Harowe Resolvers®

advertisement

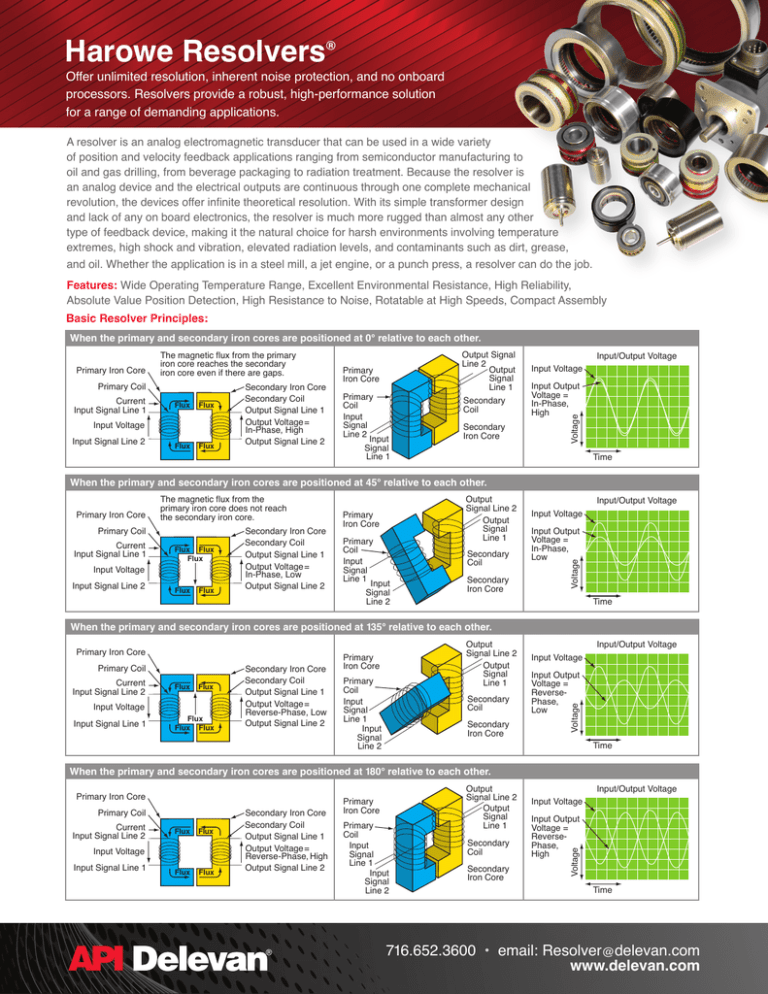

Harowe Resolvers® Offer unlimited resolution, inherent noise protection, and no onboard processors. Resolvers provide a robust, high-performance solution for a range of demanding applications. A resolver is an analog electromagnetic transducer that can be used in a wide variety of position and velocity feedback applications ranging from semiconductor manufacturing to oil and gas drilling, from beverage packaging to radiation treatment. Because the resolver is an analog device and the electrical outputs are continuous through one complete mechanical revolution, the devices offer infinite theoretical resolution. With its simple transformer design and lack of any on board electronics, the resolver is much more rugged than almost any other type of feedback device, making it the natural choice for harsh environments involving temperature extremes, high shock and vibration, elevated radiation levels, and contaminants such as dirt, grease, and oil. Whether the application is in a steel mill, a jet engine, or a punch press, a resolver can do the job. Features: Wide Operating Temperature Range, Excellent Environmental Resistance, High Reliability, Absolute Value Position Detection, High Resistance to Noise, Rotatable at High Speeds, Compact Assembly Basic Resolver Principles: When the primary and secondary iron cores are positioned at 0° relative to each other. Primary Coil Current Input Signal Line 1 The magnetic flux from the primary iron core reaches the secondary iron core even if there are gaps. Flux Flux Input Voltage Input Signal Line 2 Flux Flux Secondary Iron Core Secondary Coil Output Signal Line 1 Output Voltage= In-Phase, High Output Signal Line 2 Primary Iron Core Primary Coil Input Signal Line 2 Input Signal Line 1 Output Signal Line 2 Output Signal Line 1 Secondary Coil Secondary Iron Core Input Voltage Input/Output Voltage Input Output Voltage = In-Phase, High Voltage Primary Iron Core Time When the primary and secondary iron cores are positioned at 45° relative to each other. Primary Coil Current Input Signal Line 1 Input Voltage Input Signal Line 2 The magnetic flux from the primary iron core does not reach the secondary iron core. Flux Flux Flux Flux Flux Secondary Iron Core Secondary Coil Output Signal Line 1 Output Voltage= In-Phase, Low Output Signal Line 2 Primary Iron Core Primary Coil Input Signal Line 1 Input Signal Line 2 Output Signal Line 2 Output Signal Line 1 Secondary Coil Secondary Iron Core Input Voltage Input/Output Voltage Input Output Voltage = In-Phase, Low Voltage Primary Iron Core Time When the primary and secondary iron cores are positioned at 135° relative to each other. Primary Coil Current Input Signal Line 2 Input Voltage Input Signal Line 1 Flux Flux Flux Flux Flux Secondary Iron Core Secondary Coil Output Signal Line 1 Output Voltage= Reverse-Phase, Low Output Signal Line 2 Output Signal Line 2 Output Signal Line 1 Primary Iron Core Primary Coil Input Signal Line 1 Input Signal Line 2 Secondary Coil Secondary Iron Core Input Voltage Input/Output Voltage Input Output Voltage = ReversePhase, Low Voltage Primary Iron Core Time When the primary and secondary iron cores are positioned at 180° relative to each other. Primary Coil Current Input Signal Line 2 Flux Flux Flux Flux Input Voltage Input Signal Line 1 Secondary Iron Core Secondary Coil Output Signal Line 1 Output Voltage= Reverse-Phase, High Output Signal Line 2 Primary Iron Core Primary Coil Input Signal Line 1 Input Signal Line 2 Output Signal Line 2 Output Signal Line 1 Secondary Coil Secondary Iron Core Input Voltage Input/Output Voltage Input Output Voltage = ReversePhase, High Voltage Primary Iron Core Time 716.652.3600 • email: Resolver@delevan.com www.delevan.com Harowe Resolvers® Offer unlimited resolution, inherent noise protection, and no onboard processors. Resolvers provide a robust, high-performance solution for a range of demanding applications. A single-speed resolver features two magnetic poles. The windings for a single-speed resolver are wound such that a plot of output voltage as a function of position for the device produces one complete cycle of a sine wave and one complete cycle of a cosine wave over each 360° mechanical rotation of the shaft. As a result, a single-speed (two-pole) resolver can provide absolute position feedback. A multi-speed resolver is wound to produce multiple magnetic poles, which means that it generates multiple sine and cosine curves per mechanical revolution. A 3-speed resolver, for example, produces one sine/cosine wave cycle for each 120° of shaft rotation. As a result, it provides better accuracy; the higher the number of poles, the higher the accuracy. Basic Resolver Types: Resolver Transmitter (Stator Secondary) Resolver Receiver (Rotor Secondary) Resolver Differential (2 Primary Windings) (Synchro equivalents available) Comparison of Angle Sensors: ■ Excellent ● Good ▲ Poor Harowe® Multi-Speed Resolvers Optical Incremental Encoder Optical Absolute Encoder Hall Effect Sensor MR Sensor Accuracy ■ ■ ■ ▲ ▲ Resolution ∞ 10,000 PPR 222 cpr Up to 500 PPR Up to 4000 PPR Output Signals Absolute Angle Incremental Absolute Incremental Incremental Shock ■ ▲ ▲ ● ● Vibration ■ ▲ ▲ ● ● Heat Resistance Up to 200°C -10°C to +85°C -10°C to +85°C -10°C to +110°C -10°C to +85°C Reliability ■ ● ● ▲ ● Anti-Noise ■ ● ● ▲ ▲ Features Absolute Position Detection, High Reliability, Excellent Environmental Resistance High Resolution, Poor Reliability High Resolution, Poor Reliability Low Resolution Low Resolution (Arc-Min) ■ ▲ ▲ ▲ ▲ Heavy Duty Brushless Resolvers Harowe's frameless resolvers generate speeds and position data for robotic, machine tool and aerospace servo applications, as well as commutating brushless servo motors. The frameless construction simplifies mounting mechanics because the rotor mounts directly onto the motor shaft and the stator housing mounts directly onto the motor end bell. • Wide Range of Sizes from 10 to 55 • Multi-Speed Available • Up to 200ºC Temperature Range • Radiation-Hardened Models Available Heavy Duty Housed Resolvers Harowe's heavy duty housed resolvers provide a very tough package to withstand extreme abuse. Made of aluminum and/or steel with high integrity, static or dynamic seals, they are capable of measuring rotary motion with the accuracy of many delicate encoders. • Rugged Housing with IP65 Rating • Spaced Bearings for up to 10x the Life of Traditional Duplex Bearings • Withstands 200g Shock and 40g Vibration ACC #2-0715 716.652.3600 • email: Resolver@delevan.com www.delevan.com