Table of Contents

advertisement

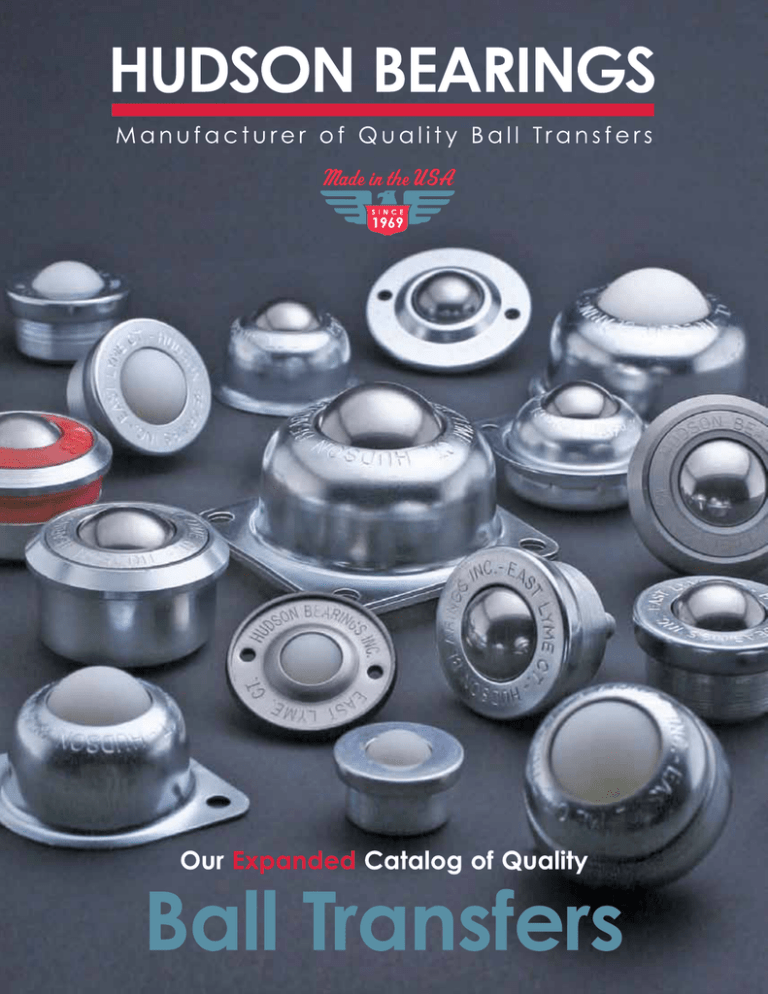

Hudson Bearings is one of the oldest manufacturers of ball transfers in the United States and one of the most innovative. Unlike most of our competitors, we manufacture our broad and rapidly expanding product line in the USA. Our quality is unsurpassed and we pride ourselves on our extensive inventory. Whether it's 10 pieces or Studded HDBT 1-3/16 Also available in stainless steel. 10 HD with Metal Cap Also available in stainless steel. 12 10,000, our responsive staff ensures your product is on a truck the day we receive your Now Available in All Stainless Steel order. Whether used in the traditional 'ball up' position for material handling or as a caster MBT-1 MBT-5/8 SMBT-5/8 MBT-1 in the 'ball down' orientation for rolling applications such as retail store displays, Hudson is ready with the right product for your unique need. Lockable Ball Transfer Coming Fall 2011! 2 HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com Table of Contents New Products 11 11 9 9 Page Application Design & Technical Information 4-5 Flange-Mounted 6-7 Flangeless 7 Stud-Mounted 8 Stud-Mounted, Machined 9 Stud-Mounted Heavy-Duty & Pipe Mounted 10 Drop-In Style 11 Heavy-Duty, Drop-In Style 12 Flying-Saucer 13 Features & Benefits 14 About Us 15 HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 3 Load Capacity Arrangement • Equal load distribution over many ball transfers is seldom, if • Arrangement of the ball transfer units depends on the ever achieved. Load distribution is governed by the flatness, hardness, and smoothness of the load surface in contact with the balls, the ball transfer installation height variance, and system deflection. • To avoid exceeding the rated capacity of any individual ball transfer unit, sufficient ball transfers should be provided to afford a safety factor of 3. For example: the number of units (75 lb. maximum capacity) required to support a load of 750 lbs. would be 10 units x 3, or 30 units to obtain smooth rolling motion under varying degrees of flatness and ball contact. This applies to both 'ball up' and 'ball down' positioning. • In addition, the force required to put a load in motion Part Number Reference Guide weight of the load, surface of the application and undersurface of the conveyed load. Determine the number of units required to support the load based on the considerations stated above. Once the number of ball transfer units has been calculated, these units should be arranged symmetrically under the load. The minimum distance between ball transfers should be the length of the shortest dimension of the load divided by 2.5. This minimum spacing will support the conveyed article and prevent it from becoming unstable. • Our technical staff is available to assist you with mounting, loading, and spacing recommendations for your particular application. is reduced as the number of ball transfer units under a load is increased, thereby reducing the coefficient of friction. • When calculating loads, the possibility of impact and unequal leveling should be considered. Self-leveling neoprene or rubber cushions placed under each unit can reduce these issues. We offer high-density neoprene cushions for several models of ball transfers in this catalog. Now offering the ability to add your company logo. Call us for details: 860-739-6988. Typical Mounting Configurations BT Series (pg 6) SBT Series (pg 8) Flangeless (pg 7) SMBT Series (pg 9) LPBT Series MBT Series Ball Transfer B T S Stud Mount M MAchined N Nylon Main Ball 1-3/16 Main Ball Size M Metal Cap C Cushion Mount 1-1/2 Main Ball Size C S P Pipe Mount C S D Deep Cup S S Stainless Steel S R Sound Reduction F S Flying Saucer L P Low Profile F L Flange-Less (formerly -2) H D Heavy Duty L LocKABLE 5/8 Main Ball Size N S No Seal 1 Main Ball Size N N No Name Carbon Steel S CS Housing & CUP SS Main & Support Balls S Example Part number for Nylon Stud Mount Ball Tansfer with 1" main ball and 1/4" thread. N S B T 1 1/4 (pg 7) (pg 11) Ball transfer units enhance conveyor systems by allowing material to move omni-directionally with little effort. Photos courtesy of Ashland Conveyor, Ashland, OH FSBT Series HDBT Series 4 PBT Series (pg 10) (pg 13) (pg 12) HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 5 BT-1 Series LPBT-1 Series 2-3/16 in. 55.6 mm 7/32 in. DIA 5.6 mm DIA 2-3/16 in. 55.6 mm 2-1/8 in. 7/32 in. DIA 54.0 mm 5.6 mm DIA 2 in. 50.8 mm BT-1CS Part Number Ball Material Housing Mat. Load Cap. BT-1CS Carbon Steel Carbon Steel 75 lbs. NBT-1CS Nylon Carbon Steel 35 lbs. BT-1CS/SS Stainless Steel Carbon Steel 75 lbs. BT-1SS Stainless Steel Stainless Steel 75 lbs. 69.9 mm Seal 1-11/16 in. 42.9 mm 2-3/4 in. 3/4 in. 69.9 mm 19.1 mm 1-15/64 in. 31.4 mm Two-hole, Flange-Mounted, All-Steel • • • • • LBT-1CS 2-3/4 in. NBT-1CS Seal 1˝ Main ball rotates on eighty 1/8˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. 42.9 mm 1/16 in. R 1.6 mm R 1-3/4 in. 44.5 mm 1-3/16 in. 7/8 in. NOTE: Also available in recessed low-profile mounting style. (Part number LPBT-1 pg. 7) BT-1-1/2 Series Housing Mat. Load Cap. Carbon Steel Carbon Steel 75 lbs. NLPBT-1CS Nylon Carbon Steel 35 lbs. LPBT-1CS/SS Stainless Steel Carbon Steel 75 lbs. LPBT-1SS Stainless Steel Stainless Steel 75 lbs. Low Profile, Two-hole, Flange-Mounted, All-Steel Designed to be recessed into the surface of the application in a 1-3/4" hole. 1˝ Main ball rotates on eighty 1/8˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. FLBT Series 2 in. 7.1 mm DIA Ball Material LPBT-1CS 30.2 mm 22.2 mm 9/32 in. DIA Part Number • • • • • • 1-11/16 in. NLBT-1CS Seal 2-7/16 in. 50.8 mm 1-5/8 in. 41.3 mm 61.9 mm 1-3/16 in. 15/16 in. 30.2 mm 23.8 mm 3 in. 61.9 mm 76.2 mm Ball Material Housing Mat. FLBT-1CS Load Cap. Carbon Steel Carbon Steel 250 lbs. NBT-1-1/2CS Nylon Carbon Steel 125 lbs. BT-1-1/2CS/SS Stainless Steel 3 in. Carbon Steel 250 lbs. 76.2 mm BT-1-1/2SS Stainless Steel Stainless Steel 2-19/32 in. 250 lbs. Four-hole, Flange-Mounted, All-Steel 1-1/2˝ Main ball rotates on ninety 3/16˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. Housing Mat. Load Cap. Carbon Steel Carbon Steel 75 lbs. NFLBT-1 Nylon Carbon Steel 35 lbs. 2-19/32 in. FLBT-1CS/SS Carbon Steel Stainless Steel 75 lbs. 65.9 mm FLBT-1-1/2CS Carbon Steel Carbon Steel 250 lbs. NFLBT-1-1/2 Nylon Carbon Steel 125 lbs. FLBT-1-1/2CS/SS Carbon Steel Stainless Steel 250 lbs. Seal Seal 1-13/32 in. 35.7 mm NOTE: Neoprene cushion available to permit vertical deflection and assist with uniform load distribution (part number CBT-1-1/2). 6 Ball Material FLBT-1CS 76.2 mm 65.9 mm HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 1-13/16 in. 46.0 mm NFLBT-1-1/2 Part Number 3 in. BT-1-1/2CS • • • • • FLBT-1 NBT-1-1/2CS CBT-1-1/2CS Part Number 2-7/16 in. 1-13/16 in. 1-13/32 in. 46.0 mm 35.7 mm FLBT-1-1/2 Flangeless, All-Steel • • • • • • FLBT-1: 1˝ Main ball rotates on eighty 1/8˝ support balls. FLBT-1-1/2: 1-1/2˝ Main ball rotates on ninety 3/16˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 7 SMBT-5/8 Series SBT-1 Series SBT-1CS1/4 1-3/4 in. NSBT-1CS1/4 Ball Material Housing Mat. Load Cap. SMBT-5/8CS 75 lbs. Carbon Steel Carbon Steel 33 lbs. NSMBT-5/8CS Carbon Steel 35 lbs. Nylon Carbon Steel 17 lbs. Stainless Steel SMBT-5/8CS/SS Stainless Steel Carbon Steel 75 lbs. Carbon Steel 33 lbs. Stainless Steel Stainless Steel Stainless Steel Stainless Steel 33 lbs. 75 lbs. SMBT-5/8SS Ball Material Housing Mat. Load Cap. SBT-1CS Carbon Steel Carbon Steel NSBT-1CS Nylon SBT-1CS/SS SBT-1SS Seal 30.2 mm 3/8 in. 1-3/8 in. 9.5 mm 34.9 mm 13/16 in. 20.6 mm 7/32 in. Stud-Mounted, All-Steel 11/16 in. 17.5 mm 1/2 in. 12.7 mm 1/4 - 20 in. THD Now available in all stainless. (part number SMBT-5/8SS). 15/16 in. NOTE: Also available with a base to ball height of 1-17/32˝ in 1/4˝ stem only (part number DSBT-1). 23.8 mm 1-13/32 in. 35.7 mm SMBT-1 Series SBT-1-1/2 Series CSBT-1-1/2CS SBT-1-1/2CS 3-1/4 in. NSBT-1-1/2CS Ball Material Housing Mat. Carbon Steel Carbon Steel 250 lbs. NSBT-1-1/2CS Nylon Carbon Steel 125 lbs. SBT-1-1/2CS/SS Stainless Steel Carbon Steel 250 lbs. 1-43/64 in. 82.6 mm Load Cap. SBT-1-1/2CS Threaded stem size: 3/8-16 1-1/2˝ Main ball rotates on (90) 3/16˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available with stainless steel balls for additional corrosion resistance. Nylon main ball is available for non-marking applications. MBT-1CS1/4 42.5 mm 2-19/32 in. 65.9 mm Seal 5/8 in. 15.9 mm Stud-Mounted, All-Steel, for Heavy-Duty Applications • • • • • • Stud-Mounted, Solid Machined, All-Steel • Solid machined cup with integral 1/4-20 threaded stem, hardened and plated for longevity. • 5/8˝ Main ball rotates on 3/32" support balls. • Available in stainless steel for additional corrosion resistance. • Nylon main ball is available for non-marking applications. 5.6 mm Threaded stem sizes available: 1/4-20, 5/16-18, 3/8-16 1˝ Main ball rotates on eighty 1/8˝ support balls. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. Part Number NSMBT-5/8CS Part Number Part Number • • • • • • SMBT-5/8CS 1-3/16 in. 44.5 mm 2-5/16 in. 58.7 mm 3/8-16 in. THD 1-1/4 in. 31.8 mm 11/32 in. NOTE: Neoprene cushion available to permit vertical deflection and assist with uniform load distribution (part number CSBT-1-1/2). Part Number Ball Material Housing Mat. Load Cap. SMBT-1CS Carbon Steel Carbon Steel 200 lbs. NSMBT-1CS Nylon Carbon Steel 100 lbs. SMBT-1CS/SS Stainless Steel Carbon Steel 200 lbs. SMBT-1SS Stainless Steel Stainless Steel 200 lbs. Stud-Mounted, Solid Machined, All-Steel 8.7 mm 3/4 in. 1 in. 25.4 mm NMBT-1CS1/4 19.1 mm 5/16 -18 in. THD 1-3/8 in. • Solid machined cup with integral 5/16-18 threaded stem, hardened and plated for longevity. • 1˝ Main ball rotates on 1/8˝ support balls. • Available in stainless steel for additional corrosion resistance. • Nylon main ball is available for non-marking applications. Now available in all stainless. (part number SMBT-1SS). 34.9 mm 8 HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 9 new MBT-5/8 Series SHDBT-1-3/16 Metal Cap 2 in. 50.8 mm MBT-5/8CS SHDBT-1-3/16 Part Number Ball Material Housing Mat. Load Cap. SHDBT-1-3/16 CS Carbon Steel Carbon Steel 750 lbs. SHDBT-1-3/16 CS/SS Carbon Steel Stainless Steel 750 lbs. SHDBT-1-3/16 SS Stainless Steel Stainless Steel 750 lbs. 0.5255 in. 1-3/16 in. 13.3 mm 30.2 mm 1-7/16 in. 36.5 mm 3/8 in. Stud Mounted, 750 LB. Capacity • • • • 1 in. 25.4 mm Available with exterior sound reduction collar (SR) • Nylon collar, recessed below the flange, reduces noise and vibration. 13/16 in. 7/32 in. 20.6 mm 5.6 mm 3/6-16 in. UNC Part Number Ball Material Housing Mat. Load Cap. MBT-5/8CS Carbon Steel Carbon Steel 33 lbs. NMBT-5/8CS Nylon Carbon Steel 17 lbs. MBT-5/8CS/SS Stainless Steel Carbon Steel 33 lbs. MBT-5/8SS Stainless Steel Carbon Steel 33 lbs. Solid-Machined, All-Steel 9.5 mm Metal-cap standard 1-3/16˝ Main ball rotates on 1/8˝ support balls. Ball support cup is machined from solid steel and is hardened and plated. Available in stainless steel for additional corrosion resistance. NMBT-5/8CS 1-3/4 in. 44.5 mm • • • • • • Integral flange at top allows unit to be dropped into 1" diameter hole. 5/8˝ Main ball rotates on 3/32˝ support balls. Ball support cup is machined from solid steel and is hardened and plated. Plated steel cover. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. Now available in all stainless. (part number MBT-5/8SS). 15/16 in. 23.8 mm MBT-1 Series PBT-1-1/2 Series 3 in. DIA 76.2 mm DIA Seal 2-19/32 in. 65.9 mm 1-13/32 in. PBT-1-1/2CS Part Number NPBT-1-1/2CS Ball Material Housing Mat. 46.0 mm 35.7 mm MBT-1CS Load Cap. PBT-1-1/2CS Carbon Steel Carbon Steel 250 lbs. NPBT-1-1/2CS Nylon Carbon Steel 125 lbs. PBT-1-1/2CS/SS Stainless Steel Carbon Steel 250 lbs. 1-43/64 in. 42.5 mm Weld Allows positioning on a 2" pipe pedestal in front of shears or press breaks. 1-1/2˝ Main ball rotates on (90) 3/16˝ support balls. Ball transfer unit is welded to a standard carbon steel 2" pipe coupling. Ball support cup is hardened and plated. Protective cover assures low torque and longevity. Available with stainless steel balls for additional corrosion resistance. Nylon main ball is available for non-marking applications. 3-13/16 in. 5/8 in. 96.9 mm Pipe-Mounted • • • • • • • 1-13/16 in. 15.9 mm Part Number Ball Material Housing Mat. Load Cap. MBT-1CS Carbon Steel Carbon Steel 200 lbs. NMBT-1CS Nylon Carbon Steel 100 lbs. MBT-1CS/SS Stainless Steel Carbon Steel 200 lbs. MBT-1SS Stainless Steel Stainless Steel 200 lbs. Solid-Machined, All-Steel 1-1/4 in. 11/32 in. 31.8 mm 8.7 mm Standard 2 in. Pipe Coupling 1-3/8 in. 34.9 mm 10 NMBT-1CS HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com • • • • • • Integral flange at top allows unit to be dropped into 1-3/8" diameter hole. 1˝ Main ball rotates on 1/8˝ support balls. Ball support cup is machined from solid steel and is hardened and plated. Plated steel cover. Available in stainless steel for additional corrosion resistance. Nylon main ball is available for non-marking applications. Now available in all stainless. (part number MBT-1SS). HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 11 FSBT HDBT-1-3/16 Series HDBT-1-3/16CS Part Number HDBT-1-3/16CSSR Ball Material Housing Mat. Load Cap. HDBT-1-3/16CS Carbon Steel Carbon Steel 500 HDBT-1-3/16CS/SS Carbon Steel Stainless Steel 500 HDBT-1-3/16SS Stainless Steel Stainless Steel 500 FSBT-1CS NFSBT-1-1/2CS 0.5255 in. 13.3 mm 500 LB. Capacity • • • • 2 in. 50.8 mm FSBT-5/8CS 1-7/16 in. Integral flange at top allows unit to be dropped into 1-3/4" diameter hole. 1-3/16˝ Main ball rotates on 1/8˝ support balls. Ball support cup is machined from solid steel and is hardened and plated. Available in stainless steel for additional corrosion resistance. 36.5 mm Available with exterior sound reduction collar (SR) • Nylon collar, recessed below the flange, reduces noise and vibration when the unit is installed in a metal application surface. • Retaining ring is solid plastic. Versatile, compact, All-Steel • • • • • 1-3/4 in. Can be recessed into the surface of the application forming a smooth, multi-directional rolling surface. Precision-formed steel housing. Integral mounting holes for ease of installation. Available with stainless steel balls for additional corrosion resistance. Nylon main ball is available for non-marking applications. 44.5 mm G new C HDBTM-1-3/16 Series F A 1" and 1-1/2" Flange Detail B D E HDBTM-1-3/16CS Part Number Ball Material Housing Mat. Load Cap. HDBTM-1-3/16CS Carbon Steel Carbon Steel 750 HDBTM-1-3/16CS/SS Carbon Steel Stainless Steel 750 HDBTM-1-3/16SS Stainless Steel Stainless Steel 750 750 LB. Capacity • • • • • • 2 in. 50.8 mm 0.5255 in. 13.3 mm 1-7/16 in. Metal cap for additional strength and durability. Integral flange at top allows unit to be dropped into 1-3/4" diameter hole. 1-3/16˝ Main ball rotates on 1/8˝ support balls. Ball support cup is machined from solid steel and is hardened and plated. Retaining ring is solid metal. Available in stainless steel for additional corrosion resistance. Available with exterior sound reduction collar (SR) • Nylon collar, recessed below the flange, reduces noise and vibration when the unit is installed in a metal application surface. 12 Metal Cap Part Number Ball Material Housing Mat. FSBT-5/8CS Carbon Steel Carbon Steel NFSBT-5/8CS Nylon Carbon Steel FSBT-5/8CS/SS Stainless Carbon Steel FSBT-1CS Carbon Steel Carbon Steel NFSBT-1CS Nylon Carbon Steel FSBT-1CS/SS Stainless Carbon Steel FSBT-1-1/2CS Carbon Steel Carbon Steel NFSBT-1-1/2CS Nylon Carbon Steel FSBT-1-1/2CS/SS Stainless Carbon Steel 36.5 mm 1-3/4 in. 44.5 mm HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com Main Ball 5/8" 15.9mm 5/8" 15.9mm 5/8" 15.9mm 1" 25.4mm 1" 25.4mm 1" 25.4mm 1-1/2" 38.1mm 1-1/2" 38.1mm 1-1/2" 38.1mm Load Capacity 20 lbs. 10 lbs. 20 lbs. 75 lbs. 40 lbs. 75 lbs. 200 lbs. 100 lbs. 200 lbs. a b c d e f g 1-11/16" 3/4" 3/8" 5/32" 31/32" 1-1/4" 9/64" 42.9mm 19.1mm 9.5mm 4.0mm 24.6mm 31.8mm 3.6mm 1-11/16" 3/4" 3/8" 5/32" 31/32" 1-1/4" 9/64" 42.9mm 19.1mm 9.5mm 4.0mm 24.6mm 31.8mm 3.6mm 1-11/16" 3/4" 3/8" 5/32" 31/32" 1-1/4" 9/64" 42.9mm 19.1mm 9.5mm 4.0mm 24.6mm 31.8mm 3.6mm 2-1/4" 1-7/32" 5/8" 3/16" 1-1/2" 1-3/4" 3/16" 57.2mm 31.0mm 15.9mm 4.8mm 38.1mm 44.5mm 4.8mm 2-1/4" 1-7/32" 5/8" 3/16" 1-1/2" 1-3/4" 3/16" 57.2mm 31.0mm 15.9mm 4.8mm 38.1mm 44.5mm 4.8mm 2-1/4" 1-7/32" 5/8" 3/16" 1-1/2" 1-3/4" 3/16" 57.2mm 31.0mm 15.9mm 4.8mm 38.1mm 44.5mm 4.8mm 3-21/32" 1-13/16" 1-9/64" 9/32" 2" 2-3/4" 9/32" 29.0mm 7.1mm 50.8mm 69.9mm 7.1mm 92.9mm 46.0mm 3-21/32" 1-13/16" 1-9/64" 9/32" 2" 2-3/4" 9/32" 29.0mm 7.1mm 50.8mm 69.9mm 7.1mm 92.9mm 46.0mm 3-21/32" 1-13/16" 1-9/64" 9/32" 2" 2-3/4" 9/32" 29.0mm 7.1mm 50.8mm 69.9mm 7.1mm 92.9mm 46.0mm HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 13 Design & Materials Manufacturing • We use minimum Grade 1000 carbon steel balls, higher • All products are made in the USA, in our East Lyme, than the competition. High grade main and support balls ensure rounder surfaces for smooth and consistent rolling. • We use a higher number of support balls to ensure load capacities are met. • In addition to the housing, support cups are zinc-plated to help retard rust and promote longer life of the ball transfer unit. All plating is RoHS compliant. • Unique dual-radius cup design: support cups are dimpled to encourage support ball fluctuation rather than simple rotation. The result is less support cup wear and longer life. • Foam seal helps wipe dirt particles away from main ball to promote easy rolling, as well as reduces contamination of support balls. • Stainless Steel balls are manufactured from Series 400 stainless steel. • Nylon main balls are machined, hardened, and non-marring. • All carbon steel units are sealed and lubricated to ensure maximum life, unless otherwise specified. • Many models are now available in all Stainless Steel (SS) for maximum corrosion resistance. • Additional types of main balls, including non-magnetic and hollow, are available on a custom order basis. Connecticut facility. • Rigorous attention to detail and quality control ensures our customers receive the finest products available. That is why we have been proud to stamp our name on all our ball transfers for over forty years. • In-house tool & die capability enables us to react quickly to our customers' needs. • CNC manufacturing capability ensures the highest tolerances, and allows us to manufacture custom products at production prices Customer Service East Lyme Manufacturing Plant • We maintain a large finished goods inventory; all products are ready for immediate shipment. • Our knowledgeable staff has extensive ball transfer and metal fabrication experience. • No minimum order size. • National network of manufacturers' representatives. • We are very capable at exporting our products and ship to clients around the world on a regular basis, including the US government and military. • For over forty years, we have built our reputation on quality and reliability. We wholeheartedly stand behind our products and service. Hudson Bearings was an early pioneer in the ball transfer industry, fabricating its first products in 1969 and quickly gaining a reputation for quality and exemplary customer service. The business grew rapidly, resulting in a move to the current production facility in East Lyme, Connecticut and the acquisition of additional stamping and turning equipment. The business was eventually passed on to the next generation who oversaw an expansion of the heavy duty product line and new distribution channels. Applications Ball transfers solve a variety of material handling and motion control challenges, whether used in the traditional 'ball up' position or as a caster in the 'ball down' orientation. Ball transfers offer advantages to traditional casters, such as lower profiles and omnidirectional movement, often at a lower cost. Common Applications • • • • • Air Cargo Robotics Store Fixtures Laser & Plasma Cutters Medical Devices • • • • • Shears Military Logistics Die Handling Glass & Metal Manufacturing Caster Substitution Snow-Shoe Patent Drawing Hudson Bearings was acquired by Jim Klingbeil Jr. and Donnie Bowman in 2009, with the goal of building a great company into an even better one. Both share a passion for American manufacturing and building quality companies. Jim was a cofounder of Atlas Snow-Shoe Company and has been awarded four U.S. utility patents for snowshoe innovations. Donnie has an extensive background in operations and sales management throughout the United States. retail store display 14 Workstations material handling/conveyor weighing systems/scales HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com We remain committed to manufacturing all of our products in the U.S. and as such, have significantly enhanced our production capability with CNC manufacturing equipment. Not only does this machinery produce higher tolerance ball transfers more consistently, it also greatly expands our ability to manufacture custom-dimension products. While we pride ourselves on great products, we take even greater pride in our small, but dedicated staff. Their experience with metal forming runs deep and they excel at providing our customers with timely and cost competitive solutions. They take great satisfaction in exceeding expectations, day in and day out. Our goal is to continually innovate and grow. We believe a company that is not trying to improve, grow, and innovate is a company that is in decline. This updated catalog reflects that goal, as does our enhanced website, new state of the art manufacturing equipment, expanded product offerings such as the Metal-cap HDBT and Studded HDBT, and most importantly, our renewed focus on our customers and their unique challenges. We look forward to helping you grow and improve your business. Visit us at www.hudsonbearings.com. CNC Lathe with Bar Feed HUDSON BEARINGS • Email: info@hudsonbearings.com • Tel: 860-739-6988 • Fax: 860-739-7251 • www.hudsonbearings.com 15 13 Colton Road East Lyme, CT 06333 Hudson Bearings has been manufacturing ball transfers since 1969 and provides the highest quality products, innovative designs and exemplary customer service. Our company manufactures all ball transfers in our own East Lyme, Connecticut facility, thus maintaining the highest quality control from raw materials through component manufacturing, assembly and shipment. Customer service includes immediate delivery from our huge inventory with no minimum order required. Please contact us for competitive pricing or assistance with specialized applications. HDBTM-1-3/16CS SHDBT-1-3/16 Hudson Bearings, LLC 13 Colton Road, East Lyme, CT 06333 Phone: 860-739-6988 • Fax: 860-739-7251 Email: info@hudsonbearings.com New Heavy-Duty Products www.hudsonbearings.com Lockable Ball Transfer Coming Soon! Studded HD and HD with Metal Cap. See pages 10 and 12 for more details.