Electronic Controls

advertisement

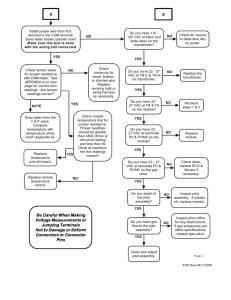

Electronic Controls The FuelMizer™ (SR501-OR) is a microprocessor-based control designed to regulate the supply water temperature of a single boiler, based on the outdoor temperature. The FuelMizer is a boiler reset control and switching relay in one unit; it is ideal for retrofit application, but may also be used in new installations as well. ©Taco Catalog #100-100 Supersedes: New Effective Date: 06/12/12 Printed in USA SR 501OR- 6 AMP INPUT 120 VAC RELAY ZONE 1 120 VAC N H N H Submittal Data Information FuelMizer™ Instruction Sheet # 102-420 Supersedes: New N POWER INPUT (120 VAC) Effective: 06/12/12 SYSTEM CIRCULATOR (OPTIONAL) H ONE ZONE INSTALLATION W/O INDIRECT DHW Application The FuelMizer (SR501-OR) includes functions such as automatic reset ratio calculation, warm weather shut down (WWSD), minimum boiler temperature setting, and boiler differential setting. The control also includes both boiler and outdoor sensors. 24 VAC THERMOSTAT THERMOSTATS (24VAC) 24 VAC ZONE VALVES PUMP END SWITCH X X BOILER CONTROL DESIGN OUTDOOR TEMPERATURE FOR 180°F SUPPLY TEMPERATURE -10 0 10 -20 20 POT1 -30 30 OFF X X R W C R W OUTDOOR BOILER TSTAT SENSOR DHW ONE ZONE SWITCHING RELAY WITH OUTDOOR RESET 40 DESIGN OUTDOOR TEMPERATURE FOR 180°F SUPPLY TEMPERATURE -10 0 10 -20 20 POT1 -30 30 OFF 40 X X R W C R W OUTDOOR BOILER TSTAT DHW VALVE 3 ZONE 2 1 2 3 4 ZONE 3 1 2 3 4 1 2 3 1 2 3 TACO 3 WIRE ZONE VALVE TACO 3 WIRE ZONE VALVE DHW OVERRIDE BOILER RELAY ZONE 1 120 VAC N H N H POWER INPUT (120 VAC) SYSTEM CIRCULATOR (OPTIONAL) Configuration OUTDOOR Dip SwitchEs TEMPERATURE CONTROL ADJUSTMENT A DHW AQUASTAT SENSOR CONNECTIONS ZONE 3 PRIORITY R W C R W C R W C ZONE 1 ZONE 2 ZONE 3 THERMOSTATS PRIORITY SYSTEM CIRCULATOR (OPTIONAL) DEMAND INPUT CONNECTIONS BOILER CONTROL CONNECTIONS THERMOSTATS (24VAC) N H MULTI-ZONE INSTALLATION WITH ZONE CONTROL, WITH INDIRECT DHW ONE ZONE INSTALLATION W/O INDIRECT DHW FUSE 5 AMP 6 AMP INPUT 120 VAC ZONE 1 120 VAC H POWER IN 24 VAC LED INDICATORS TSTAT BOILER RELAY X X ISOLATED END SWITCH SUPPLY SENSOR POWER N POWER INPUT (120 VAC) SENSOR ONE ZONE SWITCHING RELAY WITH OUTDOOR RESET SR 501OR-4 SR 501OR-4 INPUT 120 VAC ON OFF LED INDICATORS POWER EXISTING ZONE VALVE CONTROL 24 VAC ZONE VALVES PUMP END SWITCH X Relays: .....................Boiler Relay ..................................1 amp @ 24 VAC X ZONE 1 1 2 3 4 ZONE 3 PUMP END SWITCH N/O COM N/C BOILER CONTROL T STAT 1 VALVE 1 T STAT 2 VALVE 2 T STAT 3 VALVE 3 EXTERNAL DIAGNOSTIC LED'S PRIORITY ZONE 2 1 2 3 4 JUMPER 3&4 2 WIRE ZONE VALVE (NO END SWITCH) MUST USE JUMPER ZONE 3 1 2 3 4 1 2 3 1 2 3 TACO 3 WIRE ZONE VALVE TACO 3 WIRE ZONE VALVE Savings from 5% to 30% OUTDOOR SENSOR $900 BOILER SUPPLY SENSOR OFF ON $800 SW1 40 X X R W C R W OUTDOOR BOILER TSTAT DHW SENSOR ONE ZONE SWITCHING RELAY WITH OUTDOOR RESET $700 SUPPLY SENSOR Savings DESIGN OUTDOOR TEMPERATURE FOR 180°F SUPPLY TEMPERATURE -10 0 10 -20 20 POT1 -30 30 OFF LED INDICATORS POWER Sensors: ..................NTC thermistor, ..................................10 kΩ @ 77°F TSTAT SR 501OR-4 DHW OVERRIDE ..................................(25°C ±0.2°C) ..................................ß=3892 WWSD: ..................70°F (21°C) VALVE 2 T STAT 3 SW1 SUPPLY SENSOR LED INDICATORS 6 AMP Power Supply: .......120/60/1 VAC, ..................................12 amps maximum Differential: ............10°F or 20°F ..................................(6°C or 12°C) VALVE 1 T STAT 2 BOILER SUPPLY SENSOR N H N H Enclosure: ...............TYPE 1 Boiler ...................... Minimum: ...............70°F or 140°F ..................................(21°C or 60°C) LED INDICATORS T STAT 1 SW1 Control: ..................Microprocessor ..................................control. This is not ........................... a safety (limit) ........................... control. Outdoor ................ Design Temp.: ........-30°F to 40°F ..................................(-35°C to 5°C) OFF PRIORITY OFF ON DHW OVERRIDE Thermostat: ...........24 VAC ..................................Class 2 Output ON OUTDOOR SENSOR OFF ON TSTAT ..................................Circulator Relay ..................................1⁄3 HP ..................................(6 FLA, 36 LRA) ZONE 1 1 2 3 4 ZONE 3 PUMP END SWITCH N/O COM N/C 2 WIRE ZONE VALVE (NO END SWITCH) MUST USE JUMPER BOILER SUPPLY SENSOR BOILER CONTROL DHW AQUASTAT POWER JUMPER 3&4 OUTDOOR SENSOR Specifications Approvals: ..............UL listed for ..................................US and Canada, ..................................Temperature ..................................Indicating and ..................................Regulating ..................................Equipment. R W C R W C R W C ZONE 1 ZONE 2 ZONE 3 THERMOSTATS PRIORITY EXISTING ZONE VALVE CONTROL POWER Dimensions: ...........4-1⁄4" W x 5-1⁄4" H ..................................x 2-3⁄4" D A ZONE 3 PRIORITY X X ISOLATED END SWITCH FUSE 5 AMP •Full outdoor boiler reset control •Can control system or zone valve circulator •Over-ride of outdoor reset when DHW tank is calling •Easy to install and set; will not affect boiler’s warranty •Front mounted LED lights for full diagnostic information •Ideal for retrofit applications of just about any hot water boiler •Typical energy savings is about 14% with some customers experiencing up to 30% POWER IN 24 VAC Features 6 AMP INPUT 120 VAC $600 $500 Savings Range $400 $300 BOILER RELAY $200 $100 ZONE 1 120 VAC $0 N H N H $0 $1000 $2000 $3000 $4000 Yearly Amount Spent on Fuel POWER INPUT N (120 VAC) H TRANSFORMER POWER INPUT CONNECTIONS CIRCULATOR OUTPUT CONNECTIONS SYSTEM CIRCULATOR (OPTIONAL) MULTI-ZONE INSTALLATION WITH ZONE CONTROL, WITH INDIRECT DHW FUSE The installer must ensure that this control and its wiring are isolated and/or shielded from strong sources of electromagnetic noise. This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. Taco Inc., 1160 Cranston Street. Cranston, RI 02920 / (401) 942-8000 / Fax (401) 942-2360 Taco (Canada) Ltd., 8450 Lawson Road, Unit #3, Milton, Ontario L9T 0J8 / (905) 564-9422 / Fax (905) 564-9436 www.taco-hvac.com