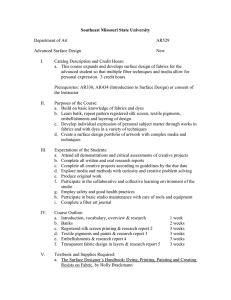

fibres and fabrics

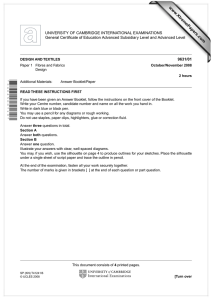

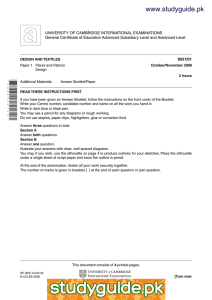

advertisement