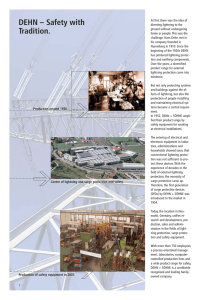

DEHN, Inc. Technical Presentation

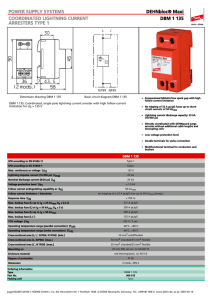

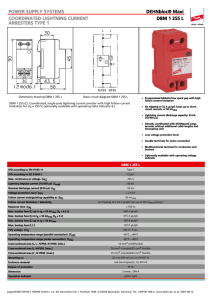

advertisement

® ® ® DEHN, Inc. Technical Presentation © 2014 DEHN, INC. 1 ® ® ® DEHN, Inc. Technical Presentation Effective Installations of AC & DC Power Surge Protective Devices (SPD) © 2014 DEHN, INC. 2 Presenter ® Frank Basciano USA Product Manager; Sr. Application pp Engineer g 26 years in industry – In 7th year with DEHN Eaton/Cutler-Hammer E t /C tl H – Product Manager – Power Quality Division Innovative Technology, Inc. – – – – – Director of Product Mgmt Director of Engineering Director of Operations Design Engineer Quality Engineer © 2014 DEHN, INC. IEEE Member IEEE SPD Standards Committee IEC SC37 SPD St Standards d d C Committee itt 3 ® ® ® The Nature of Lightning © 2014 DEHN, INC. 4 Slow Motion Lightning Event © 2014 DEHN, INC. ® 5 Lightning g g strike, Dubai 2010 – Not highest nearby point © 2014 DEHN, INC. ® 6 Some Lightning Facts ® 1 Lightning is NOT a single stroke 1. stroke, 4 -17 17 strikes in one event!! 2. Lightning does NOT always hit the highest point!! 3. Lightning does NOT need a metal conductor – it uses air, it likes trees and the earth itself!! 4 There is a higher probability that Lightning will strike 4. high metal objects over other materials or places. © 2014 DEHN, INC. 7 Lower 48 Distribution of Lightning © 2014 DEHN, INC. ® 8 National Weather Service – USA © 2014 DEHN, INC. ® 9 Protect Yourself! Crouch down, down do NOT lie down Keep at least 3m distance from objects & people Put feet closely together Wrap arms around legs & tuck your chin © 2014 DEHN, INC. ® Open Field Exposure 10 Lightning g g Damage g © 2014 DEHN, INC. ® 11 ® ® Power SPD Specifications & Installations “No matter “N tt who’s h ’ product d t you iinstall, t ll if it iis not isntalled well, all bets are off. The SPD will not perform well or as expected expected.” Frank Basciano © 2014 DEHN, INC. 12 SPD Company Specifications ® SPD ratings Are the values tested by third party? – IEC standards are performance & safety standards – Therefore, if IEC certified by third party (KEMA), then results are verified, like DEHN Peak Surge Current Inflated Numbers Additive Rule (per phase, per mode) Often not tested values When tested, tested numbers given are typically best case, case DEHN publishes worst case © 2014 DEHN, INC. 13 Maximum Surge Capability: Limited by Electromechanical Connections ® AC P Protector t t R Rated t d ffor 85 kA kA, 8/20 µs Connector blew off ff at 20 kA, 8/20 s © 2014 DEHN, INC. 14 Maximum Surge Capability: Limited by Printed Circuit Design ® AC Protector Rated for 100 kA,, 8/20 µs Neutral trace vaporized at 18 kA 8/20 / s © 2014 DEHN, INC. 15 Maximum Surge Capability: Limited by SPD Internal Fusing ® AC Protector Rated for 160 kA, 8/20 µs Fuse opened p at 8 kA 8/20 s © 2014 DEHN, INC. 16 Summary on Specifications ® IEC Tested Products – values are verified by Third-Party Third Party Lab UL does NOT test “peak peak surge current current” UL only assigns VPR and verifies Nominal Discharge Current © 2014 DEHN, INC. 17 National Electric Code – 2014 SPD Installations ® Article 285 285.5 – Listed - An SPD shall be a listed device. Which one is “Listed”? © 2014 DEHN, INC. 18 “Listed” per 2014 NEC Definition ® Listed. Equipment, materials, Equipment materials or services included in a list published by an organization that is acceptable to the authority having jurisdiction and concerned with evaluation of products or services, that maintains periodic i inspection ti off production d ti off listed li t d equipment i t or materials t i l or periodic i di evaluation of services, and whose listing states that either the equipment, material, or service meets appropriate designated standards or has been tested d and d found f d suitable bl for f a specified f d purpose. Informational Note: The means for identifying listed equipment may vary for each organization concerned with product evaluation, some of which do not recognize equipment as listed li d unless l it i is i also l labeled. l b l d Use off the h system employed by the listing organization allows the authority having g jurisdiction j to identify fy a listed product. p © 2014 DEHN, INC. 19 Bottom Line on “Listed” ® A th it H Authority Having i JJurisdiction i di ti AHJ © 2014 DEHN, INC. 20 2014 NEC® - SPD Installation ® 285.12 285 12 Routing of Connections Connections. The conductors used to connect the SPD to the line or bus and to ground shall not be anyy longer g than necessaryy and shall avoid unnecessaryy bends. The intent of this article is for Parallel Wired SPD Series Wired SPD we don’t care about lead length © 2014 DEHN, INC. 21 ® ® ® Installation Practices Examples of Good and Poor Installations – and why it‘s bad Form, Fit & Function © 2014 DEHN, INC. 22 SPD Installation Practices ® Nobody sets out to create a poor or bad SPD install!!! p What you don’t know, you don’t know. © 2014 DEHN, INC. 23 Two Basic SPD Styles = Form ® Wired in Parallel = most common Wired in Series 1 1. Most common 1 1. More difficult install 2. Most misunderstood 2. Limited Current, limited use 3. Most problems with correct 3. Terminal & product heat install buildup 4. Easiest to install 4. People think power filter 5. p think “gray g y box” People 5. SCCR coordination issue 6. SCCR coordination issues 6. Few problems SPD installs 7 7. Large for mains use © 2014 DEHN, INC. 24 How do these things get into our systems Parallel Wiring © 2014 DEHN, INC. ® Series Wiring 25 Installation Practices = Fit ® Parallel Products Typical installs are usually not good for lightning & surge protection Lead Length Matters!!! – Longer g Lead Length g decreases performance p – Often makes the SPD ineffective Wire Dress matters – not in the way you think!! – Neat N t is i nott always l b bestt for f SPD performance f Increases LTV (MLV) – Odds of downstream equipment q p failure increase – Not what you paid for – Equipment & facility – NOT protected! © 2014 DEHN, INC. 26 Parallel Installations ® Typical USA Installation Three Phase Wye Distribution Panel Neat on the outside Don’t D ’ kknow about b the h iinside id Where is the ground bar usually? Do you see anything wrong or inefficient in the installation? © 2014 DEHN, INC. 27 Installation Comparison p with lightning g g currents © 2014 DEHN, INC. ® 28 Electrodynamic Forces - (EMF) ® Si Simplified lifi d Calculation C l l ti – Force F in i N/ N/m Remember this as we proceed through the next slides. slides © 2014 DEHN, INC. 29 Not too bad of an install – Long Leads But could have been made better!! © 2014 DEHN, INC. ® 30 Not too bad of an install – Long Leads But could have been made better!! ® Big boxes make for difficult installs this size installs, SPD is too much. A series wired install would have improved this SPD performance. © 2014 DEHN, INC. 31 Poor Install Too long of a ground wire © 2014 DEHN, INC. ® 32 Poor Install – Long Leads Did a few things right – perpendicular wires! © 2014 DEHN, INC. ® 33 Poor Installation: Excessive Lead Length ® US West Co. - Council Bluffs, Iowa Switchgear Protected by Surge Protector © 2014 DEHN, INC. AC Surge P Protector 34 ® NEC 110 110.13 13 and 110 110.14 14 violations and 285.12 © 2014 DEHN, INC. 35 Poor Wire Dress, Ineffective SPD due to installation ® Wire tie wrapped, but unnecessarily long © 2014 DEHN, INC. 36 Poor Installation: Disconnect adds excessive lead length ® Panel Protected by Surge Protector AC Surge Protector © 2014 DEHN, INC. Disconnect for Surge Protector 37 Function Wire Length – IEEE, Guide to Surge Protection Wire Voltage Drop: VL = L(di/dt) + (IL * RL) © 2014 DEHN, INC. ® VL – Voltage drop of wire IL – current through the wire RL – resistance of length of wire di/dt – change of current over change of time L – inductance of wire length 38 Installed Let Through Voltage ® Surge Protector + Connecting Leads © 2014 DEHN, INC. 39 Influence of the connecting leads on the real protection level ® L/N Udynamic 1 isurge Uprospection Udynamic 1+ Utotal = Uprospection + Udynamic 2 Udynamic 2 PE Udynamic = ((i • R)) + (di/dt) ( )L © 2014 DEHN, INC. 40 Calculated Wire Voltage Drop 5 ft,, 1/0 / AWG Connection Leads Applied Surge = 30 kA, 8/20 µs ® Wire Voltage Drop: VL = L(di/dt) + (IL * RL) (IL * RL) = 30 kA x 5 ft x 0.1 mΩ/ft = 15 volts L (di/dt) = 5 ft x 0.4 μH/ft x (30 kA / 8 μs) = 2 μH H x 3.75 3 75 x 109 A/s A/ = 7,500 volts (7.5 kVpk) V is approximately 7,515 volts peak © 2014 DEHN, INC. 41 5 ft, 1/0 AWG Connection Leads 10 kA, 8/20 µs ® Dead Short - 5 ft,1/0 f AWG - 6 in. separation Let Through 2,140 Volts © 2014 DEHN, INC. 42 5 ft, 1/0 AWG Connection Leads 10 kA, 8/20 µs ® Dead Short - 5 ft 1/0 AWG - with wire ties Let Through 1 280 Volts 1,280 © 2014 DEHN, INC. 43 Influence of the connecting leads on the real protection level Laboratory testing - Low impulse current 5 kA 8/20 µs ® DEHNguard 275 Lead length Equivalent circuit diagram Generator 30 kV 1 Up 0m A 5 kA (8/20 µs) 0.3 m Test setset-up © 2014 DEHN, INC. Connecting g lead 44 1m 2m Influence of the lead length on the real protection level Lab testing - Low impulse current 5 kA 8/20 µs Test result ® 6 i [kA] Up [kV] 3.0 Surge current 5 kA (8/20µs) 2.5 5 Protection level 2 meter lead length 1 meter lead length 0,3 0 3 meter lead length "ideal" connection 2.0 1.5 15 3 1.0 2 0.5 1 0.0 0 -0.5 0 © 2014 DEHN, INC. 4 5 10 15 20 25 30 35 40 -1 45 50 time t [µs] 45 Influence of the lead length on the real protection level Lab testing - Increased impulse current 15 kA 8/20 µs ® Surge current 15 kA (8/20 µs) Test result Up [kV] 16 4.0 14 3.5 12 Protection P t ti level l l 3.0 1 meter lead length 2.5 0.3 meter lead length 2.0 "ideal" "id l" connecting ti 8 6 1.5 4 1.0 10 2 0.5 0 0.0 00 -2 -0.5 -1.0 0 10 -4 5 10 15 20 25 30 35 40 45 50 time t [µs] © 2014 DEHN, INC. 46 i [kA] Summary Graphic © 2014 DEHN, INC. ® 47 So, how long is acceptable? ® No USA standard – ugh! The NEC is the best we have now. now However there is an IEC standard (no surprise) However, IEC 60364-5-53/A2 60364 5 53/A2 " ... increasing the length of connecting conductors of SPDs reduces the effectiveness of overvoltage protection“ “ ... Optimum p overvoltage g protection p is achieved when all connecting g conductors of SPDs are as short as possible“ © 2014 DEHN, INC. 48 Influence of the connecting leads on the real protection level ® IEC 60364-5-53/A2- Installation requirements: q Connecting g leads a+b 0.50 m a S P D b 0.50 m S P D E/I E/I b b EBB © 2014 DEHN, INC. EBB 49 Installation of SPDs in stub-wiring Parallel Installation ® L1´ L2´ L3´ PEN´ Input O t t Output Service Entrance Box DEHNport Maxi SPD No. 900 104 L1 L2 L3 PEN Service cable © 2014 DEHN, INC. B UC IImp 255 V ~ 50 kA (10/350) Up 4 kV DEHNport Maxi SPD No. 900 104 B UC IImp 255 V ~ 50 kA (10/350) Up 4 kV DEHNport Maxi SPD No. 900 104 B UC IImp 255 V ~ 50 kA (10/350) Up 4 kV EBB 50 Technical solutions to reduce the dynamic voltage drop across the connecting leads ® INPUT OUTPUT L1´ L2´ L3´ PEN´ HAK L1 L2 L3 N Power Supply EBB Serial connection of the lightning current arrester = Reduction of the lead lengths © 2014 DEHN, INC. 51 Technical solutions to reduce the dynamic voltage drop across the connecting leads ® L1´ L2´ L3´ N´ PE´ OUTPUT INPUT HAK DEHNventil ® TT Coordinated-SPD B DEHNventil ® TT D No. 900 375 Uc IImp Up 255 V ~ 25 / 100 kA ((10/350)) 1,5 kV (L-N/N-PE) 315 A (L) 125 A (L-L´) L1 L2 L1´ H1 L2´ L3 H2 L3´ N H3 N´ PE Power pp y Supply L1 L2 L3 N EBB - Double terminals for serial connection: Avoiding any dynamic voltage drop - Additional earth terminal: Avoiding dynamic voltage drop and current distribution between multiple conductors © 2014 DEHN, INC. 52 ® Series Wired Installation Parallel SPD using g the built in terminals like the previous slide © 2014 DEHN, INC. 53 How to make it better! ® 1 1. Twist phase wires together 2. Cut and bond ground wire directly to the panel using a lug listed for that purpose,allowed by NEC 285 28 this will shorten this 285.28, lead considerably, remember, ≈100 Vpk/inch degradation Downsides: At the bottom of the panel, panel transient voltage must travel down the bus to the bottom b f before it sees the th SPD! © 2014 DEHN, INC. 54 City of Orlando & Clearwater Installs Good Installs © 2014 DEHN, INC. ® 55 Good Install © 2014 DEHN, INC. ® 56 Good Install © 2014 DEHN, INC. ® 57 MCC #1 install City of Orlando, Lift Station, 480 wye, no neutral – Good Install © 2014 DEHN, INC. ® 58 Summary – Simple Rules ® 1 Keep the overall length of phase conductors short – cut 1. them! Twist the phase conductors together!! 2. Use high strand count wire – 133 strands or more (welding cable) 3. Use largest gauge wire possible – recommend 6 AWG 4 Avoid any sharp bends 4. bends, if must bend make the bend a large radius The above is in order of importance!! © 2014 DEHN, INC. 59 ® ® ® Questions & Further Discussion © 2014 DEHN, INC. 60 ® ® Thank you for attending © 2014 DEHN, INC.