Hazloc High Bay Sell Sheet

advertisement

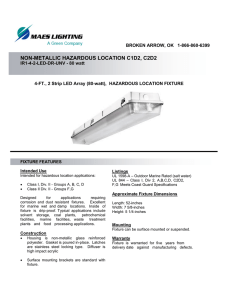

hazardousLOCATION high bay LIGHTING for indoor & outdoor hazardous locations. UL 844 The danger of fire or explosion to people and property is a very real possibility. Workers may be exposed daily and ordinary people can possibly be exposed at a variety of at-risk locations. Lighting these environments while protecting from the risk of hazard led us to design, develop, lab test, certify and rate our made in the USA Class 1-Div 2, Class 2-Div 1 and Class 2-Div 2 LED light fixtures. Certifications / Ratings Our wide range of HazLoc-LED lights can be used in commercial and industrial locations for both indoor and outdoor lighting applications. UL 844 UL 1598/A C22.2 No. 137 SPECIFICATION & FEATURES CONSTRUCTION - Low Profile die cast aluminum round housing with cooling fins. - Housing is enclosed & fully gasketed for hazardous locations. - Designed and gasketed for wet locations (IP 66). - Drivers mounted externally with flat bracket. - Standard fixture color is powdercoated grey. OPTICS - Tempered Glass lens. - CRI: >70 - Illumination by LED arrays produce exceptional output & efficacy. ELECTRICAL - Power Factor: >.95 - TC/ER Rated - 600v Power Cord. - Available in 120-270 Universal voltage & 347-480 High voltage. INSTALLATION - Pendant Mount (PM) - Flat Bracket (FB) OPTIONS - Surge Protection Device with inline fuse & LED indicator light. WARRANTY - Five Year Limited Warranty. - Optional Ten Year Limited Warranty. NOTE: - Lumen output may vary relevant to color temperature (CCT). - Consult factory on any customization requests as this is a lab certified light fixture. PRODUCT ORDERING GUIDE CATALOG NUMBER WATTAGE VOLTAGE KELVIN LUMENS LUMENS/WATT MAX AMBIENT TEMP TEMP CLASS / VOLTAGE HH06-055-50-EX-X 55w 120-277 / 347-480 HH12-104-50-EX-X 104w 120-277 / 347-480 HH18-170-50-EX-X 170w HH22-215-50-EX-X-6 CLASS / DIV RATE 5,000k 6,158 112 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 5,000k 12,289 118 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 120-277 / 347-480 5,000k 18,064 106 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 215w 120-277 / 347-480 5,000k 19,869 92 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 HH22-215-50-EX-X 215w 120-277 / 347-480 5,000k 21,890 102 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 HH27-279-50-EX-X 279w 120-277 / 347-480 5,000k 28,574 102 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 HH32-368-50-EX-X 368w 120-277 / 347-480 5,000k 35,925 98 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 HH40-419-50-EX-X 419w 120-277 / 347-480 5,000k 41,369 99 65˚C / 149˚F 120-277 T5 / 347-480 T4A C1D2 C2D1 C2D2 Specifications and data are subject to change without notice. technicalDATA & TYPICAL APPLICATIONS Hazardous (Classified) Locations in Accordance with Article 500, NEC - 1990 Class 1 - Flammable Gases or Vapors Class 2 - Combustible Dusts G N DI DIVISION 1 DIVISION 2 In which combustible dusts: • Exists under normal conditions. • Exists because of mechanical failure or abnormal operation of equipment and machinery. This might also provide a source of ignition through simultaneous failure of electric equipment, operation of protection devices or from other causes. • Present in hazardous quantities of electrically conductive nature. In which ignitable concentration of flammable gases or vapors: • Are normally confined within closed containers when handled, processed and / or used. • Are normally prevented by positive mechanical ventilation. • Are adjacent to a Class 1, Division 1 location. N E P Applies to Group A, Group B, Group C and Group D according to certain physical characteristics of their explosive behavior. DIVISION 2 Surface Temperature Classification Reference TEMPERATURE CLASS MAXIMUM SURFACE TEMPERATURE OF THE EQUIPMENT IGNITION TEMPERATURES OF COMBUSTIBLE SUBSTANCES T1 450˚C / 842˚F >450˚C / >842˚F T2 300˚C / 572˚F >300˚C / >572˚F T3 300˚C / 392˚F >300˚C / >392˚F T4 135˚C / 275˚F >135˚C / >275˚F T4A 120˚C / 248˚F >120˚C / >248˚F T5 100˚C / 212˚F >100˚C / >212˚F T6 85˚C / 185˚F >85˚C / >185˚F Equipment that corresponds to a higher temperature class can also be used for applications with a lower temperature class. Flammable gases and vapors are assigned to the relevant temperature class according to ignition temperature. In which combustible dusts: • Are not normally in the air. • Accumulations are not sufficient to interfere with normal operations. • Are suspended in the air as a result of infrequesnt malfunctioning of - Handling equipment - Processing equipment • Accumulations may be sufficient to interfere with the safe dissipation of heat from electrical equipment. • Accumulation may be ignitable by abnormal operation or failure of electrical equipment. Applies to Group E, Group F and Group G according to the types of material that makes up the dust. Groups Group A Group B Group C Group D • Acetylene • Hydrogen • Butadine • Ethylene Oxide • Propylene Oxide • Acrolien • Ethylene • Cyclopropane • Ethyl Ether • Propane • Acetone • Ammonia • Benzene • Butane • Ethanol • Gasoline • Hexane • Methanol • Naptha • Natural Gas • Toluene Group E * Group F ** Group G *** • Aluminum • Magnesium • Commercial Alloys • Coal • Carbon Black • Charcoal • Coke Dusts • Flour • Grain • Wood • Plastic • Chemicals G N I D PEN Group E * - Combustible Metal Dusts | Group F ** - Combustible Carbonaceous Dusts | Group G *** - Other Combustible Dusts Typical Applications for Class 1 Division 2 • Hazardous Research • Ethanol Refinement • Laboratories • Mining • Food Processing • Bio Fuel Production • Breweries • NASA • Compressed Gas Storage • Oil & Gas Refineries • Hospitals • Bakeries • Water Treatment • Fuel Storage • Forensic Laboratories • Gas & Vapor Areas • Government Installations • Oil & Gas Refineries • Forensic Laboratories • Plastics Processing • Charcoal & Coke • Clothing Manufacturing • Fuel Storage • Schools • Carbon Handling • Flour Handling Typical Applications for Class 2 Division 1 & 2 • Hazardous Research • Paper Processing • Laboratories • Mining • Coal Handling • Combustible Dust Areas • Food Processing • Grain Handling • Hospitals • Wood Processing • Alloy Handling moreQUALITY PRODUCTS Visit www.SolasRay.com for information on more indoor & outdoor products. 1524 Jackson Street | Anderson 46016, IN U.S.A. www.SolasRay.com | phone: 765.298.8030 | fax: 765.755.0044 Hazloc 01.25.16