Essentials of Clinical Laboratory Management in Developing

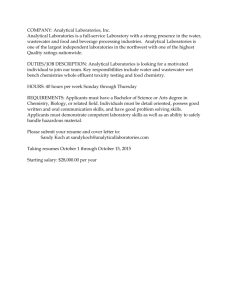

advertisement