Bioslurry = Brown Gold - Food and Agriculture Organization of the

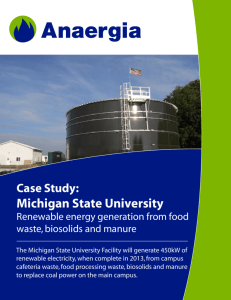

advertisement