HVAC Proposed Language - Title24Stakeholders.com

advertisement

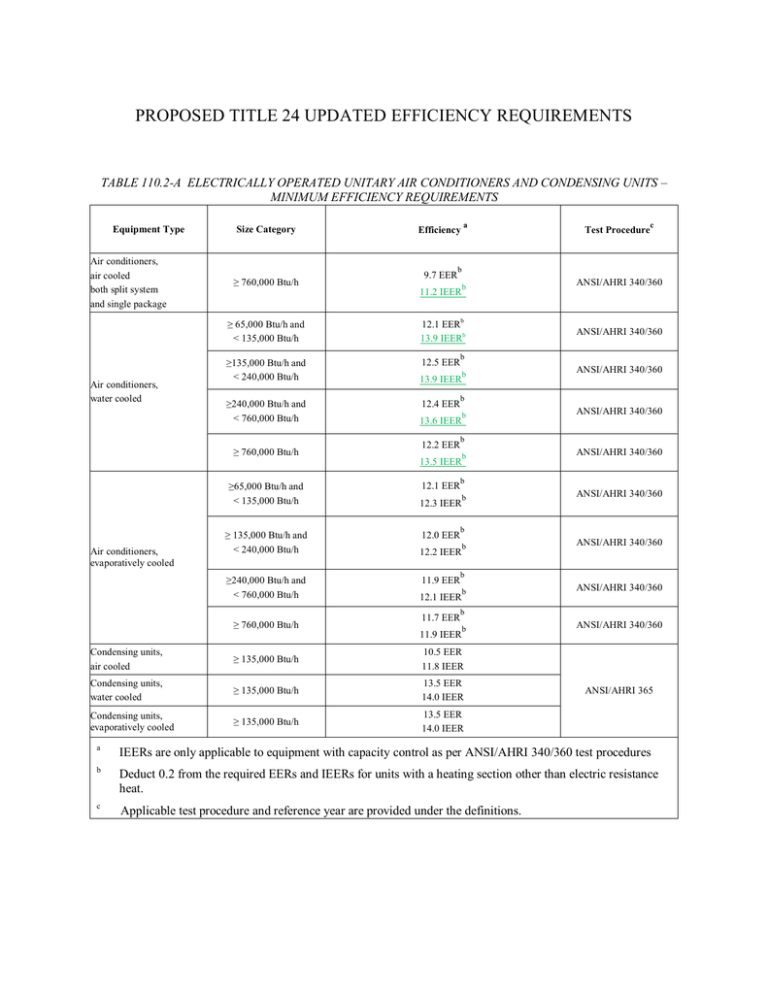

PROPOSED TITLE 24 UPDATED EFFICIENCY REQUIREMENTS TABLE 110.2-A ELECTRICALLY OPERATED UNITARY AIR CONDITIONERS AND CONDENSING UNITS – MINIMUM EFFICIENCY REQUIREMENTS Equipment Type Air conditioners, air cooled both split system and single package Air conditioners, water cooled Size Category ≥ 760,000 Btu/h Efficiency 9.7 EER b ≥ 65,000 Btu/h and < 135,000 Btu/h 12.1 EERb 13.9 IEERb ≥135,000 Btu/h and < 240,000 Btu/h 12.5 EER ≥240,000 Btu/h and < 760,000 Btu/h ≥ 135,000 Btu/h and < 240,000 Btu/h ≥240,000 Btu/h and < 760,000 Btu/h ≥ 760,000 Btu/h c 13.9 IEER 12.4 EER 12.1 EER b ANSI/AHRI 340/360 b ANSI/AHRI 340/360 b ANSI/AHRI 340/360 b b ANSI/AHRI 340/360 b 12.1 IEER 11.7 EER ANSI/AHRI 340/360 b 12.2 IEER 11.9 EER b b 12.3 IEER 12.0 EER ANSI/AHRI 340/360 b 13.6 IEER 12.2 EER ANSI/AHRI 340/360 b 13.5 IEER ≥65,000 Btu/h and < 135,000 Btu/h Test Procedure b 11.2 IEER ≥ 760,000 Btu/h Air conditioners, evaporatively cooled a b ANSI/AHRI 340/360 b 11.9 IEER b Condensing units, air cooled ≥ 135,000 Btu/h 10.5 EER 11.8 IEER Condensing units, water cooled ≥ 135,000 Btu/h 13.5 EER 14.0 IEER Condensing units, evaporatively cooled ≥ 135,000 Btu/h 13.5 EER 14.0 IEER ANSI/AHRI 340/360 ANSI/AHRI 365 a IEERs are only applicable to equipment with capacity control as per ANSI/AHRI 340/360 test procedures b Deduct 0.2 from the required EERs and IEERs for units with a heating section other than electric resistance heat. c Applicable test procedure and reference year are provided under the definitions. TABLE 110.2-B UNITARY AND APPLIED HEAT PUMPS, MINIMUM EFFICIENCY REQUIREMENTS Equipment Type Air Cooled (Cooling Mode) Size Category Subcategory or Rating Condition Efficiency a ≥ 65,000 Btu/h and < 135,000 Btu/h 11.0 EERb 11.2 IEERb ≥ 135,000 Btu/h and < 240,000 Btu/h 10.6 EERb 10.7 IEERb Split system and single package Test Procedurec ANSI/AHRI 340/360 9.5 EERb 9.6 IEERb ≥ 240,000 Btu/h Water source (cooling mode) ≥ 65,000 Btu/h and < 135,000 Btu/h 86ºF entering water 13.0 EER Water source (cooling mode) ≥ 135,000 Btu/h and < 240,000 Btu/h 86ºF entering water 13.0 EER 59ºF entering water 18.0 EER ISO-13256-1 77ºF entering water 14.1 EER ISO-13256-1 86ºF entering water 10.6 EER ISO-13256-2 59ºF entering water 16.3 EER ISO-13256-1 77ºF entering water 12.1 EER ISO-13256-2 47° F db/43° F wb outdoor air 3.3 COP 17° F db/15° F wb outdoor air 2.25 COP Groundwater source (cooling mode) < 135,000 Btu/h Ground source (cooling mode) < 135,000 Btu/h Water source water-towater (cooling mode) < 135,000 Btu/h Groundwater source water-to-water (cooling mode) < 135,000 Btu/h Ground source brineto-water (cooling mode) < 135,000 Btu/h Air Cooled (Heating Mode) Split system and single package ≥ 65,000 Btu/h and < 135,000 Btu/h (cooling capacity) ISO-13256-1 ANSI/AHRI 340/360 ≥ 135,000 Btu/h (cooling capacity) 47° F db/43° F wb outdoor air 3.2 COP 17° F db/15° F wb outdoor air 2.05 COP Size Category Subcategory or Rating Condition Efficiency a Test Procedurec Water source (heating mode) < 135,000 Btu/h (cooling capacity) 68ºF entering water 4.3 COP ISO-13256-1 Water source (heating mode) 135,000 Btu/h and < 240,000 Btu/h (cooling capacity) 68ºF entering water 2.9 COP ISO-13256-1 < 135,000 Btu/h (cooling capacity) 50ºF entering water 3.7 COP ISO-13256-1 < 135,000 Btu/h (cooling capacity) 32ºF entering water 3.2 COP ISO-13256-1 < 135,000 Btu/h (cooling capacity) 68ºF entering water 3.7 COP ISO-13256-2 < 135,000 Btu/h (cooling capacity) 50ºF entering water 3.1 COP ISO-13256-2 < 135,000 Btu/h (cooling capacity) 32ºF entering water 2.5 COP ISO-13256-2 Equipment Type Groundwater source (heating mode) Ground source (heating mode) Water source water-towater (heating mode) Groundwater source water-to-water (heating mode) Ground source brine-towater (heating mode) a IEERs are only applicable to equipment with capacity control as per ANSI/AHRI 340/360 test procedures. b Deduct 0.2 from the required EERs and IEERs for units with a heating section other than electric resistance heat. c Applicable test procedure and reference year are provided under the definitions. TABLE 110.2-C AIR-COOLED GAS-ENGINE HEAT PUMPS Equipment Type Size Category Subcategory or Rating Condition Efficiency Test Procedurea Air-Cooled GasEngine Heat Pump (Cooling Mode) All Capacities 95° F db Outdoor Air 0.60 COP ANSI Z21.40.4A Air-Cooled GasEngine Heat Pump (Heating Mode) All Capacities 47° F db/43° F wb Outdoor Air 0.72 COP ANSI Z21.40.4A a Applicable test procedure and reference year are provided under the definitions. TABLE 110.2-D WATER CHILLING PACKAGES – MINIMUM EFFICIENCY REQUIREMENTS a,b Equipment Type Air Cooled, With Condenser Electrically Operated Size Category Path A Efficiency a,b Path B Efficiency a,b < 150 Tons ≥ 10.100 EER ≥ 13.700 IPLV ≥ 9.700 EER ≥ 15.800 IPLV ≥ 150 Tons ≥ 10.100 EER ≥ 14.000 IPLV ≥ 9.700 EER ≥ 16.100 IPLV Test Procedure c AHRI 550/590 Air Cooled, Without Condenser All Capacities Air-cooled chillers without condensers must be rated with matching condensers and comply with the aircooled chiller efficiency requirements. All Capacities Reciprocating units must comply with the watercooled positive displacement efficiency requirements. Electrically Operated Water Cooled, Electrically Operated, Reciprocating AHRI 550/590 (Reciprocating) < 75 Tons ≤0.750 kW/ton ≤ 0.600 IPLV ≤ 0.780 kW/ton ≤ 0.500 IPLV ≥ 75 tons and < 150 tons ≤ 0.720 kW/ton ≤ 0.560 IPLV ≤ 0.750 kW/ton ≤ 0.490 IPLV ≥ 150 tons and < 300 tons ≤ 0.660 kW/ton ≤ 0.540 IPLV ≤ 0.680 kW/ton ≤ 0.440 IPLV ≥ 300 tons and < 600 tons ≤ 0.610 kW/ton ≤ 0.520 IPLV ≤ 0.625 kW/ton ≤ 0.410 IPLV ≥ 600 tons ≤ 0.560 kW/ton ≤ 0.500 IPLV ≤ 0.585 kW/ton ≤ 0.380 IPLV < 150 Tons ≤ 0.610 kW/ton ≤ 0.550 IPLV ≤ 0.695 kW/ton ≤ 0.440 IPLV ≥ 150 tons and < 300 tons ≤ 0.610 kW/ton ≤ 0.550 IPLV ≤ 0.635 kW/ton ≤ 0.400 IPLV ≥ 300 tons and < 400 tons ≤ 0.560 kW/ton ≤ 0.520 IPLV ≤ 0.595 kW/ton ≤ 0.390 IPLV ≥ 400 tons and < 600 tons ≤ 0.560 kW/ton ≤ 0.500 IPLV ≤ 0.585 kW/ton ≤ 0.380 IPLV ≥ 600 Tons ≤ 0.560 kW/ton ≤ 0.500 IPLV ≤ 0.585 kW/ton ≤ 0.380 IPLV Water Cooled, Electrically Operated Positive Displacement Water Cooled, Electrically Operated, Centrifugal AHRI 550/590 Size Category Path A Efficiency a,b Path B Efficiency a,b All Capacities ≥0.600 COP N.A. d Water Cooled Absorption, Single Effect All Capacities ≥ 0.700 COP N.A. d Absorption Double Effect, Indirect-Fired All Capacities ≥ 1.000 COP ≥ 1.050 IPLV N.A. d Absorption Double Effect, Direct-Fired All Capacities ≥ 1.000 COP ≥1.000 IPLV N.A. d Water Cooled Gas Engine Driven Chiller All Capacities ≥ 1.2 COP ≥ 2.0 IPLV N.A. d Equipment Type Air Cooled Absorption, Test Procedure c Single Effect a ANSI/AHRI 560 ANSI Z21.40.4A No requirements for: • Centrifugal chillers with design leaving evaporator temperature < 36°F; or • Positive displacement chillers with design leaving fluid temperature ≤ 32°F; or • Absorption chillers with design leaving fluid temperature < 40°F b Must meet the minimum requirements of Path A or Path B. However, both the full load (COP) and IPLV must be met to fulfill the requirements of the applicable Path. c See Section 100.1 for definitions d NA means not applicable TABLE 110.2-E PACKAGED TERMINAL AIR CONDITIONERS AND PACKAGED TERMINAL HEAT PUMPS – MINIMUM EFFICIENCY REQUIREMENTS Equipment Type Size Category (Input) Subcategory or Rating Condition Efficiency PTAC (Cooling mode) Newly constructed or newly conditioned buildings or additions All Capacities 95°F db Outdoor Air 14.0 - (0.300 x Cap/1000)a EER PTAC (Cooling mode) Replacements b All Capacities 95°F db Outdoor Air 10.9 - (0.213 x Cap/1000)a EER PTHP (Cooling mode) Newly constructed or newly conditioned buildings or additions All Capacities 95°F db Outdoor Air 14.0 - (0.300 x Cap/1000)a EER PTHP (Cooling mode) Replacements b All Capacities PTHP (Heating Mode) Newly constructed or newly conditioned buildings or additions All Capacities - 3.7 - (0.052 x Cap/1000)a COP PTHP (Heating mode) Replacements b All Capacities - 2.9 - (0.026 x Cap/1000)a COP Test Procedure c ANSI/AHRI/CSA 310/380 95°F db Outdoor Air 10.8 - (0.213 x Cap/1000)a EER Equipment Type SPVAC (Cooling Mode) SPVHP (Cooling Mode) SPVHP (Heating Mode) SPVAC (Cooling Mode), nonweatherized space constrained SPVHP (Cooling Mode), nonweatherized space constrained SPVHP (Heating Mode), nonweatherized space constrained Size Category (Input) Subcategory or Rating Condition Efficiency <65,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER ≥65,000 Btu/h and <135,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER ≥135,000 Btu/h and <240,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER <65,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER ≥65,000 Btu/h and <135,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER ≥135,000 Btu/h and <240,000 Btu/h 95°F db / 75°F wb Outdoor Air 10.0 EER <65,000 Btu/h 47°F db / 43°F wb Outdoor Air 3.0 COP ≥65,000 Btu/h and <135,000 Btu/h 47°F db / 43°F wb Outdoor Air 3.0 COP ≥135,000 Btu/h and <240,000 Btu/h 47°F db / 43°F wb Outdoor Air 3.0 COP <30,000 Btu/h 95°F db / 75°F wb Outdoor Air 9.2 EER ≥30,000 Btu/h and <36,000 Btu/h 95°F db / 75°F wb Outdoor Air 9.2 EER <30,000 Btu/h 95°F db / 75°F wb Outdoor Air 9.2 EER ≥30,000 Btu/h and <36,000 Btu/h 95°F db / 75°F wb Outdoor Air 9.2 EER <30,000 Btu/h 47°F db / 43°F wb Outdoor Air 3.0 COP ≥30,000 Btu/h and <36,000 Btu/h 47°F db / 43°F wb Outdoor Air 3.0 COP Test Procedure c ANSI/AHRI 390 TABLE 110.2-F HEAT TRANSFER EQUIPMENT Equipment Type Liquid-to-liquid heat exchangers Subcategory Minimum Efficiencya Test Procedure b Plate type NR ANSI/AHRI 400 a NR = no requirement b Applicable test procedure and reference year are provided under the definitions TABLE 110.2-G PERFORMANCE REQUIREMENTS FOR HEAT REJECTION EQUIPMENT Performance Total System Heat Rejection Capacity at Rated Conditions Subcategory or Rating Condition Propeller or axial fan Open-circuit cooling towers All 95°F entering water 85°F leaving water 75 °F entering air wb 42.1 gpm/hp CTI ATC-105 and CTI STD-201 Centrifugal fan Open-circuit cooling towers All 95°F entering water 85°F leaving water 75 °F entering air wb 20.0 gpm/hp CTI ATC-105 and CTI STD-201 Propeller or axial fan closed-circuit cooling towers All 102°F entering water 90°F leaving water 75 °F entering air wb 14.0 gpm/hp CTI ATC-105S and CTI STD-201 Centrifugal fan closed-circuit cooling towers All 102°F entering water 90°F leaving water 75 °F entering air wb 7.0 gpm/hp CTI ATC-105S and CTI STD-201 All R-507A test fluid 165°F entering gas temperature 105°F condensing temperature 75°F entering wetbulb 157,000 Btu/h·hp CTI ATC-106 All Ammonia test fluid 140°F entering gas temperature 96.3°F condensing temperature 75°F entering wetbulb 134,000 Btu/h·hp CTI ATC-106 All R-507A test fluid 165°F entering gas temperature 105°F condensing temperature 75°F entering wetbulb 135,000 Btu/h·hp CTI ATC-106 All Ammonia test fluid 140°F entering gas temperature 96.3°F condensing temperature 75°F entering wetbulb 110,000 Btu/h·hp CTI ATC-106 All R22 test fluid 125°F condensing temperature 190°F entering gas temperature 15°F subcooling 95°F entering drybulb 176,000 Btu/h·hp ANSI/AHRI 460 Equipment Type Propeller or axial fan evaporative condensers Propeller or axial fan evaporative condensers Centrifugal fan evaporative condensers Centrifugal fan evaporative condensers Air cooled condensers a a ,b, c, d Required , Test Procedure e For purposes of this table, open-circuit cooling tower performance is defined as the water flow rating of the tower at the given rated conditions divided by the fan motor nameplate power. b For purposes of this table, closed-circuit cooling tower performance is defined as the process water flow rating of the tower at the given rated conditions divided by the sum of the fan motor nameplate rated power and the integral spray pump motor nameplate power . c For purposes of this table air-cooled condenser performance is defined as the heat rejected from the refrigerant divided by the fan motor nameplate power. d Open cooling towers shall be tested using the test procedures in CTI ATC-105. Performance of factory assembled open cooling towers shall be either certified as base models as specified in CTI STD-201 or verified by testing in the field by a CTI approved testing agency. Open factory assembled cooling towers with custom options added to a CTI certified base model for the purpose of safe maintenance or to reduce environmental or noise impact shall be rated at 90 percent of the CTI certified performance of the associated base model or at the manufacturer’s stated performance, whichever is less. Base models of open factory assembled cooling towers are open cool ing towers configured in exact accordance with the Data of Record submitted to CTI as specified by CTI STD-201. There are no certification requirements for field erected cooling towers. e Applicable test procedure and reference year are provided under the definitions. TABLE 110.2-H Electrically Operated Variable Refrigerant Flow (VRF) Air Conditioners Minimum Efficiency Requirements Equipment Type VRF Air Conditioners, Air Cooled Size Category Heating Section Type Sub-Category or Rating Condition Minimum Efficiency <65,000 Btu/h All VRF Multi-split System 13.0 SEER ≥65,000 Btu/h and <135,000 Btu/h Electric Resistance (or none) VRF Multi-split System ≥135,000 Btu/h and <240,000 Btu/h Electric Resistance (or none) VRF Multi-split System ≥240,000 Btu/h Electric Resistance (or none) VRF Multi-split System Test a Procedure 11.2 EER 13.1 IEER b ANSI/AHRI 1230 11.0 EER 12.9 IEER b 10.0 EER 11.6 IEER b a Applicable test procedure and reference year are provided under the definitions. b IEERs are only applicable to equipment with capacity control as per ANSI/AHRI 1230 test procedures. TABLE 110.2-I Electrically Operated Variable Refrigerant Flow Air-to-Air and Applied Heat Pumps - Minimum Efficiency Requirements Equipment Type Sub-Category or Rating Condition Minimum Efficiency All VRF Multi-split System 13.0 SEER ≥65,000 Btu/h and <135,000 Btu/h Electric Resistance (or none) VRF Multi-split System a ≥135,000 Btu/h and <240,000 Btu/h Electric Resistance (or none) VRF Multi-split System a Electric Resistance (or none) VRF Multi-split System a All VRF Multi-split systems a Size Category <65,000 Btu/h VRF Air Cooled, (cooling mode) ≥240,000 Btu/h <65,000 Btu/h Heating Section Type Test Procedure b 11.0 EER 12.9 IEER c AHRI 1230 10.6 EER 12.3 IEER c 9.5 EER 11.0 IEER c 12.0 EER AHRI 1230 86ºF entering water VRF Water source ≥65,000 Btu/h and (cooling mode) <135,000 Btu/h ≥135,000 Btu/h All VRF Multi-split System a 12.0 EER 86ºF entering water All VRF Multi-split System a 10.0 EER 86ºF entering water <135,000 Btu/h All VRF Groundwater source (cooling mode) VRF Multi-split System 16.2 EER AHRI 1230 59ºF entering water ≥135,000 Btu/h All VRF Multi-split System a 13.8 EER 59ºF entering water <135,000 Btu/h All VRF Ground source (cooling mode) VRF Multi-split System a 13.4 EER 77ºF entering water ≥135,000 Btu/h All VRF Multi-split System a 77ºF entering water 11.0 EER AHRI 1230 Equipment Type Size Category Heating Section Type Sub-Category or Rating Condition Minimum Efficiency Test Procedure b <65,000 Btu/h --- VRF Multi-split System 7.7 HSPF AHRI 1230 --- VRF Multi-split system 3.3 COP (cooling capacity) ≥65,000 Btu/h and <135,000 Btu/h 47ºF db/ 43ºF wb outdoor air (cooling capacity) VRF Multi-split system 2.25 COP VRF Air Cooled 17ºF db/15ºF wb outdoor air (heating mode) ≥135,000 Btu/h --- (cooling capacity) VRF Multi-split system 3.2 COP 47ºF db/ 43ºF wb outdoor air VRF Multi-split system 2.05 COP 17ºF db/15ºF wb outdoor air <135,000 Btu/h VRF Water source --- (cooling capacity) VRF Multi-split System 4.2 COP AHRI 1230 68ºF entering water (heating mode) ≥135,000 Btu/h --- (cooling capacity) VRF Groundwater source (heating mode) <135,000 Btu/h --- <135,000 Btu/h VRF Multi-split System 3.6 COP AHRI 1230 50ºF entering water --- (cooling capacity) VRF Ground source 3.9 COP 68ºF entering water (cooling capacity) ≥135,000 Btu/h VRF Multi-split System VRF Multi-split System 3.3 COP 50ºF entering water --- (cooling capacity) VRF Multi-split System 3.1 COP AHRI 1230 32ºF entering water (heating mode) ≥135,000 Btu/h (cooling capacity) --- VRF Multi-split System 2.8 COP 32ºF entering water a Deduct 0.2 from the required EERs and IEERs for Variable Refrigerant Flow (VRF) Multi-split system units with a heating recovery section. b c Applicable test procedure and reference year are provided under the definitions. IEERs are only applicable to equipment with capacity control as per ANSI/AHRI 1230 test procedures. . TABLE 110.2-J Warm-Air Furnaces and Combination Warm-Air Furnaces/Air-Conditioning Units, Warm-Air Duct Furnaces, and Unit Heaters Equipment Type Warm-Air Furnace, GasFired Size Category (Input) < 225,000 Btu/h ≥ 225,000 Btu/h Warm-Air Furnace, oilFired < 225,000 Btu/h ≥ 225,000 Btu/h Subcategory or Rating Condition Minimum Efficiency Test Procedurea Maximum Capacityb 78% AFUE or 80% Et DOE 10 CFR Part 430 or Section 2.39, Thermal Efficiency, ANSI Z21.47 Maximum Capacityb 80% Et Section 2.39, Thermal Efficiency, ANSI Z21.47 Maximum Capacityb 78% AFUE or 80% Et DOE 10 CFR Part 430 or Section 42, Combustion, UL 727 Maximum Capacityb 81% Et Section 42, Combustion, UL 727 Warm-Air Duct Furnaces, Gas-Fired All Capacities Maximum Capacityb 80% Ec Section 2.10, Efficiency, ANSI Z83.8 Warm-Air Unit Heaters, Gas-Fired All Capacities Maximum Capacityb 80% Ec Section 2.10, Efficiency, ANSI Z83.8 Warm-Air Unit Heaters, Oil-Fired All Capacities Maximum Capacityb 81% Ec Section 40, Combustion, UL 731 a Applicable test procedure and reference year are provided under the definitions. b Compliance of multiple firing rate units shall be at maximum firing rate. c Combustion units not covered by NAECA (3-phase power or cooling capacity greater than or equal to 19 kW) may comply with either rating. d Et= thermal efficiency. Units must also include an interrupted or intermittent ignition device (IID), have jacket losses not exceeding 0.75% of the input rating, and have either power venting or a flue damper. A vent damper is an acceptable alternative to a flue damper for those furnaces where combustion air is drawn from the conditioned space. e f Ec= combustion efficiency (100% less flue losses). See test procedure for detailed discussion. As of August 8, 2008, according to the Energy Policy Act of 2005, units must also include interrupted or intermittent ignition device (IID) and have either power venting or an automatic flue damper. TABLE 110.2-K Gas- and Oil-Fired Boilers, Minimum Efficiency requirements Minimum Efficiency b,c Equipment Sub Size Category Test Procedure a Type Category (Input) Before 3/2/2022 After 3/1/2022 < 300,000 Btu/h 82% AFUE 80% Et 80% Et 82% Ec 82% Ec 84% AFUE 84% AFUE 82% Et 82% Et 84% Ec 84% Ec 80% AFUE 80% AFUE DOE 10 CFR Part 430 79% Et 79% Et DOE 10 CFR Part 431 79% Et 79% Et DOE 10 CFR Part 431 77% Et 79% Et DOE 10 CFR Part 431 e 77% Et 79% Et < 300,000 Btu/h 82% AFUE 82% AFUE ≥ 300,000 Btu/h and ≤ 2,500,000 Btu/h d > 2,500,000 Btu/h e 81% Et 81% Et DOE 10 CFR Part 431 81% Et 81% Et DOE 10 CFR Part 431 ≥ 300,000 Btu/h and Gas-Fired ≤ 2,500,000 Btu/h d > 2,500,000 Btu/h e Boiler, hot water < 300,000 Btu/h Oil-Fired ≥ 300,000 Btu/h and ≤ 2,500,000 Btu/h d > 2,500,000 Btu/h e Gas-Fired < 300,000 Btu/h ≥ 300,000 Btu/h Gas-Fired and all, except ≤ 2,500,000 Btu/h d natural e draft > 2,500,000 Btu/h ≥ 300,000 Btu/h and Gas-Fired, d Boiler, steam natural ≤ 2,500,000 Btu/h draft > 2,500,000 Btu/h Oil-Fired DOE 10 CFR Part 430 82% AFUE DOE 10 CFR Part 431 DOE 10 CFR Part 430 DOE 10 CFR Part 431 DOE 10 CFR Part 431 DOE 10 CFR Part 430