Natural Daylight Design Through Rooflighting

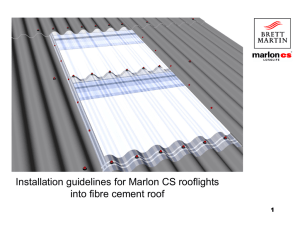

advertisement