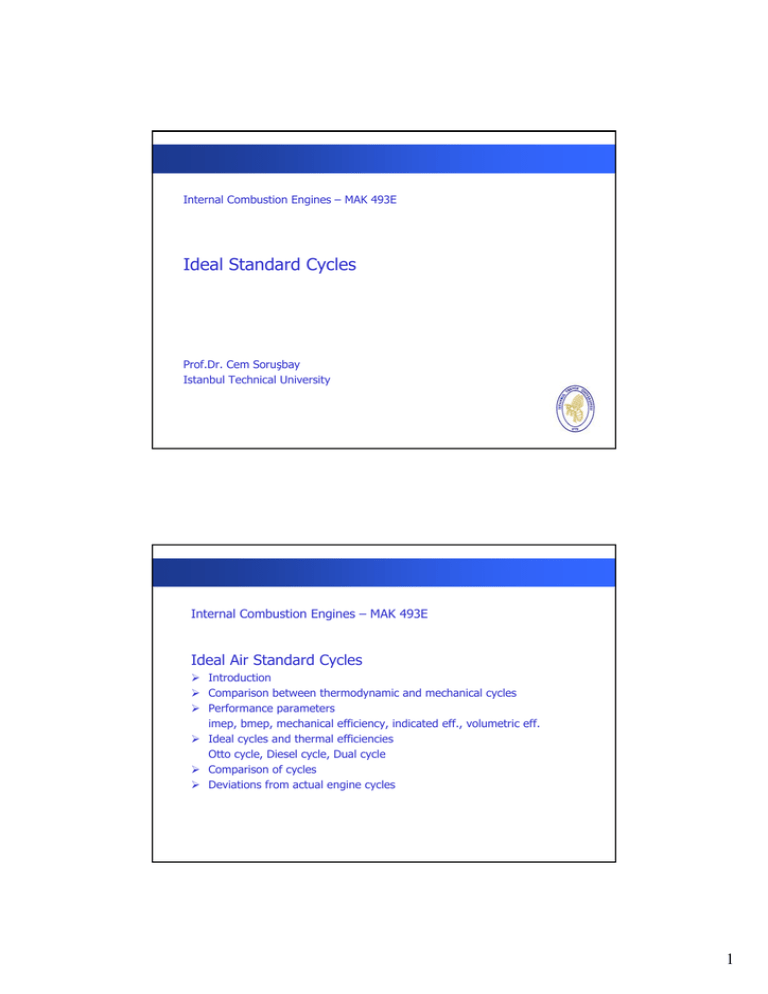

Ideal Standard Cycles

advertisement

Internal Combustion Engines – MAK 493E Ideal Standard Cycles Prof.Dr. Cem Soruşbay Istanbul Technical University Internal Combustion Engines – MAK 493E Ideal Air Standard Cycles ¾ Introduction ¾ Comparison between thermodynamic and mechanical cycles ¾ Performance parameters imep, bmep, mechanical efficiency, indicated eff., volumetric eff. ¾ Ideal cycles and thermal efficiencies Otto cycle, Diesel cycle, Dual cycle ¾ Comparison of cycles ¾ Deviations from actual engine cycles 1 Ideal Air Standard Cycles Refferences : Heywood, J.B., Internal Combustion Engine Fundamentals, McGraw Hill Book Comp, New York, 1988. Pages 161 – 183 Soruşbay, C., Ergeneman, M., Arslan, E., Safgönül, B., İçten Yanmalı Motorlar, Birsen Yayınevi, İstanbul, 2002 (3. Baskı) Pages 3 – 23 and 38 - 41 Stone, R., Introduction to IC Engines, Macmillan, London, 1994. Pages 33 - 34 Assumptions Air standard cycles, serve as introduction to the more detailed and accurate models of IC engines provide insight into some of the important parameters that effect engine performance Assumptions; • Neglect heat transfer to and from cylinder walls, • Replace combustion process by a heat addition process that occurs at constant volume (in Otto cycle) or at constant pressure (in Diesel cycle), • Do not consider gas exchange process, • Assume cylinder charge as a perfect gas (cp and cv are assumed constant) which is pure air. 2 Otto Cycle The Otto cycle is used as a basis of comparison for SI engines The cycle consists of four processes, 1–2 isentropic compression from V1 to V2 2–3 addition of heat Q23 at constant volume 3–4 isentropic expansion to the original volume 4–1 rejection of heat Q41 at constant volume Otto Cycle 3 Otto Cycle Work done during the cycle, 1-2-3-4 is, Wcycle = ∫ p dV = ∫ T ds Constant volume heat input to the cycle per unit mass of working fluid Q23 = T3 ∫c v dT = cv (T3 − T2 ) T2 Constant volume heat extraction from the cycle per unit mass T1 Q41 = − ∫ cv dT = - cv (T1 − T4 ) = cv (T4 − T1 ) T4 Otto Cycle 1st law of thermodynamics dE = dQ − dW dE = 0 Thermal efficiency η t -otto = work done W = Q23 heat input η t -otto = Q23 − Q41 Q = 1 − 41 Q23 Q23 η t -otto = 1 − T4 − T1 T3 − T2 4 Otto Cycle Initial pressure p1 and temperature T1 p1V1k = p2V2k using for an adiabatic compression pV = mRT and ⎛V ⎞ p2 = p1 ⎜⎜ 1 ⎟⎟ ⎝ V2 ⎠ from ideal gas law k ⎛V ⎞ T2 = T1 ⎜⎜ 1 ⎟⎟ ⎝ V2 ⎠ V1 V2 ε = compression ratio k −1 k= cp cv (sıkıştırma oranı) T2 = T1 ε k −1 Otto Cycle from 2 → 3 , constant volume heat addition p3V3 = mRT3 p2V2 = mRT2 T3 = T2 defining β = p3 p2 V2 = V3 p3 p2 “pressure ratio” (basınç artış oranı) T3 = T1 β ε k −1 5 Otto Cycle from 3 → 4 , adiabatic expansion, p4V4k = p3V3k p4V4 V4k −1 = p3V3 V3k −1 From ideal gas law p4V4 = mRT4 p3V3 = mRT3 V4 V1 = =ε V3 V2 T4V4k −1 = T3V3k −1 T4 = T3 ε k −1 T4 = T1 β Thermal Efficiency Thermal efficiency of Otto cycle is given by, η t -otto = 1 − T4 − T1 T3 − T2 placing the temperatures T2, T3 and T4 in terms of T1 ηt −otto = 1 − 1 ε k −1 6 Thermal Efficiency Diesel Cycle 7 Diesel Cycle Work done during the cycle, 1-2-3-4 is, Wcycle = ∫ p dV = ∫ T ds Constant pressure heat input to the cycle per unit mass of working fluid Q23 = T3 ∫c p dT = c p (T3 − T2 ) T2 Constant volume heat extraction from the cycle per unit mass T1 Q41 = − ∫ cv dT = - cv (T1 − T4 ) = cv (T4 − T1 ) T4 Diesel Cycle 1st law of thermodynamics dE = dQ − dW dE = 0 Thermal efficiency ηt-diesel = W work done = Q23 heat input ηt-diesel = Q23 − Q41 Q = 1 − 41 Q23 Q23 ηt-diesel = 1 − T4 − T1 k (T3 − T2 ) 8 Diesel Cycle T2 = T1 ε k −1 T3 = T2 T4 = V3 = T1 α ε k −1 V2 T3α k −1 ε k −1 = T1 α k Diesel Cycle Defining “cut-off ratio” or “load ratio” (hacim artış oranı) α = V3 V2 9 Thermal Efficiency Thermal efficiency of Diesel cycle is given by, ηt -diesel = 1 − T4 − T1 T3 − T2 placing the temperatures T2, T3 and T4 in terms of T1 ηt −diesel = 1 − 1 ε k −1 α k −1 k (α − 1) Thermal Efficiency As the value of α increases ( heat addition is extended towards expansion) the efficiency is reduced due to additional heat required to compansate the expansion 10 Dual Cycle Dual Cycle Work done during the cycle, 1-2-3’-3-4 is, Wcycle = ∫ p dV = ∫ T ds Constant volume heat input followed by constant pressure heat input to the cycle per unit mass of working fluid Q23 = cv (T3' − T2 ) + c p (T3 − T3' ) Constant volume heat extraction from the cycle per unit mass T1 Q41 = − ∫ cv dT = - cv (T1 − T4 ) = cv (T4 − T1 ) T4 11 Dual Cycle Thermal efficiency ηt-dual = 1 − cv (T4 − T )1 cv (T3' − T2 ) + c p (T3 − T3' ) Dual Cycle T2 = T1 ε k −1 T3' = T1 β ε k −1 T3 = T1 β α ε k −1 T4 = T1 α k β 12 Thermal Efficiency Thermal efficiency of Dual cycle is given by, ηt −dual = 1 − Putting βα k − 1 β − 1 + k β (α − 1) 1 ε k −1 α=1 Otto cycle thermal efficiency β=1 Diesel cycle thermal efficiency is obtained Thermal Efficiency Otto cycle ηth −Otto = 1 − 1 ε k −1 Diesel cycle ηth − Diesel = 1 − 1 ε k −1 α k −1 k (α − 1) Dual cycle ηth − Dual = 1 − 1 ε k −1 β α k −1 β − 1 + kβ (α − 1) 13 Comparison of Ideal Cycles For α > 1 and k > 1 αk −1 k (α − 1) term is greater than 1 therefore ηt-otto > ηt-diesel Also ηt-otto > ηt-dual > ηt-diesel for a constant value of compression ratio efficiency of Dual cycle lies between Otto and Diesel cycles according to the value of β Comparison of Ideal Cycles In real engines, SI engines have a compression ratio between 10:1 to 12:1 this value is limited due to engine knock CI engines have compression ratio higher than 14:1 to provide temperature and pressure required for self ignition of the fuel compression ratio of 16:1 to 18:1 is sufficient for efficiency, but used for improving ignition quality high compression ratio increases thermal and mechanical stresses 14