Reaction Torque Sensor

advertisement

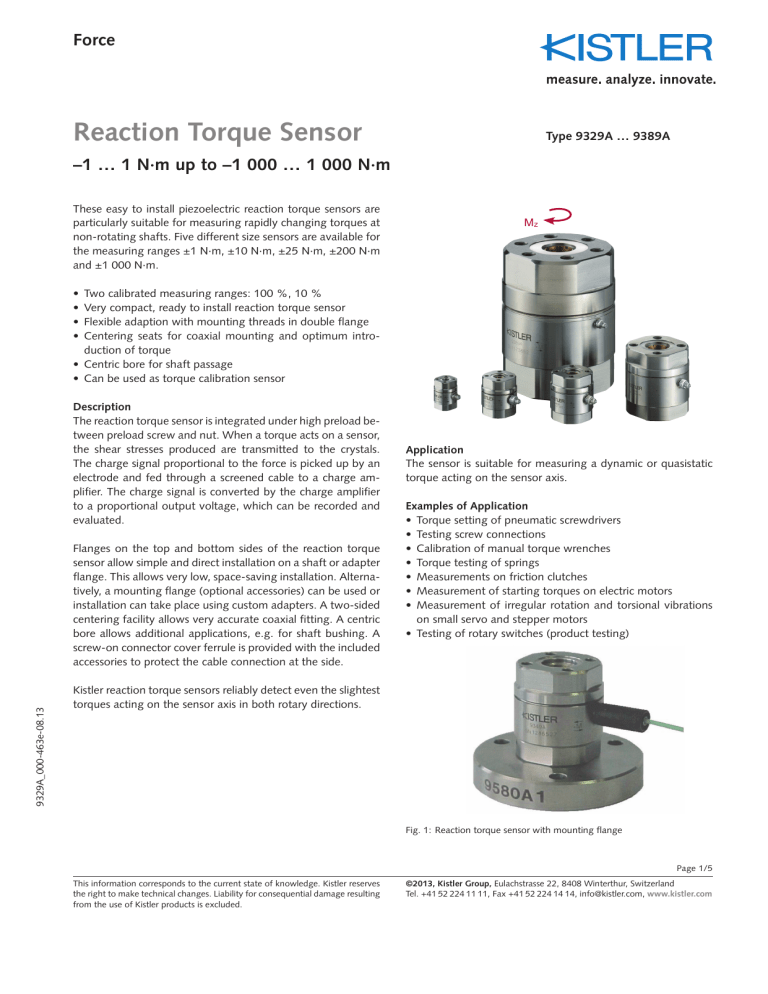

Force Reaction Torque Sensor Type 9329A … 9389A –1 … 1 N·m up to –1 000 … 1 000 N·m These easy to install piezoelectric reaction torque sensors are particularly suitable for measuring rapidly changing torques at non-rotating shafts. Five different size sensors are available for the measuring ranges ±1 N·m, ±10 N·m, ±25 N·m, ±200 N·m and ±1 000 N·m. Mz • • • • Two calibrated measuring ranges: 100 %, 10 % Very compact, ready to install reaction torque sensor Flexible adaption with mounting threads in double flange Centering seats for coaxial mounting and optimum introduction of torque • Centric bore for shaft passage • Can be used as torque calibration sensor Description The reaction torque sensor is integrated under high preload between preload screw and nut. When a torque acts on a s­ ensor, the shear stresses produced are transmitted to the c­rystals. The charge signal proportional to the force is picked up by an electrode and fed through a screened cable to a charge amplifier. The charge signal is converted by the charge amplifier to a proportional output voltage, which can be ­recorded and evaluated. 9329A_000-463e-08.13 Flanges on the top and bottom sides of the reaction torque sensor allow simple and direct installation on a shaft or adapter flange. This allows very low, space-saving installation. Alternatively, a mounting flange (optional accessories) can be used or installation can take place using custom adapters. A two-sided centering facility allows very accurate coaxial fitting. A centric bore allows additional applications, e.g. for shaft bushing. A screw-on connector cover ferrule is provided with the included accessories to protect the cable connection at the side. Application The sensor is suitable for measuring a dynamic or quasistatic torque acting on the sensor axis. Examples of Application • Torque setting of pneumatic screwdrivers • Testing screw connections • Calibration of manual torque wrenches • Torque testing of springs • Measurements on friction clutches • Measurement of starting torques on electric motors • Measurement of irregular rotation and torsional vibrations on small servo and stepper motors • Testing of rotary switches (product testing) Kistler reaction torque sensors reliably detect even the slightest torques acting on the sensor axis in both rotary directions. Fig. 1: Reaction torque sensor with mounting flange Page 1/5 This information corresponds to the current state of knowledge. Kistler reserves the right to make technical changes. Liability for consequential damage resulting from the use of Kistler products is excluded. ©2013, Kistler Group, Eulachstrasse 22, 8408 Winterthur, Switzerland Tel. +41 52 224 11 11, Fax +41 52 224 14 14, info@kistler.com, www.kistler.com Reaction Torque Sensor, –1 … 1 N·m up to –1 000 … 1 000 N·m, Type 9329A … 9389A Dimensions Reaction Torque Sensor Type 9329A … 9389A Mz B 4,8 KIAG 10-32 neg. Connecting cable h9 C E Connector protection G Connecting cable F ø6 KIAG 10-32 neg. R4 Fig. 3: Type 9329A h9 9329A_000-463e-08.13 Fig. 2: Type 9339A … 9369A with connector protection Dimensions in mm Type D 9329A 20 9339A 30 9349A 36 9369A 54 9389A 100 D1 14 21 26 40 70 D2 6 10 14 21 30 D3 4,4 8,3 11,7 18,1 24,5 D3* 4 8 11 17 23,5 Fig. 4: Type 9389A with connector protection D4 19,5 28,5 34,5 53 98 H 26 34 42 60 130 A 3 4 5 8 14 B 13,2 16,6 21,7 32,5 69,2 C 7,4 10,1 10,2 10,4 10,4 17 26 32 48 90 E 27,4 40,1 46,2 64,4 110,4 F – 36 39 48 70,4 G 36 43,5 46,5 56 80,5 K M3 M4 M5 M8 M12 T 6 8 9 13 30 * Free access with mounted centering rings Page 2/5 This information corresponds to the current state of knowledge. Kistler reserves the right to make technical changes. Liability for consequential damage resulting from the use of Kistler products is excluded. ©2013, Kistler Group, Eulachstrasse 22, 8408 Winterthur, Switzerland Tel. +41 52 224 11 11, Fax +41 52 224 14 14, info@kistler.com, www.kistler.com Reaction Torque Sensor, –1 … 1 N·m up to –1 000 … 1 000 N·m, Type 9329A … 9389A Technical Data Reaction Torque Sensor Type Measuring range Mz N·m Overload Mz N·m Calibrated measuring ranges 100 % Mz N·m 10 % Mz N·m Threshold Mz mN·m Sensitivity pC/N·m Linearity, all measuring ranges %FSO Hysteresis, all measuring ranges %FSO Tensile/compression force, max. Fz kN Crosstalk Fz → Mz mN·m/N Side force, max. 1) Fx,y kN (Mz = 100 %; Fz = 0) Crosstalk (typical) Fx,y → Mz mN·m/N Bending moment, max. Mx,y N·m (Mz = 100 %; Fz = 0) Crosstalk Mx,y → Mz mN·m/N·m Rigidity cϕ (Mz) mN·m/μrad 9329A –1 … 1 –1,2/1,2 9339A –10 … 10 –12/12 9349A –25 … 25 –30/30 9369A –200 … 200 –240/240 9389A –1 000 … 1 000 –1 200 … 1 200 –1 … 1 –0,1 … 0,1 <0,03 ≈–2 170 ≤±0,2 ≤0,3 –10 … 10 –1 … 1 <0,18 ≈–460 ≤±0,2 ≤0,3 –25 … 25 –2,5 … 2,5 <0,35 ≈–230 ≤±0,2 ≤0,3 –200 … 200 –20 … 20 <0,62 ≈–130 ≤±0,2 ≤0,3 –1 000 … 1 000 –100 … 100 <0,78 ≈–100 ≤±0,2 ≤0,3 –3/9 ≤±0,01 0,47 –5/14 ≤±0,05 0,38 –10/8 ≤±0,01 0,44 –10/10 ≤±0,02 0,27 –60/60 ≤±0,01 3,66 <0,5 17,3 <0,3 20 <0,3 30 <0,3 27 <0,2 698 <8 <8 <8 <12 <10 ≈17 >53 –20 … 80 0,02 ≈96 >36 –40 … 120 –­0,02 ≈189 >33 –40 … 120 –­0,02 ≈924 >23 –40 … 120 –­0,02 ≈1 540 >11 –40 … 120 –­0,02 Natural frequency (torsion) fn kHz Operating temperature range °C Temperature coefficient %/°C of sensitivity Insulation resistance at 20 °C Ω >1013 >1013 Capacitance pF ≈73 ≈43 Connection Connector protector no yes Degree of protection (with cable connected) EN60529 Case material DIN Weight g 50 137 1) >1013 >1013 ≈340 ≈350 KIAG 10-32 neg. yes yes IP65 1.4542 243 800 >1013 ≈910 yes 6 720 Application of force in plane of flange 9329A_000-463e-08.13 General The torque should be introduced by the smallest possible ­eccentricity of the axes to be connected (<0,02 mm). Bending moment and shear forces should be avoided as far as ­possible. The surfaces contacting the reaction torque sensor must be flat, rigid and clean. The centering facility on both sides of the reaction torque sensor using centering rings (included accessories) allow very accurate coaxial fitting. The sensor can be fitted directly via the integral flanges on two sides. Special adapters can be manufactured for adaptation to the customer's specific applications. Page 3/5 This information corresponds to the current state of knowledge. Kistler reserves the right to make technical changes. Liability for consequential damage resulting from the use of Kistler products is excluded. ©2013, Kistler Group, Eulachstrasse 22, 8408 Winterthur, Switzerland Tel. +41 52 224 11 11, Fax +41 52 224 14 14, info@kistler.com, www.kistler.com Reaction Torque Sensor, –1 … 1 N·m up to –1 000 … 1 000 N·m, Type 9329A … 9389A Overview of Installation Variants Adaption A: Installation in Shaft with Adapter for Shaft Journal with Pin Adaption B: Installation in Shaft with Adapter Flange Mz Mz Adapter for tool shank with pin Pinned during installation Customized centering ring (g6) Centering rings (incl. accessories) Adapter flange for flat mounting in shaft Adapter for cylinder bore recess with pin Pinned during ­installation Customized tool adapter Adaption C: Installation with Shaft with Integrated Flange Customized centering ring (g6) Adaption D: Adapter Flange for Wrenches with External Square Head Mz Mz 9329A_000-463e-08.13 Centering rings (incl. accessories) Centering pin g6 on customized shaft Mounting flange Type 9580A… (optional accessories) Page 4/5 This information corresponds to the current state of knowledge. Kistler reserves the right to make technical changes. Liability for consequential damage resulting from the use of Kistler products is excluded. ©2013, Kistler Group, Eulachstrasse 22, 8408 Winterthur, Switzerland Tel. +41 52 224 11 11, Fax +41 52 224 14 14, info@kistler.com, www.kistler.com Reaction Torque Sensor, –1 … 1 N·m up to –1 000 … 1 000 N·m, Type 9329A … 9389A Adaption E: Screw Plate with Spring Assembly Adaption F: Desktop Installation with Mounting Flange Mz Mz Test screw Spring assembly Customized screw plate Centering rings (incl. accessories) 9329A_000-463e-08.13 Customized mounting plate Ordering Key Scope of Delivery Including Accessories Type Reaction Torque Sensor • 2 x Centering ring 9329A 3.420.196 Reaction Torque Sensor • Connector protection • 2 x Centering ring 9339A 3.414.366 3.420.179 Reaction Torque Sensor • Connector protection • 2 x Centering ring 9349A 3.414.366 3.420.180 Reaction Torque Sensor • Connector protection • 2 x Centering ring 9369A 3.414.366 3.420.181 Reaction Torque Sensor • Connector protection • 2 x Centering ring 9389A 3.414.366 3.420.197 Optional Accessories • Connecting cable (see data sheet 1631C_000-346) • Mounting flange Type 9580A… Centering rings (incl. accessories) Mounting flange Type 9580A… (optional accessories) Mounting Flange Fig. 5: Type 9580A9 ... A2 for Type 9329A 9339A 9349A 9369A 9389A Type 9580A9 9580A0 9580A1 9580A2 9580A4 D1 14 21 26 40 70 d d1 40 30 62 50 70 55 100 78 180 135 Fig. 6: Type 9580A4 d2 6 10 14 21 30 d3 4,5 5,5 6,6 13,5 17 d4 3,2 4,3 5,3 8,4 13 d5 4,5 8,5 12 18 25 d6 5,6 7,5 9 14 20 H2 T1 N 8 2 3 11 2 5 13 2 6 22 2 9 30 2,5 13 Page 5/5 This information corresponds to the current state of knowledge. Kistler reserves the right to make technical changes. Liability for consequential damage resulting from the use of Kistler products is excluded. ©2013, Kistler Group, Eulachstrasse 22, 8408 Winterthur, Switzerland Tel. +41 52 224 11 11, Fax +41 52 224 14 14, info@kistler.com, www.kistler.com