ABB - Electrical Power and Controls Inc.

advertisement

Thermal

Overload relays

Thermal overload relays

Type TA

Class 10

Class 20

Description

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

2

• CSA File No: LR98336

• Available for starter construction with

A Line contactors and separate panel

mounting

• Trip indication

• Remote trip and reset option available

• Designed for close couple mounting

• Single phase and phase unbalance protection

• Separate base mounting available for all

overload relays

• Isolated alarm circuit (N.O.) contact

• Class 10 adjustable overload relays are

standard with all ABB Line starters

• Ambient compensation:

-25°C to +55°C (-13oF to +131oF)

• Reset can also be adjusted to function as a

stop button

• Manual test

• Manual or automatic reset

• Screwdriver guide holes

• Factory calibrated and tested

• All terminal screws are available from the

front

• Wide adjustment range

• UL File No: E48139

Tripping classes of the thermal overload relays

Standard classes in IEC 947-4-1 are classes: 10 A, 10, 20, 30. The tripping class indicates

according to IEC 947-4-1 the maximum tripping time in seconds under specified conditions of

test at 7.2 times the setting current and specifies tripping and non tripping times for 1.5 and 7.2

times the setting current. Mostly used class is 10 A.

Abstract from IEC 947-4-1

Tripping class

Max. tripping time

at 1.5 x setting current

(warm state)

Tripping time at

7.2 x setting current

(cold state)

At 1.05 x setting current

Low Voltage Products & Systems

Th

Ov erm

e

a

re rloa l

lay d

s

10 A

10

20

30

(s)

120

240

480

720

(s)

2 – 10

4 – 10

6 – 20

9 – 30

no tripping

2.1

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

2

Description

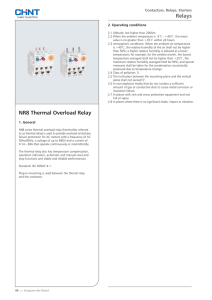

TA thermal overload relays are used with A Line contactors for the protection of

motors having a nominal voltage of up to 600VAC max per UL/CSA (690VAC and

800VDC per IEC).

Product range

• Standard relays:

Types: TA25DU, TA42DU, TA75DU, TA80DU, TA110DU, TA200DU and TA450DU

– TA25 to TA110 and TA200 are directly connected in the motor circuit.

– TA450DU relays are fed through a linear type transformer

• Special construction

Thermal overload relays with different certifications and approvals.

Relays for protection EEx e motors.

Construction and function

• General

Thermal O/L relays and their accessories meet UL, CSA and most other important

international standards (IEC), European standards (EN) and the most important

national standards (DIN-VDE, NFC-UTE, BS, etc.). They meet the certification

and approval directives required throughout the world.

Thermal overload relays are 3 pole. The motor current flows through their bimetals

(1 per phase) which are indirectly heated. Under the effect of the heating, the

bimetals bend, cause the relay to trip and the position of the auxiliary contacts to

change.

The relay setting range is graduated in amps. In compliance with international and

national standards, the setting current is the motor nominal current and not the

tripping current (no tripping at 1.05 x setting current, tripping at 1.2 times setting

current).

The tripping curves (cold or warm starting, 3 phases and 2 phases) are shown on

page 2.14.

The relays are built to be self protecting in the event of an overload until the short

circuit protection device is activated.

Terminals L1, L3, L5

Manual test

Manual or automatic reset

Frame size

TA....DU

Trip indication light

Tripping contact (95, 96)

Amp setting range

Signaling contact, (97, 98)

2.2

1SXU000023C0202

Terminals T1, T2, T3

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Description

2

Application

Technical data

• All the relays have:

–

–

–

–

–

Free tripping: the resetting button, even if held in, does not prevent tripping of the thermal overload relay in the

event of a fault.

Temperature compensation

Phase failure protection according to IEC 947-4-1: Within the limits of the setting range, a reduced tripping time, and

thus improved motor protection, is obrtained in case of a phase failure.

Tripping class: 10A, for TA relays

Test functions and resetting: see table below.

• Auxiliary contacts

The relays have two built in auxiliary contacts: NC marked 95-96; NO marked 97-98. Both contacts are physically separate

and can thus be used for 2 different circuits (control circuit and indication circuit).

Function of TA25DU – TA450DU thermal O/L relays

Resetting

Relay tripped

Effect of blue

TA25DU

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Relay not tripped

Contacts

Manual

Automatic

Resetting

Yes

No

button indexed

95-96

on R

(RESET ONLY)

97-98

Effect of blue

Open

{95-96

97-98 Closed

Resetting

Closed when the

button is pressed

No effect

Closed

{ 95-96

97-98 Open

Both manual and automatic

No

No effect

Open when the

button is pressed

Yes

No

No

button indexed

95-96

on R/O

Closed when the

No effect

button is released

Open when the button is pressed

Closed when the button is released

(RESET/OFF)

97-98

Open when the

button is pressed

No effect

2.3

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

Selection guide

TA25DU – TA80DU

2

Types

TA25DU

TA42DU

TA75DU

TA80DU

Main characteristics

Construction

3 pole with ambient temperature variation compensation.

Protection against single phase operation. Built in auxiliary contacts: 1N.O. + 1N.C.

Resetting

Convertible:

Setting ranges

Number

18

3

from

to

0.1 – 0.16A

24 – 32A

18 – 25A

29 – 42A

Manual to Automatic

6

4

18 – 25A

60 – 80A

29 – 42A

60 – 80A

Mounted with contactors

Mounting kit

No kit is required for mounting thermal O/L relays below contactors

Types of contactors

A/AE/AL9

for combined mounting

A/AE/AL12

A/AE/AL16

A/AE/AL26

A/AE/AL30

A/AE30

A/AE40

A/AE/AL40

A/AE/AF50

A/AE/AF63

A/AE/AF75

Mounted separately (i.e. separate from contactor)

Separate mounting kit

DB25

A/AE/AF95

A/AE/AF110

DB80

Accessories

Tripping coil

DS25-A

Resetting coil

DR25-A

Terminal shroud

Terminals protected against direct contact (without the addition of terminal shrouds)

Function markers

2.4

1SXU000023C0202

BA5-50

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Selection guide

TA110DU – TA450DU

2

Types

TA110DU

TA200DU

TA450DU

Main characteristics

Construction

3 pole with ambient temperature variation compensation.

Protection against single phase operation. Built in auxiliary contacts: 1N.O. + 1N.C.

Resetting

Setting ranges

Number

from

to

1

3

5

2

4

6

R

95

97

96

98

Convertible: manual to automatic

A

A

2

6

3

65 – 90

80 – 110

65 – 90

150 – 200

130 – 185

220 – 310

Mounted with contactors

Mounting kit

No kit is required for mounting thermal O/L relays

See page 2.7.

Types of contactors

for combined mounting

A/AE/AF95

A/AE/AF110

A/AF145

A/AF185

A/AF210 + DT450/A300

A/AF260 + DT450/A300

A/AF300 + DT450/A300

Mounted separately (i.e. separate from contactor)

Separate mounting kit

DB200

No kit required for separate mounting of thermal O/L relays

Accessories

Tripping coil

Resetting coil

Terminal shroud

1

LT200 –

Function markers

LT450 –

BA5-50

1 Terminals protected against direct contact (without the addition of terminal shrouds)

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

2.5

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

TA25 - TA450

Class 10

for Contactors A9 – A/AF300

2

For

Contactor

TA25DU

A/AE/AL9 – A/AE/AL40

A/AE30 - A/AE/40

TA42DU

A/AE/AF50 - A/AE/AF75

A/AE/AF95 - A/AE/AF110

TA75DU

A/AF145 - A/AF185

A/AF210 - A/AF300

Setting Range

A

0.1 - 0.16

0.16 - 0.25

0.25 - 0.4

0.4 - 0.63

0.63 - 1.0

1.0 - 1.4

1.3 - 1.8

1.7 - 2.4

2.2 - 3.1

2.8 - 4.0

3.5 - 5.0

4.5 - 6.5

6.0 - 8.5

7.5 - 11

10 - 14

13 - 19

18 - 25

24 - 32

18 - 25

22 - 32

29 - 42

18 - 25

22 - 32

29 - 42

36 - 52

45 - 63

60 - 80

29 -42

36 - 52

45 - 63

60 - 80

65 - 90

80 - 110

65 - 90

80 - 110

100 - 135

110 - 150

130 - 175

150 - 200

130 - 185

165 - 235

220 - 310

AF400 - AF750

Suffix

Code

Catalog

Number

A

TA25DU0.16

B

TA25DU0.25

C

TA25DU0.4

D

TA25DU0.63

E

TA25DU1.0

F

TA25DU1.4

G

TA25DU1.8

H

TA25DU2.4

J

TA25DU3.1

K

TA25DU4.0

L

TA25DU5.0

M

TA25DU6.5

N

TA25DU8.5

P

TA25DU11

Q

TA25DU14

R

TA25DU19

S

TA25DU25

T

TA25DU32

A

TA42DU25

B

TA42DU32

C

TA42DU42

A

TA75DU25

B

TA75DU32

C

TA75DU42

D

TA75DU52

E

TA75DU63

F

TA75DU80

C

TA80DU42

D

TA80DU52

E

TA80DU63

F

TA80DU80

A

TA110DU90

B

TA110DU110

A

TA200DU90

B

TA200DU110

C

TA200DU135

D

TA200DU150

E

TA200DU175

F

TA200DU200

A

TA450DU185 1

B

TA450DU235

C

TA450DU310

See electronic overloads, pages 2.21

List

Price

$ 63

78

102

135

165

165

225

488

1 TA450 overloads require mounting kits for installation.

TA80DU

TA110DU

2.6

1SXU000023C0202

Discount schedule TAA [OW] — TA25

Discount schedule TBA [OX] — TA42, TA75

Discount schedule TCA [OY] — TA80, TA110, TA200, TA450

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

TA25 - TA80

Class 20

for Contactors A9 - A80

2

Setting range

A ... A

TA25DU

TA42DU

TA75DU

Packing

unit piece

Catalog number

List

price

TA25DU1.8-20

TA25DU2.4-20

TA25DU3.1-20

TA25DU4.0-20

TA25DU5.0-20

TA25DU6.5-20

TA25DU8.5-20

TA25DU11-20

TA25DU14-20

TA25DU19-20

TA25DU25-20

TA25DU32-20 (1)

$ 63

TA42DU trip class 20 for contactors A30, A40 and (T) AL30, (T) AL40

18 … 25

AZ

1

1SAZ311401R1001

22 …32

BZ

1

1SAZ311401R1002

29 … 42

CZ

1

1SAZ311401R1003

TA42DU25-20

TA42DU32-20

TA42DU42-20

$ 78

TA75DU trip class 20 for contactors A50 … A75 and AE50 … AE75

18 … 25

AZ

1

1SAZ321401R1001

22 … 32

BZ

1

1SAZ321401R1002

29 … 42

CZ

1

1SAZ321401R1003

36 … 52

DZ

1

1SAZ321401R1004

45 … 63

EZ

1

1SAZ321401R1005

60 … 80

FZ

1

1SAZ321401R1006

TA75DU25-20

TA75DU32-20

TA75DU42-20

TA75DU52-20

TA75DU63-20

TA75DU80-20

$ 102

TA80DU trip class 20 for contactors A95, A110, AE 95 and AE110

29 … 42

AZ

1

1SAZ331401R1003

36 … 52

BZ

1

1SAZ331401R1004

45 … 63

CZ

1

1SAZ331401R1005

60 … 80

DZ

1

1SAZ331401R1006

TA80DU42-20

TA80DU52-20

TA80DU63-20

TA80DU80-20

$ 135

Suffix

Reference code

TA25DU trip class 20 for contactors A9 … A40 and (T) AL9 … (T) AL30

1.3 … 1.8

GZ

1

1SAZ211401R1025

1.7 … 2.4

HZ

1

1SAZ211401R1028

2.2 … 3.1

JZ

1

1SAZ211401R1031

2.8 … 4.0

KZ

1

1SAZ211401R1033

3.5 … 5.0

LZ

1

1SAZ211401R1035

4.5 … 6.5

MZ

1

1SAZ211401R1038

6.0 … 8.5

NZ

1

1SAZ211401R1040

7.5 … 11

PZ

1

1SAZ211401R1043

10 … 14

QZ

1

1SAZ211401R1045

13 … 19

RZ

1

1SAZ211401R1047

18 … 25

SZ

1

1SAZ211401R1051

TZ

1

1SAZ211401R1053

24 … 32 (1)

(1)

with terminal block DX25: 1x16mm2

No Tripping at 1.05 Ie

Tripping at 1.2 Ie within 2 hours

Time

Class 30 9 - 30 sec

Class 20 6 - 20 sec

TA80DU

Class 10 4 - 10 sec

Ie (adjusted current)

1.2 Ie

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

7.2 Ie

Discount schedule TAA [OW] — TA25

Discount schedule TBA [OX] — TA42, TA75

Discount schedule TCA [OY] — TA80, TA110, TA200, TA450

2.7

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

Accessories

2

Separate mounting kits

DB25/25A

For O/L

Amps

relays

TA25DU

TA25DU

TA42DU, TA75DU, TA80DU

TA110DU, TA200DU

0.1 – 25

24 – 32

18 – 80

100 – 200

Catalog

number

DB25/25A

DB25/32A

DB80

DB200

List

price

$ 30

38

45

60

Terminal block — AWG #8 cable

Mounting on:

Catalog

number

TA25DU (25A or less) or DB25/25A

List

price

$ 15

DX25

LC terminal blocks can be used to convert standard connections into Faston connections: 2 x 6.3mm or 4 x 2.8mm per pole.

The connections are protected against accidental contact.

The LC30-T has a terminal block for the 3 power terminals and a second for the 4 auxiliary terminals of a TA25DU thermal

O/L relay.

The LC26-B1 has two identical terminal blocks each for 3 power terminals. This block allows the power terminals to be

mounted with two DB25 kits or a TA25DU thermal O/L relay and DB25 kit assembly.

NOTE: According to DIN 46429 part 1 and NFC 20-120 the max. capacity of a Faston connection is 25 A.

DB80

Mounting kit – for TA450 overload relay

For contactor

Catalog

number

A145 – A185

A210 – A300

DT450/A185

DT450/A300

List

price

$ 225

Terminal shrouds – for contactors and overload relays

DB200

Contactor

Overload

relay

TA25DU

A9 – A16

A26 – A40

Catalog

number

Included

List

price

—

A30 – A40

TA42DU

Included

—

A50 – A75

TA75DU

Included

—

A95 – A110

TA80DU

TA110DU

Included

A145 – A185

TA200DU

LT185-AY

A145 – A185

Load side of TA200DU

LT200A185

—

$ 10

50

Terminal lug kits

2.8

1SXU000023C0202

Wire

range

6 – 250MCM

4 – 400MCM

(2) 4 – 500MCM

For

overloads

TA110DU, TA200DU

TA450DU185

TA450DU310

Discount schedule ABA [OF] — A-contactor accessories

Discount schedule TAA [OW] — TA25

Discount schedule TBA [OX] — TA42, TA75

Discount schedule TCA [OY] — TA80, TA110, TA200, TA450

Catalog

number

List

price

EHTK210

ATK300HK

ATK300/2HK

$ 45

78

120

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Accessories

2

Remote tripping coils

U voltage at 50/60 Hz

DS25A

Catalog

number 1

DS25-A remote tripping coil

24V

48V

110V

220/380V

500V

DS25-A-24

DS25-A-48

DS25-A-110

DS25-A-220/380

DS25-A-500

DS25-A remote resetting coil

24V

48V

110V

220/380V

500V

DR25-A-24

DR25-A-48

DR25-A-110

DR25-A-220/380

DR25-A-500

List

price

$ 60

Application

•The DS25-A coil is used for remote electrical tripping of the TA25 DU thermal O/L relay and is connected to the relay's

normally closed 95-96 auxiliary contact.

•The DR 25-A coil is used for remote electrical resetting of the TA25DU thermal O/L relay which is

adjusted for “Manual resetting;” it is connected to the relay’s normally open 97-98 auxiliary contact.

The coils are not designed for continuous duty. Impulse duration: 0.2 to 0.35 s.

Set the button to “Man” (Manual resetting).

Mounting: clipped on to TA25DU thermal O/L relay.

DR25A

Installation diagrams

For connection of DS25-A to TA25DU relay

L1

L2/N

START

STOP

21

For connection of DR25-A to TA25DU relay

13

22

14

L1

OL

A1

M

A2

95

96

21

13

22

M

13

L2/N

START

STOP

14

OL

M

A1

13

E2

OL

97

98

OL

TRIPPING

COIL

OFF

24

13

14

OL

A1

M

A2

95

96

OVERLOAD

TRIP

L1

E2

OFF

HAND

L2/N

AUTO

23

24

13

14

OL

M

A1

OVERLOAD

RESET

E1

E1

OL

RESETTING

COIL

L2/N

AUTO

23

96

14

OVERLOAD

RESET

E1

HAND

95

M

14

OVERLOAD

TRIP

L1

A2

E2

95

96

OL

97

OL

TRIPPING

COIL

A2

98

E1

E2

OL

RESETTING

COIL

1 Cannot be used with TA42, TA75, or TA200 overload relays.

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Discount schedule TAA [OW] — TA25

2.9

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

Technical data

TA25DU – TA450DU

2

Intermittent duty

Switching frequency

For intermittent operations, the diagram opposite specifies relay operating limits.

s

0.5

120

100

ta

=

80

To avoid untimely tripping, TA and T thermal O/L relays have been designed to withstand roughly 15 switching operations

per hour with an approximately equal distribution between working and rest cycles.

In these conditions, the motor starting time must not exceed 1 second and the starting current must be lower than or equal

to 6 times the motor In.

ta =

(ops/h)

140

Switching frequency:

1s

Example: Motor starting time:

1 sec.

Load factor:

40 %

Switching frequency:

60 ops./h according to diagram

ta

40

ta =

20

ta = 3.5

For a higher number of operations and for load variations (e.g. frequent starting and braking), it is advisable to use

CUSTORAPID® protection.

60

=1

.5s

For motors subject to particularly severe operating conditions (e.g. locked rotor) it is advisable to use protection combined

with a thermal O/L relay and the CUSTORAPID® system.

3s

Protection of motors with long starting time

s

See electronic overload relay section, pages 2.21 - 2.32.

0

0

20

40

60

Closing time

80 100(%)

Switching frequency

in relation to load factor.

ta: motor starting time.

Mounting position

On a support at an angle of ± 30° in relation to the vertical plane (standard position).

Other mounting positions possible, except mounting on a horizontal plane (in this case the tripping

mechanism would be located above the bimetals).

Special version for EEx e motors

Consult factory.

[s]

40

Tripping limits at ambient temperatures varying by + 20°C

Ambient temperature compensation

Thermal O/L relays are compensated against ambient temperature

variations by a compensation bimetal which is sensitive to the

ambient temperature.

Tripping time

11

10

Thermal O/L relays are designed to operate between –5 °C and

+40 °C in compliance with standard IEC 947-4-1. For a wider range

of –25° C to +55 °C consult the graph opposite.

6

4

3

2

Example: tripping at – 25 °C. Tripping takes place before 1.5 times

the setting current.

1

Resetting: TA25DU – TA450 DU thermal O/L relays have convertible

manual/automatic resetting.

7 8

7.4

Multiple of the setting current

3

4

5

6

TA thermal O/L relay cold-state

tripping characteristics

2.10

1SXU000023C0202

Delivery: in manual resetting mode.

1.5

Ambient temperature

compensation limits

according to IEC 947-4-1

1.4

Multiple of the setting current

20

1.3

Tripping

1.2

1.1

No tripping

1.0

0.9

-20

-10

0

10

20

30

Ambient temperature

40

50

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Technical data

TA25DU – TA80DU

Types

TA25DU

TA42DU

Standards:

(international, European)

2

TA80DU

IEC 947-4-1, EN 60947-4-1

Rated insulation voltage Ui

according to IEC 947-4-1

Rated impulse withstand voltage Uimp

according to IEC 947-4-1

Permissible ambient temperature

– for storage

– for operation

V

690

kV

6

°C

°C

–40 to +70

–25 to +55 with temperature compensation (maximum values: see page 2.9)

Climatic withstand DIN 50017

Mounting positions

Humidity in alternate climate KFW, 30 cycles

On a support at an angle of ±30° in relation to the vertical plane (standard position). Other positions

possible except mounting on a horizontal plane (in this case the tripping mechanism

would be located above the bimetals).

Shock withstand

shock duration ms

at nominal Ie Critical direction

of shocks A1, A2

multiples of g

Resistance to vibrations

(±1 mm, 50 Hz)

Mounting

TA75DU

15

12

multiples of g

8

– on contactor Latching below the contactor, screw fixing on main terminals

– separate with DB - kit Using screws: 2 x M4 or 35 mm EN 50022

Terminals and cross-sectional areas for main conductors (motor side)

• screw terminal

– with cable clamp

– via tunnel connector

– flat type for lug or bar

A2

A1

• conductor cross-sectional area

– rigid solid or rigid stranded

– flexible with cable end

– recommended bars

mm2

mm2

mm

TA25DU setting ranges:

from 0.1-0.16A 24-32 A

to 18-25A

M4

–

–

M5

–

–

2 x 1.5 - 6

2 x 1.5 - 4

–

1 x 10 2 x 0.75- 6 –

M6

–

–

M6

–

M6

–

1 x 2.5 - 35 or 2 x 2.5 x 16

1 x 2.5 - 25 or 2 x 2.5 x 10

–

–

Terminals and cross-sectional area

for auxiliary conductors

• screw terminal (screw size)

– with cable clamp

• conductor cross-sectional area

– rigid solid or rigid stranded

– flexible with cable end

M 3.5

2 x mm2

2 x mm2

Degree of protection

0.75 - 4

0.75 - 2.5

All the terminals are protected against direct contact according to

VDE 0106/Part. 100. (without additional terminal shrouds)

Pole Technical Characteristics

Types

TA25

DU

Number of poles

Resistance per phase in mΩ

and heat dissipation in W

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

TA80

DU

TA10

DU

TA200

DU

TA450

DU

see page 2.6

Tripping class according to IEC 947-4-1, EN 60947-1

Max. switching frequency

without untimely tripping

TA75

DU

direct contact according to

VDE0106/part 100 (with

additional terminal shrouds

for the main terminals

3

Setting ranges

Rated operational frequencies

TA42

DU

All the terminals are

protected against direct

10 A

Hz

0 - 400

50/60

Up to 15 starts/h or 60 starts/h with 40 % on-load factor when neither

the starting current of 6 x In nor the starting time 1 s are exceeded.

see page 2.13

2.11

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

2

Technical data

TA110DU – TA450DU

Types

TA110DU

TA200DU

Standards:

(international, European)

Rated insulation voltage Ui

according to IEC 947-4-1

Rated impulse withstand voltage Uimp

according to IEC 947-4-1

Permissible ambient temperature

– for storage

– for operation

TA450DU

IEC 947-4-1, EN 60947-4-1

V

690

1000

kV

6

8

°C

°C

–40 to +70

–25 to +55 with temperature compensation (maximum values: see page 2.9)

Climatic withstand DIN 50017

Mounting positions

Humidity in alternate climate KFW, 30 cycles

On a support at an angle of ±30° in relation to the vertical plane (standard position). Other positions possible except mounting on a horizontal plane (in this case the tripping mechanism would

be located above the bimetals).

Shock withstand

shock duration ms

at nominal Ie 15

Critical direction

of shocks A1, A2

multiples of g

12

Resistance to vibrations

(±1 mm, 50 Hz)

multiples of g

8

Mounting

– on contactor

4 x M5 screws

– separate with DB - kit

Terminals and cross-sectional areas for main conductors (motor side)

• screw terminal

A2

– with cable clamp

A1

– via tunnel connector

– flat type for lug or bar

• conductor cross-sectional area

– rigid solid or rigid stranded

– flexible with cable end

– recommended bars

mm2

mm2

mm

–

HC, M8

–

–

–

M10

16 – 35

16 – 35

12 x 3

–

–

M10

25 – 120

25 – 95

20 x 4

2 x 240

2 x 240

20 x 4...5

Terminals and cross-sectional area

for auxiliary conductors

• screw terminal (screw size)

– with cable clamp

• conductor cross-sectional area

– rigid solid or rigid stranded

– flexible with cable end

M 3.5

2 x mm2

2 x mm2

Degree of protection

0.75 - 4

0.75 - 2.5

All the terminals are protected against direct contact according to

VDE 0106/Part. 100. (with additional terminal shrouds)

Technical characteristics of auxiliary contacts for thermal O/L relays: TA25DU to TA450DU

Auxiliary contacts

normally closed N.C.

normally open N.O.

Terminal marking

95-96

97-98

VAC

500

500

Conventional thermal current (in free air) Ith

A

10

6

Rated operational current Ie, AC-15

up to 240 V

up to 440 V

up to 500 V

A

A

A

3.0

1.9

1.0

1.5

0.95

0.75

Rated operational current Ie DC-13

up to 250 V

A

0.12

0.04

Protection against short circuits

gG (gl) fuses (according to IEC 269)

S 271/S 281circuit-breaker

A

A

10

k3

6

k1

VAC

VDC

500

440

500

440

Rated operational voltage Ue

Maximum potential difference between N.C. and N.O. auxiliary contacts

2.12

1SXU000023C0202

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Technical data

Motor protection; Choice of protective device

2

Motor Protection — general

It is very important to choose an adequate protective device for the safety of the motor during operation and for its durability.

The efficiency of protection methods varies according to the application. The overview below will help you to choose.

There is no general rule and we are available to advise you for special applications and especially in the case of difficult starting.

Protective devices and efficiency

Protection in relation to current:

Protection in relation to temperature:

Fuses

Protective relay with

phase fault protection

Motor protection

via CUSTORAPID®

thermistor

Motor protection

via SPEM electronic

relay

SPEM

M

3~

M

3~

M

3~

M

3~

Causes of dangerous overloads for the motor windings

1 Overload with current 1.2 times the nominal current

❑

●

●

●

2 S1-S8 nominal duties

according to IEC 34-I

❑

■

●

●

3 Operation with starting,

braking, reversal in operating direction

❑

■

●

●

4 Operation with starting

rate at > 15 cycles/hour

❑

■

●

●

■ for motors with

special rotor

●

●

●

5 Locked rotor

■

●

6 Overloads due to phase failure

❑

●

7 Network undervoltage or overvoltage

❑

●

●

●

8 Fluctuation of network frequency

❑

●

●

❑

9 Ambient temperature too high

❑

●

●

❑

10 Overheating due to external

cause (i.e. overheating of bearings)

❑

❑

●

❑

11 Motor cooling disturbed ❑

❑

●

❑

12

Undercurrent protection

on drop in load

13

Protection of asymmetry:

wrong phase direction

rotation or asymmetrical load

14

Earth fault protection

15

Automatic disconnection for

auxiliary load fault

Protection efficiency:

Note: Fuses

Fuses do not protect motors against overloads. They are only used to protect installations and lines against short circuits.

❑ unsuitable

To ensure efficient protection of a motor against short circuits, it is advisable to use aM type fuses in association with thermal

OLR relays.

■ very average efficiency

For the selection of fuses or circuit-breakers, refer to the indications given in this catalogue concerning contactors on the one

hand and thermal O/L relays on the other.

● perfectly efficient

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

In general, fuse protection for direct-on-line starting must be sized as follows:

– aM fuses: choose the fuse rating immediately above the full load value of the motor current.

– gG (gI) fuses: determine the fuse rating immediately above the motor current value and choose the next highest fuse rating.

2.13

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

2

Technical data

Resistance and Joule losses per phase

Short circuit protection

Resistance and Joule losses per phase, short circuit protection

Setting range

Resistance

current

per phase

from – to

A A

mΩ

TA25DU

0.1– 0.16

0.16– 0.25

0.25– 0.4

Joule losses

per phase at

max. setting

W

85850

85150

13750

2.2

2.2

2.2

0.4– 0.63

0.63– 1.0

1.0– 1.4

5370

2190

1120

2.2

2.2

2.2

1.3– 1.8

1.7– 2.4

2.2– 3.1

670

383

229

2.2

2.2

2.2

2.8– 4.0

3.5– 5.0

4.5– 6.5

137

87.5

61

2.2

2.2

2.2

6.0– 8.5

7.5– 11

10– 14

13– 19

18– 25

24– 32

30.4

18.2

11.2

6.3

4.7

3.2

2.2

2.2

2.2

2.3

2.9

3.3

TA42DU

18– 25

22– 32

29– 42

5.5

2.89

1.84

3.43

2.91

3.24

TA75DU

18– 25

22– 32

29– 42

36– 52

45– 63

60– 80

5.5

2.89

1.84

1.3

0.936

0.615

3.43

2.91

3.24

3.51

3.72

3.94

TA80DU

29– 42

36– 52

45– 63

60– 80

1.84

1.3

0.936

0.615

3.24

3.51

3.72

3.94

2.14

1SXU000023C0202

Setting range

Resistance

current

per phase

from – to

A A

mΩ

Joule losses

per phase at

max. setting

W

TA110DU

80– 110

0.378

3.78

TA200DU

100– 135

110– 150

130– 175

150– 200

0.318

0.255

0.214

0.182

5.79

5.74

6.55

7.28

TA450DU

130– 185

165– 235

220– 310

—

—

—

2.5

2.5

2.5

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Technical data

Tripping curves

2

TA25DU

TA75DU

TA110DU/SU

TA450DU

TA-DU thermal O/L relays are 3-pole with manual or automatic resetting mode selection.

The resetting button can also be used for stopping.

Built-in auxiliary contacts are physically separate and, consequently, can be used in different circuits (control circuit/indication circuit).

Each relay is temperature compensated and ensures phase failure protection.

Protective relays up to size TA75DU are protected against direct contact via the front face. Terminal shrouds are available for TA200DU to TA450DU size relays.

The connecting terminals are delivered in open position with (+,-) pozidriv screws and screwdriver guidance. It is advisable to tighten unused terminal screws.

Thermal O/L relay tripping curves

TA25DU TA42DU, TA75DU and TA80DU 40

40

40

20

20

20

10

8

6

10

8

6

1

2 Phases

2

2 Phases

1

40

3 Phases

20

Seconds

Seconds

2 Phases

3 Phases

4

2

10

8

6

from warm state

4

from warm state

1.5

2

3

4

5

6

7

8 9 10

3 Phases

10

8

6

2 Phases

4

1

0.8

Tripping current

in multiples of the setting current

1 1.2

1.5

2

3

4

5

6

7

8 9 10

Tripping current

in multiples of the setting current

TA200DU 0.8

1 1.2

1.5

2

3

4

5

6

7

8 9 10

Tripping current

in multiples of the setting current

TA450DU

(tripping class 10A)

(tripping class 10A)

120

100

80

60

120

100

80

60

40

40

20

20

10

8

6

10

8

6

2

2 Phases

1

3 Phases

40

Triping time

from cold state

minutes

4

4

Minutes

3 Phases

2

1

1 1.2

2 Phases

1

from warm state

1

0.8

from cold state

2

20

3 Phases

2

4

40

2 Phases

3 Phases

10

8

6

Minutes

4

Tripping time

Tripping time

from cold state

2

10

8

6

from cold state

Seconds

4

Minutes

120

100

80

60

20

Tripping time

(tripping class 10A)

120

100

80

60

40

from cold state

2

2 Phase

1

40

3 Phase

20

seconds

20

Seconds

TA110DU

(tripping class 10A) 120

100

80

60

Minutes

Tripping time

(tripping class 10A) 2 Phases

10

8

6

2

2 Phase

4

3 Phases

4

10

8

6

3 Phase

2

from warm state

from warm state

1

1

0.8

1 1.2 1.5

2

3

4

5

6 7 8 9 10

Tripping current

in multiples of the setting current

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

0.8

1 1.2

1.5

2

3

4

5

6 7 8 9 10

Tripping current

as multiple of setting current

2.15

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

Technical data, Class 20 OLR

Resistance and Joule losses per phase

Short circuit protection

2

UL

UL

Resistance

per phase

Power Loss

per phase

gL/gG

A

600V

CB

A

mOhm

Thermal overload relay TA25DU trip class 20

1.3 … 1.8

10

1.7 … 2.4

16

2.2 … 3.1

16

2.8 … 4.0

20

3.5 … 5.0

25

4.5 … 6.5

25

6.0 … 8.5

32

7.5 … 11

40

10 … 14

50

13 … 19

63

18 … 25

80

24 … 32

100

Fuse/600V

K5

A

at upper

current setting

W

25

25

25

25

25

25

32

40

50

63

80

100

6

10

10

15

20

25

35

45

60

60

70

100

-

670.3

381

235.3

140.7

91.2

54.5

32.1

15.5

12

6.3

4.7

3.2

2.2

2.2

2.3

2.3

2.3

2.3

2.3

1.9

2.4

2.3

3.0

3.3

Thermal overload relay TA42DU trip class 20

18 … 25

100

22 … 32

125

29 … 42

160

160

160

160

80

100

150

80

80

80

5.5

2.89

1.84

3.43

2.91

3.24

Thermal overload relay TA75DU trip class 20

18 …25

100

22 … 32

125

29 …42

160

36 … 52

200

45 … 63

200

60 … 80

250

160

160

160

200

250

250

80

100

150

175

200

250

80

80

80

125

125

125

5.5

2.89

1.84

1.3

0.936

0.615

3.43

2.91

3.24

3.51

3.72

3.94

Thermal overload relay TA80DU trip class 20

29 … 42

160

36 … 52

200

45 … 63

200

60 … 80

250

160

200

250

250

150

175

200

250

80

125

125

150

1.84

1.3

0.936

0.615

3.24

3.51

3.72

3.94

Setting Range

from ... to

A

A

Short-circuit protection (fuses)

Type "2"

co-ordination

Type "1"

co-ordination

gL/gG

A

Type 1 co-ordination according to IEC 60947-4-1: Under short-circuit conditions, the starter shall cause no danger to persons or

installation and may not be suitable for further service without repair and replacement of parts.

Type 2 co-ordination according to IEC 60947-4-1: Under short-circuit conditions, the contactor or starter shall cause no danger

to persons or installation and shall be suitable for further use. The risk of contact welding is recognized, in which case the manufacturer shall indicate the measures to be taken as regards the maintenance of the equipment.

Standard technical data, operating data and dimensions see TA...Relay Main Catalog

2.16

1SXU000023C0202

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Technical data, Class 20 OLR

Short-circuit ratings

2

Setting Range

Catalog number

A ... A

480V

1.3 … 1.8

1.7 … 2.4

2.2 … 3.1

2.8 … 4.0

3.5 … 5.0

4.5 … 6.5

6.0 … 8.5

7.5 … 11

10 … 14

13 … 19

18 … 25

24 … 32

18 … 25

22 …32

29 … 42

18 … 25

22 … 32

29 … 42

36 … 52

45 … 63

60 … 80

29 … 42

36 … 52

45 … 63

60 … 80

TA25DU-1.8-20

TA25DU-2.4-20

TA25DU-3.1-20

TA25DU-4.0-20

TA25DU-5.0-20

TA25DU-6.5-20

TA25DU-8.5-20

TA25DU-11-20

TA25DU-14-20

TA25DU-19-20

TA25DU-25-20

TA25DU-32-20

TA42DU-25-20

TA42DU-32-20

TA42DU-42-20

TA75DU-25-20

TA75DU-32-20

TA75DU-42-20

TA75DU-52-20

TA75DU-63-20

TA75DU-80-20

TA80DU-42-20

TA80DU-52-20

TA80DU-63-20

TA80DU-80-20

Setting Range

Catalog number

A ... A

1.3 … 1.8

1.7 … 2.4

2.2 … 3.1

2.8 … 4.0

3.5 … 5.0

4.5 … 6.5

6.0 … 8.5

7.5 … 11

10 … 14

13 … 19

18 … 25

24 … 32

18 … 25

22 …32

29 … 42

18 … 25

22 … 32

29 … 42

36 … 52

45 … 63

60 … 80

29 … 42

36 … 52

45 … 63

60 … 80

Voltage

TA25DU

TA42DU

TA75DU

TA80DU

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

TA25DU

TA42DU

TA75DU

TA80DU

10 kA

18 kA

Fuse K5

CB

Fuse K5

CB

Fuse K5

CB

6

10

10

15

20

25

35

45

60

60

70

100

80

100

150

80

100

150

175

200

250

150

175

200

250

80

80

80

80

80

80

125

125

125

80

125

125

150

6

10

10

15

20

25

35

45

60

60

70

100

80

100

150

80

100

150

175

200

250

150

175

200

250

-

6

10

10

15

20

25

35

45

60

60

70

100

150

150

200

150

150

200

250

250

250

150

175

250

250

-

Fuse K5

CB

Fuse K5

CB

Fuse K5

CB

6

10

10

15

20

25

35

45

60

60

70

100

80

100

150

80

100

150

175

200

250

150

175

200

250

80

80

80

80

80

80

125

125

125

80

125

125

150

6

10

10

15

20

25

35

45

60

60

70

100

80

100

150

80

100

150

175

200

250

150

175

200

250

-

6

10

10

15

20

25

35

45

60

60

70

100

150

150

200

150

150

150

175

250

250

150

175

250

250

-

Voltage

600V

TA25DU-1.8-20

TA25DU-2.4-20

TA25DU-3.1-20

TA25DU-4.0-20

TA25DU-5.0-20

TA25DU-6.5-20

TA25DU-8.5-20

TA25DU-11-20

TA25DU-14-20

TA25DU-19-20

TA25DU-25-20

TA25DU-32-20

TA42DU-25-20

TA42DU-32-20

TA42DU-42-20

TA75DU-25-20

TA75DU-32-20

TA75DU-42-20

TA75DU-52-20

TA75DU-63-20

TA75DU-80-20

TA80DU-42-20

TA80DU-52-20

TA80DU-63-20

TA80DU-80-20

5 kA

5 kA

10 kA

18 kA

2.17

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

2

Technical data, Class 20 OLR

Table for tripping time

Tripping times of thermal overload relays as a function of a multiple of the setting current from cold state

(tolerance +/- 20% of the tripping time).

Tripping times of thermal overload relays:

at multiple of setting current

Setting Range

3

4

from ... to

A

A

5

6

7.2

8

Tripping times in seconds

Thermal overload relays TA25DU trip class 20

1.3 … 1.8

1.7 … 2.4

2.2 … 3.1

2.8 … 4.0

3.5 … 5.0

4.5 … 6.5

6.0 … 8.5

7.5 … 11

10 … 14

13 … 19

18 … 25

24 … 32

47.1

43.3

47.5

45.6

47.8

47.4

46.1

42.3

39.4

38.1

44.4

44.4

27

25

28

27

29

28

27

25

25

21

25

27

Thermal overload relays TA42DU, TA75DU, TA80DU trip class 20

18 … 25

51.6

29

22 … 32

67.9

38

29 … 42

58.8

33

36 ... 52

59.9

34

45 ... 63

65.8

34

60 ... 80

71.9

35

2.18

1SXU000023C0202

20.3

18.9

20.8

19.8

21.2

20.3

20

17.8

16.8

13.6

16.1

17.7

15.8

14.4

16

15.3

16

15.5

15

14.1

13

10

11

13

12.7

11.9

13.1

12.5

13.2

12.5

11.7

10.9

9.9

7.4

9

9.8

11.5

10.4

11.8

11

11.8

11

10

10.5

8.5

6.2

8

8.5

20.3

26.9

22.5

22.7

22.4

23.4

15

20

16

16

16

17

11.7

14.8

12.2

12.3

12.4

13.9

10

12.5

10.3

10.5

10.5

12

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Approximate dimensions

T25DU – TA42DU

00.00

Inches

00.00

[Millimeters]

2

TA25DU

0.51

13

3.70

3.15

94

80

TA25DU32

only

0.24

6

3.70

1.73

94

44

TA25DU & DB25

TA25/32A

4.25

108

0.24

1.73

6

44

0.35

6

1.38

35

0.51

13

1.88

3.31

48

84

0.17

4.2

TA25DU & DB25/32

TA25+AB25

1.73

4.25

44

108

0.24

6

0.35

6

1.38

35

0.51

13

1.88

4.41

48

112

0.17

4.2

TA42DU

TA25/32A+AB32

0.51

13

3.54

90

0.24

6

4.35

2.13

110.5

54

TA42

TA42DU / TA75DU & DB80

5.03

127.7

2.36

60

0.24

1.97

6

50

0.51

13

3.86

2.95

98

75

0.17

4.2

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

2.19

1SXU000023C0202

TA75+AB80A

al

rm ad

e

Th erlo s

Ov elay

r

2

Approximate dimensions

TA75DU – TA200DU

00.00

Inches

00.00

[Millimeters]

TA75DU

0.51

13

3.99

93

0.24

6

4.35

2.13

110.5

54

TA80DU

2.85

72.3

TA75

TOUCH SAFE COVER

0.47

12.0

3.77

0.47

1.18

12.0

30.0

0.50

12.5

95.7

2 - M4 Mtg. Slots

4.37

2.12

111.0

54.0

TA110DU

TA80 OVERLOAD RELAY

TOUCH SAFE COVER

1.48

37.5

5.44

0.24

6.0

2.52

138.1

64.0

6 - 0.21 HOLES

.61

15.5

3.14

80.0

0.24

6.0

4.73

120.1

0.07

1.7

1.98

50.2

TA200DU

TA110 OVERLOAD RELAY

2.20

1SXU000023C0202

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Th

Ov erm

e

a

re rloa l

lay d

s

Approximate dimensions

TA450DU

00.00

Inches

00.00

[Millimeters]

2

TA450DU

0.18

4.5

0.24

2.99

6.0

76.0

0.2 DIA.

5.0 DIA.

6.62

168.0

2.17

0.96

0.82

55.0

24.5

21.0

2

1.11

4

6

28.3

7.60

193.0

2.28

58.0

2.28

58.0

T450DU/SU

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

2.21

1SXU000023C0202

al

rm ad

e

Th erlo s

Ov elay

r

Notes

2

2.22

1SXU000023C0202

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Electronic overload relays

E16DU – E1250DU

El

e

Ov ctro

e

n

re rloa ic

lay d

s

Electronic

Overload relays

2

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Description

• Available for starter construction with

A Line contactors and separate panel

mounting

• Designed for close couple mounting

• Separate base mounting available for

all overload relays

• E16DU Class 10, 20, & 30, field

selectable

• E200DU – E800DU Class 10, 20 & 30,

field selectable

• Stop button

• Screwdriver guide holes

• All terminal screws are available from the

front

• Single phase and phase unbalance

protection

• Isolated alarm circuit (N.O.) contact

• Ambient compensation:

-25°C to +70°C (-13oF to +158oF)

• Manual test

• Manual or automatic reset

• Factory calibrated and tested

• Wide adjustment range

• UL File No: E48139

• CSA File No: LR98336

Tripping classes of the thermal overload relays

Standard classes in IEC 947-4-1 are classes: 10 A, 10, 20, 30. The

tripping class indicates according to IEC 947-4-1 the maximum tripping

time in seconds under specified conditions of test at 7.2 times the

setting current and specifies tripping and non tripping times for 1.5 and

7.2 times the setting current. Mostly used class is 10 A.

Abstract from IEC 947-4-1

Tripping class

Max. tripping time

at 1.5 x setting current

(warm state)

Tripping time at

7.2 x setting current

(cold state)

At 1.05 x setting current

10 A

10

20

30

(s)

120

240

480

720

(s)

2 – 10

4 – 10

6 – 20

9 – 30

no tripping

2.23

1SXU000023C0202

nic

ro ad

t

ec o

El verl ys

O ela

r

Catalog number explanation

2

Reset, manual or automatic

Nominal current setting

Trip indicator test function

Stop button

Catalog number explanation

E16DU 1.0

Frame size

E16DU

E200DU

E320DU

E500DU

E800DU

2.24

1SXU000023C0202

Amp rating

1.0

200

320

500

800

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

El

e

Ov ctro

e

n

re rloa ic

lay d

s

Selection by motor horsepower

UL/CSA Starters with electronic overload

2

200V

Motor horsepower

3 Phase, 1800 RPM

230V

460V

575V

—

—

—

—

—

—

1/2

3/4

—

1

2

3

5

—

7 1/2

10

—

10

15

20

25

30

—

40

50

60

75

100

125

150

200

250

—

—

—

—

—

1/2

—

3/4

1

1 1/2

2

3

5

7 1/2

10

10

—

15

20

—

30

—

40

50

60

75

100

—

5/6

200

250

300

1/4

1/3

1/2

3/4

—

1 1/2

2

—

3

5

7 1/2

10

15

20

25

—

30

40

50

60

75

—

100

125

150

200

250

300

400

500

600

700

—

1/4,1/3

—

1/2

3/4

1

1 1/2

2

—

3

5

7 1/2

10

15

20

—

25

30

40

50

60

—

75

100

125

150

200

250

350

400

500

600

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Starter components

Open

Complete starter

Catalog number

List Price

11-2B1

Contactor

Catalog number

List Price

A9-30-10-84

11-2C1

A9-30-10-84

Overload relay

Catalog number

List Price

E16DU1.0 (0.3 - 1.0)

$ 78

E16DU2.7 (0.9-2.7)

$ 198

$ 96

11-2D1

A9-30-10-84

E16DU6.3 (2.0-6.3)

11-2E1

21-2E1

31-2E1

204

233

A9-30-10-84

A12-30-10-84

A16-30-10-84

84

102

E16DU18.9 (5.7-18.9)

41-2E1

336

A26-30-10-84

183

E45DU30 (9-30)

51-2E2

414

A30-30-10-84

252

E45DU45 (15-45)

61-2E2

71-2E1

81-2E1

91-2E1

472

544

608

649

A40-30-10-84

A50-30-11-84

A63-30-11-84

A75-30-11-84

297

330

372

413

E45DU45 (15-45)

112

E80DU80 (27-80)

188

861

A110-30-11-84

480

E140DU140 (50-140)

261

E200DU200 (60-200)

325

E320DU320 (100-320)

775

E500DU500 (150-500)

865

E800DU800 (250-800)

950

105

A1-2E1

B1-2E2

C1-2E2

D1-2E3

E1-2E3

F1-2E3

G1-70E5

H1-70E5

T1-70E8

U1-70E8

1,415

1,830

2,422

3,027

3,177

4,125

5,700

8,346

8,646

A145-30-11-84

A185-30-11-84

A210-30-11-84

A260-30-11-84

A300-30-11-84

AF400-30-11-70

AF460-30-11-70

AF580-30-11-70

AF750-30-11-70

Discount schedule TS [OZ]

825

1,290

1,635

1,815

1,875

3,120

4,425

6,900

7,200

2.25

1SXU000023C0202

nic

ro ad

t

ec o

El verl ys

O ela

r

E16DU – E1250DU

for contactors and mini contactors

2

Catalog

number

Setting

range

Trip

class

List

price

Contactor

Suffix

code

0.1-0.32A

0.3-1.0A

0.9-2.7A

2.0-6.3A

5.7-18.9A

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

$ 96

B...6-B...7 / A...9...A...16...

B...6-B...7 / A...9...A...16...

B...6-B...7 / A...9...A...16...

B...6-B...7 / A...9...A...16...

B...6-B...7 / A...9...A...16...

A1

B1

C1

D1

E1

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

10, 20, 30

105

112

188

261

325

775

865

950

2,970

A...26 ... A...40

A...26 ... A...40

A...50 ... A...75

A...95 ... A...110

A...145 ... A...185

A...210 ... A...300

AF...400 ... AF...460

AF...580 ... AF...750

AF...1350 ... AF...1650

E1

E2

E1

E1

E2

E3

E5

E8

E12

Trip Class, Selectable 10, 20, 30

E16DU

E45DU

E16DU0.32

E16DU1.0

E16DU2.7

E16DU6.3

E16DU18.9

Trip Class selectable, 10, 20, 30

E80DU

E140DU

E45DU30

E45DU45

E80DU80

E140DU140

E200DU200

E320DU320

E500DU500

E800DU800

E1250DU1250

9-30A

15-45A

27-80A

50-140A

65-200A

105-320A

170-500A

270-800A

375-1250A

NOTE: Electronic overload relays are not suitable for single-phase and DC motors.

Universal motor controller

E200DU

E320DU

Universal motor controller with thermal overload protection 0.24 - 63 A in a single device type. Bushing-type

transformer, cable cross section 25mm2 (max. diameter including insulation - 11mm). Integrated motor control

functions: Direct starting, reverse starting, star-delta starting, servo-drive functions. Diagnostic functions:

Overload phase failure, trip categories, 5, 10, 20, 30. Integrated storage of parameters and motor data. 6 digital

inputs, 3 relay outputs. Fieldbus-independent interface for connection to FBP fieldbus connectors, interface to

operating panel ACS100-PAN.

Description

E500DU

E800DU

E1250DU

UMC22-FBP.0

Contactor

Setting range

A9 - AF1650

0.63 - 63 A

Trip class

5, 10, 20, 30

Catalog number

1SAJ510000R0600

List price

$ 603

Universal Motor Controller, UMC22-FBP.0

2.26

1SXU000023C0202

Discount schedule TS [OZ]

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

El

e

Ov ctro

e

n

re rloa ic

lay d

s

Accessories

2

Mounting kits

for direct mounting on contactors AF400 – AF750

For

overload relays

On

contactor

Catalog

number

List

price

E500DU

AF400 – AF460

AF400 – AF460 w/reversing kits

DT500/AF460S

DT500/AF460L

$ 395

E800DU

AF580 – AF750

AF580 – AF750 w/reversing kits

DT800/AF750S

DT800/AF750L

415

Separate mounting kits

DB16E

For

overload relays

Catalog

number

List

price

E16DU

DB16E

$ 15

E45DU

DB45E

39

E80DU

DB80E

48

E140DU

DB140E

70

Lug kits

Wire range

6– 250 MCM

4– 400 MCM

(2) 4– 500 MCM

(2) 2/0– 500 MCM

(3) 2/0– 500 MCM

(4) 1/0– 750 MCM

Electronic

overload

Catalog

number

E200DU200

E320DU320

E320DU320

E500DU500

E800DU800

E12150DU1250

ATK185

ATK300

ATK300/2

ATK580/2HK

ATK750/3HK

ATK1350/4

List

price

$ 45

68

110

160

235

235

Terminal shrouds

Operating panel, ACS100-PAN

For

overload relays

Catalog

number

E200DU

E320DU

LT200E

LT320E

E500DU

E800DU

LT500E

LT800-E

List

price

$ 41

52

60

Accessories for universal motor controller UMC22-FBP

Operating, diagnostics and parameter setting panel for Universal Motor Controller UMC22-FBP.

Setting of motor and bus parameters.

Type

Designation

Usage with

Catalog number

ACS100-PAN

Operating panel

UMC22-FBP

1SAJ510001R0002

List price

$ 114

Accessories for operating panel ACS100-PAN

Extension cable 3 m and door mounting set IP65 (front side) for ACS100-PAN operating panel.

Type

Designation

Usage with

Catalog number

ACS100-CAB.300

Extension cable 3m with door

mounting set

List price

ACS100-PAN

1SAJ510002R0001

$ 98

ACS100-CAB.070

Extension cable 3m with front

mounting set

ACS100-PAN

1SAJ510003R0001

67

Current transformers for use with the universal motor controller UMC22-FBP

Secondary-linear transformer, 3-phase with terminal block, intended for conductors Cu 2.5mm2.

Type

Designation

KORC 4L 185 R/4

Current transformer

Current range recommended

60 - 185 A

Catalog number

KORC-4L-185R/4

List price

$ 600

Connection kit for use with the KORC-current transformers

Connection kit for applications with KORC-current transformers with A-series contactors

Type

Designation

Appropriate for contactor type

Catalog number

List price

DT 450 / A185

Connection kit

AF145 - AF185

DT450/A185

$ 225

DT 450 / A300

Connection kit

AF260 - AF300

DT450/A300

225

DT 500 / AF460L

Connection kit 1

AF400 - AF460

DT500/AF460L

395

DT 800 / AF750L

Connection kit 1

AF580 - AF750

DT800/AF750L

415

1 Connection kit for Star-Delta-Starter

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Discount schedule ABA [OF] – All products except DB16E

Discount schedule TS [OZ] – DB16E

2.27

1SXU000023C0202

nic

ro ad

t

ec o

El verl ys

O ela

r

Technical data

E16/E45/E80/E140DU

2

General technical data

E16DU

Type

E45DU30

E45DU45

E80DU80

Standards:

Approvals and certificates

IEC/EN 60 947-4-1 / IEC/EN 60 947-5-1

UL, CSA

V

Rated insulation voltage Ui V

Rated operating voltage Ue kV

Impulse withstand voltage Uimp Permissible ambient temperature

– Storage °C

– Operation

°C

Climatic resistance according to

Mounting position

Resistance to shock

Shock duration ms

multiple of g

Resistance to vibrations to EN 61373

Mounting

– by screws:

600

600

– 25 to + 70

– 25 to + 70

on request

on request (1)

on request

separate mounting with Kit for single set up by screws 4xM5

– onto contactor:

• Connection cross-sections

– single-core or stranded – flexible with wire end ferrule or direct mounting onto contactor - no kit necessary

mm2

mm2

M5/2,3 ... 2,6 Nm

M8/6 ... 6,5 Nm

1 x 2,5 ... 16

2 x 2,5 ... 16

1 x 10 ... 95

2 x 6 ... 35

1 x 2,5 ... 10

2 x 2,5 ... 10

1 x 10 ... 70

2 x 6 ... 35

Connection to aux.-contacts terminals

• Screw terminal

– with self-disengaging clamping piece

• Connection cross-sections

– single-core or stranded mm2

– flexible with wire end ferrule 600

600

6

Connection terminals and attachment type

Main contactors (load side)

• Screw terminal

– with self-disengaging clamping piece

E140DU140

M3,5/0,8 ... 1,0 Nm

1 x 1 ... 4

2 x 1 ... 4

mm2

1 x 0,75 ... 2,5

2 x 0,75 ... 2,5

Protection degree to IEC/EN 60 947-1

IP 20

IP 10

All terminals are safe from finger-touch and safe from touch

by the back of the hand to EN 50274

Technical data of the conducting paths

E16DU

Type

Number of conducting paths

Setting ranges

Tripping classes to IEC/EN 60 947-4-1

Frequency range Switching frequency

without early tripping

A ... A

Hz

0,1 ... 18,9

E45DU30

E45DU45

E80DU80

E140DU140

3

9 … 30

15 ... 45

27 ... 80

10 or selectable 10, 20, 30

50 and 60 (only for a.c. operating 3 phase)

80 ops./h with 40% if the making current does not

exceed 6 x in and starting time does not exceed 1s.

50 ... 140

Load rating of auxiliary contacts

Contact

Rated operating voltage Ue

Rated thermal continuous current

Rated operating current Ie at AC-15 230 V

at AC-15 400 V

at AC-15 500 V

at DC-13 24 V

at DC-13 60 V

at DC-13 110 V

at DC-13 220 V

Short-circuit protection fuse gG

STOTZ safety circuit-breaker: S271, S281

V

A

A

A

A

A

A

A

A

A

NC (95-96)

600

6

3

1,1

0,7

1,5

0,5

0,4

0,2

6

(2)

NO (97-98)

600

6

3

1,1

0,7

1,5

0,5

0,4

0,2

6

(2)

(1) on request

2.28

1SXU000023C0202

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

El

e

Ov ctro

e

n

re rloa ic

lay d

s

Technical data

E200/ 320/500/ 800/1250DU

2

General technical data

E200DU

Type

Standards:

Approvals and certificates

Rated insulation voltage Ui

Rated operating voltage Ue

Impulse withstand voltage Uimp

Permissible ambient temperature

– Storage

– Operation

Climatic resistance according to

Mounting position

Resistance to shock

Resistance to vibrations to EN 61373

Mounting

– by screws:

E320DU

V

V

kV

°C

°C

IEC 68-2-1, IEC 68-2-2

IEC 68-2-14, IEC 68-2-30

Shock duration ms

multiple of g

by screws

4 x M5

– onto contactor:

Connection terminals and attachment type

Main contuctors (load side)

• Screw terminals

– with busbar or cable lugs

Connection terminals and attachment type

Auxiliary contacts

• Screw terminal

– with self-disengaging clamping piece

– tigtening torque

• Connection cross-sections

– single-core or stranded – flexible with wire end ferrule M8

Protection degree to IEC/EN 60 947-1

E800DU

E1250DU

– 25 to + 70

– 25 to + 70

IEC 68-2-1, IEC 68-2-2,

IEC 68-2-30

any

30

5

category 1 class B

by screws

by screws

by screws

4 x M5

4 x M5

4 x M6

with DT ...

with DT ...

mounting kit

mounting kit

M10

M10

(rail order

separately)

M12

(rail order

separately)

by screws

4 x M6

with DT ...

mounting kit

M12

M3,5

1,0

Nm

mm2

mm2

E500DU

IEC/EN 60 947-4-1 / IEC/EN 60 947-5-1

UL, CSA

600

600

6

2 x 0,75 ... 4

2 x 0,75 ... 2,5

All terminals are safe from finger-touch and safe from touch

by the back of the hand to EN 50274

IP 00

Technical data of the conducting paths

Type

E200DU

Number of conducting paths

Setting ranges

Tripping classes to IEC/EN 60 947-4-1

Frequency range

Switching frequency

without early tripping

3

60 ... 200

100 ... 320

150 ... 500

250 ... 800

375 ... 1250

10, 20, 30 selectable

50 and 60 (only for a.c.operating 3 phase)

80 ops./h with 40% if the making current does not

exceed 6 x in and starting time does not exceed 1s.

A ... A

Hz

E320DU

E500DU

E800DU

E1250DU

Load rating of auxiliary contacts

E200DU, E320DU, E500DU, E800DU, E1250DU

Type

Contact

Rated operating voltage Ue

Rated thermal continuous current

at AC-15 230 V

Rated operating current Ie

at AC-15 400 V

at AC-15 500 V

at DC-13 24 V

at DC-13 60 V

at DC-13 110 V

at DC-13 220 V

Short-circuit protection fuse

gG

STOTZ safety circuit-breaker: S271, S281

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

V

A

A

A

A

A

A

A

A

A

NC (95-96)

600

6

3

1,1

0,7

1,5

0,5

0,4

0,2

6

(1)

NO (97-98)

600

6

3

1,1

0,7

1,5

0,5

0,4

0,2

6

(1)

2.29

1SXU000023C0202

nic

ro ad

t

ec o

El verl ys

O ela

r

2

Technical data

Universal motor controller

UMC22-FBP

General technical data

Type

UMC22-FBP

Rated operating voltage Ue (three-phase system) V AC/Hz

max. 690/50

Rated operating current range

A

0.24 ... 63

Trip classes

5, 10, 20, 30

Short-circuit-protection

separate fuses on power line side

Supply voltage

V DC

19.2 ... 31.2, including ripple

Supply current

mA

max. 130 (at 18 ... 30 V DC)

Total device power dissipation

W

max. 3.1 (at 24 V DC)

LEDs on front

LED 1, green: device ready for operation

LED 2, yellow: motor current > 33 % of Is

LED 3, red: fault (trip, device fault, etc.)

Mechanical relay contact lifetime 500 000 switching cycles

Electrical lifetime 250 V AC / 0.5 A 100 000 switching cycles

250 V AC / 1.5 A 50 000 switching cycles

mm2 max. 2.5, max. 2 x 1.5

Terminal conductor cross section Current transformer bushing holes Internal clearance and creepage distances

mm Mounting Dimensions (W x H x D)

Net weight 11 mm Ø (25 mm“)

> 5.5 (safety insulation up to 250 V AC)

on DIN rail (EN 50022-35) or wall mounting with 4 screws M4

mm 70 x 105 x 110 (incl. FieldBusPlug and Control Panel)

kg

0.39 (current transf. + control unit)

Degree of protection

Storage temperature range °C

Operating temperature range

°C

IP 20

-25...+70

0...+55

Technical description Order Code 2CDC 135 004 D02xx

FieldBusPlug connection

see FBP catalogue

Digital inputs

Number of digital inputs 6 (DI0 ... DI5)

Power supply for digital inputs

1-Signal (range including ripple)

18 … 30V, 70 mA

+13 V ... +31,2 V

0-Signal (range including ripple) -31,2 V ... +13 V

Input current per channel (24 V DC) typ. 6.0 mA

Input resistor to 0 V 3.9 kOhm

Line length unshielded

Line length shielded 4

1

3

max. 600 m

max. 1000 m

Digital outputs

Number of digital relay outputs

3 (DO0...DO2)

Grouping of contacts mon

3 contacts with 1 com-

2

5

Switching capacity per relay contact

AC15: DC13: 120 V AC,

max. 3 A 240 V AC,

max. 1.5 A

24 V DC, max. 0.1 A

125 V DC, max. 0.22 A

250 V DC, max. 0.11 A

max. load for all contacts

4 A (terminal 5 or 6)

min load for switching signals

12 V, 1 W or 1 VA

PTC Input - direct connection of PTC sensors from the motor

Conductor holes through the current transformers max. 25 mm2

(max. diameter incl. insulation 11 mm)

2.30

1SXU000023C0202

6

Parameter Options:

1 = Control function

2 = check back via aux.-contact

3 = Fault output, e.g. to lamp

4 = PTC Input

5 = digital inputs for control signals

6 = Connections for earth fault monitor

Low Voltage Products & Systems

ABB Inc. • 888-385-1221 • www.abb.us/lowvoltage

Technical data

Terms and technical definitions

El

e

Ov ctro

e

n

re rloa ic

lay d

s

2

Altitude

Characterizes the place of use. It is expressed in meters above sea

level.

Circuits

• Auxiliary circuit – all the conductive parts of a contactor designed

to be inserted in a different circuit from the main circuit and the

contactor control circuits.

• Control circuit – all the conductive parts of a contactor (other

than the main circuit and the auxiliary circuit) used to control the

contactor’s closing operation or opening operation or both.

• Main circuit – all the conductive parts of a contactor designed to

be inserted in the circuit that it controls.

Insulation Class according to NFC 20 040 and VDE 0110

Characterizes adaptation of the devices to ambient temperature and

operating conditions. For given clearances and creepage distances,

a device will have different insulating voltages depending on

insulation classes A, B, C & D. Class C corresponds to most industrial

applications. The devices in this catalog belong to Class C.

Coordination of equipment protections during a short circuit

This is the addition upstream of the contactor and thermal overload

relay of a short circuit (SCPD) protection device such as a circuit

breaker, a fuse with a high breaking capacity or other fuses.

IEC publication 947-4-1 defines coordination Types 1 & 2:

• Type 1 – Coordination requires that, in the event of a short circuit,

the contactor or starter does not endanger persons or installations

and will not be able to operate without being repaired or parts being

replaced.

• Type 2 – Coordination requires that, in short circuit conditions, the