubes with viscous dissipation, Int. J. Heat Mass Transfer, 2001, 44, 2395-2403. June 22-24, 2005, Budapest, Hungary 14th THERMO June 22-24, 2005, Budapest, Hungary 14th THERMO END June 22-24, 2005, Budapest, Hungary