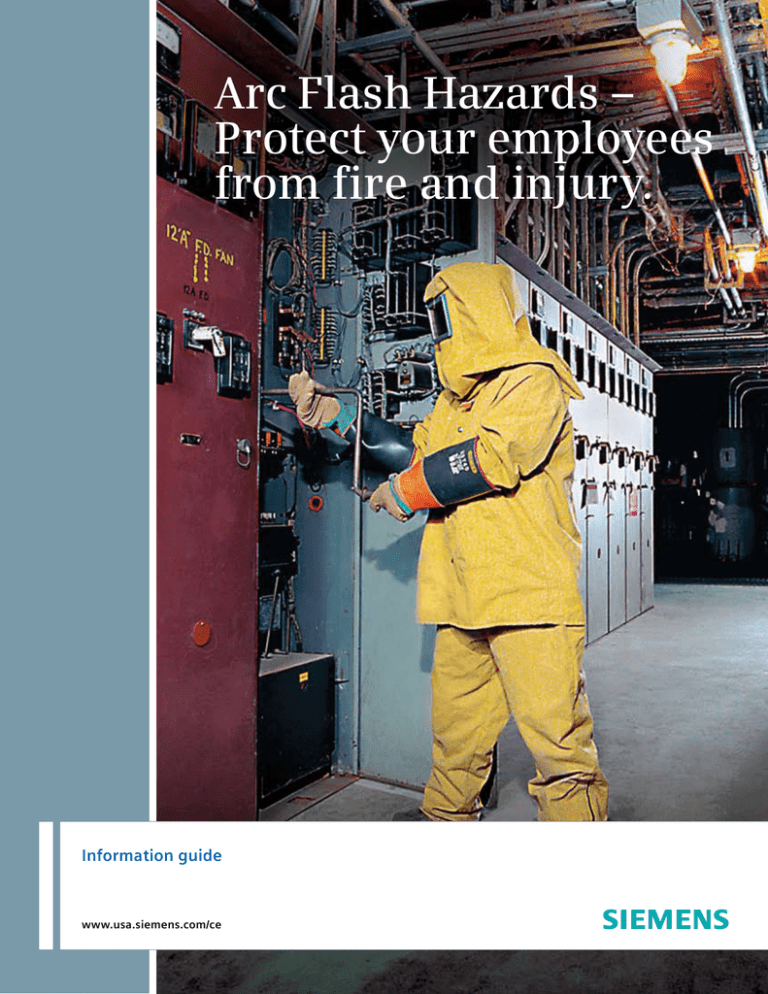

Arc Flash Hazards –

Protect your employees

from fire and injury.

Information guide

www.usa.siemens.com/ce

What causes an arc flash? Are you familiar with the changing

codes and government regulations? What can you do to protect

your employees from fire and injury? This paper is designed to

address those concerns and answer questions to help protect your

assets.

What is an arc flash?

An arc flash is a current flowing through air that flashes from one

exposed live conductor to another conductor or to ground. When

an arc flash happens, the temperatures can reach up to 35,000

degrees Fahrenheit. This is four times the temperature on the

surface of the sun.

The result can be destruction of equipment, fire, and injury.

What steps can help protect employees from arc flash?

1. Work de-energized.

2. Have a professional engineer calculate the short circuits.

3. Perform a Protective Device Coordination Study.

4. Perform an arc flash calculation.

5. Document the findings.

6. Determine specifics of unsafe work locations.

7. Eliminate hazards through system changes or operational

procedures.

8. Apply hazard labels describing required PPE and boundaries for

equipment use.

9. Establish safe work practice procedures.

Are the generic PPE recommendations of the National Fire

Protection Association (NFPA) 70E sufficient?

What causes an arc flash?

An arc flash occurs when electrical clearances are reduced or

compromised by deteriorating insulation or human error. The

arc flash follows a conductive path between two hot (energized)

wires or between a hot wire and ground.

How can I protect employees from arc flashes?

Following NFPA 70E guidelines is highly recommended, however,

the actual field conditions can be more hazardous than the NFPA

70E guidelines. An arc flash study can reveal equipment with

elevated hazard levels. This will help you protect your employees.

The General Duty Clause and the Occupational Safety &

Health Administration (OSHA)

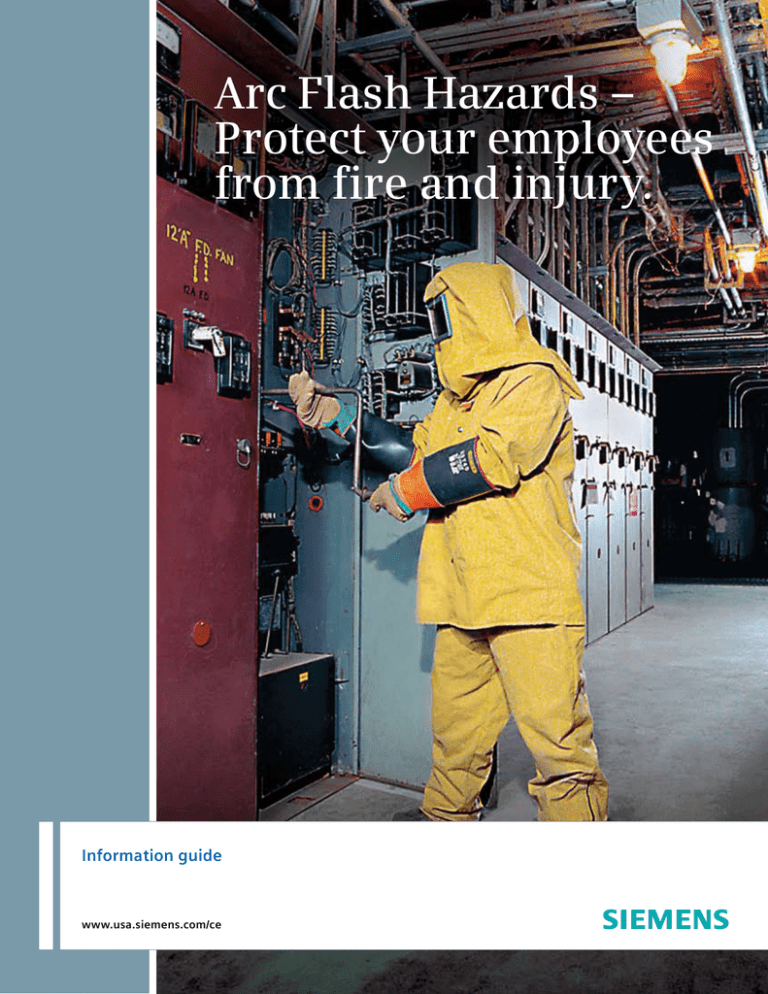

The recommended way to protect employees is to de-energize

equipment prior to working on it. When de-energization is not

feasible per code, enforce safe work practices. Require your

employees to be properly suited in conjunction with a recent

arc flash study. Actions that require PPE include, but are not

limited to, operating a breaker with the deadfront cover removed,

voltage testing, working on energized equipment, and racking in

or out drawout units.

The General Duty Clause states “each employer shall furnish . . .

a place of employment . . . free from recognized hazards that are

causing or are likely to cause death or serious physical harm to his

employees . . . ” The clause does not provide enough detail to

determine the proper level of PPE required.

Why is an arc flash study important?

•

•

•

•

Without an arc flash study you will not know the actual level of

danger or the appropriate personal protective equipment (PPE)

required for employees. Electrical systems are dynamic and

change over time. Internal changes, such as adding new

equipment can affect the level of arc flash energy. A study must

be updated every time the system changes. External changes,

such as a utility changing transformers or changes at your utility’s

closest substation can severely impact your level of arc flash

energy. Performing this study will help you create a safer work

environment.

OSHA has referenced the “General Duty Clause” when citing

employers for:

Failing to keep the jobsite free from hazards.

Hazards that are likely to cause serious harm or death.

Recognizing the hazard, but not taking corrective action.

Failing to take advantage of “feasible and useful methods” to

protect against the hazard.

Proper PPE is cited as a “feasible and useful method” for

addressing hazards while using a piece of equipment. The only

way to provide this level of detail is to perform the arc flash study.

Explanation of the 2008 National Electrical Code®

(NEC®) Section 110.16

“Electrical equipment such as switchboards, panelboards,

industrial control panels, meter socket enclosures, and motor

control centers that are in other than dwelling occupancies and

are likely to require examination, adjustment, servicing, or

maintenance while energized shall be field marked to warn

qualified persons of potential electric arc flash hazards. The

marking shall be located so as to be clearly visible to qualified

persons before examination, adjustment, servicing, or

maintenance of the equipment.”

FPN No. 1: NFPA 70E-2000. Electrical Safety Requirements for Employee

Workplaces, provides assistance in determining severity of potential

exposure, planning safe work practices, and selecting personal protective

equipment (PPE).

FPN No. 2: ANSI® Z535.4-1998, Product Safety Signs and Labels, provides

guidelines for the design of safety signs and labels for application to

products.

Understanding the NEC

“. . . other than dwelling occupancies . . .” What is

considered a dwelling?

Per the NEC, a dwelling is a single unit, providing complete and

independent living facilities for one or more persons. This

includes permanent provisions for living, sleeping, cooking, and

sanitation. If the building is a dwelling, it does not require arc

flash labeling. Office buildings, plants, stadiums, malls, and

schools are not considered dwelling occupancies, therefore are

covered by the NEC provision requiring an arc flash warning.

“. . . are likely to require examination, adjustment, servicing,

or maintenance while energized . . .” Will these happen in my

facility?

Quite possibly. NFPA 70E states that equipment can be worked

hot during “infeasible conditions” which include start-up testing,

troubleshooting and diagnostics or a continuous process

segment. If electricians are starting up your facility, doing

troubleshooting, or if your facility is a continuous process, then

they need to be protected.

Whenever possible, it is recommended that work is completed

when equipment is de-energized.

“. . . shall be field marked . . .” What does this mean?

This is a field marking rather than a factory marking since it is

application oriented.

“. . . to warn qualified persons of potential electric arc flash

hazards . . .” Who is a qualified person?

Per the NEC, a qualified person is one who has skills and

knowledge related to the construction and operation of the

electrical equipment and installations and has received safety

training to recognize and avoid the hazards involved. Refer to

NFPA 70E-2004, Standard for Electrical Safety in the Workplace,

for electrical safety training requirements.”

Will a generic label suffice?

While the generic label like the one below, left, will meet the NEC

requirements to field mark and warn, it will not address actual

site conditions, safe work boundaries, or PPE. The label

on the right is from a study and provides the additional useful

information on clothing and safe work boundaries.

What is OSHA’s Stance on Personal Protective

Equipment (PPE)?

In most cases, OSHA requires employers to furnish PPE.

http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_

table=NEWS_RELEASES&p_id=14739

In November 2007, OSHA announced the employer-paid personal

protective equipment final rule.

WASHINGTON – The U.S. Department of Labor’s Occupational

Safety and Health Administration (OSHA) [November 14, 2007]

announced a final rule on employer-paid personal protective

equipment (PPE). Under the rule, all PPE, with a few exceptions,

will be provided at no cost to the employee. OSHA anticipates

that this rule will have substantial safety benefits that will result

in more than 21,000 fewer occupational injuries per year.

The rule will be published in the Federal Register on

November 15, 2007.

“Employees exposed to safety and health hazards may need to

wear personal protective equipment to be protected from injury,

illness, and death caused by exposure to those hazards,” said

Assistant Secretary of Labor for OSHA Edwin G. Foulke Jr. “This

final rule will clarify who is responsible for paying for PPE, which

OSHA anticipates will lead to greater compliance and potential

avoidance of thousands of workplace injuries each year.”

The final rule contains a few exceptions for ordinary safety-toed

footwear, ordinary prescription safety eyewear, logging boots,

ordinary clothing, and weather-related gear. The final rule also

clarifies OSHA’s requirements regarding payment for employeeowned PPE and replacement PPE. While these clarifications have

added several paragraphs to the regulatory text, the final rule

provides employees no less protection than they would have

received under the 1999 proposed standard. The rule also

provides an enforcement deadline of six months from the date of

publication [May 15, 2008] to allow employers time to change

their existing PPE payment policies to accommodate the final rule.

How many people are hurt by Arc Flash?

Capelli-Schellpfeffer, Inc. of Chicago, a national tracking

service, reports 5 to 10 arc flash injuries a day that require

hospitalization. However, there are additional arc flash incidents

that are not documented for national tracking. Regardless,

5 to 10 per day equates to 1,800 to 3,600 injuries per year

nationwide.

The 2009 Edition of NFPA 70E will require equipment to be field

marked with the available incident energy or the required level of

PPE.

Conclusion

Arc flashes can maim or kill. Having Siemens perform an arc flash

study is a feasible and useful first step for protection. The study

will determine the appropriate PPE at that time. If an arc-flash

hazard is present, or likely to be present, then you, the employer,

must select, purchase, and require employees to use the

protective apparel. Employers who conduct the hazard/risk

assessment, and select, purchase, and require their employees to

use protective clothing and other PPE appropriate for the task, as

stated in the NFPA 70E standard, 2000 Edition, are deemed in

compliance with the Hazard Assessment and Equipment Selection

OSHA standard.

NFPA, NEC and National Electric Code are registered trademarks of the

National Fire Protection Association.

ANSI is a registered trademark of the American National Standards

Institute.

Under the Occupational Safety and Health Act of 1970, employers

are responsible for providing safe and healthful workplaces for

their employees. OSHA’s role is to assure the safety and health of

America’s working men and women by setting and enforcing

standards; providing training, outreach and education;

establishing partnerships; and encouraging continual process

improvement in workplace safety and health. For more

information, visit www.osha.gov.

Siemens Industry, Inc.

Building Technologies Division

5400 Triangle Parkway

Norcross, GA 30092

1-800-964-4114

Subject to change without prior notice

Order No.: PDBR-ARCFH-1009

All rights reserved

Printed in USA

The information provided in this brochure contains merely

general descriptions or characteristics of performance

which in case of actual use do not always apply as described

or which may change as a result of further development

of the products. An obligation to provide the respective

characteristics shall only exist if expressly agreed in the

terms of contract.

©2009 Siemens Industry, Inc.

info.us@siemens.com

www.usa.siemens.com/ce

All product designations may be trademarks or product

names of Siemens AG or supplier companies whose use by

third parties for their own purposes could violate the rights

of the owners.