N123-135 Series Snap Trac Dual Signal Conditioner

advertisement

N123-135 Series

Snap Trac

Dual Signal Conditioner

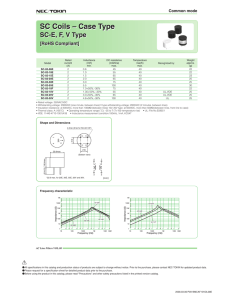

SPECIFICATIONS

Drift:

(for each output as referred to its input)

<2.4µV/°C over temperature range

0°C to 50°C.

Long-term drift typically

<3µV/month.

Temperature Range:

-20°C to 50°C (-4°F to 122°F)

Power Required:

±15 VDC at ±22mADC, regulated,

3-wire

(±E) at terminals 12, 13, and 14.

This power is available from Model

N121-132A Snap Trac

Servocontroller.

TP13

TP4

TP5

TP2

TP1

Inputs:

Two differential inputs; one across

terminals 6-7, another across terminals

9-10.

Input signals may range from ±0.01

to ±1.0 VDC.

Input source impedance <1KΩ.

One single-ended input at terminal 3.

Insert R13 (10KΩ ≤ R13 ≤ 1.0 MΩ).

Outputs:

Summed signal outputs at terminals

1 and 2.

Outputs from individual differential

inputs at terminals 4 and 5.

Maximum output signals ≤±10 VDC.

Minimum load impedance ≥5KΩ each.

Frequency Response:

<–3dB down at 1600 Hz

(45° at ≈ 1250 Hz).

COMMON

R18

GAIN

R20

R19

R17

R21

A4

R14

R15

BIAS

R22

R16

R13

R8

R30

ZERO-2

ZERO-1

R34

R12

2

C3

C4

3

R9

R31

4

R10

5

R11

A3

1

The N123-135 Snap Trac Signal Conditioner provides stable amplification for

low level DC signals obtained from strain gage sensors such as load cells and

pressure transducers. This dual-channel module provides two independent

channels of signal conditioning with wide ranges of amplification and signal

zero adjustments.

Provisions are included for summing the two signals with precision

weighting. This may be used for an accurate force signal when sensing

pressures of an unequal-area cylinder.

R32

R33

6

R26

7

R5

SPAN-1

CH2

A1

R2

14

R1

R7

C2

C1

CH1

13

3.25 in x 5.50 in long

Maximum Component Height: 0.69 in

R6

R3

12

DIMENSIONS

R27

A2

R4

11

Plug-in connectors for quick installation of board.

Test points on all critical signals for easy system setup.

Component standoffs on all user-configurable components.

Twenty-turn potentiometers for all adjustable controls.

Rugged construction with solder mask for reliability.

R23

10

➢

➢

➢

➢

➢

R29

R24

9

Construction

SPAN-2

P1

8

FEATURES

R28

R25

MODEL: N123-135

SN:

N123-135 DUAL SIGNAL CONDITIONER SCHEMATIC

+E

C1

10uf

25V

+E

R8

100K

COMMON INPUT

R1

11

ZERO-1

CW

R9

C3

2MEG

.001uf

-E

{

CH1

-E

4

6

2 A1 OP-07CP

7

+E

R4

R2

10

3

10K

R3

9

10K

1MEG

3

SINGLE-ENDED

INPUT

R7

+

R5

SPAN-1 10K

100K

R6

CW

100K

-E

4

A3A 1

3 +

8 TL082CP

+E

R11

20K

2

E5

8

24.9K

{

7

6

+

CW

.001uf

SUMMED SIGNAL

OUTPUT (INVERTED)

3

2

10K

+

-E

4

A2

-

CH2

R29

6

100K

7

+E

R26

1MEG

R27

CW

SPAN-2 10K

R28

-E

4

5 +A3B

8

+E

R33

20K

R22

R34

10K

100K

1

SUMMED SIGNAL

NORMAL OUTPUT

(NON-INVERT)

4

DIFFERENTIAL

OUTPUT #2

R21

GAIN

5

R32

CW

10K

R19

-E

OP-07CP

R18

4.99K

C4

R31

2MEG

R23

R25

2

R20

10K

-E

R17

+E

ZERO-2

10K

DIFFERENTIAL

OUTPUT #1

TP2

+E

8

1

2 A4A TL082CP

4

-E

R24

5

R16

1MEG

DIFFERENTIAL

INPUT #2

-15VDC REGULATED

AT 22 mADC

3.01K

R30

100K

COMMON INPUT

12

INDICATES PIN-1 ON PCB

2MEG

100K

COMMON

R12

10K

R14

+E

13

TP5 (TEST POINT)

3

CW R15

C2

10uf

25V

-

R13

BIAS

+15VDC REGULATED

AT 22 mADC

R10

1MEG

DIFFERENTIAL

INPUT #1

-E

14

TP13

4.99K

10K

-E

6 4

5 +A4B

8

+E

TP1

7

E1

TL082CP

TP4

6

7

TL082CP

NOTES:

24.9K

1. ■ – INDICATES SQUARE PAD ON PCB (PIN 1)

2.

– INDICATES COMPONENT STANDOFF

3. NF – INDICATES “NO-FIT” COMPONENTS (NOT SUPPLIED)

4. CW – CLOCKWISE

5 R19 – USED TO CONFIGURE OP AMP FOR HIGHER DESIRED GAINS

ADJUSTMENTS

CIRCUITRY

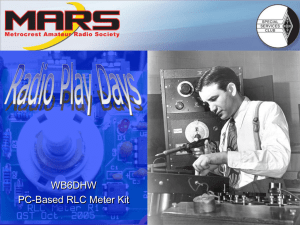

One signal input is applied to

terminals 6-7 and the other to

terminals 9-10. Differential inputs are

used to improve noise immunity and

to allow several strain gage bridges to

be excited from a common power

source.

Output signals corresponding to

each input are provided at terminals 4

and 5, respectively.Typical gains of

output to input are 100 to 500

Volts/Volt.The two outputs are

summed at amplifier stage A4A, having

an inverted output at terminal 2 and

normal output on terminal 1.The gain

range of A4A is adjustable by R18

from 0.5 to 1.5 Volts/Volt. Higher

gains can be obtained by inserting a

suitable value of R19.

If e4 = rod end pressure and

e5 = piston head pressure, then the

signal at terminal 1 (e1) will be

proportional to piston force when

R34

___

R12

=

head end area

____________

rod end area

Select resistors from 10KΩ to 100KΩ.

BIAS potentiometer R15

provides zero output adjustment for

terminals 1 and 2 when terminals

4 and 5 are zero. R13 may be inserted

to give an additional input at

terminal 3.

ZERO 1 and 2 (R8 and R30) –

adjust null of outputs for zero

transducer conditions (e.g.

zero pressure).

SPAN 1 and 2 (R5 and R27) –

adjust gain to set maximum

signal sensitivities (e.g. +10

VDC outputs for maximum

pressure).

GAIN (R18) – adjusts gain to set

sensitivity of summed

signals (e.g. +10 VDC for

maximum differential pressure

across piston).

BIAS (R15) – adjusts bias of

summed signals.

MOUNTING:

Mount using Curtiss type TR-3

plastic track (Moog P/N 65419-1)

FORCE SERVO WITH UNBALANCED ACTUATOR

Model N123-135 Dual Signal Conditioning Amplifier Card can be used to process pressure signals to obtain a force feedback signal from an unequal area actuator.

Strain-gage type pressure transducers are often used in such applications.The Signal Conditioning Amplifier provides stable amplification of the millivolt-level strain-gage

outputs. DC voltmeters can be connected to Terminal 4 & 5 to give visual indication of hydraulic pressure.

MODEL N121-132A

SERVOCONTROLLER

(Snap-Trac Card)

26

27

230 VAC

50-60 Hz

28

SCALE

29

FORCE COMMAND

20

CMD or FBK

LOOP

GAIN-1

SUMMER

3

+Er (+10V)

16

-Er (-10V)

15

DRIVER

A1A

A1B

13

A2B

12

CMD INPUT

1

+E

21

+15V reg

19

-E

17

-15V reg

SERVOVALVE

R

Ps

12

MODEL N123-135

SIGNAL CONDITIONER

(Snap-Trac Card)

C2

13

C1

14

FORCE

ON

LOAD

2

+

BIAS

4

(Neg) ROD PRESSURE

5

(Pos) HEAD PRESSURE

ACTUATOR

ZERO-1

+

A3A

-

9

+

10

A1

-

+

+

-

GAIN

SPAN-1

11

-

A4A

STRAIN GAGE

PRESSURE

TRANSDUCERS

+

ZERO-2

8

A3B

+

7

-

6

A2

SPAN-2

-

Industrial Controls Division

Moog Inc., East Aurora, NY 14052-0018

Telephone: 716/655-3000

Fax: 716/655-1803

Toll Free: 1-800-272-MOOG

CDL6171 Rev B 500-190 798