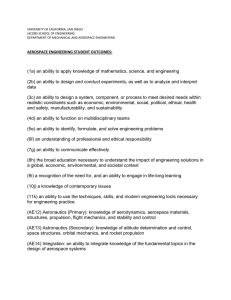

Mechanical, Materials, and Aerospace Engineering Department of

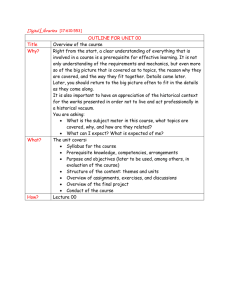

advertisement