Air Distribution Products

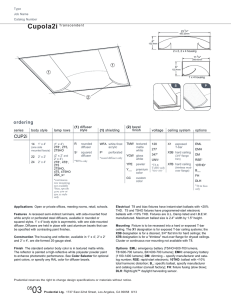

advertisement

Fans | Air Handling Units | Air Distribution Products | Fire Safety | Air Curtains and Heating Products | Tunnel Fans

Air Distribution Products

Basic Product Range

Disclose the secret of fresh air!

Systemair has been taking care of Indoor Air

Quality (IAQ) as an essential resource since

1974. Today Systemair is one of the leading

ventilation companies worldwide. A success

story,

which

started

in

Skinnskatteberg,

Sweden with the invention of the inline

duct fan. This invention revolutionised the

ventilation world. Since then the company

has continuously advanced and now offers

a comprehensive range of products for all

ventilation

requirements.

The

expert

at

Systemair have the required knowledge and

understanding in finding solutions when

considering the ventilation of shopping centres,

domestic ventilation of a family home to the complex ventilation of tunnels and

metro stations. More than 2500 employees and in excess of 60 subsidiaries in 40

countries globally we are available to our customers.

With this catalogue which features air distribution products and accessories we

give you as our customer a general overview of what Systemair can offer within

this range. For further information about all the other Systemair products you can

contact your local Systemair company or you can just visit our online catalogue on

www.systemair.com.

Quality

Systemair has been certified according to ISO 9001, ISO 14001 and ATEX. Our R&D

centre remains one of the most modern facilities in Europe. We test in compliance

with the international standards EN, ISO and AMCA.

© Systemair 2011. Systemair reserves the right to make technical changes. For updated documentation, please refer to www.systemair.com.

Contents

Systemair......................................................................................... 2

Group product overview.............................................................4-5

A good indoor climat is vital.......................................................... 6

Marketing tools............................................................................... 7

ADP basic product range.......................................................... 8-11

Technical data

Air valves........................................................................ 12-26

Wall grilles & diffusers.................................................. 27-36

Linear wall & ceiling diffusers............................................. 37

Floor & step diffusers.................................................... 38-39

Transfer & door grilles................................................... 40-41

Duct mounted grilles & diffusers.................................. 42-44

Square ceiling diffusers................................................. 45-53

Round ceiling diffusers.................................................. 54-65

Jet diffusers.................................................................... 66-67

Displacement diffusers.................................................. 68-69

Air volume controllers................................................... 70-78

Louvers........................................................................... 79-80

Plenum boxes................................................................. 81-83

Theory....................................................................................84-100

Index............................................................................................101

Systemair

The straight way

The straight way was our first production

idea and led to the circular duct fan. Today

“the straight path” represents our ambition

to simplify the life of our customers. Stocked

products are delivered in Europe within 24

hours from local warehouses and within 72

hours from distribution centres. High product

quality, correct technical data and fast deliveries

are always in focus.

Systemair

Systemair was established in Sweden in

1974 and is today the parent company in an

international group with 50 subsidiaries and

approximately 2500 employees. The Group’s

head office and largest production plant is

located in Skinnskatteberg with some 400

employees and a floor area of 50,000 m2.

Production

We are proud of our production units. The aim

has been to have both effective production

of bulk products and, at the same time, an

efficient and flexible approach to producing

small volumes. This has steered our choice of

machinery and how we plan our production,

with focus on the working environment. Our

premises are light and pleasant and we invest

in tools that facilitate work and provide our

employees with a safe and efficient workplace.

Technical data

Our development centre in Skinnskatteberg

is one of the most modern in Europe for air

flow measurements, acoustic measurements,

efficiency

measurements,

low

speed

measurements on air terminal devices, etc. All

measurements are performed in compliance

with applicable standards as set out in AMCA

and ISO.

Dal, Eidsvoll–Norway

Quality and environment

Systemair is certified according to ISO 9001

and ISO 14001. Our quality system allows

us to continuously improve our products and

our customer service. Certification means

that we have undertaken to minimise our

environmental impact. We always take the

environment into consideration when we

choose sub-suppliers, materials, production

methods, etc. An important factor is that

we continuously work to reduce our energy

consumption and reduce waste. Through

increased recovery and heightened awareness

we have been able to reduce our waste by

90%. Quality and environment management

systems are under continuous development.

These are audited twice a year by the

certification body BVQI (Bureau Veritas Quality

International).

Bouctouche - Canada

In Eidsvoll, Norway we manufacture

air handling units for the Norwegian

market. The Norwegian warehouse for

fans is also located here.

In Bouctouche, Canada we primarily

produce duct fans and heat exchangers

used in residential ventilation for the

North American market.

Detailed product information can be found on

our website, www.systemair.com

Kansas City – USA

In Kansas City we produce roof fans,

roof extractor fans, wall fans and

recirculating air units.

Production in Skinnskatteberg is virtually fully automated with modern machinery featuring advanced

computer support. Also located here is the company’s most advanced test installation for measuring

technical data.

Hässleholm - Sweden

Skinnskatteberg - Sweden

Main plant

The main plant in Skinnskatteberg

houses one of the company’s two central

warehouses and the largest production

installation as well as the group’s head

office. Fans and accessories are produced

here as stock items.

Klockargården

Systemair’s small air handling units are

made at Klockargården in Skinnskatteberg.

Frico’s central warehouse of approximately

8,000 m2 is also located here.

VEAB

VEAB in Hässleholm manufactures first and

foremost heating coils and hot air fans.

Ukmerge – Lithuania

Production of air handling units for homes.

Bratislava – Slovakia

The factory in Bratislava manufactures air

distribution products and fire dampers.

Maribor – Slovenia

The factory in Maribor, Slovenia specialises in

high temperature fans for flue gas ventilation.

Kuala Lumpur – Malaysia

Production and marketing of products for tunnel

and garage ventilation

India

A broad assortment of air distribution

products are manufactured, along with a

wide range of the Systemair products are

offered in parallel, Noida - INDIA

Madrid – Spain

Hasselager - Denmark

Windischbuch - Germany

The factory in Madrid, Spain makes air

handling units for the southern European

market.

The factory in Hasselager, Denmark manufactures large air handling units. All production here is order based

In Windischbuch, Germany a broad

assortment of fans are manufactured, of

which the majority are stock items. One of

Systemair’s central warehouses is located

here.

4

Other products from Systemair

Systemair has an extensive range of ventilation products: fans including smoke

extract, tunnel and car park fans ,explosion proof fans, air handling units from

large central units to small residential units with energy recovery, air distribution

products and fire dampers.

These products are installed in a variety of locations, including homes, offices,

healthcare premises, shops, industrial buildings, tunnels, parking garages, training

facilities, sports centres.

Air handling units

Compact air handling units

False ceiling units

Systemair produces a wide range of air

handling units.

Compact supply air handling unit with

heating battery and filter for use in petrol

stations, schools, stores, offices and smaller

premises. The units are compact in dimensions and are easy to install.

Air flow: 20-1400 l/s

Compact and easy to maintain air handling

unit with heat recovery and control system.

Mounted in a false ceiling or in the attic.

Air flow: 20-1500 l/s

Horizontal units

Vertical units

A broad range of horizontal air handling

units with or without heat recovery. Useable everywhere from minor premises to

schools, stores and larger offices.

Air flow: 20-1500 l/s

A broad range of vertical air handling units

with or without heat recovery. Useable everywhere from minor premises to schools,

stores and larger offices.

Air flow: 20-1500 l/s

RESIDENTIAL VENTILATION

Residential units

Cooker hoods

Complete energy-efficient air handling

units with heat recovery and built-in control

systems. Designed to be mounted over the

cooker, on walls or horizontally in attics.

For homes with living areas of 60-320 m2.

Good at capturing odours even at low

airflows.

5

Catalogues for other products

We have seperate catalogues for Air Handling Units and Air Distribution Products as well as leaflets and brochures for all of our products. Contact us for

printed versions or download on www.systemair.com.

FIRE AND SMOKE DAMPERS

Fire & smoke dampers

Systemair produces fans, dampers and

control equipment for dual use, i.e. for normal operation and certified for use during

normal operation and in the event of a fire.

Dampers that reduce the spread of smoke

and fire.

AIR DISTRIBUTION PRODUCTS

Circular & rectangular fans

Roof fans

Fans

Systemair has a wide range of fans for use

in various applications from small office

premises to larger industrial applications.

Common to all items in the range is that

components have been developed to

satisfy stringent demands for low energy

consumption.

Wide range of use for all kinds of installations

Effective exhaust air system for horizontal

or vertical air discharge

Axial fans

Explosion proof fans & smoke

extract fans

The fans have all undergone extensive testing, both in the laboratory and out in the

field, in order to comply with current and

future demands for low energy consumption. All products are also manufactured to

comply with environmental requirements.

Effective supply and exhaust system for

industrial buildings applications

fans for explosion hazardous areas & smoke

and heat extract

6

A good indoor climate is vital

We often take natural resources such as fresh air for granted. We must however

remain frugal with this essential resource and mindful of maintaining a responsible balance between the designing of good ventilation systems and considering

energy consumption and well thought out material usage and production methods. Systemair has recognized this need and has developed the "Green Ventilation" registered trade mark for ventilation labelling these products.

Heat recovery

Pressure

In areas with a relatively low average

annual temperature, ventilation systems

employ effective heat recovery that returns

energy from extract air to the supply air. A

good rotating heat exchanger can recover

up to 90% of the energy present.

The design of the duct system and the unit

has an impact on required system pressure.

There are often tens, sometimes hundreds,

of Pascals to be saved here.

Energy-efficient fans

Today, there is a new generation of fan motors that contribute to a dramatic reduction

in energy consumption, as much as 50% in

some cases. The new EC motors are better

suited to speed control functions, which

is where considerable energy savings can

be made. Further benefits are of quieter

operation as well as extended product life.

Cool recovery

In warmer parts of the world, energy savings may be possible by drawing cool nighttime supply air into premises, thus cooling

the building structure.

to ensure that our products maintain a

high standard and are approved by various

bodies. For units, this may mean Eurovent

certification or other local certification for

the country in question. To achieve this, you

need resources and expertise. Within the

Group, you will find, among other things,

one of Europe’s most modern development

centres, which is AMCA-certified.

Quality-certified products

How can you choose the right solution and

product when there are so many alternatives? Nowadays, most major suppliers are

ISO-certified and have CE-marked products,

but is that enough? At Systemair we are

going one step further and working hard

One of Europe's most modern development centres

A room that is so quiet that the only thing

you’ll hear is your heartbeat.

The development centre in Skinnskatteberg, recently accredited by AMCA, signifies

an investment of EUR 700,000 and is fitted

with measurement and testing equipment,

making it one of the most modern facilities

of its kind in Europe.

The quiet room is one of the test stations

or a “reverberation chamber”, producing

a background sound of less than 10 dBA.

When measuring supply air terminals, a

green laser is used to show how the air

is expelled from wall-mounted or ceilingmounted devices. There is also a climate

chamber that cools the air to -20°C, which

means we can use it all year round to

develop our recovery units. In addition to

the test centre in Skinnskatteberg, there are

also test facilities in Germany and Denmark

where we can measure air volumes of

more than 400 000 m3/h.

7

Selection tools

We have developed this overview to make it easier for you to get an idea of

which product best suits your specific needs. More detailed analysis or planning

usually requires additional information, which is where the following tools come

in.

Product catalogue and specification

data

More detailed technical information, sufficient to carry out complete planning, is

available in separate catalogues and specification data. These describe all incorporated functions, available accessories, and

additional technical data.

Online catalogue and computer

software

For those who prefer to work online, it is

possible to select and dimension most products (except DV and NB) using Systemair’s

online catalogue.

In addition to complete product information, there is also a selection function that

suggests alternative products to suit actual

needs. For certain products, such as Topvex,

medium pressure axial fans, air handling

units DV and NB, there is computer software

that you can download and install locally.

Personal support

Systemair aims to have local expertise

close to the customer. You can find upto-date information and contact details

for each country on our website, www.

systemair.com.

| Content

Balance-E

Air Valves

Return Plastic Air Valve

Elegant-VE

Supply Air Valve

BHC

Return Air Regulatoring Motorized

Valve with Presence & Humidity Sensor

OVE

Transfer Air Valve

Wall Grilles and Diffusers

8

NOVA-A

Double Deflection Grille

Used for Supply and Return

Sinus-BR

Nozzle Diffuser for Supply Return Air

Balance-S

Supply Plastic Air Valve

Elegant-VS

Supply Air Valve

AL

Return Self Regulating Air Valve

OVR

Transfer Air Valve

NOVA-L

Linear Bar Grille Used for

Supply and Return

Sinus-BS

Nozzle Diffuser for Supply Return Air

EFF

Return Metal Air Valve

Elegant-VI

Supply Air Valve

AE

Return Self Regulating Air Valve

TFF

Supply Metal Air Valve

Elegant-VT

Supply Air Valve

VTK

Self Adjusting Inlet Air Valve

OVX

Transfer Air Valve

NOVA-R

Non Vision Return Air Grille

NOVA-F

Non Vision Return Air Grille

with G3 Filter

Floor & Step

Diffusers

Linear Wall &

Ceiling Diffusers

Content |

Hella-A

Linear Slot Diffuser

Elegant-AT

Transfer &

Door Grilles

Supply Air Valve

NOVA-D

Square Ceiling Diffusers

Duct Mounted

Grilles & Diffusers

Non Vision Transfer Air Door Grille

NOVA-C

Single or Double Deflection Duct

Grilles for Supply and Return Air

Kvadra

Louvre Faced Ceiling Diffuser

for Supply and Return Air

VVKR

Swirl Ceiling Diffuser Used for Supply

and Return Air with Adjustable Blades

SFD

Floor Diffuser

NOVA-E

Egg Crate Return Air Grille

Sinus-DC

Circular Duct Mounted

Nozzle Diffuser for Supply Air

CRS-T

Square Ceiling Swirl Diffuser

with Fixed Air Guiding Blades

TSF

Perforated Face Return Air Diffusers

Sinus-DR

Rectangular Duct or Wall Mounted

Nozzle Diffuser for Supply Air

VVKN

Swirl Ceiling Diffuser Used for Supply

and Return air With Fixed Blades

TSO

Perforated Face Supply Air Diffuser

9

Square Ceiling

Diffusers

10 | Content

Sinus-A

Square Multi Nozzle Ceiling Diffuser

for Plaster or False Ceiling

Displacement

Diffusers

Jet Diffusers

Round Ceiling Diffusers

Konika

Circular Fixed Cones

Ceiling Diffuser

TST

Circular Ceiling Diffuser with

Adjustable Front Plate

Sinus-G

Sinus-F

Square Multi Nozzle Ceiling Diffuser

for Plaster or False Ceiling

Konika-A

Square Multi Nozzle Ceiling Diffuser

for T-Bar ceiling

CRS

Circular Adjustable Cone

Ceiling Diffuser

Circular Metal Swirl Diffuser

with Fixed Blades

TSK

TSR

Circular Ceiling Diffuser with

Adjustable Perforated Front Plate

Circular Ceiling Diffuser with

Adjustable Front Plate for

Apparent Installations

CRSP

Circular Swirl Diffuser

with Fixed Blades

TSP

Circular Ceiling Diffuser with

Adjustable Front Plate for

Apparent installations

Sinus-C

Sinus-C/T

IKD

TSD

Circular Nozzle Ceiling Diffuser

Complete with Side Entry Plenum

Box for Visible Installation

Circular Nozzle Ceiling Diffuser

Complete with Top Entry Plenum

Box for Visible Installation

Circular Ceiling Diffuser with Dual

Adjustable Cones

for High Installations

Circular Swirl Diffuser with Adjustable

Blades for Horizontal or

Vertical Air Pattern

AJD

Long Throw Adjustable

Nozzles

LPS

Displacement Diffuser Suspended or

Mounted Against the Ceiling for Low

Velocity Ceiling Air Distribution

JSR

Circular Multi-Cone Jet Diffuser with

Narrow Concentric or Wide Cones for

Long or Short Air Pattern

Content | 11

RDA

Air Volume Controllers

Constant Volume Regulator

for Duct or Air Inlets

SPM

Iris Damper for Measuring

and Adjusting Air Flow with

More Choking Ability

RSK

SPI

Iris Damper for Measuring and

Adjusting the Air Flow

SPI-F

SPM-F

Actuator Driven Iris Dampers

Actuator Driven Iris Dampers

with More Choking Ability

VKK

VK

Louver Shutters

with Circular Inlet and Outlet

Louver Shutters

for Vertical Mounting on a Wall

Louvers

Back Draft Damper

for Circular Ducts

RPK-R

Constant Air Volume Controller

with Adjustable Air Flow

IGC

IGK

Plenum Boxes

Circular External Louver

PRG

Rear, Side or Top Entry Insulated

Plenum Boxes Designed for

Rectangular Grilles

Square External Louver

PER

Side Entry Plenum Boxes

Designed for

Circular Inlet Diffusers

VVK

Side Entry Plenum Boxes

Designed for

Square Ceiling Diffusers

Hella-A-PB

Side Entry Plenum Box

Designed for

Linear Slot Diffusers

12 | Air valves

Balance-E

Return plastic air valve

Dimensions

Function

The Balance-E is a round exhaust valve with

an aerodynamically shaped valve cone. The

Balance-E performs extremely well with regard to sound level, pressure drop and air flow

characteristics. The Balance-E is installed in a

frame or directly into the duct.

Design

The Balance-E is manufactured from recyclable polypropylene and tolerates temperatures

up to 100°C. This material also withstands

most chemicals in small concentrations, Polyether gasket. The Balance-E is supplied in a

white finish which matches RAL 9010.

ØA

ØB ØC D

Balance-E-100

100 70 142 61

Balance-E-125

125 87 160 61

Balance-E-160

160 118 195 57

Balance-E-200

200 167 240 64

5

10

15

Air flow and pressure drop

Balance-E

Adjustment

The cone is screwed a number of turns

clockwise or anticlockwise so as to achieve

the air gap in mm which corresponds to the

pressure drop and required air flow shown in

the diagram. The pressure drop is checked by

pushing a suitable test probe into the front of

the unit behind the valve cone.

a, (mm) -7.5 -5

0

100k-factor 0.83 1.09 1.46 2.00 2.28 2.69

125k-factor 0.85 1.11 1.63 2.15 2.41 3.45

a, (mm) -2.5

0

5

20

a, (mm) -5

0

5

10

15

20

Accessories

RFP, RFU Mounting frame.

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

RFP

ØA

RFP 100

RFP 125

ΔPi, find the mean pressure

RFU

hole dimension

120

97

Ø103

146

122

Ø128

RFP 160

180

157

Ø163

RFP 200

220

197

Ø203

ØA

RFU 100

RFU 125

hole dimension

120

97

Ø103

146

122

Ø128

RFU 160

180

157

Ø163

RFU 200

220

197

Ø203

Air flow range (m3/h, l/s) and ∆Pt - Pressure (Pa)

Balance-E

RFP

RFU

100

6961

6125

6130

95

161

125

6962

6126

6131

88

159

160

6963

6127

6134

31

200

6964

6128

6135

43

3

m /h

40

60

80

l/s

11

17

22

20-25

30

35-40

241

82

Size of

ØD

Balance-E

Art No

Size of

ØD

Acoustic performance in dB(A):

15

200 k

-factor 4.43 5.74 7.30 8.4410.18 11.50

a = air gap in mm

Ordering code

Balance - E 100

(E=Exhaust Air, Diameter)

Size

10

160k-factor 2.02 2.63 3.93 4.53 6.08 7.56

133

33

66

109

100

130

180

230

28

36

50

64

Air valves | 13

Balance-S

Supply plastic air valve

Function

The Balance-S is a round supply-air valve

with an aerodynamically shaped valve cone.

The Balance-S performs extremely well with

regard to sound level, pressure drop, air flow

and self-damping. The Balance-S is installed in

a frame or directly into the duct.

Design

The Balance-S is manufactured from recyclable polypropylene and tolerates temperatures

up to 100°C. This material also withstands

most chemicals in small concentrations, Polyether gasket. The Balance-S is supplied in a

white finish which matches RAL 9010.

Adjustment

The valve cone is screwed a number of turns

clockwise or anti-clockwise so as to achieve

the air gap in mm which corresponds to the

pressure drop and required air flow shown in

the diagram. The pressure drop is checked by

removing the front plug and pushing in a suitable test probe.

Dimensions

ØA

ØB ØC D

Balance-S-100

100 81 156 72

Balance-S-125

125 104 182 78

Balance-S-160

160 120 206 86

10

20

Air flow and pressure drop

Balance-S

a, (mm) 2.5

4

5

7.5

100k-factor 1.08 1.67 2.16 3.10 4.05 5.17

120k-factor 1.15 1.96 2.92 3.73 4.79 7.59

160k-factor 1.86 2.75 3.46 4.81 6.62 10.32

a = air gap in mm

Accessories

RFP, RFU Mounting frame.

Ordering code

Balance - S 100

(S = supply air, diameter)

Size of

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

RFP

ØA

ØD

hole dimension

RFP 100

RFP 125

120

97

Ø103

146

122

Ø128

RFP 160

180

157

Ø163

RFP 200

220

197

Ø203

ΔPi, find the mean pressure

RFU

ØA

RFU 100

RFU 125

Size of

ØD

hole dimension

120

97

Ø103

146

122

Ø128

RFU 160

180

157

Ø163

RFU 200

220

197

Ø203

Balance-S

Size

Art No

Air flow range (m3/h, l/s) and throw I0,2 (m)

Balance-S

RFP

RFU

100

6965

6125

6130

1

125

6966

6126

6131

1

160

6967

6127

6134

2

3

2

2

∆Pt - Pressure drop (Pa)

62

120

217

45

164

224

1

2

2

70

102

223

m3/h

55

75

100

120

195

20-25

30

35-40

l/s

15

21

28

33

54

dB (A)

14 | Air valves

EFF

Return metal air valve

Dimensions

Function

The EFF is an exhaust device for installation

on ceiling or wall. It can also be used for supply air. The device has a lockable central cone

which is rotated to adjust the pressure and

consequently the air volume.

Design

The EFF is manufactured from sheet metal

with a white powder-coated finish (RAL

9010-80) and is available in the following

diameters: Ø63, Ø80, Ø100, Ø125, Ø150,

Ø160 and Ø200.

Accessories

RFP, RFU Mounting frame.

Mounting

All sizes can be installed directly onto the duct

ØA

ØB

C

EFF 63

63

90

15

EFF 80

80

106

15

EFF 100

100

135

15

EFF 125

125

160

15

EFF 150

149

191

15

EFF 160

160

195

15

EFF 200

200

238

18

Adjustment

The pressure is adjusted by rotating the valve

cone.

RFP

Ordering code

EFF-100

Dimensions

ØA

RFP 100

RFP 125

hole dimension

120

97

Ø103

146

122

Ø128

RFP 160

180

157

Ø163

RFP 200

220

197

Ø203

Selection Table

Table below shows the general product performance for more details please see selection software or contact your local systemair

office.

RFU

ØA

RFU 100

RFU 125

Art No

EFF

PER

RFP

hole dimension

120

97

Ø103

146

122

Ø128

RFU 160

180

157

Ø163

RFU 200

220

197

Ø203

Air flow range (m3/h, l/s) and ∆Pt - Pressure (Pa)

RFU

63

6144

80

6145

37

100

6146

6125

6130

125

6147

6522

6126

6131

33

102

156

150

7490

B505

B509

6132

22

78

124

160

6148

6523

6127

6134

23

80

125

200

6149

6524

6128

6135

6129

Acoustic performance in dB(A):

20

236

84

272

149

10

62

136

3

m /h

40

65

90

100

l/s

11

18

25

28

20-25

30

35-40

Size of

ØD

EFF

Size

Size of

ØD

44

84

124

150

190

250

310

42

53

69

86

Not Available

Air valves | 15

TFF

Supply metal air valve

Function

The TFF is a circular supply valve for ceiling

installation. The TFF consists of an inlet cone

and diffuser unit containing sound absor -bent

material. The technical specifications of the

diffuser unit give it a wide range of applications. By rotating diffuser unit, the throw and

pressure drop can be adjusted steplessly. Both

concentric and eccentric distribution patterns

can be selected by using the shielding device

provided.

Design

The TFF is manufactured from sheet steel with

a white powder-coated finish (RAL 9010-80)

and is available in the following diameters:

Ø80, Ø100, Ø125, Ø150, Ø160 and Ø200.

How to use for exhaust air

This device can be used for exhaust air as

explained.

Mounting

The TFF is easily fitted, either into the mounting frame or directly onto the duct using its

friction springs. If the TFF is fitted to a PER

plenum box, there must be a straight length, 4

times the duct’s diameter, in front of the

PER plenum box.

Dimensions

TFF

A

B

C

D

E

F

G

ØL

hole

ØK

DI

D2

080

-

-

-

-

-

-

-

26-56 106

dim

80

-

-

100

-

-

-

-

-

-

-

87

26-56 135 100

-

-

107

H

□J

125+PER 100-125320 250 150

47

185 115 190 26-56 160 125

160+PER 125-160360 250 160

47

210 120 200 26-56 191 160 124 162 167

200+PER 160-200450 300 195

47

280 138 235 29-59 238 200 159 202 207

Accessories

TPP Ceiling plate (600x600), RFP, RFU Mounting frame and PER Plenum box with removable damper and test points.

Ordering code

TFF-125

Size

ØA

RFP 100

RFP 125

ØD

hole dimension

120

97

Ø103

146

122

Ø128

RFP 160

180

157

Ø163

RFP 200

220

197

Ø203

RFU

127 132

Size of

RFP

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

99

ØA

RFU 100

RFU 125

Size of

ØD

hole dimension

120

97

Ø103

146

122

Ø128

RFU 160

180

157

Ø163

RFU 200

220

197

Ø203

TFF

Size

80

Art No

TFF

PER

RFP

6089

Air flow range (m3/h, l/s) and throw I0,2 (m)

RFU

6129

2

4

∆Pt - Pressure drop (Pa)

5

2

6

2

3

45

65

100

6090

6125

6130

14

33

57

125

6091

6522

6126

6131

4

5

6

19

43

80

150

7509

B505

B509

6132

3

3

4

14

34

69

160

6092

6523

6127

6134

3

4

5

13

34

70

200

6093

6524

6128

6135

3

4

6

5

29

78

20-25

30

35-40

3

m /h

30

60

75

85

115

165

265

l/s

8

17

21

24

32

46

74

dB (A)

Not Available

16 | Air valves

Elegant-VE

Supply air valve

Function

The Elegant has been especially developed

for providing a draught-free air supply from

the rear walls of offices, hotel rooms etc. The

guide jet prevents the air stream from falling

into the occupied zone before it has reached

an acceptable temperature. Max. temperature

difference ΔT 10K is permissible. The Elegant

is also suitable for VAV systems, as the distribution pattern is maintained across the entire

flow area.

Dimensions

Design

The Elegant is manufactured from steel and

consists of a convex front plate with perforations and guide jet opening. The front plate is

finished in the standard white powder-coating

(RAL 9010-80).

6298

6827

160

6828

12

14

6

9

87

Elegant VE-125

123 165

115 89

Elegant VE-160

158 198 124 86

125250500 1K 2K 4K 8K

VE 100

17 12 7

1

0

0

2

VE 125

17 12 7

1

0

0

2

VE 160

16 14 6

1

0

0

3

LW(dB) = LpA + Kok (LpA = diagram Kok = table)

correction factor Kok

Mid-frequencyband,Hz

Air flow range (m3/h, l/s) and throw I0,2 (m)

7

D

111 Sound power level, LW

Elegant-VE

125

C

165 Mid-frequency band, Hz

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

100

ØB 98 Mounting

The diffuser is installed directly onto the spiral

duct. Dismantling of the supply air unit: Turn

the unit and pull straight out.

Art No

ØA

Elegant VE-100

Sound attenuation, ΔL (dB)

Versions

The Elegant is available in sizes Ø100, Ø125

and Ø160, and in five different versions: VE is

the basic version with perforated front plate.

Size

12

∆Pt - Pressure drop (Pa)

38

117

187

36

76

143

2

3

5

14

49

116

m3/h

50

75

100

140

215

20-25

30

35-40

l/s

14

21

28

39

60

dB (A)

63 125250500 1K 2K 4K 8K

VE 100

13 -1 -2

0

-1 -6 -9 -14

VE 125

13 -1 -2

0

-1 -6 -9 -14

VE 160

14 3

3

-1 -8 -14 -15

1

Air valves | 17

Elegant-VS

Supply air valve

Function

The Elegant has been especially developed for

providing a draught-free air supply from the

rear walls of offices, hotel rooms etc. The VI

or VS version with guide jet is recommended

for cooled air. The guide jet prevents the air

stream from falling into the occupied zone

before it has reached an acceptable temperature. Max. temperature difference ΔT 10K is

permissible. The Elegant is also suitable for

VAV systems, as the distribution pattern is

maintained across the entire flow area.

Dimensions

Design

The Elegant is manufactured from steel and

consists of a convex front plate with perforations and guide jet opening. The front plate is

finished in the standard white powder-coating

(RAL 9010-80).

With the pressure

distribution plate in the

back of the diffuser, the

airflow can be adjusted

by using different number of plastic plugs, see

diagram.

Versions

The Elegant is available in sizes Ø125 and

Ø160, and in five different versions: VS has

a perforated front plate, guide jet, test points,

damper.

ØA

ØB C

D

Elegant VS-125

123 165 240 214

Elegant VS-160

158 198 274 236

Sound attenuation, ΔL (dB)

Mid-frequency band, Hz

125250500 1K 2K 4K 8K

VS 125

19 13 5

1

0

0

2

VS 160

15 11 6

0

1

0

1

Sound power level, LW

LW(dB) = LpA + Kok (LpA = diagram Kok = table)

correction factor Kok

Mid-frequencyband,Hz

Mounting

The diffuser is installed directly onto the spiral

duct. Dismantling of the supply air unit: Turn

the unit and pull straight out.

63 125250500 1K 2K 4K 8K

VS 125

4

VS 160

15 3

-2 -3

1

1

0

2

-2 -7 -13 -20

-4 -11 -20

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

Elegant-VS

Size

Art No

125

6831

160

6832

Air flow range (m /h, l/s) and throw I0,2 (m)

3

6

9

12

10

14

m3/h

60

90

120

160

l/s

17

25

33

44

56

∆Pt - Pressure drop (Pa)

23

70

17

32

66

101

200

20-25

30

35-40

dB (A)

115

18 | Air valves

Elegant-VI

Supply air valve

Function

The Elegant has been especially developed for

providing a draught-free air supply from the

rear walls of offices, hotel rooms etc. The VI

or VS version with guide jet is recommended

for cooled air. The guide jet prevents the air

stream from falling into the occupied zone

before it has reached an acceptable temperature. Max. temperature difference ΔT 10K is

permissible. The Elegant is also suitable for

VAV systems, as the distribution pattern is

maintained across the entire flow area.

Dimensions

Design

The Elegant is manufactured from steel and

consists of a convex front plate with perforations and guide jet opening. The front plate is

finished in the standard white powder-coating

(RAL 9010-80).

160

6830

D

115 89

Elegant VI-160

158 198 124 86

125250500 1K 2K 4K 8K

VI 125

19 13 5

1

0

0

2

VI 160

15 11 6

0

1

0

1

Sound power level, LW

LW(dB) = LpA + Kok (LpA = diagram Kok = table)

correction factor Kok

Mid-frequencyband,Hz

Elegant-VI

6829

C

165 Mid-frequency band, Hz

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

Art No

ØB 123 Mounting

The diffuser is installed directly onto the spiral

duct. Dismantling of the supply air unit: Turn

the unit and pull straight out.

Size

ØA

Elegant VI-125

Sound attenuation, ΔL (dB)

Versions

The Elegant is available in sizes Ø125 and

Ø160, and in five different versions: VI has a

perforated front plate, guide jet, test point.

125

Air flow range (m /h, l/s) and throw I0,2 (m)

3

6

9

12

10

15

m3/h

60

90

120

170

l/s

17

25

33

47

61

∆Pt - Pressure drop (Pa)

23

70

19

34

78

124

220

20-25

30

35-40

dB (A)

119

63 125250500 1K 2K 4K 8K

VI 125

11 -6 -5 -1

0

-4 -7 -15

VI 160

8

0

-5 -12 -20

-1 -1

1

Air valves | 19

Elegant-VT

Supply air valve

Function

The Elegant has been especially developed

for providing a draught-free air supply from

the rear walls of offices, hotel rooms etc.

Maximum temperature difference ΔT 10K is

permissible. The Elegant is also suitable for

VAV systems, as the distribution pattern is

maintained across the entire flow area.

Design

The Elegant is manufactured from steel and

consists of a convex front plate with perforations and guide jet opening. The front plate is

finished in the standard white powder-coating

(RAL 9010-80).

Dimensions

165

33.2

59.3

Versions

The Elegant is available in sizes Ø100 and

Ø125, and in five different versions : VT has

a perforated front plate. Can be mounted

directly in a T-piece or pre-embeded bend.

The air flow can be adjusted by using different

number of plastic plugs.

Sound attenuation, ΔL (dB)

With the pressure

distribution plate in the

back of the diffuser, the

airflow can be adjusted

by using different number of plastic plugs.

Mid-frequency band, Hz

63 125250500 1K 2K 4K 8K

VT 100

9

-7 -3

0

-1 -6 -7 -11

VT 125

9

-3 -1

1

0

-8 -10 -15

Sound power level, LW

Mounting

The diffuser is installed directly onto the spiral

duct. Dismantling of the supply air unit : Turn

the unit and pull straight out.

LW(dB) = LpA + Kok (LpA = diagram Kok = table)

VT 100

9

-7 -3

0

-1 -6 -7 -11

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

VT 125

9

-3 -1

1

0

correction factor Kok

Mid-frequencyband,Hz

63 125250500 1K 2K 4K 8K

-8 -10 -15

Elegant-VT

Size

Art No

100

6202

125

6207

Air flow range (m /h, l/s) and throw I0,2 (m)

3

10

16

20

4

5

m3/h

45

60

75

l/s

12

17

21

22

∆Pt - Pressure drop (Pa)

11

34

6

37

28

50

80

20-25

30

35-40

dB (A)

57

20 | Air valves

BHC

Return air self regulating motorized valve

with presence and humidity sensor

Function

BHC 100 is a motorized damper with integrated motion (PIR) and humidity sensor for bathroom

installations. The extract units may be installed either on the wall (in a vertical or horizontal position), or the ceiling. The humidity and the motion sensors work independently of each other. The

damper opens whenever motion is indicated and closes 25 min after the last indication. The humidity sensor controls the fully modulating damper from RH 30% to 75%. The movement sensor

is dependent on a power supply and the BHC uses either a 9V battery or 12V AC. The humidity

sensors will open the damper regardless of a power supply.

Spigot Versions

Ø100 mm and Ø125 mm (with adapter).Ø80 mm (with special sleeve Ø80 mm). note: the BPD

is delivered with adapter Ø100 mm. The BPD dampers are especially useful in constant pressure

systems for example block of flats.

Accessories

100/125 inlet adapter and 12/9 v transformer.

Airflow/Pressure Chart

enables to adapt the fixed shutter position. supplied on installation instruction)

Type

BHC-100

Transformer-12V

Inlet adapter Ø100- Ø125

Art No

7178

7387

7484

Dimensions

More Standard and better longevity:

2 x 1.5 Volts AAA LR03 Batteries.

Buzzer:

Enables to inform the occupant when the

battery needs to be replaced (i.e. when the

battery level is below 2.2V). This buzzer rings

when the presence sensor or the switch is

activated.

Possibility to connect a dedicated “CAL” for

12VAC supply.

Air valves | 21

AL

Return air self regulating valve

Function

Intended to equip the facilities housing MEV, housing and local service, the range of the AL

extraction air valves self meets the regulatory requirements while combining aesthetics and

technology. Design fluid grid in several colors, reliability mechanical, proven functionality, performance ventilation and noise are the major assets of all AL air valves series. The AL air valves

meets the residential requirements of the NF MEV. Single or double speed, both models perfectly

consistent allow a uniform architectural treatment between kitchen, bathroom and WC.

Model

Produced in white polystyrene(standard), the AL air valve, installed in WC room and baths, provides a flow of extraction determined.

Operation

The regulator consists of a rigid component and ensures a determined air flow of extraction

within a range of pressure between 50 and 160 Pascals.

Design

1. Collar Ø 125 with lip seal (delivered

separately).

2. Body of the valve.

3. Regulator.

4. Removable grille.

AL is available in the following air flow: 15, 30, 45, 60, 75, 90, 120 and 150 m3/h

Maintenance

To maintain maximum efficiency, it is necessary to conduct a periodic cleaning:

Acoustic charecteristics

• Remove the grille (4) and regulator (3) the body of the valve (removed from the sleeve if

necessary).

• The sleeve (1) shall not be detached from the duct.

• Clean all either in the upper part of a dishwasher, either manually with soap and water, nothing

disassemble the regulator.

• Walk up the valve.

AL

Installation

The AL is installed in vertical walls by simple fitting onto a 125 Ø sleeve fixed on the aeration

duct. The lip seal ensures that the sleeve is securely fixed and watertight. Possible fitting with Ø

99, 116, 150 or 160 mm. When ceiling mounted, an adapted sleeve can be used (125 Ø, 3-claw

plasterboard sleeve, or 125 Ø plastic sleeve for penetrating slabs for use with the 125 Ø sleeve).

100

Ø125

Ø125

155

3-Claw plasterboard sleeve

275

Slab penetration sleeve (Polystyrene)

LW dB(A)

70Pa

100Pa

15 m3/h

19

27

31

34

30 m3/h

27

30

33

36

45 m3/h

27

33

34

37

Type

AL 15

AL 30

AL 45

AL 60

AL 75

AL 90

AL 120

AL 150

130Pa 160Pa

Art No.

35028

35029

35030

35031

35032

35033

35034

35035

22 | Air valves

AE

Return air self regulating motorized valve

Function

Intended to equip the facilities housing MEV, housing and local service, the range of the AE

extraction air valves self meets the regulatory requirements while combining aesthetics and

technology. Reliability mechanical, proven functionality, performance ventilation and noise are

the major assets of all AE air valves series. The AE air valves meets the habitat requirements of

the NF MEV. Single or double speed, both models perfectly consistent allow a uniform architectural treatment between kitchen, bathroom and WC.

Model

Produced in white polystyrene(standard), the AE air valve, installed in WC room and baths, provides a flow of extraction determined.

Operation

The regulator consists of a rigid component and ensures a determined air flow of extraction

within a range of pressure between 50 and 160 Pascals.

Principals

The extract is always on tension thanks to a connection normally switched off.An impulse on the

switch creates a power cut which opens the extract to its maximumflow (opening time: around

40 seconds).The 230 V supply of the extract is provided by two wires (2 x 1.5 mm²) to be

connected,going out by the back of the support plate (see drawing). This must have a protectiondevice clearly identified on the electric board - class II electric appliance -.After taking out the

casing vent (2), unscrew the box (5). The wires go through a cableat the back of the plate and

linked to the connection box.The support-plate of the extract must be screwed on the wall.On

the first stand-by mode, the AE valve will normally extract the maximum air-flow.

Design

4

3

5

1

2

1. 2. 3. 4. 5. Removable louver grill

Casing vent

Support plate with sleeve and rubber ring

Control module

Electric connection box

Acoustic charecteristics

AE

LW dB(A)

70Pa

100Pa

130Pa 160Pa

15/30 m3/h

24

27

30

30/60 m3/h

25

31

34

36

45/120 m3/h 27

33

34

37

Wiring

Before any operation on the support plate (3), the tension must be switched off (the time-switch

being constantly on stand-by mode) The tension is made through a push button specially dedicated to this specification.

Maintenance

The Extract AE must be periodically cleaned (at least twice a year) in order to keep their entire

efficiency. Cleaning procedure :• Remove the casing vent (2) of the plate (3) and remove the

flap (4).• The plate (3) linked to the duct must not be touched. The elements on it do not need

any cleaning.• Clean the casing vent (2), the grill (1) and the control module (4)with soapy water

then rince.• Fix back the control momule (4)• Fix back the casing part (2) on the plate (3)

Ceiling mounting

Ceiling mounting, the unit can be fixed on the ceiling using a three-claw plasterboard sleeve or a

125 Ø plastic sleeve for penetrating slabs. A ceiling mounting needs the using of a return angle

guide for the concerned models.

Ø125

48

100

Ø125

Ø125

275

155

Three-claw plasterboard sleeve

Ø 125 :

17

plastic sleeve for penetrating

slabs :

Return angle guide :

200

Przepływ powietrza q

120

150

100

60

45

50

0

30

15

40

60

80

100

120

140

160 Pa

Spadek ciśnienia ∆pt

Type

AE 15/30

AE 30/60

AE 45/120

Art No

31412

31413

31414

33

Air valves | 23

VTK

Self adjusting inlet air valve

Function

This self-adjusting fresh air vent has a temperature sensitive thermostat bulb which

regulates the vent plate, adjusting the air gap

and air flow according to the outside temperature. When it is set to ‘automatic’ the valve

disc reduces the air supply when the outside

temperature falls, and increases the flow

when the outside temperature rises. Spacers

for maintaining minimum air flow are available

as an accessory. Supplied complete with a

thermostat bulb for temperatures between -5

and +10°C, plus a wall duct and external grille.

Max wall thickness is 270 mm.

Accessories

- Spacer ring 2mm (100 & 160mm)

- Spacer ring 4mm (100 & 160mm)

- Filter (100 & 160mm)

Dimensions

ØA

ØB ØC VKT 80

80

40 147 ØD

85

VKT 100

95 40

147 104

VKT 160

157 47 207 163

VTK

Size

Art No

80

5657

100

5658

160

5659

Ring2mm

Ring4mm

Q Min (m3/hr - l/s)

Min Pressure (pa)

QMax (m3/hr - l/s)

Max Pressure (pa)

5406

5407

20 / 6

3

100 / 28

63

5664

5406

5407

20 / 6

3

100 / 28

64

5567

5406

5407

30 / 8

3

165 / 46

80

Filter

Not Available

24 | Air valves

OVE

Transfer air valve

Function

The OVE can be used in all types of premises.

In the OVE the outside casing of the air transfer device is acoustically insulated to reduce

the risk of sound interference.

Dimensions

Design

The OVE is manufactured from steel and the

outside casing has a white powder-coated finish (RAL 9010-80). Available in the following

sizes: Ø100, Ø125, Ø160 and Ø200.

6183

6184

160

6185

200

6186

Air flow range (m3/h, l/s) and ∆Pt - Pressure (Pa)

75

22

138

80

24

176

45

91

15

33

132

3

m /h

80

120

160

235

460

l/s

22

33

44

65

128

Acoustic performance in dB(A):

20-25

100 70-145

W

OVE 125

175

62 125 70-145

OVE 160

210

72 160 70-145

OVE 200

250 72 200 70-145

63 125250500 1K 2K 4K Rw

OVE 125 19 20 24 22 23 30 32 25

OVE 160 19 19 24 21 25 30 32 26

OVE 200 18 20 19 21 26 30 32 26

OVE

125

Øh 62 OVE 100 19 21 25 23 22 31 32 25

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

100

D

150

Ordering Code

The ordering code is OVE - 100.

Art No

ØC

OVE 100

The diagram shows

Air volume (l/s and m3/h), total pressure (Pa)

and sound pressure level [dB(A)].

Mid-frequencyband,Hz

Mounting OVE

The two mounting rings screws directly onto

the wall or are fitted together with the bolting

that are included, after which the outside casing can be pressed into place.

Size

30

35-40

Air valves | 25

OVR

Transfer air valve

Function

The OVR can be used in all types of premises.

In this both the outside casing and the middle

section are acoustically insulated, providing a

high level of sound attenuation. The OVR is

also lightproof.

Dimensions

Design

The OVR is manufactured from steel and the

outside casing has a powder-coated finish in

standard white (RAL 9010-80). The acoustic

insulation is fibre-free. Available in two sizes:

Ø125 and Ø160.

ØC

D

Øh OVR 125

175

62 125 70-145

W

OVR 160

210 72 160 70-145

The diagram shows

Air volume (l/s and m3/h), total pressure (Pa)

and sound pressure level [dB(A)].

Mid-frequencyband,Hz

Mounting OVR

Two mounting rings are included which are

fitted onto the middle section without the

need for tools. Screw the mounting rings

directly onto the wall or fit them together with

the bolting that are included, after which the

outside casing can be pressed into place.

63 125250500 1K 2K 4K Rw

OVR 125 15 35 29 22 24 24 32 24

OVR 160 15 35 29 22 24 24 32 24

Ordering Code

The ordering code is OVR - 125.

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

OVR

Size

Art No

Air flow range (m3/h, l/s) and ∆Pt - Pressure (Pa)

125

6187

160

6188

14

3

m /h

80

120

160

260

l/s

22

33

44

72

53

88

49

Acoustic performance in dB(A):

20-25

113

30

35-40

26 | Air valves

OVX

Transfer air valve

Function

The OVX is an air transfer device with rectangular front panels which is suitable for use in

all types of premises.

Dimensions

0

B

A

L

Mounting

The frame screws directly onto the wall, after

which the outside casing can be suspended.

20 50 100 150 lis.

H X L = size of hole required

Ordering Code

OVX - 300 with dimensions.

H

L

130 50 300

OVX 500

570

130

50 500

OVX 700

770

130

50 700

OVX 850

920 130

50 850

The diagram shows

Air volume (l/s and m3/h), total pressure (Pa)

and sound pressure level [dB(A)].

Mid-frequencyband,Hz

H

Sound reduction factor

The sound reduction factor (R) indicates a

wall’s total sound reduction included the air

transfer device. The following definitions are

used to calculate R:

B

370

0

Design

The air transfer device consists of two frames

and two front panels, which can be installed

whatever the thickness of the wall. Both front

panels are acoustically-insulated, making this

air transfer device suitable for use in premises

where low sound levels are required. The

device is manufactured from steel and the

front panels have a white powder-coated finish (RAL 9010-80). The OVX is available in the

following sizes: 300, 500, 700 and 850.

A

OVX 300

63 125250500 1K 2K 4K Rw

OVX 300

OVX 500

OVX 700

OVX 850

39

39

36

36

24

23

19

21

23

22

20

19

23

23

19

22

32

32

31

29

52

50

42

48

71

71

68

69

30

30

27

27

1. Use the formula

Where R0 = The wall’s reduction factor (dB)

depending on the wall material (obtainable

from the supplier. Rw The air transfer device’s

reduction factor (dB), obtained from the table.

2. Use the diagram

where ΔR=The difference between the reduction factors of the wall and the air transfer

device.

A = The wall’s area (m2).

Rm= The decrease of the wall’s reduction factor

due to the air transfer device.

3. Use the formula

R = R0 - Rm

Where R = The sound reduction factor (dB).

Where R0 = The wall’s reduction factor (dB)

depending on the wall material (obtainable

from the supplier).

Selection Table

Table below shows the general product performance for more details please see selection

software or contact your local systemair office.

Rm = The decrease of the wall’s reduction

factor due to the air transfer device reduction

with the air transfer device installed.

OVX

Size

Art No

300

6189

500

6190

700

850

Air flow range (m3/h, l/s) and ∆Pt - Pressure (Pa)

26

61

161

23

63

172

6191

25

72

128

6192

17

47

81

3

m /h

120

180

290

465

615

l/s

33

50

81

129

171

Acoustic performance in dB(A):

20-25

30

35-40

Wall grilles and diffusers | 27

NOVA-A

Double defflection grille for supply and return air

Function

The grille directs the air with help of deflectors to both horizontal and vertical directions. The

damper or plenum box provides even distribution of air through the whole grill.

Description

NOVA-A is rectangular aluminium grille with adjustable deflectors. NOVA-A grille can be used in

commercial and industrial premises and can be used for supply, or return air. It is intended for

mounting into wall, ceiling, or into window sill. NOVA-A is supplied with springs as a standard.

Design

NOVA-A grille is manufactured from aluminium profiles white painted to RAL 9010.

Mounting

The NOVA-A grille can be mounted directly into a duct or wall with mounting frame and springs.

Ordering Code

The ordering code is NOVA-A-Size

Selection Table

Table below shows the general product performance for more details please see selection software or contact your local systemair office.

Accessories

R1 NOVA damper

Opposed blade damper Air volume flow can be

adjusted with turning the screwdriver, Depth

of the grille is 40 mm.

NOVA UR Mounting Frame

First the mounting frame is fixed to wall or

duct with screws or detachable arms, then the

grille is fixed with springs to mounting frame.

PRG Plenum box

Insulated plenum box with inlet measuring

damper control

PRG 1 = Rear connection

PRG 2 = Side connection

PRG 3 = Top/bottom connection

Dimensions

28 | Wall grilles and diffusers

NOVA-A

Size

Art No

NOVA-A

UR

R1

PRG1

PRG2

PRG3

200 x 100

41232

41266

41287

6211

200 x 150

41233

42112

42016

6220

6426

300 x 100

41235

41267

41288

6212

6221

6427

400 x 100

41237

41269

41290

6214

6223

6428

Air flow range (m3/h, l/s) and throw I0,2 (m)

7

10

B505

∆Pt - Pressure drop (Pa)

9

19

33

8

14

13

17

6

16

29

8

13

18

7

18

31

18

7

18

24

m3/h

150

225

300

9

375

16

500

575

20-25

30

35-40

l/s

42

62

83

104

139

160

dB (A)

NOVA-A

Size

Art No

NOVA-A

UR

R1

PRG1

PRG2

PRG3

500 x 150

41241

41273

41294

6217

6226

6432

400 x 200

41239

41271

41292

800 x 100

41249

41281

41299

600 x 150

41245

41277

41297

1000 x 100

41228

41263

41284

300 x 150

41236

41268

41289

6213

500 x 100

41240

41272

41293

6216

300 x 200

41234

42124

42028

400 x 150

41238

41270

41291

600 x 100

41244

41276

41296

Air flow range (m3/h, l/s) and throw I0,2 (m)

B505

12

18

24

6

11

20

12

17

23

5

10

17

13

18

24

6

12

21

11

16

22

4

8

14

16

22

4

8

14

7

17

26

11

6222

6430

11

16

6225

6429

10

16

B505

6215

6224

21

20

9

6431

B505

18

9

18

10

∆Pt - Pressure drop (Pa)

15

7

15

25

20

4

15

19

20

4

15

19

4

11

22

30

35-40

21

3

m /h

375

500

575

725

825

1100

l/s

104

139

160

201

229

306

20-25

dB (A)

NOVA-A

Size

Art No

NOVA-A

UR

R1

PRG1

PRG2

PRG3

500 x 200

41242

41274

41295

6218

6193

6433

600 x 200

41246

41278

41298

6219

6194

6434

Air flow range (m3/h, l/s) and throw I0,2 (m)

13

20

14

19

19

800 x 150

41250

41282

41302

14

1000 x 150

41230

41264

41285

13

500 x 300

41243

41275

42049

800 x 200

41251

41283

41303

26

5

11

18

24

5

8

13

24

22

12

B505

21

16

∆Pt - Pressure drop (Pa)

21

5

8

13

30

3

9

16

29

3

8

14

29

4

7

13

600 x 300

41247

41279

42065

15

26

32

3

10

14

1000 x 200

41231

41265

41286

14

25

31

3

9

12

600 x 400

41248

41280

42066

35

3

8

13

m3/h

725

825

1100

1425

17

1950

27

2350

3000

20-25

30

35-40

l/s

201

229

306

396

542

653

833

dB (A)

Wall grilles and diffusers | 29

NOVA-L

Linear bar grille for supply and return air

Dimensions

(H-20)x(L-20)

s

HxL

Design

NOVA-L grille is manufactured from natural anodized aluminium profiles white painted to RAL

9010. Dimensions from 200x100 to 1000x200 are available on stock.

25

Description

NOVA-L is rectangular aluminium grille with fixed deflectors and can be used in commercial and

industrial premises. The grille is intended for supply, or return air. It is build into wall, ceiling, or

window sill. NOVA-L is supplied with springs as a standard. As an accessory there are plenum

boxes, mounting frames and dampers available.

Mounting

The NOVA-L grille can be mounted directly into a duct or wall with mounting frame and springs.

Ordering Code

The ordering code is NOVA-L-Size

Selection Table

Table below shows the general product performance for more details please see selection software or contact your local systemair office.

Accessories

R1 NOVA damper

Opposed blade damper Air volume flow can be

adjusted with turning the screwdriver, Depth

of the grille is 40 mm.

NOVA UR Mounting Frame

First the mounting frame is fixed to wall or

duct with screws or detachable arms, then the

grille is fixed with springs to mounting frame.

PRG Plenum box

Insulated plenum box with inlet measuring

damper control

PRG 1 = Rear connection

PRG 2 = Side connection

PRG 3 = Top/bottom connection

5

20

(H+30)x(L+30)

Function

The grille directs the air with help of horizontal deflectors. The damper or plenum box provides

even distribution of air through the whole grille.

30 | Wall grilles and diffusers

NOVA-L

Size

Art No

NOVA-L

UR

R1

PRG1

PRG2

PRG3

200 x 100

41304

41266

41287

6211

6220

6426

200 x 150

42905

42112

42016

300 x 100

41305

41267

41288

Air flow range (m3/h, l/s) and throw I0,2 (m)

6

B505

6212

6221

6427

∆Pt - Pressure drop (Pa)

9

13

11

26

59

7

10

15

10

24

46

7

10

15

10

24

46

400 x 100

41307

41269

41290

6214

6223

6428

9

13

17

13

25

44

300 x 150

41306

41268

41289

6213

6222

6430

8

11

16

9

17

32

6216

6225

6429

8

11

15

500 x 100

41309

41272

41293

300 x 200

42906

42124

42028

400 x 150

41308

41270

41291

600 x 100

41314

41276

41296

B505

6215

6224

9

6431

B505

16

20

7

15

28

7

22

34

10

13

17

10

17

28

10

14

17

10

19

31

30

35-40

m3/h

80

120

185

260

350

450

550

l/s

22

33

51

72

97

125

153

20-25

dB (A)

NOVA-L

Size

Art No

NOVA-L

UR

R1

PRG1

PRG2

PRG3

500 x 150

41310

41273

41294

6217

6226

6432

400 x 200

41313

41271

41292

800 x 100

41316

41281

41299

600 x 150

41315

41277

41297

1000 x 100

41319

41263

41284

500 x 200

41311

41274

41295

6218

6193

6433

600 x 200

41312

41278

41298

6219

6194

6434

800 x 150

41317

41282

41302

1000 x 150

41320

41264

41285

500 x 300

42907

41275

42049

800 x 200

41318

41283

41303

600 x 300

42908

41279

42065

1000 x 200

41321

41265

41286

600 x 400

41530

41280

42066

12

Air flow range (m3/h, l/s) and throw I0,2 (m)

∆Pt - Pressure drop

(Pa)

15

10

17

25

7

17

32

10

17

25

7

17

33

10

12

B505

18

16

15

11

23

18

17

10

24

16

23

12

20

13

12

19

20

13

17

32

7

20

29

23

7

14

20

25

6

19

28

6

18

27

7

12

26

22

16

B505

7

25

27

20

30

16

24

30

7

17

25

15

22

27

5

12

18

27

7

11

16

17

22

19

23

36

6

9

21

m3/h

350

450

550

775

950

1175

1450

2225

20-25

30

35-40

l/s

97

125

153

215

264

326

403

618

dB (A)

Wall grilles and diffusers | 31

NOVA-R

Non-vision return air grille

Dimensions

(H-20)x(L-20)

HxL

Design

NOVA-R grille is manufactured from natural anodized aluminium profiles white painted to RAL

9010. Deflectors are at 45° angle inclined downwards for anti-rain function with 20 mm pitch.

25

Description

NOVA-R is rectangular aluminium grille with fixed deflectors and can be used in commercial and

industrial premises. The grille is intended for return air. It is build into wall or ceiling. NOVA-R is

supplied with springs as a standard.

Mounting

The NOVA-R grille can be mounted directly into a duct or wall with mounting frame and springs.

Ordering Code

The ordering code is NOVA-R-Size

Selection Table

Table below shows the general product

performance for more details please see selection software or contact your local systemair office.

Accessories

R1 NOVA damper

Opposed blade damper Air volume flow can be

adjusted with turning the screwdriver, Depth

of the grille is 40 mm.

NOVA UR Mounting Frame

First the mounting frame is fixed to wall or

duct with screws or detachable arms, then the

grille is fixed with springs to mounting frame.

PRG Plenum box

Insulated plenum box with inlet measuring

damper control

PRG 1 = Rear connection

PRG 2 = Side connection

PRG 3 = Top/bottom connection

40

5

(H+30)x(L+30)

Function

The grille is used to intake the air from internal premises. Because of the inclined deflectors its

not possible to see through the grille. The damper or plenum box balances the air.

32 | Wall grilles and diffusers

NOVA-R

Size

Art No

Air flow range (m3/h, l/s) and DPt Pressure (Pa)

NOVA-R

UR

R1

PRG1

PRG2

PRG3

200 x 100

41140

41266

41287

6211

6220

6426

500 x 150

41519

41273

41294

6217

6226

6432

800 x 100

41527

41281

41299

200 x 150

41141

42112

42016

300 x 100

41512

41267

41288

6212

6221

6427

400 x 100

41515

41269

41290

6214

6223

6428

300 x 150

41513

41268

41289

6213

6222

6430

5

14

500 x 100

41518

41272

41293

6216

6225

6429

4

12

300 x 200

41514

42124

42028

400 x 150

41516

41270

41291

600 x 100

41522

41276

41296

Acoustic performance in dB(A):

4

B505

10

29

2

12

22

2

12

22

6

12

B505

6215

6224

6431

B505

20-25

30

4

10

18

4

10

18

20

21

18

3

9

14

4

11

16

4

12

18

3

m /h

40

60

100

140

180

220

270

360

l/s

11

17

28

39

50

61

75

100

35-40

NOVA-R

Size

Art No

UR

R1

400 x 200

41517

41271

41292

600 x 150

41523

41277

41297

1000 x 100

41137

41263

41284

500 x 200

41520

41274

41295

6218

6193

6433

3

600 x 200

41524

41278

41298

6219

6194

6434

2

7

800 x 150

41528

41282

41302

3

10

1000 x 150

41138

41264

41285

500 x 300

41521

41275

42049

800 x 200

41529

41283

41303

600 x 300

41525

41279

42065

1000 x 200

41139

41265

41286

600 x 400

41526

41280

42066

Acoustic performance in dB(A):

20-25

PRG1

PRG2

Air flow range (m3/h, l/s) and DPt Pressure (Pa)

NOVA-R

PRG3

4

B505

5

12

18

7

4

19

12

18

11

16

16

15

4

B505

9

14

4

9

14

4

9

13

3

6

9

4

8

13

3

30

35-40

8

12

3

m /h

220

270

360

450

550

675

825